Experimental and Modeling Analysis on the Hysteretic Behavior of the Novel Disc-shaped Steel Wire Rope Ring Vibration Isolator

-

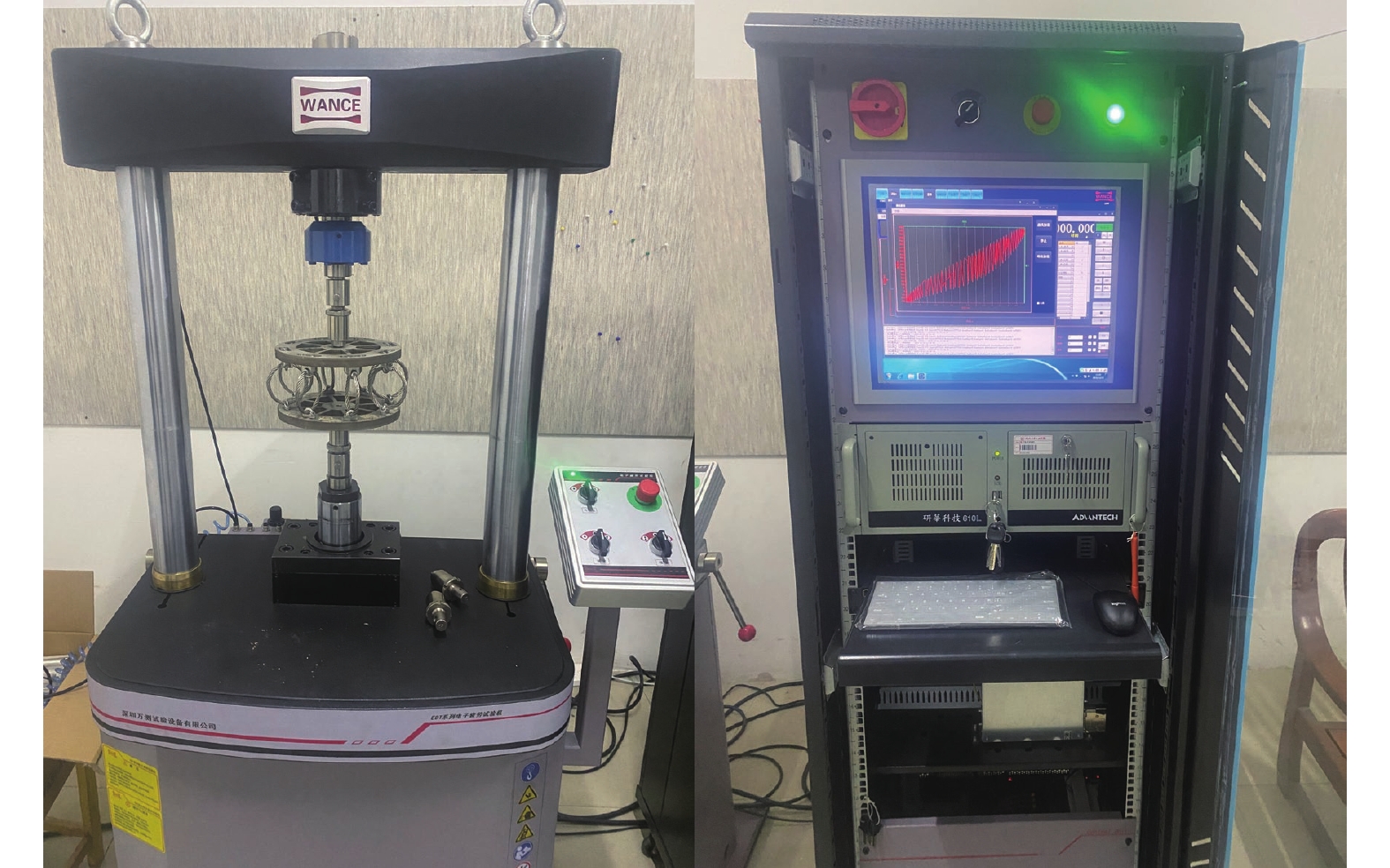

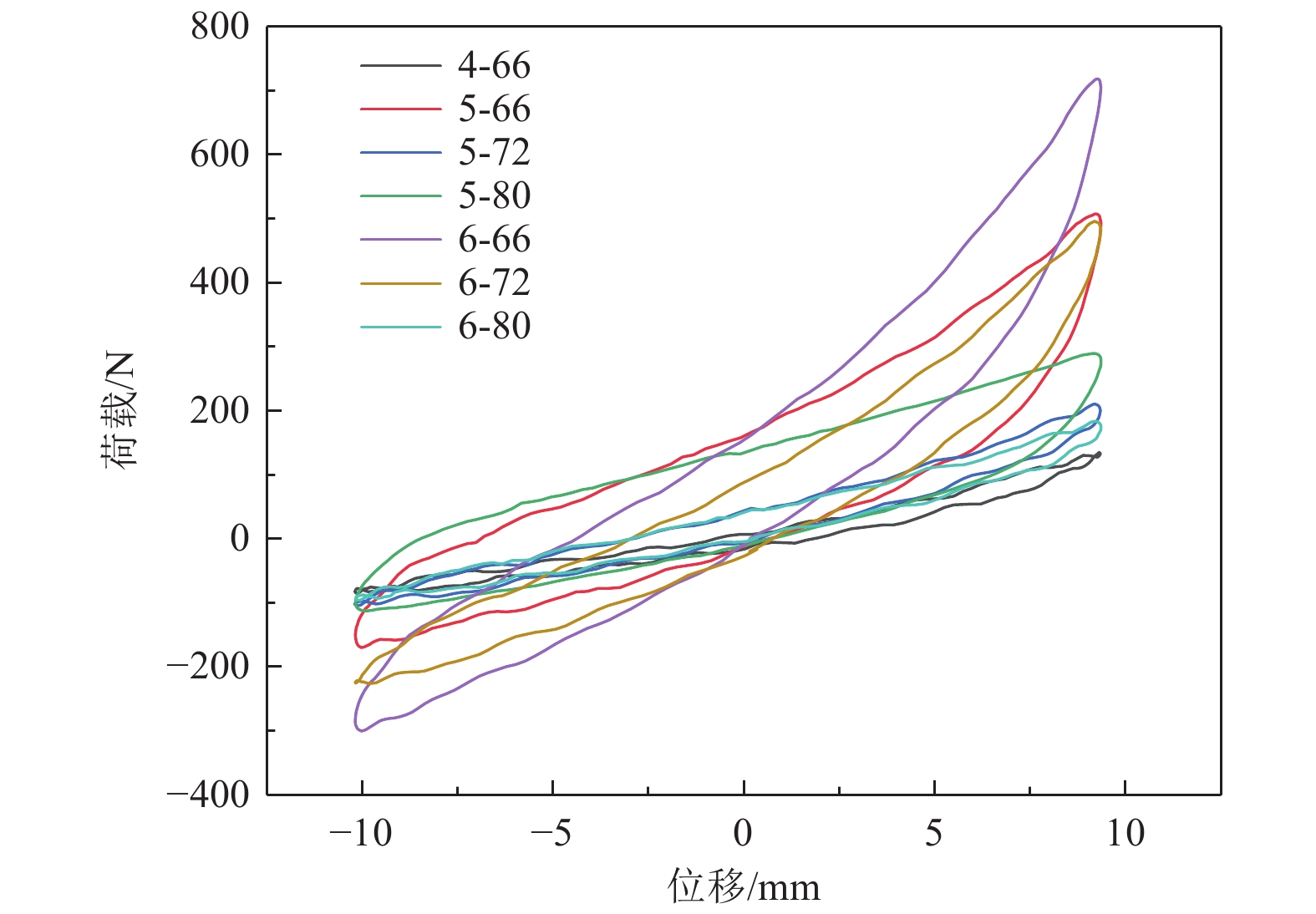

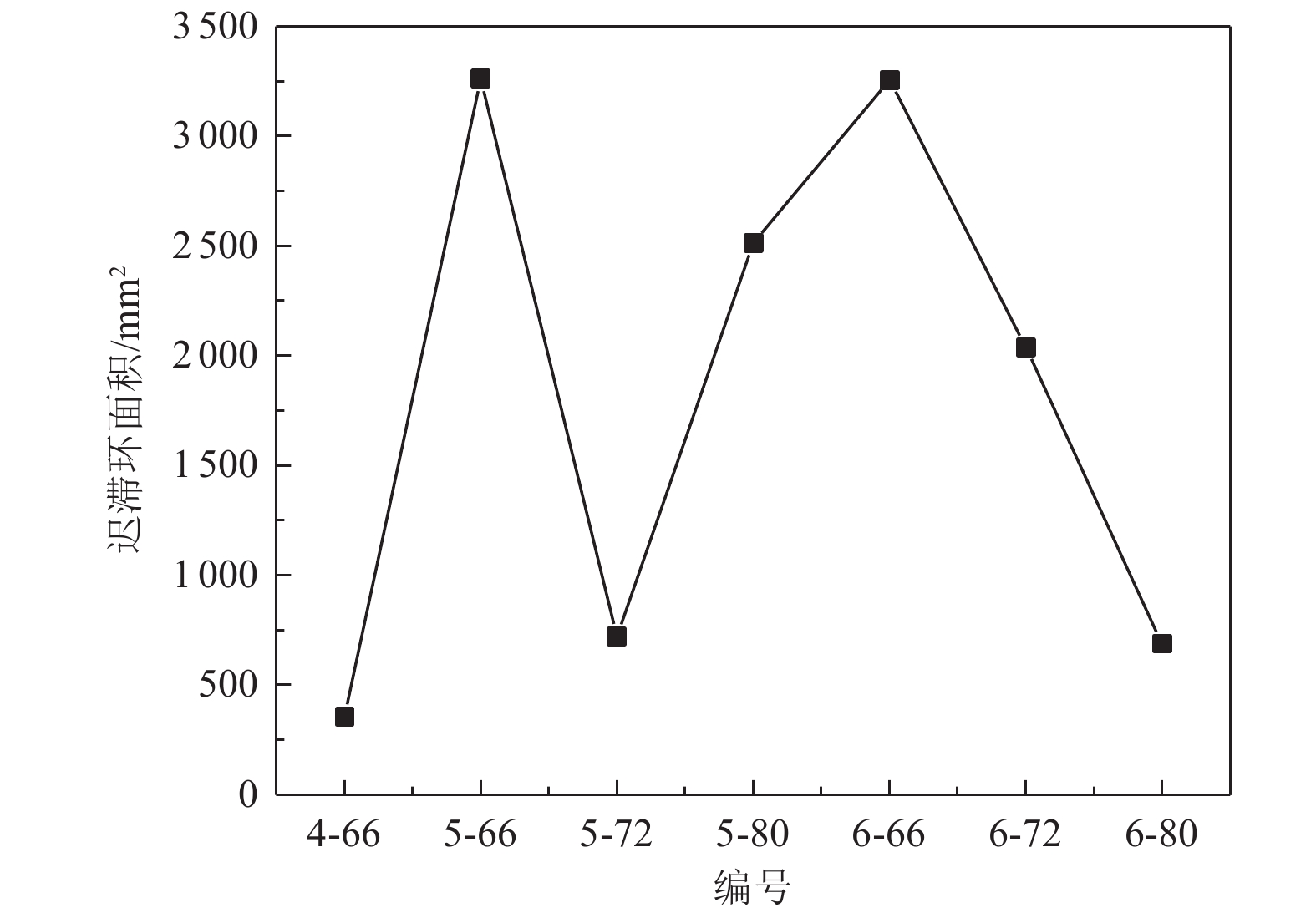

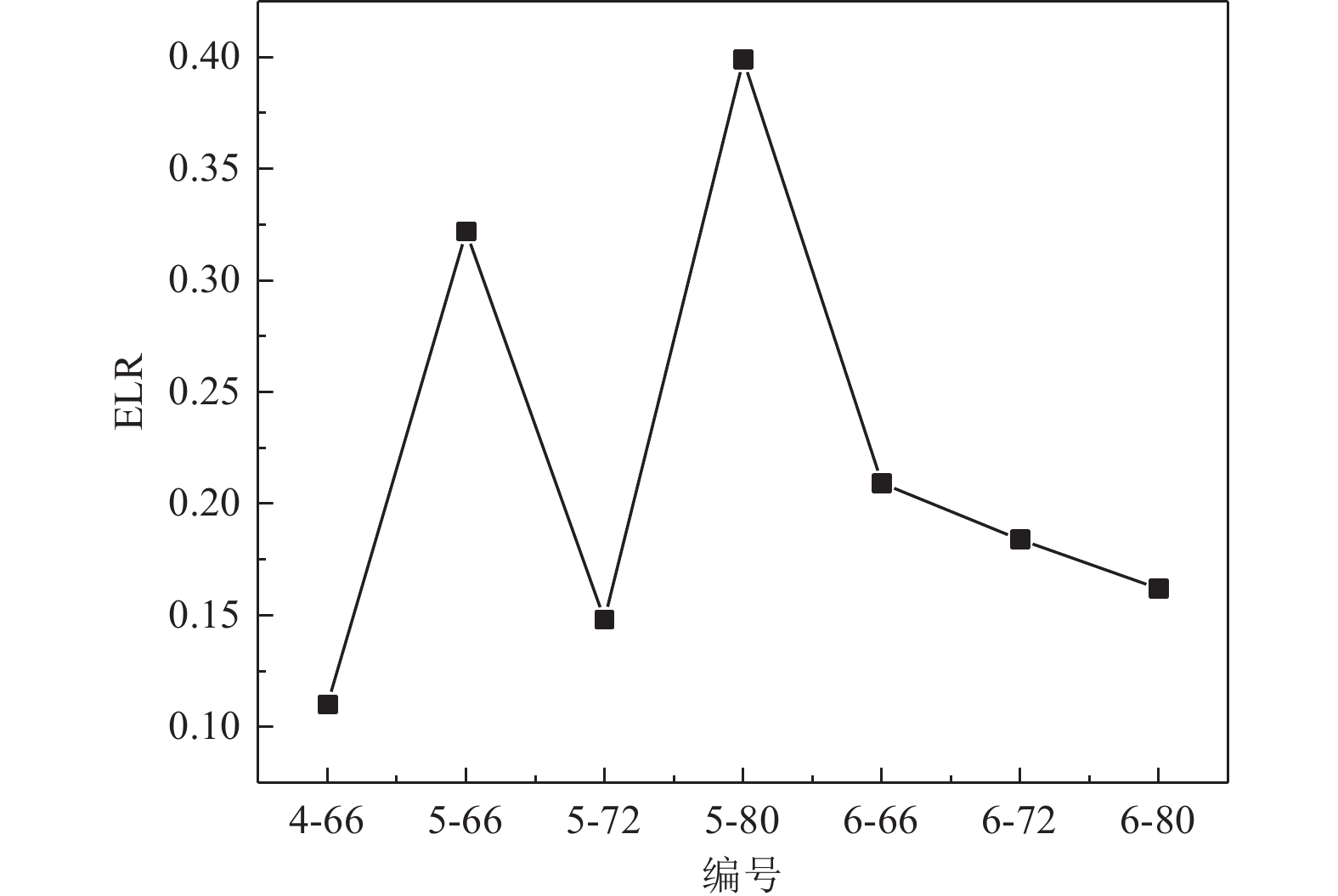

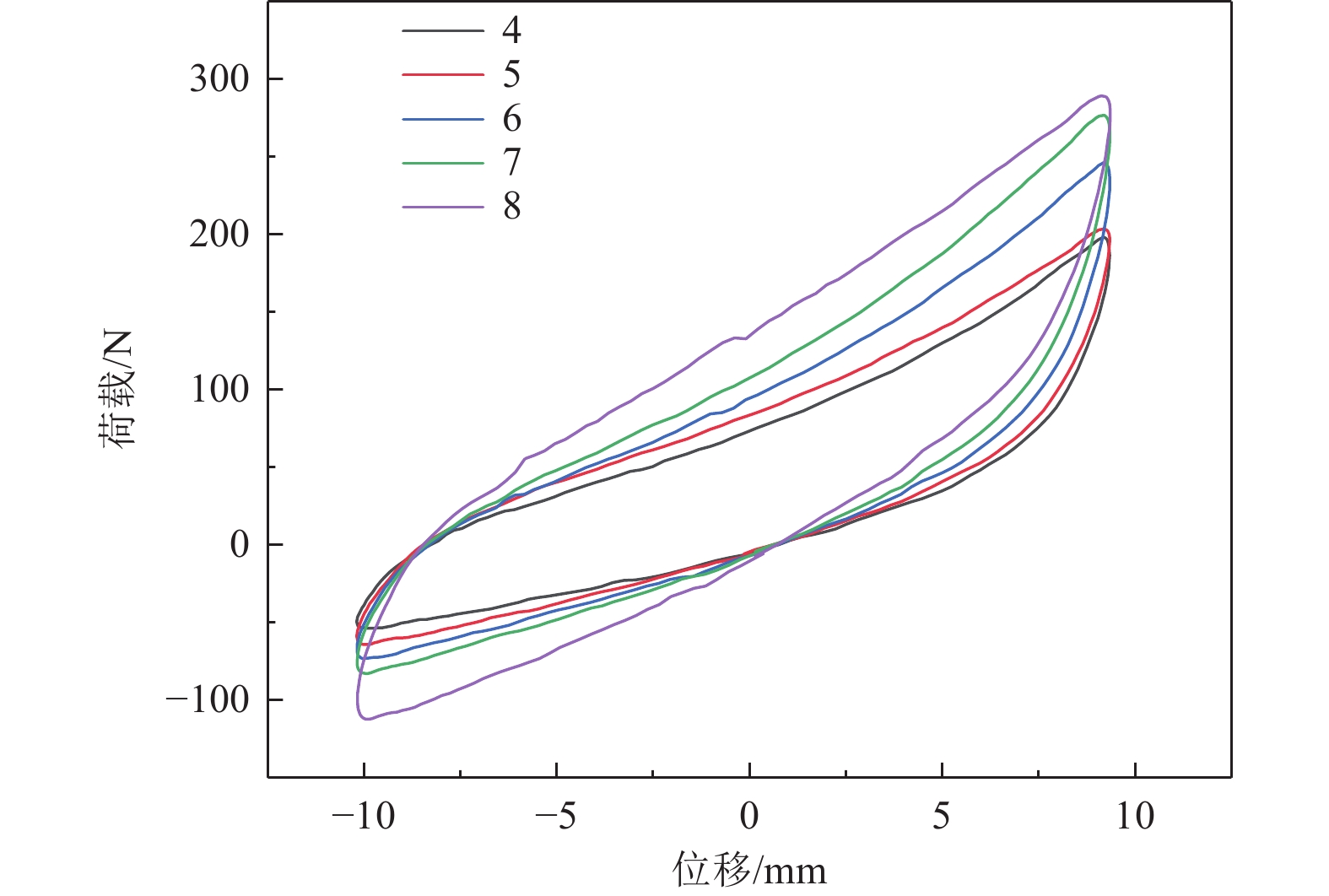

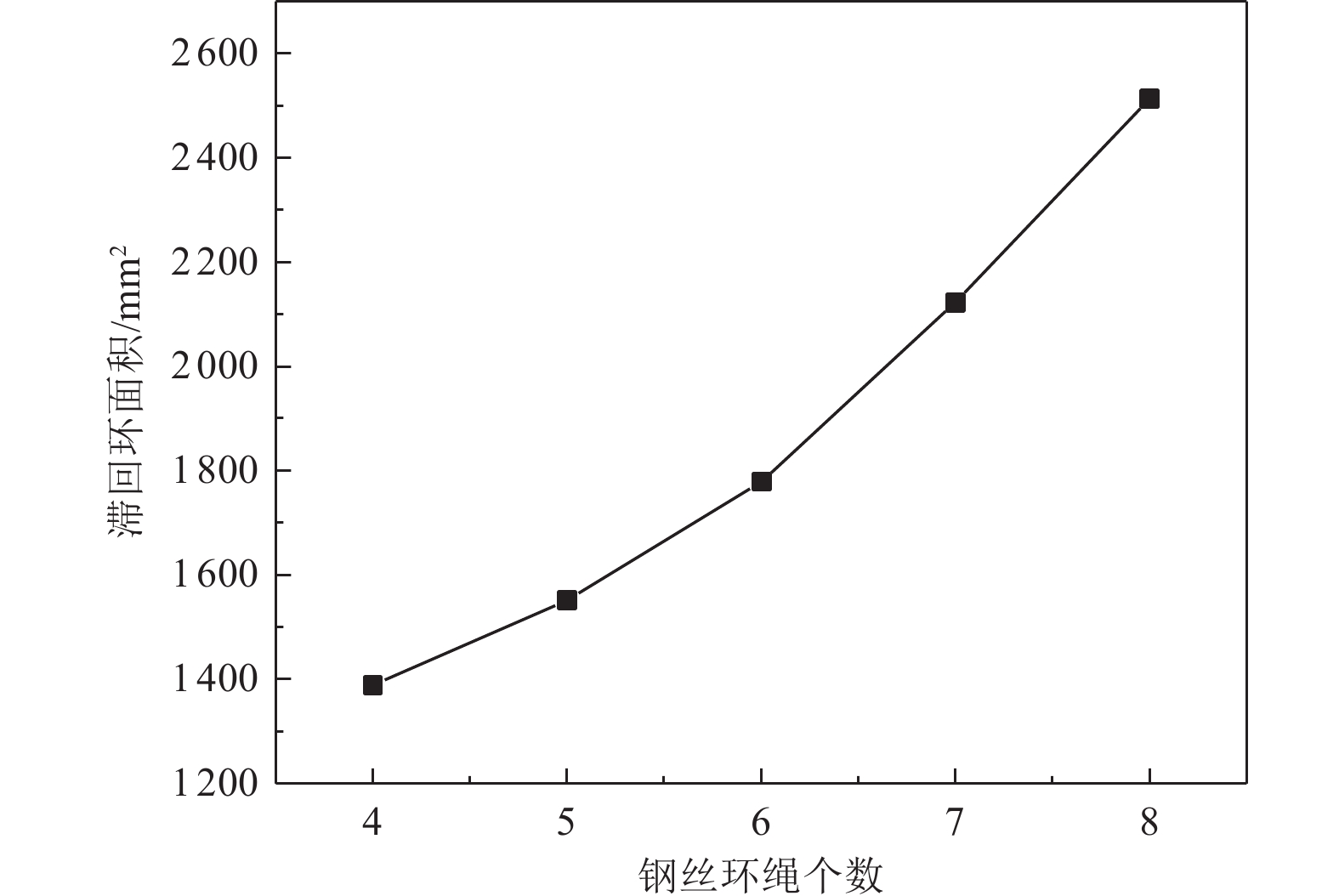

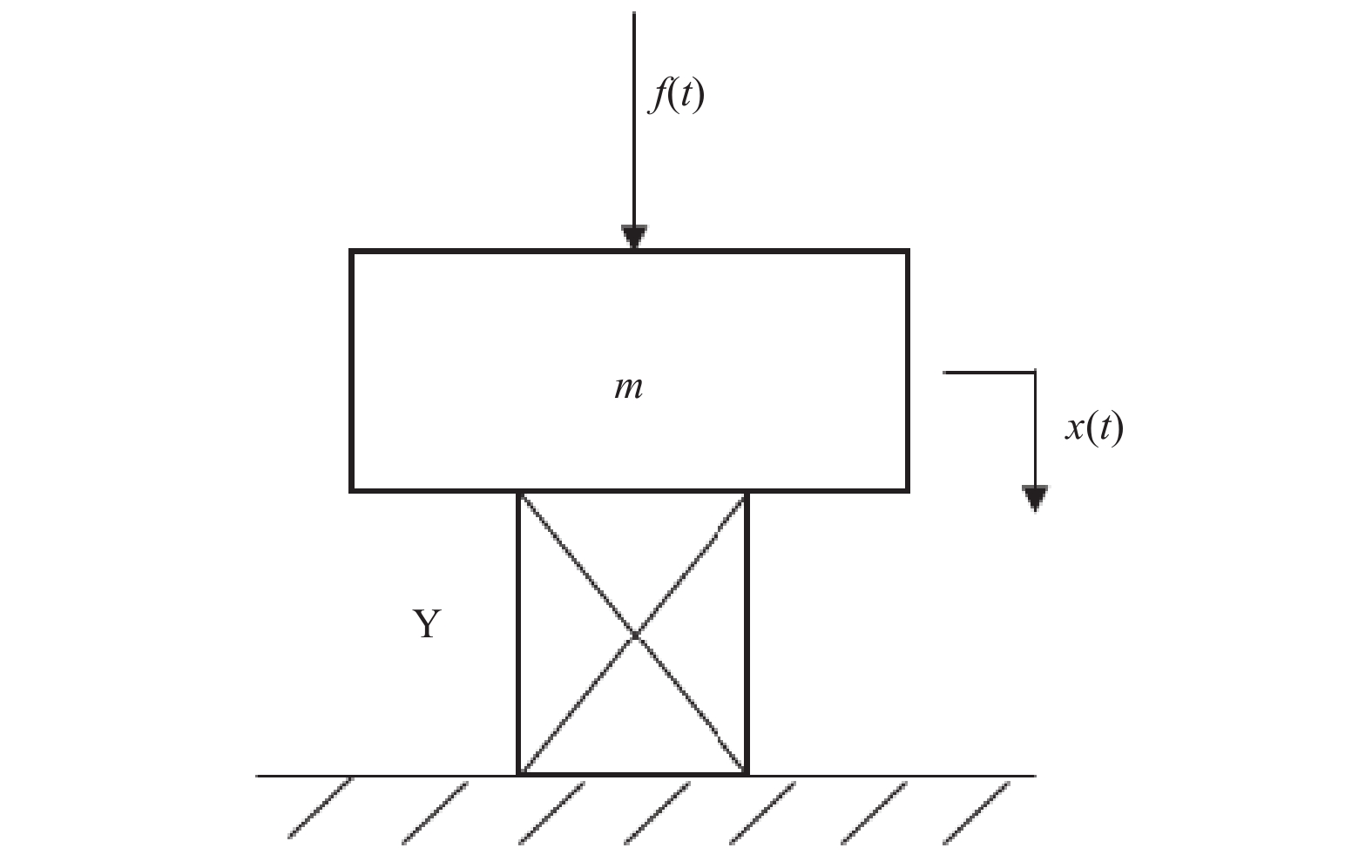

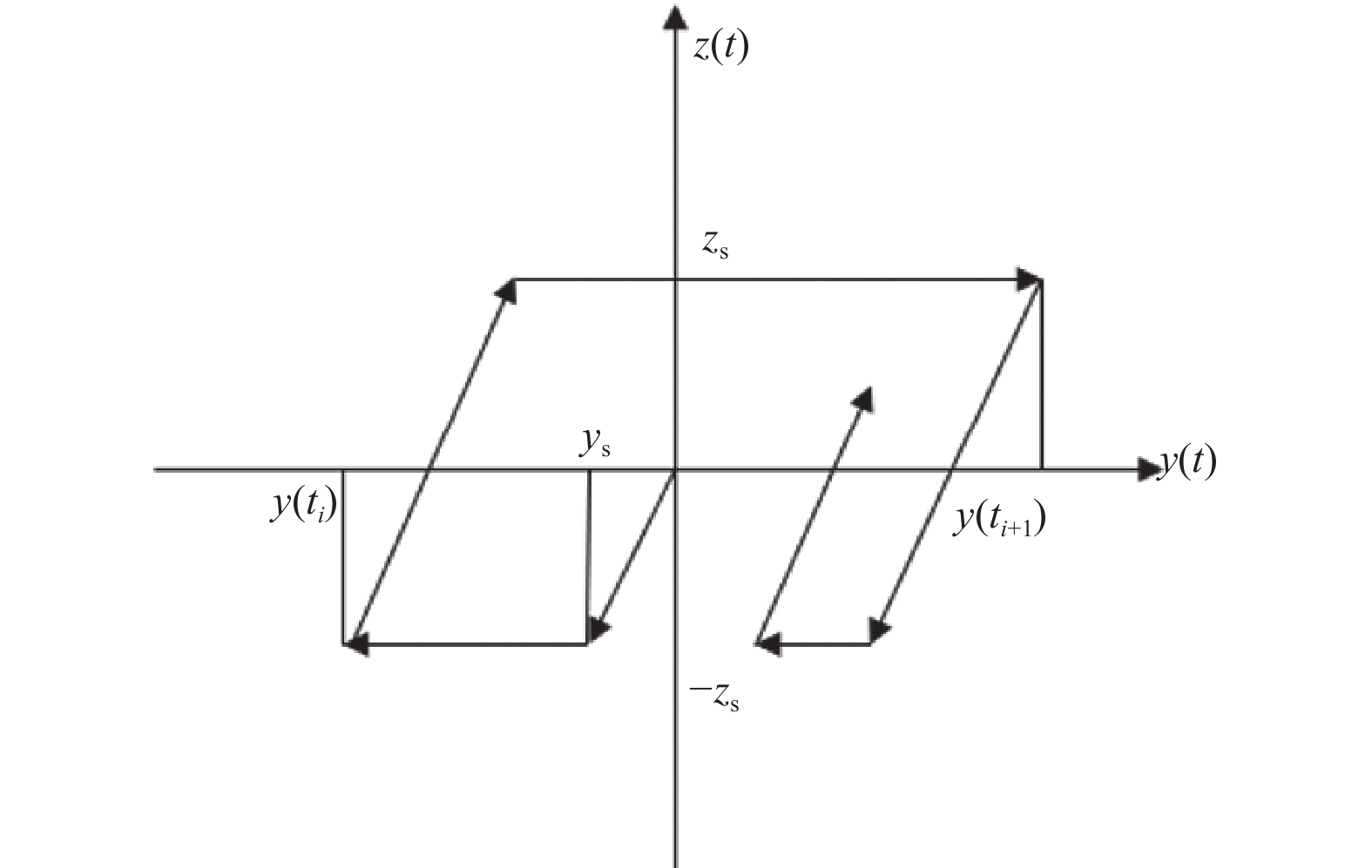

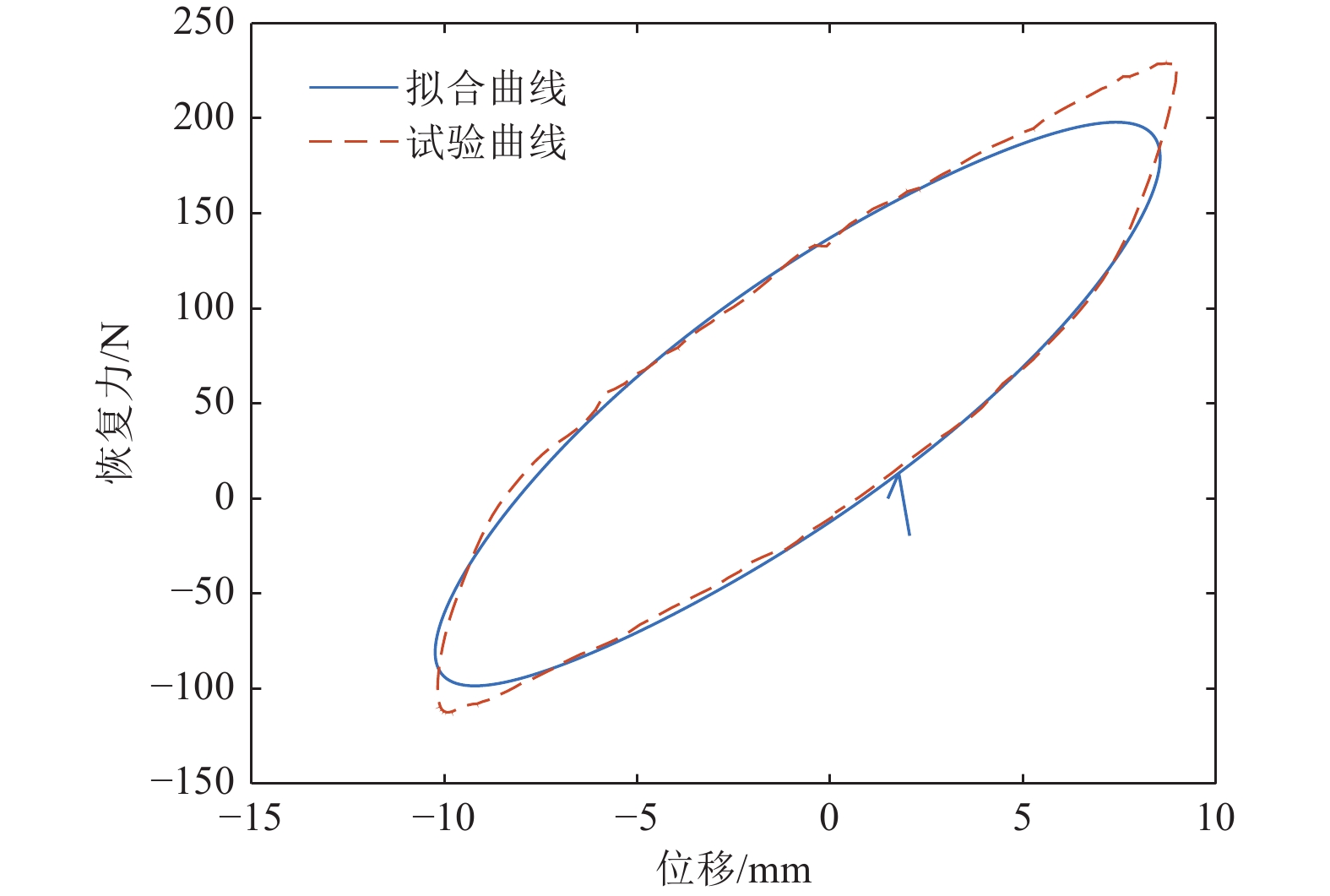

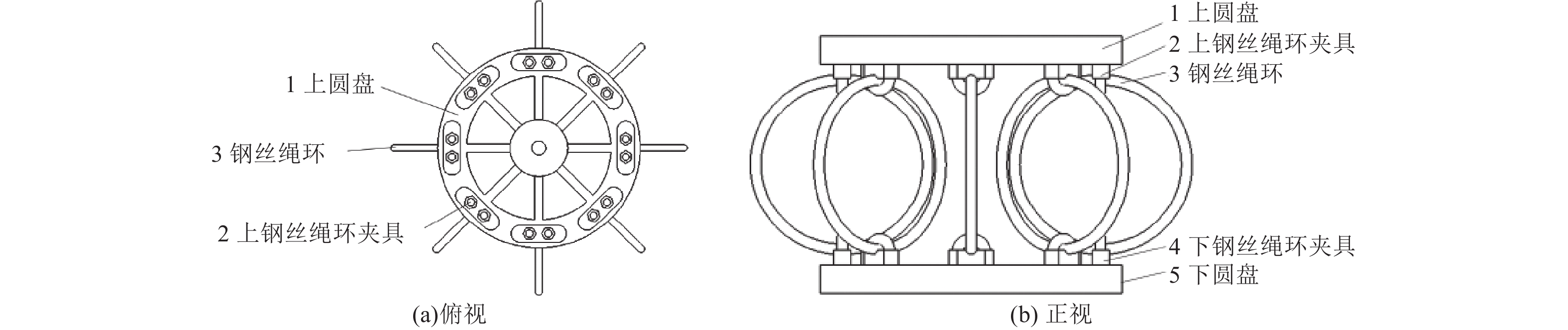

摘要: 针对目前钢丝绳环隔振器刚度与阻尼特性不易调节、成型与维修难度高、精度低等问题,研制了新型圆盘形钢丝绳环隔振器并对其开展试验研究,获得了钢丝绳直径、钢丝绳环直径与个数等对其刚度与阻尼特性的影响规律。基于圆盘形钢丝绳环隔振器试验滞回特性曲线,建立了考虑误差的非线性滞回模型,并采用间接傅里叶级数法结合最小二乘法完成了滞回模型参数识别。研究结果表明,本研究中的隔振器刚度与阻尼特性可根据钢丝绳环结构参数与个数进行调节以满足不同工况需求;所建滞回模型拟合曲线与试验曲线的最大误差为2.49%,验证了所建模型的有效性,为后续钢丝绳环隔振器非线性滞回性能的进一步研究和新型圆盘型钢丝绳环隔振器推广应用奠定了理论与试验基础。Abstract: To address the challenges associated with the stiffness and damping characteristics of current wire rope ring vibration isolators—such as difficulty in adjustment, shaping, maintenance, and low precision—a new disc-shaped wire rope ring vibration isolator was developed, and experimental research was conducted. The study identified the influence of factors such as wire rope diameter, and the number and diameter of wire rope rings on the stiffness and damping characteristics of the isolator. Based on the test hysteresis characteristic curve of the disc-shaped isolator, a nonlinear hysteresis model accounting for errors was established. The model's parameters were identified using the indirect Fourier series method combined with the least squares method. The results indicate that the stiffness and damping characteristics of the vibration isolator can be adjusted by modifying structural parameters and the number of wire rope rings, making it adaptable to different working conditions. The maximum error between the fitted curve of the established hysteresis model and the test curve is 2.49%, validating the model’s accuracy. This research lays a theoretical and experimental foundation for further investigations into the nonlinear hysteresis behavior of wire rope ring vibration isolators and the promotion and application of the new disc-shaped isolator design.

-

Key words:

- Vibration isolator /

- Wire line thimble /

- Stiffness /

- Damping /

- Nonlinear /

- Hysteresis model

-

表 1 滞回环面积与ELR

Table 1. Hysteresis area and ELR

隔振器编号 钢丝绳直径d/mm 钢丝绳环直径D/mm D/d比值 滞回环面积 S/mm2 能量损失率ELR 4-66 4 66 16.5 354.34 0.110 5-66 5 66 13.2 3 263.15 0.322 5-72 5 72 14.4 720.35 0.148 5-80 5 80 16.0 2 513.50 0.399 6-66 6 66 11.0 3 255.70 0.209 6-72 6 72 12.0 2 037.92 0.184 6-80 7 80 13.3 689.46 0.162 表 2 不同钢丝绳环个数下滞回环面积与ELR

Table 2. Hysteresis area and ELR with different number of rope rings

类别 绳环个数 4 5 6 7 8 滞回环面积S/mm2 1 388.11 1 551.16 1 779.09 2 122.72 2 513.5 能量损失率ELR 0.377 0.397 0.381 0.383 0.399 -

胡海岩,1988. 振动控制中的非线性组合结构动力学研究. 南京:南京航空航天大学. 胡海岩,李岳锋,1989. 具有记忆特性的非线性隔振器参数识别. 振动工程学报,2(2):17−27.Hu H. Y., Li Y. F., 1989. Parametric identification of nonlinear vibration isolators with memory. Journal of Vibration Engineering, 2(2): 17−27. (in Chinese) 李韶华,杨绍普,2006. 滞后非线性模型的研究进展. 动力学与控制学报,4(1):8−15. doi: 10.3969/j.issn.1672-6553.2006.01.003Li S. H., Yang S. P., 2006. Research status of hysteretic noniinear models. Journal of Dynamics and Control, 4(1): 8−15. (in Chinese) doi: 10.3969/j.issn.1672-6553.2006.01.003 束立红,周炜,吕志强等,2006. 钢丝绳环隔振器在大型机械设备的振动冲击隔离设计中的应用. 振动与冲击,25(4):78−81. doi: 10.3969/j.issn.1000-3835.2006.04.021Shu L. H., Zhou W., Lü Z. Q., et al., 2006. Stainless steel wire-rope isolator used in vibration and impact isolation design for large machine equipment. Journal of Vibration and Shock, 25(4): 78−81. (in Chinese) doi: 10.3969/j.issn.1000-3835.2006.04.021 孙洪军,钱网生,2005. 拱形钢丝绳环隔振器冲击特性研究. 噪声与振动控制,25(5):7−9.Sun H. J., Qian W. S., 2005. Study on shock characteristics of the arch type steel wire isolators. Noise and Vibration Control, 25(5): 7−9. (in Chinese) 唐斌,安西方,何鑫等,2012. 橡胶钢丝绳复合隔振器动力学建模与参数识别. 振动、测试与诊断, 32 (5):746−749.Tang B. , An X. F. , He X. , et al. , 2012. Dynamic model and parameter identification of rubber and wire-cable composite vibration isolator. Journal of Vibration, Measurement & Diagnosis, 32 (5): 746−749. (in Chinese) 王红霞,2015. O型钢丝绳环隔振器特性研究. 重庆:重庆大学.Wang H. X., 2015. Research on the property of an O type wire-cable vibration isolator. Chongqing:Chongqing University. (in Chinese) 王红霞,龚宪生,潘飞等,2016. O型钢丝绳环隔振器的三向动态特性. 振动、测试与诊断, 36 (6):1190−1195.Wang H. X. , Gong X. S. , Pan F. , et al, 2016. Research on the dynamic behavior of O type wire-cable vibration isolator in three modes. Journal of Vibration, Measurement & Diagnosis, 36 (6): 1190−1195. (in Chinese) 张春辉,卢凯田,张磊等,2020. 钢丝绳环隔振器的力学性能研究综述. 兵器装备工程学报,41(3):231−236.Zhang C. H., Lu K. T., Zhang L., et al., 2020. Literature review of mechanical of wire rope isolators. Journal of Ordnance Equipment Engineering, 41(3): 231−236. (in Chinese) 张春辉,卢凯田,张磊等,2021. 新型双向压缩式钢丝绳环隔振器的力学性能试验研究. 中国科学:物理学 力学 天文学, 51 (12):129612.Zhang C. H. , Lu K. T. , Zhang L. , et al. , 2021. Experimental study on mechanical properties of new biaxial compression wire rope isolator. Scientia Sinica: Physica, Mechanica & Astronomica, 51 (12): 129612. (in Chinese) 周桐,刘青林,2007. 钢丝绳隔振系统简化模型分析. 振动与冲击,26(9):55−59.Zhou T., Liu Q. L., 2007. Simplified model Analysis of wire-rope vibration Isolator. Journal of Vibration and Shock, 26(9): 55−59. (in Chinese) Balaji P. S., Moussa L., Khandoker N., et al., 2017. Experimental study on vertical static stiffnesses of polycal wire rope isolators. IOP Conference Series: Materials Science and Engineering, 217(1): 012032. Calabrese A., Spizzuoco M., Losanno D., et al., 2020. Experimental and numerical investigation of wire rope devices in base isolation systems. Earthquakes and Structures, 18(3): 275−284. Hussain A., Balaji P. S., 2018. Stiffness characteristics of a polycal wire rope isolators. IOP Conference Series: Materials Science and Engineering, 402(1): 012058. Ting Y. S., Khandoker N., Rahman M. E., et al., 2019. Lateral stiffness of polycal wire rope isolators – an experimental study. IOP Conference Series: Materials Science and Engineering, 495(1): 012087. -

下载:

下载: