Effect of Tie Bars between Columns in the Seismic Capacity of Light Frame Structures

-

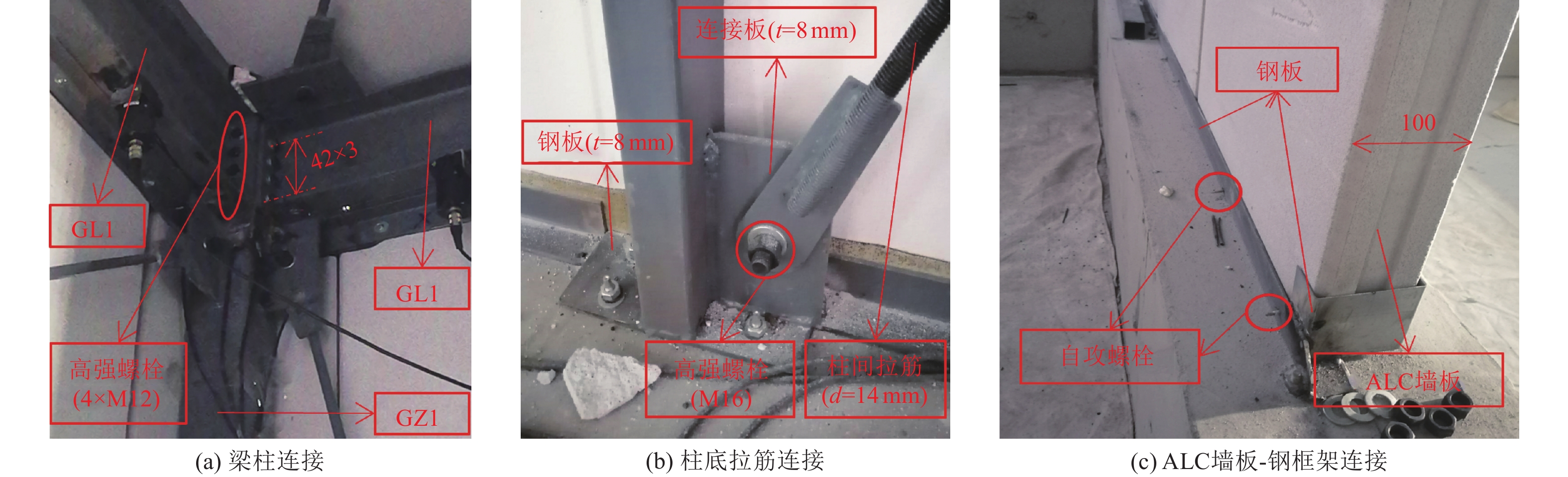

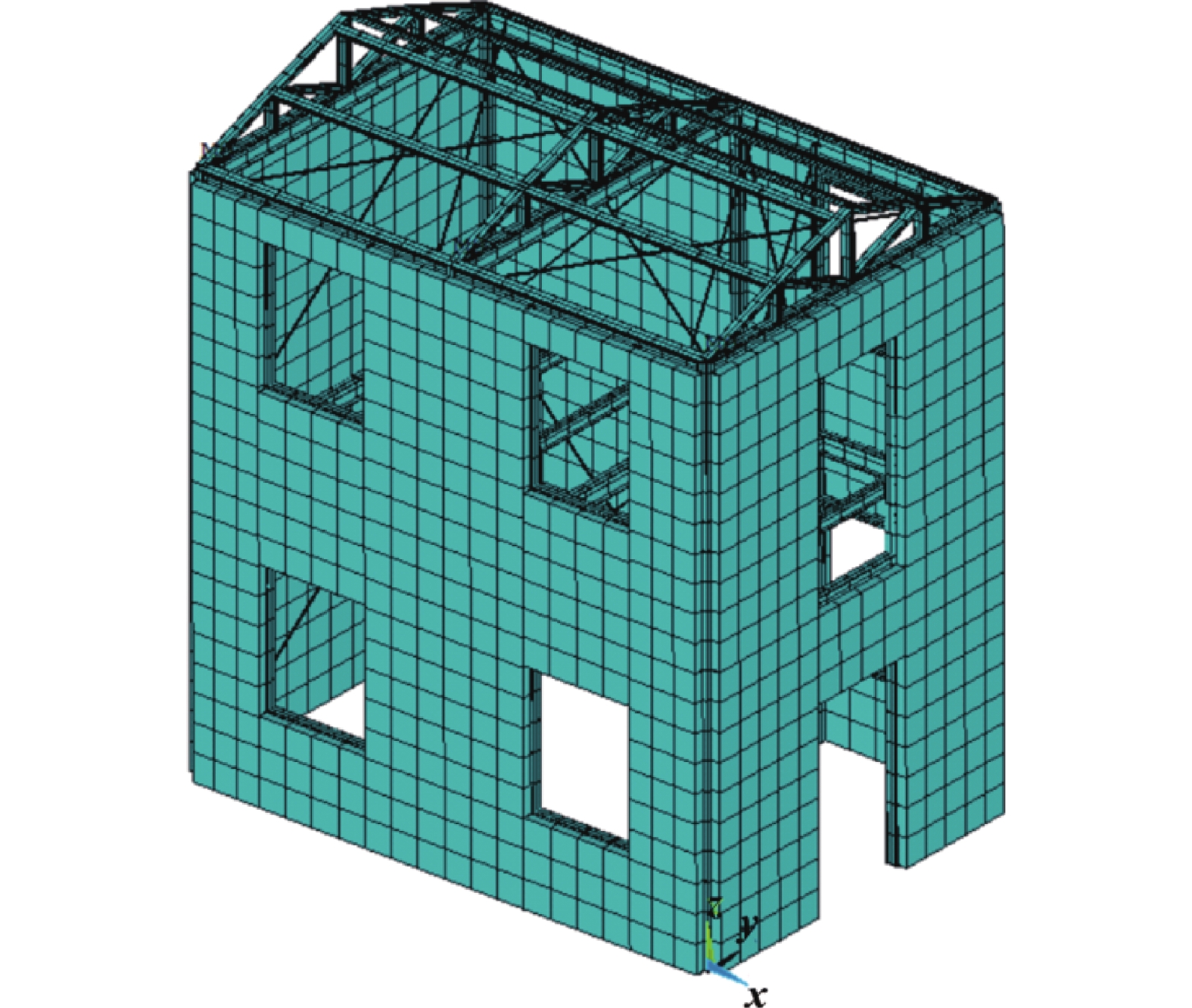

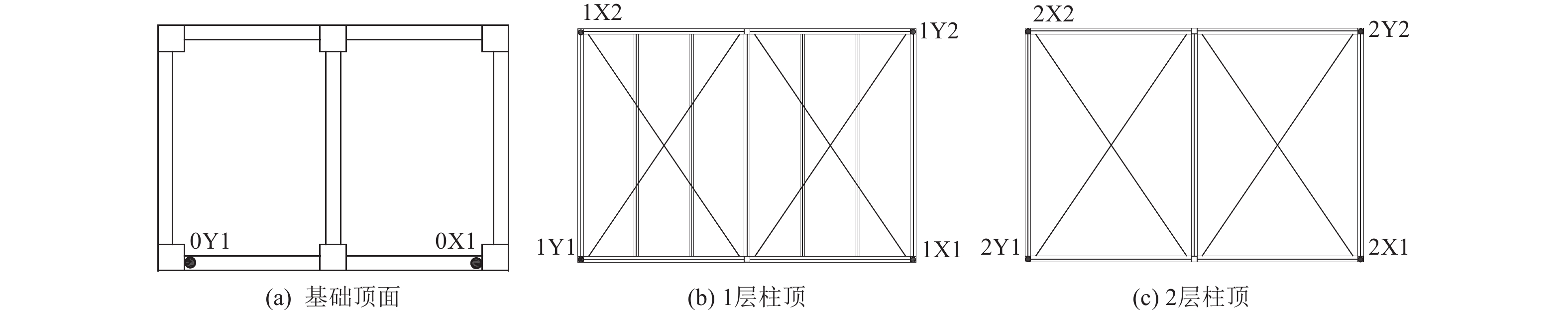

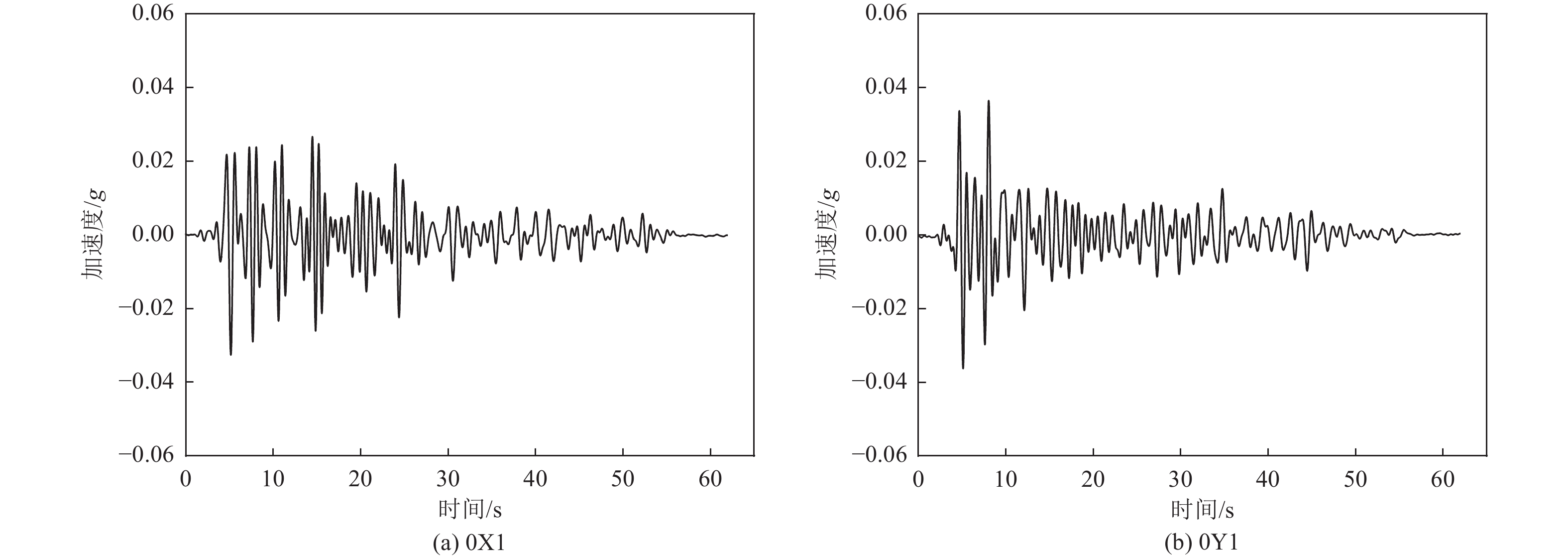

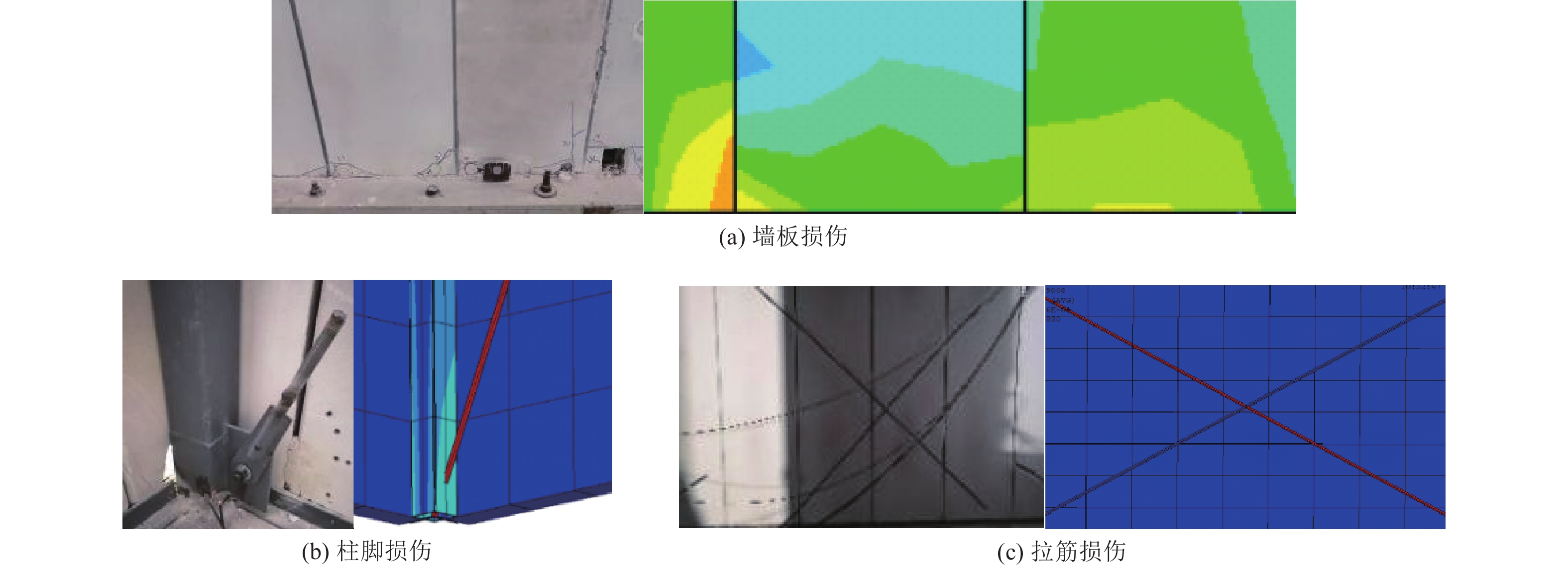

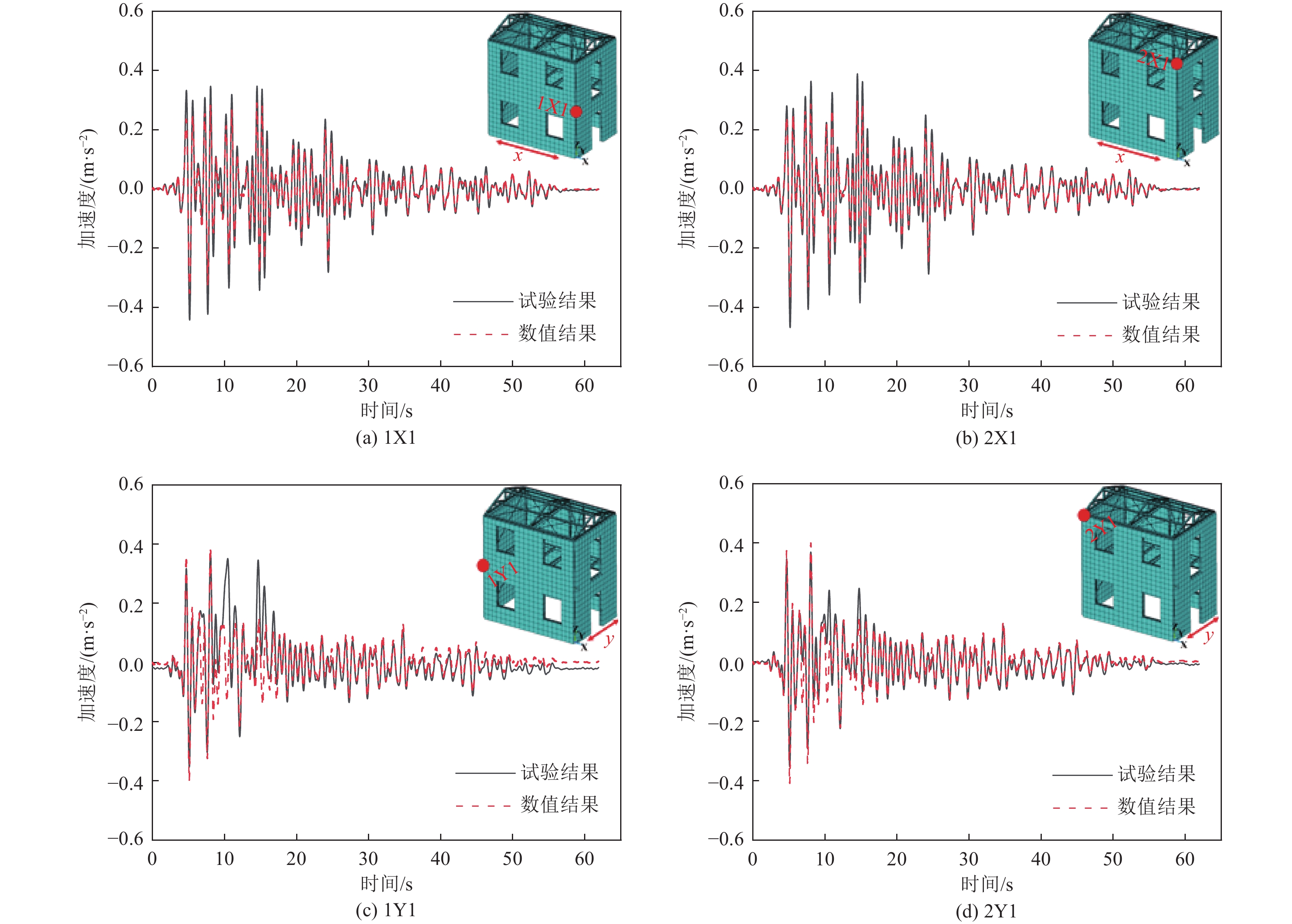

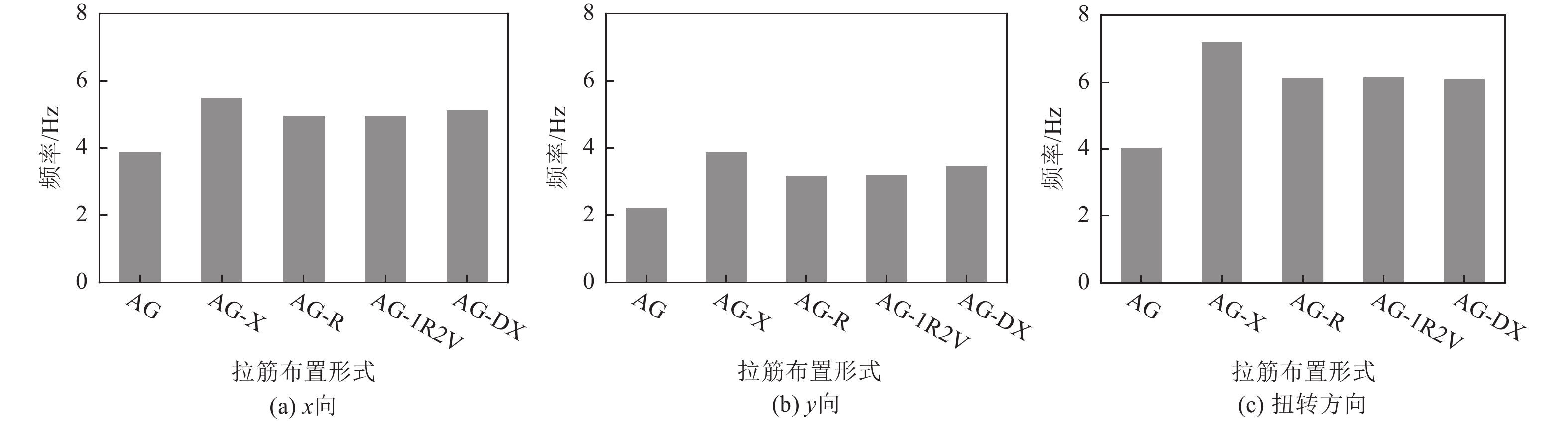

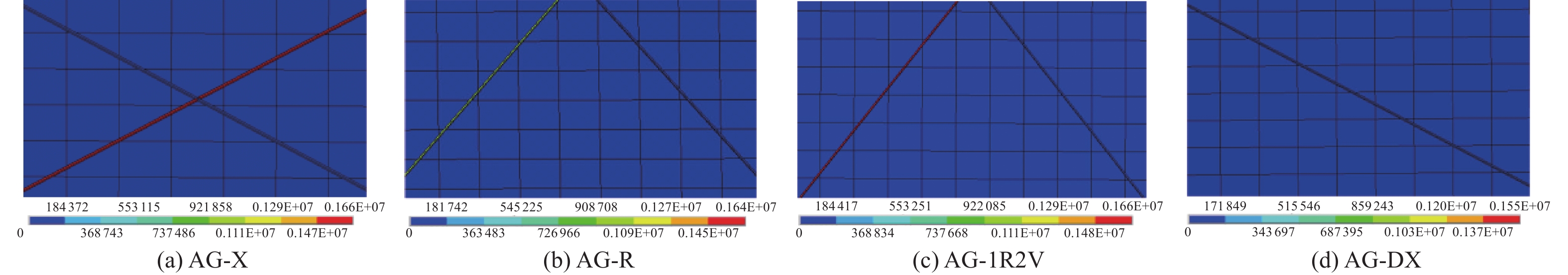

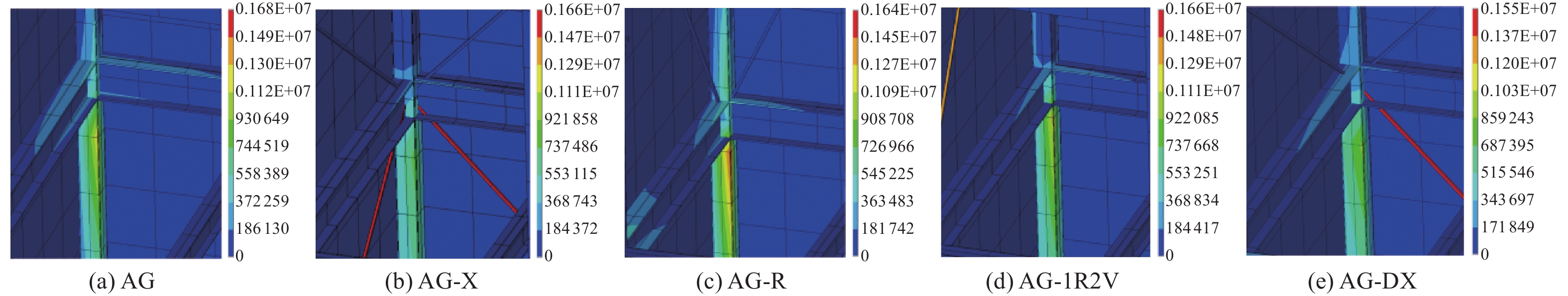

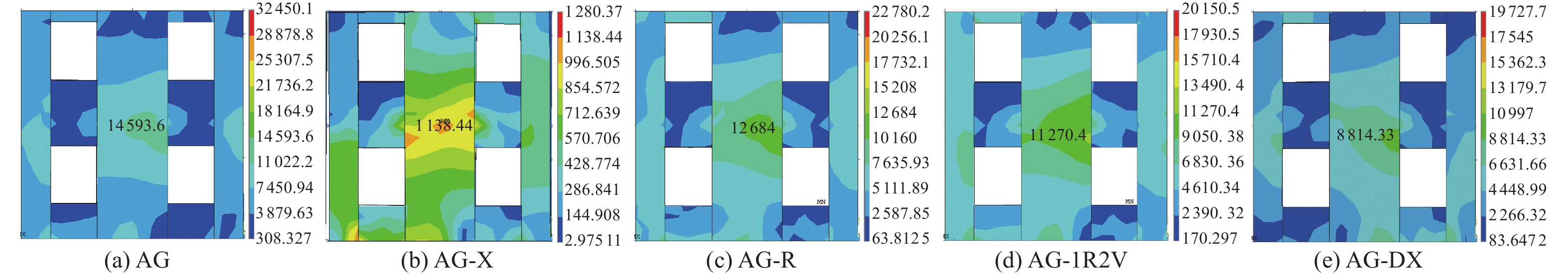

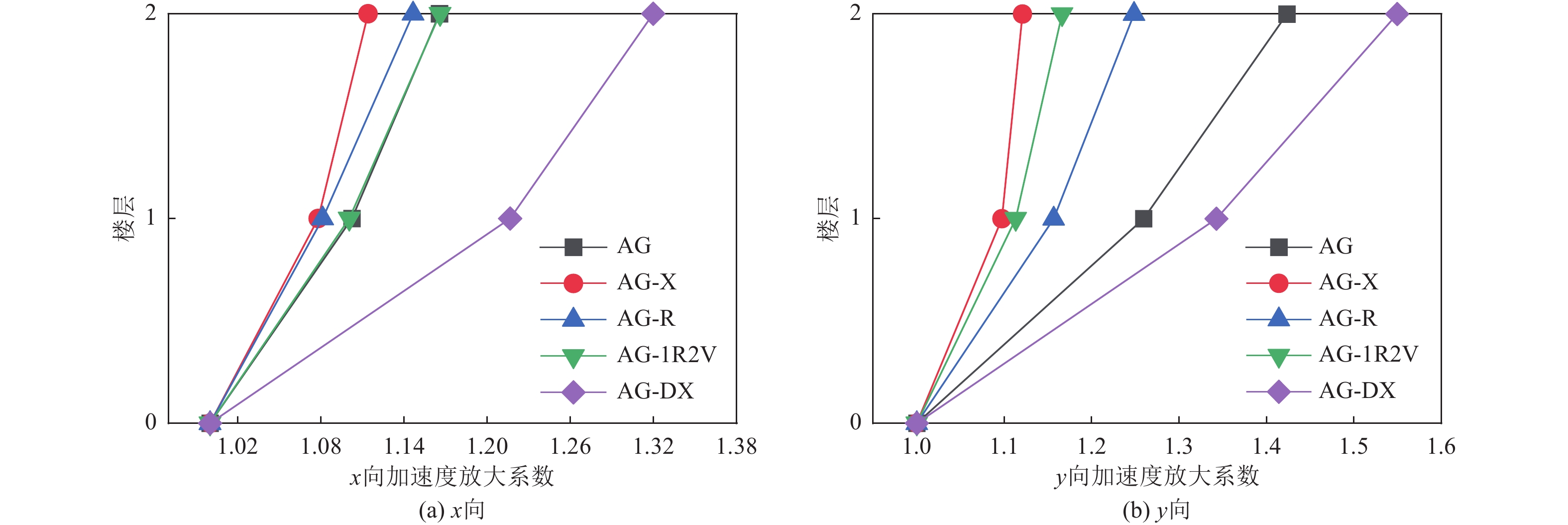

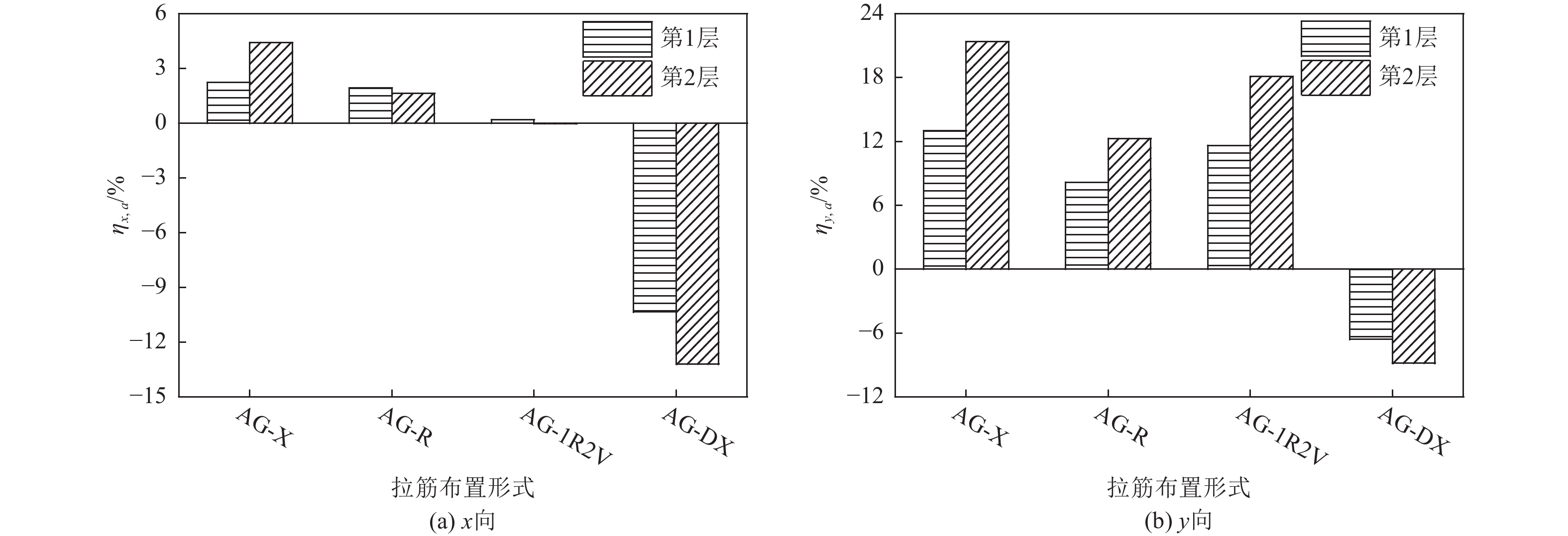

摘要: 以钢框架作为结构主体,外挂ALC墙板作为填充墙体的轻型钢框架结构体系经济安全、施工效率高、环保利废。振动台试验表明,柱间拉筋对轻框结构体系抗震性能有显著影响。为进一步了解柱间拉筋在轻框结构体系抗震能力提升中的作用,从而更好地将其用于新型农村住房建设,依托已开展的振动台试验,基于ANSYS软件平台建立了多种拉筋形式的轻框结构数值模型,系统研究了柱间拉筋布置形式和截面尺寸对轻框结构抗震性能的影响。研究结果表明,数值模拟分析结果与振动台试验结果吻合较好;设置柱间拉筋可改善轻框结构抗震能力,还可减小梁柱节点、ALC墙板应力响应;设置X形拉筋的轻框结构抗震性能表现最好;在一定范围内,柱间X形拉筋截面尺寸越大,轻框结构抗震性能越好,实际工程中需结合实施地区的经济情况进行选择。Abstract: The light steel frame structure system consists of steel frames as the primary structural elements, with external ALC (autoclaved lightweight concrete) wall panels serving as infill walls. This system offers several advantages, including cost-effectiveness, safety, high construction efficiency, environmental friendliness, and waste utilization. Previous shaking table tests have shown that the reinforcement between columns significantly influences the seismic performance of light frame structures. To further investigate the role of column-to-column tie bars in enhancing the seismic capacity of these structures and to facilitate their application in the construction of rural housing, this study develops numerical models based on ANSYS software. These models examine various configurations of tie bars and their impact on the seismic performance of light frame structures. The results demonstrate that the numerical model’s predictions align well with the experimental shaking table test outcomes. Specifically, the incorporation of tie bars between columns improves the seismic resistance of light frame structures, reduces the stress response at beam-column joints, and alleviates the stresses on ALC wall panels. Among the different configurations, X-shaped tie bars are particularly effective in enhancing seismic performance. Additionally, within certain limits, increasing the cross-sectional size of the X-shaped tie bars further improves the seismic performance of the structure. In practical engineering applications, the selection of tie bar configurations and cross-sectional sizes should consider the economic conditions of the implementation area. Properly designed tie bars can significantly improve the seismic resilience of light frame structures.

-

表 1 构件材料力学参数

Table 1. Material parameters of components

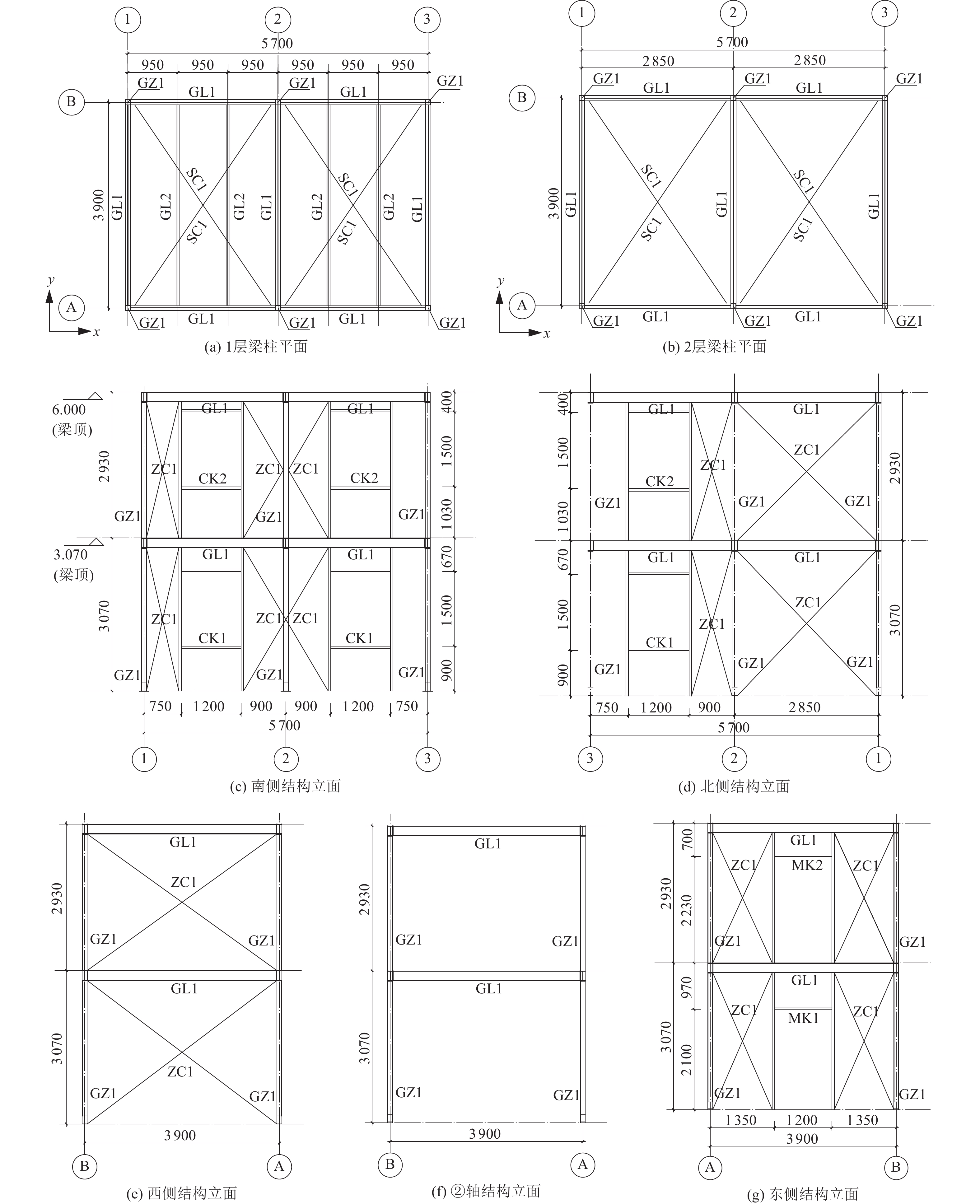

构件 材质 截面/mm 弹性模量/MPa 密度/(kg·m−3) 屈服强度/MPa 抗拉强度/MPa 抗压强度/MPa GZ1 Q235B钢 □100×100×4 2.06×105 7 850 235 215 215 GL1 Q235B钢 HN200×100×5.5×8 2.06×105 7 850 235 215 215 GL2 Q235B钢 HN150×75×5×7 2.06×105 7 850 235 215 215 MK1、MK2 Q235B钢 □50×100×3 2.06×105 7 850 235 215 215 CK1、CK2 Q235B钢 □50×100×3 2.06×105 7 850 235 215 215 ZC1 Q235B钢 ϕ14 2.06×105 7 850 235 215 215 SC1 Q235B钢 ϕ14 2.06×105 7 850 235 215 215 高强螺栓 钢 M12、M16、M24 2.06×105 7 850 — 430 430 自攻螺栓 钢 8 2.06×105 7 850 — 400 400 外墙板 ALC 1800 ×600×1002.2×104 491 — — 3.5 楼板 ALC 1800 ×600×1002.2×104 491 — — 3.5 屋顶 ALC 1800 ×600×1002.2×104 491 — — 3.5 表 2 轻框结构拉筋布置形式

Table 2. Layout of tie bars in light frame structure

标记 说明 ①轴钢架立面 ③轴钢架立面 A轴钢架立面 B轴钢架立面 AG 柱间不布置拉筋

AG-X 在柱间、门窗框与

柱间呈对角布置X形拉筋

AG-R 在柱间、门窗框与柱间

沿梁中心布置人字形拉筋

AG-1R2V 在柱间、门窗框与柱间沿梁

中心1层布置人字形拉筋、

2层布置V形拉筋

AG-DX 在柱间、门窗框与柱间

沿节点布置单个斜杆

注:除拉筋布置形式不同,其他构件均一致。 表 3 结构频率响应

Table 3. Frequency response of structure

一阶频率 试验结果/Hz 有限元结果/Hz 相对误差/% x向 3.98 5.50 38.2 y向 4.00 3.86 3.5 扭转 — 7.19 — 注:表中试验结果为拧紧拉杆后的结果。 表 4 最大加速度对比

Table 4. Comparison of peak acceleration response

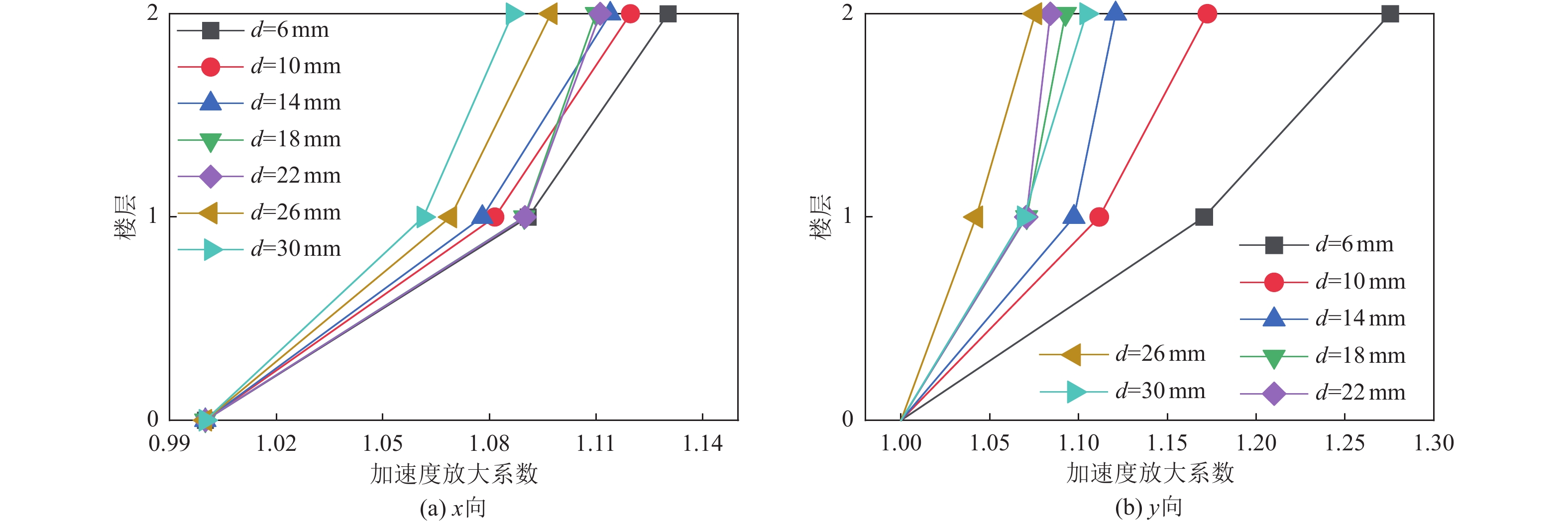

测点 1X1(2层) 2X1(屋顶) 1Y1(2层) 2Y1(屋顶) 试验得到的最大加速度/(m·s−2) 0.443 1(5.144 1 s) 0.468 4(5.151 9 s) 0.370 2 (8.034 0 s) 0.369 9(8.026 2 s) 数值模拟得到的最大加速度/(m·s−2) 0.351 4(5.144 1 s) 0.363 2(5.151 9 s) 0.400 0(5.093 4 s) 0.408 5(5.109 0 s) 相对误差/% 20.70 22.46 8.05 10.44 注:括号内为加速度达到最大值的时间。 表 5 最大加速度响应

Table 5. Peak acceleration response under different types of tie bars

模型名称 楼层 x向最大加速度ax,max/(m·s−2) x向加速度减震率ηx,a/% y向最大加速度ay,max/(m·s−2) y向加速度减震率ηy,a/% AG 1 0.359 4 — 0.459 7 — 2 0.380 0 — 0.519 5 — AG-X 1 0.351 4 2.23 0.400 0 12.99 2 0.363 2 4.42 0.408 5 21.37 AG-R 1 0.352 5 1.92 0.422 2 8.16 2 0.373 8 1.63 0.455 7 12.28 AG-1R2V 1 0.358 7 0.19 0.406 3 11.62 2 0.380 1 −0.03 0.425 6 18.08 AG-DX 1 0.396 6 −10.35 0.490 1 −6.61 2 0.430 2 −13.21 0.565 5 −8.85 -

陈世玺,吴杨周,于海丰等,2022. 剪切型耗能梁K形偏心支撑钢框架结构抗震性能研究. 建筑结构,52(24):50−56,76.Chen S. X., Wu Y. Z., Yu H. F., et al., 2022. Study on seismic behavior of K-shaped eccentrically braced steel frame structures with shear links. Building Structure, 52(24): 50−56,76. (in Chinese) 戴绍斌,余欢,黄俊,2005. 填充墙与钢框架协同工作性能非线性分析. 地震工程与工程振动,25(3):24−28.Dai S. B., Yu H., Huang J., 2005. Non-linear analysis of coordinated working performance between infilled wall and steel frame. Earthquake Engineering and Engineering Vibration, 25(3): 24−28. (in Chinese) 金勇,程才渊,2009. 蒸压加气混凝土墙板连接节点性能实验研究. 墙材革新与建筑节能,(2):34−37.Jin Y., Cheng C. Y., 2009. Experimental study on connection joint of autoclaved aerated concrete slabs. Wall Materials Innovation & Energy Saving in Buildings, (2): 34−37. (in Chinese) 李国强,方明霁,刘宜靖等,2005. 钢结构住宅体系加气混凝土外墙板抗震性能试验研究. 土木工程学报,38(10):27−31,38.Li G. Q., Fang M. J., Liu Y. J., et al., 2005. An experimental study on the seismic behavior of ALC external wall panels in steel frames. China Civil Engineering Journal, 38(10): 27−31,38. (in Chinese) 刘文超,曹万林,张克胜等,2020. 装配式轻钢框架-复合轻墙结构抗震性能试验研究. 建筑结构学报,41(10):20−29.Liu W. C., Cao W. L., Zhang K. S., et al., 2020. Seismic performance of fabricated composite structures with lightweight steel frames and single-row-reinforced recycled concrete wallboards. Journal of Building Structures, 41(10): 20−29. (in Chinese) 娄宇,温凌燕,李伟等,2022. 钢框架-K形支撑结构体系抗震性能试验研究. 建筑结构学报,43(11):32−40.Lou Y., Wen L. Y., Li W., et al., 2022. Experimental study on seismic performance of steel frame-K shaped brace structure system. Journal of Building Structures, 43(11): 32−40. (in Chinese) 孟祥君,2018. 蒸压加气混凝土砌块隔墙板受力性能研究. 沈阳:沈阳建筑大学.Meng X. J., 2018. Study on mechanical performance of autoclaved aerated concrete block partition board. Shenyang:Shenyang Jianzhu University. (in Chinese) 孙立建,郭宏超,刘云贺等,2017. 外挂再生混凝土墙板钢框架结构抗震性能有限元分析. 地震工程与工程振动,37(4):67−76.Sun L. J., Guo H. C., Liu Y. H., et al., 2017. Finite element analysis on seismic behavior of steel frame structure with recycled concrete external wall. Earthquake Engineering and Engineering Dynamics, 37(4): 67−76. (in Chinese) 孙庆,2021. 基于不同类型支撑的钢框架结构抗震性能分析. 青岛:青岛理工大学.Sun Q., 2021. Research on seismic performance of steel frame structure based on different brace. Qingdao:Qingdao University of Technology. (in Chinese) 王波,王静峰,李响等,2014. 填充ALC墙板钢管混凝土框架抗震试验与数值模拟. 土木工程学报,47(S2):56−61.Wang B., Wang J. F., Li X., et al., 2014. Experiments and analysis of CFST frames with ALC walls under seismic action. China Civil Engineering Journal, 47(S2): 56−61. (in Chinese) 王娇,2009. 两种偏心支撑钢框架的抗震性能比较分析. 四川建筑,29(5):123−125. 徐怡婷,2020. 装配式轻质ALC复合条板抗弯性能试验研究. 沈阳:沈阳建筑大学.Xu Y. T., 2020. Experimental study on bending behavior of assembled lightweight ALC composite strip boards. Shenyang:Shenyang Jianzhu University. (in Chinese) 张靖,王杰,李茂,2014. 轻钢框架-支撑结构振动台试验研究及有限元分析. 建筑科学,30(7):65−69.Zhang J., Wang J., Li M., 2014. Light steel frame-bracing structure shaking table test and finite element analysis. Building Science, 30(7): 65−69. (in Chinese) 邹昀,张振炫,李凯文等,2011. 轻型钢框架支撑体系振动特性与抗震性能分析. 工程力学,28(S1):48−52.Zou Y., Zhang Z. X., Li K. W., et al., 2011. Analysis on dynamic characteristics and seismic behavior of centrically braced steel frame. Engineering Mechanics, 28(S1): 48−52. (in Chinese) Corte G. D., Cantisani G., 2023. FEM Analysis of steel eccentric braces for seismic retrofitting. Procedia Structural Integrity, 44: 472−479. doi: 10.1016/j.prostr.2023.01.062 Fang M. J., Wang J. F., Li G. Q., 2013. Shaking table test of steel frame with ALC external wall panels. Journal of Constructional Steel Research, 80: 278−286. doi: 10.1016/j.jcsr.2012.07.009 Hsu H. L., Li Z. C., 2015. Seismic performance of steel frames with controlled buckling mechanisms in knee braces. Journal of Constructional Steel Research, 107: 50−60. doi: 10.1016/j.jcsr.2015.01.010 Liu Z. L., Wang M. F., Hogan L. S., 2023. Evaluation of seismic performance of precast concrete walls with X-shaped steel plate bracings. Structures, 48: 1548−1566. doi: 10.1016/j.istruc.2023.01.055 -

下载:

下载: