Research on Seismic Performance and Ecological Benefits of CFRP Confined Recycled Concrete Piers

-

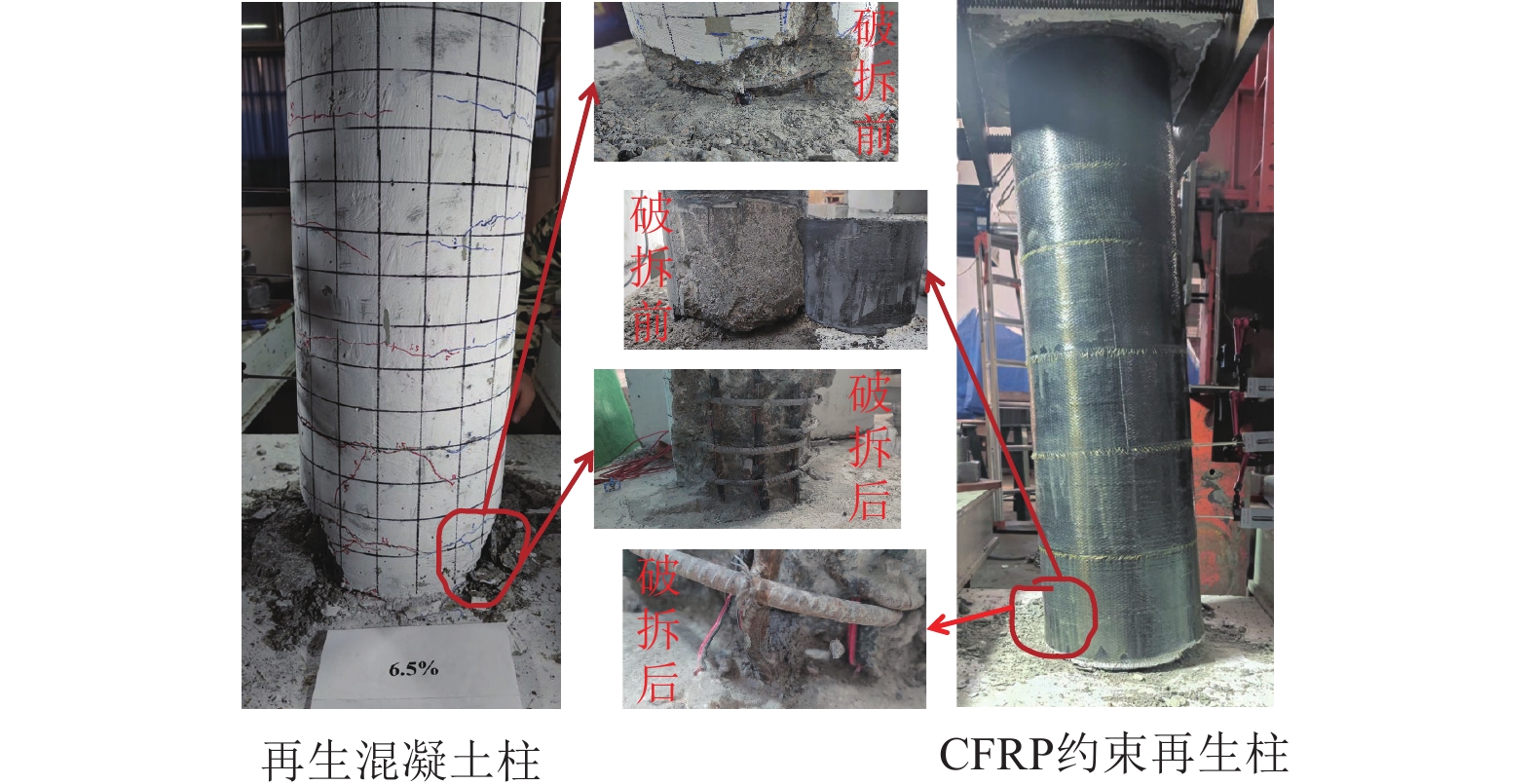

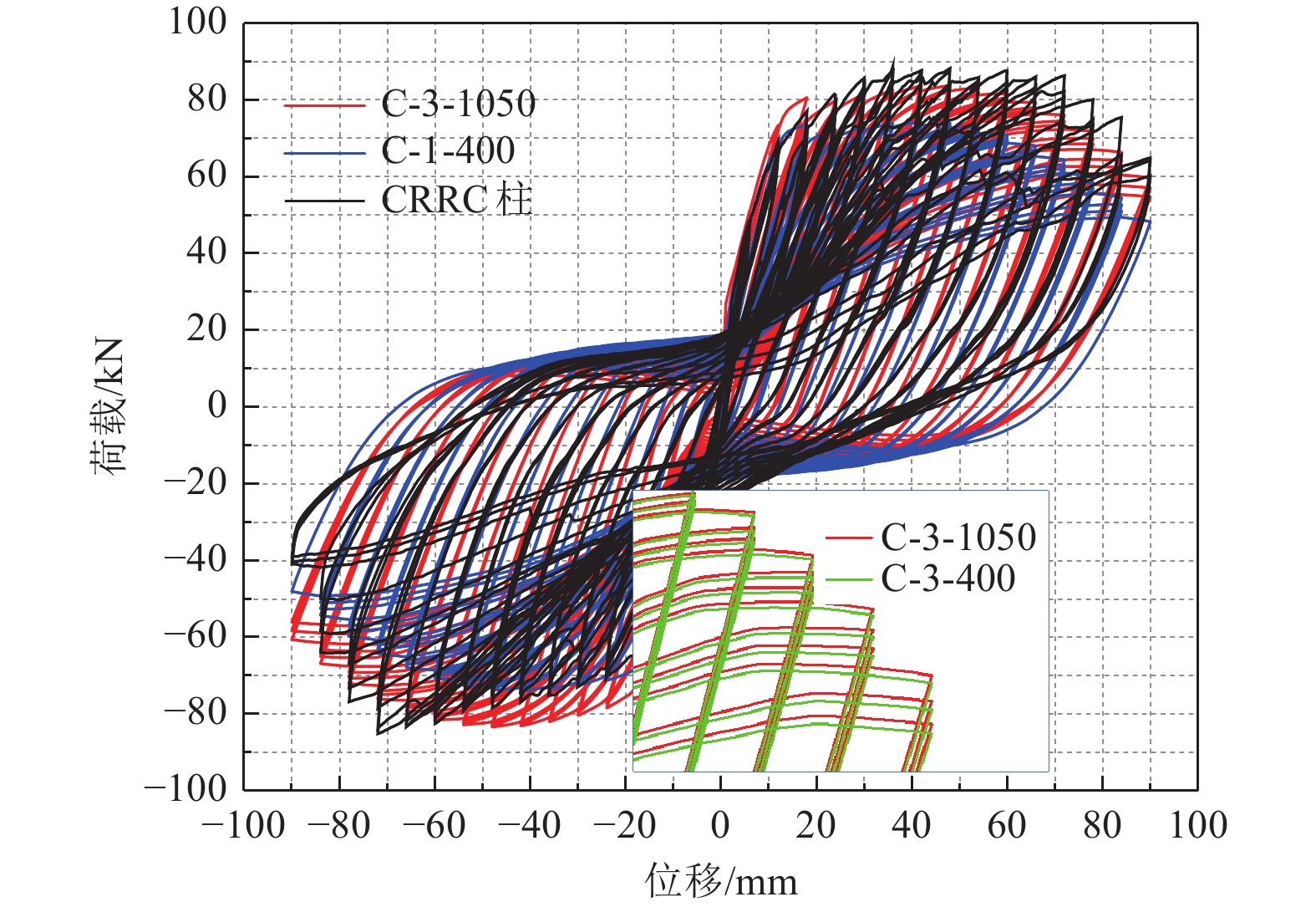

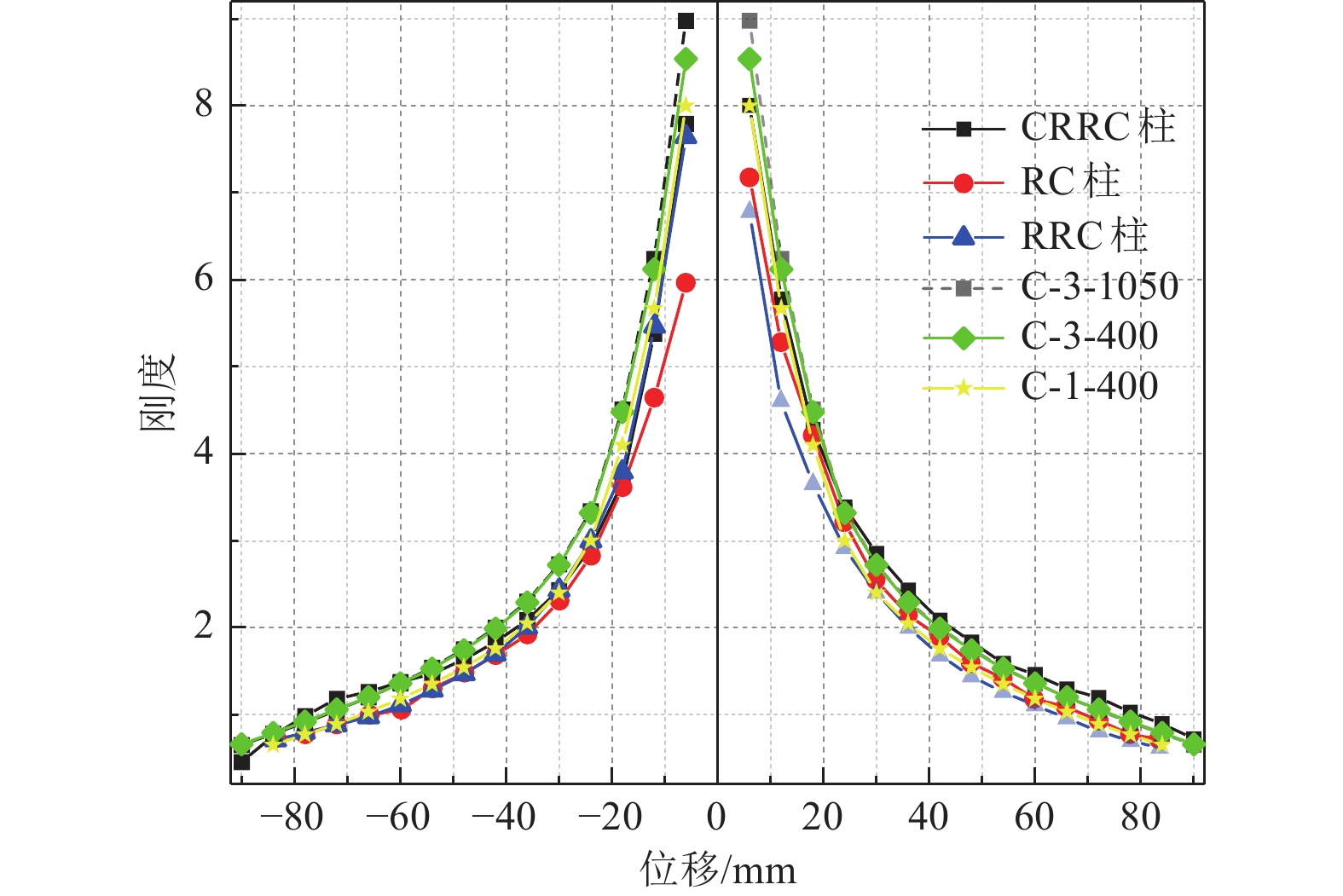

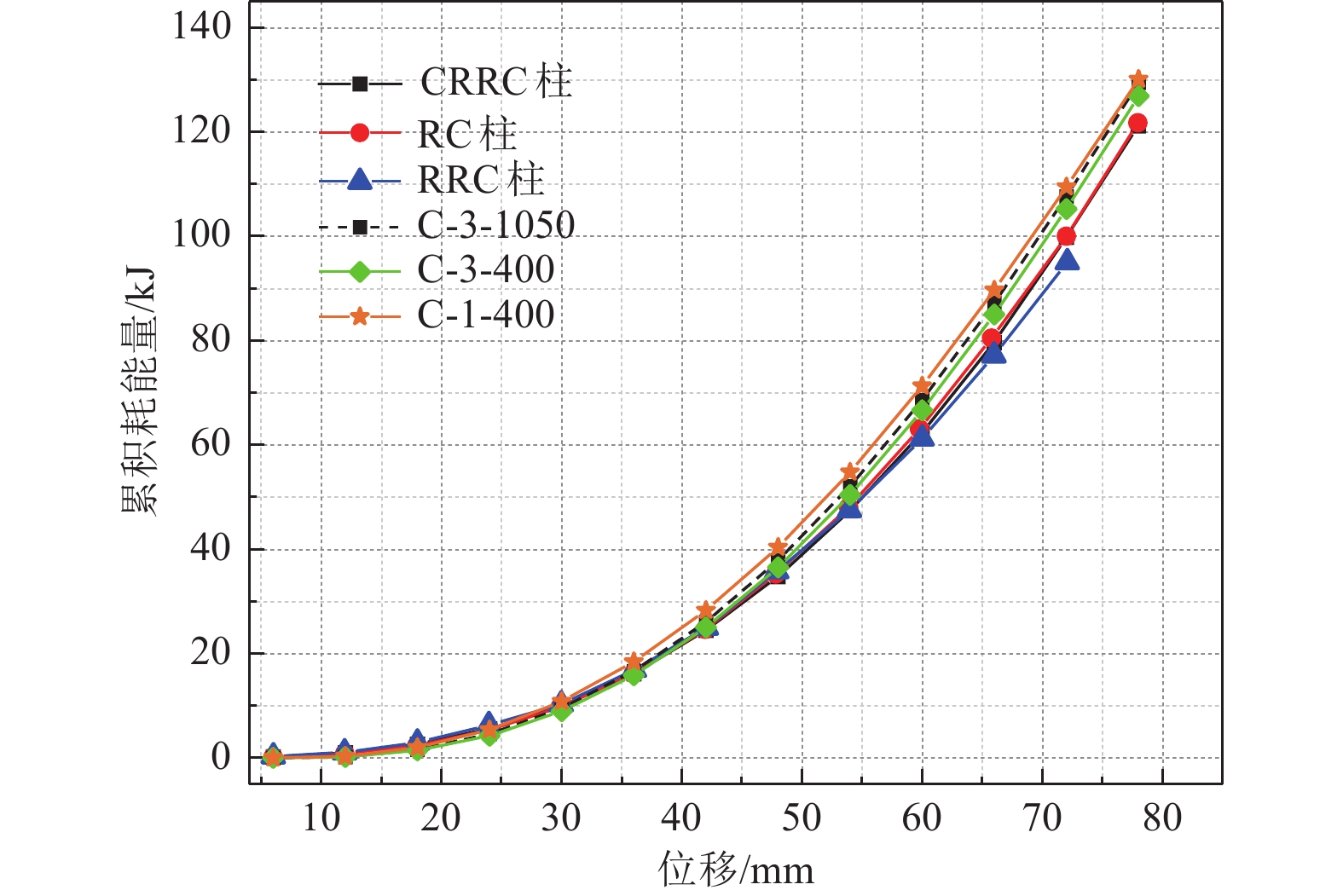

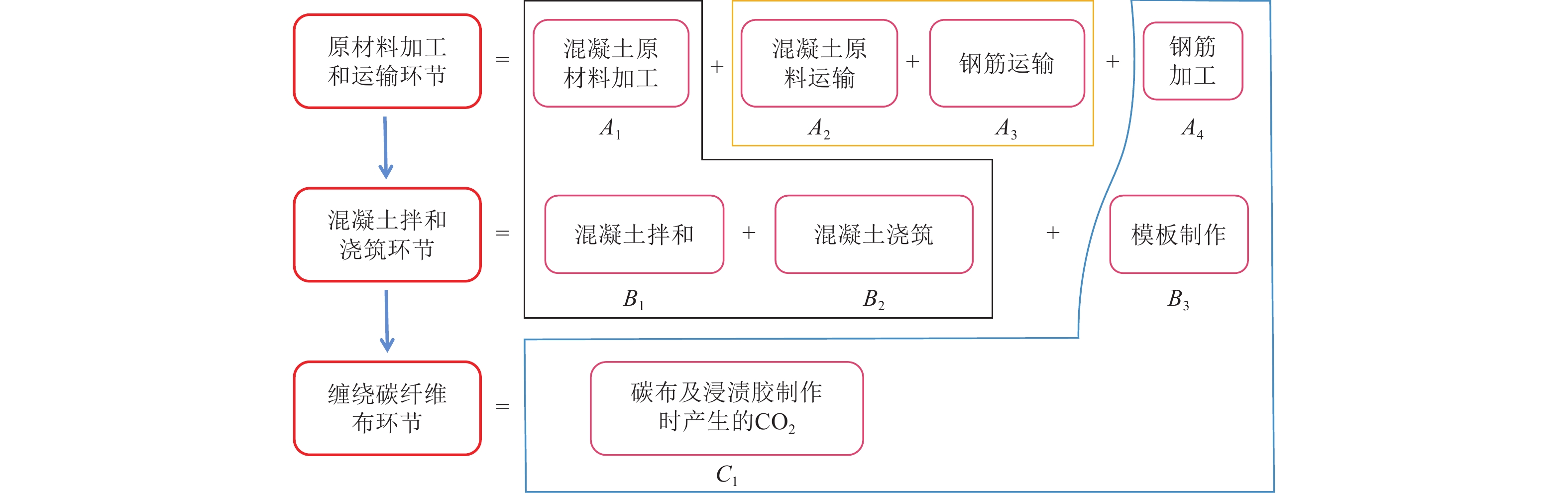

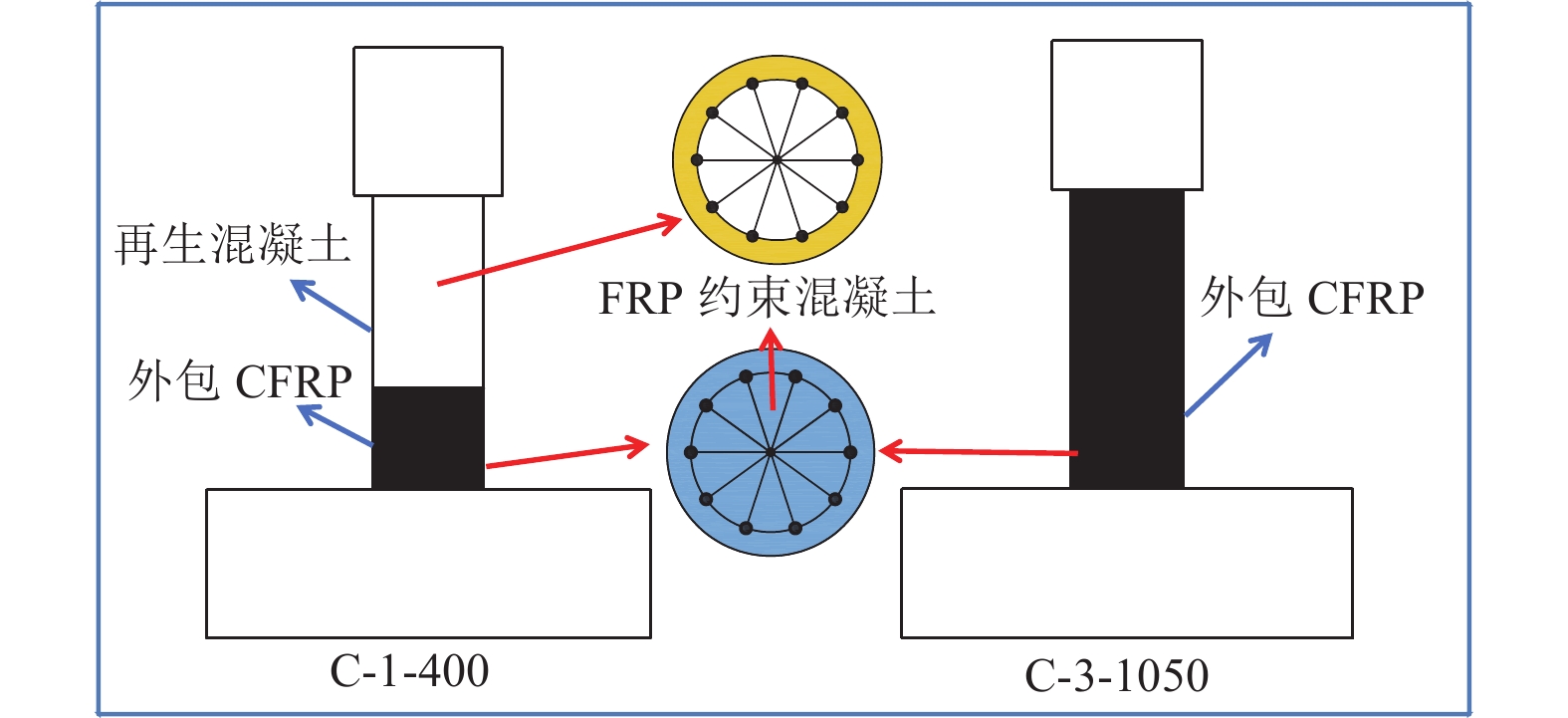

摘要: 随着大规模基础设施的建设及自然资源的逐步匮乏,再生混凝土逐渐应用到桥梁工程结构中。相对普通混凝土桥墩,再生混凝土桥墩的抗震性能偏弱。将碳纤维复合材料(CFRP)与再生混凝土相结合可提升桥墩的抗震性能。通过对普通混凝土柱、再生混凝土柱及CFRP约束再生混凝土柱进行拟静力试验及数值模拟研究,结果表明,再生混凝土柱经碳布包裹后最大承载力及位移延性系数分别提高了18.8% 和2.2%,达到了普通混凝土柱的水平。CFRP约束再生混凝土柱具有更大的初始刚度与残余刚度,累计总耗能量较再生混凝土柱提高28.1%。通过对碳布缠绕层数和缠绕高度的合理设置可提高再生混凝土柱的性能,从而达到和普通混凝土柱性能相近的目的。对CFRP约束再生混凝土柱的生态效益研究表明,CFRP约束再生混凝土柱其制备产生的二氧化碳总量比普通混凝土柱降低4.3%。CFRP约束再生混凝土桥墩的抗震性能及生态效益优于普通混凝土桥墩,因此具有一定的应用前景。Abstract: With the development of large-scale infrastructure and the growing scarcity of natural resources, recycled concrete is increasingly being used in bridge engineering. However, recycled concrete piers generally exhibit weaker seismic performance compared to conventional concrete piers. To enhance their seismic performance, carbon fiber reinforced polymer (CFRP) materials are applied to reinforce recycled concrete. Through quasi-static tests and numerical simulations on ordinary concrete columns, recycled concrete columns, and CFRP-confined recycled concrete columns, the results indicate that recycled concrete columns wrapped with carbon fiber cloth exhibit an 18.8% increase in maximum bearing capacity and a 2.2% increase in displacement ductility, reaching the performance level of ordinary concrete columns. CFRP-restrained recycled concrete columns also demonstrate greater initial and residual stiffness, with a cumulative total energy dissipation 28.1% higher than that of recycled concrete columns without CFRP. By optimizing the number of CFRP layers and wrapping height, the seismic performance of recycled concrete columns can be further improved to match that of conventional concrete columns. Furthermore, an analysis of the ecological benefits reveals that the carbon dioxide emissions associated with the production of CFRP-confined recycled concrete columns are 4.3% lower than those of ordinary concrete columns. Overall, CFRP-restrained recycled concrete bridge piers offer superior seismic performance and ecological benefits compared to conventional concrete piers, demonstrating promising potential for practical applications.

-

Key words:

- Bridge engineering /

- Confined recycled concrete /

- CFRP /

- Seismic performance /

- Ecological benefit

-

表 1 材料性能

Table 1. Materials performance

类别 取代率% 强度$f $/MPa 单位面积质量/(kg·m−2) 弹性模量E/MPa 伸长率/% 混凝土 0 47.3(fcu,抗压强度) — 29800 — 30 44.5(fcu,抗压强度) — 29300 — 钢筋 — 432.5(fy,屈服强度) — 208000 — 510.4(fs,极限强度) 碳布 — 3512.7(抗拉强度) 200 240000 1.7 浸渍胶 — 60.1(抗拉强度) — 2913 3.4 73.6(抗弯强度) 表 2 工况情况

Table 2. Specimen situation

试件编号 轴压比 取代率/% 包裹层数/层 缠绕高度/mm 试验工况 RC 0.15 — — — RRC 0.15 30 — — CRRC 0.15 30 3 1050 模拟工况 C-3-1050 0.15 30 3 1050 C-3-400 0.15 30 3 400 C-1-400 0.15 30 1 400 注:RC代表普通混凝土,RRC代表再生混凝土,CRRC代表CFRP约束再生混凝土。 表 3 参数取值

Table 3. Raber parameter value

屈服强度fy/MPa 极限强度fsu/MPa 硬化应变εsh 极限应变εsu 弹性模量/MPa 硬化模量/MPa 430 510 0.01 0.15 208000 6000 表 4 混凝土参数取值

Table 4. Concrete parameter value

无约束混凝土

峰值强度Fco/MPa无约束混凝土

峰值应变εto无约束混凝土

弹性模量Ec/MPa约束混凝土

极限强度Fcu/MPa约束混凝土

极限应变εcu约束混凝土

弹性模量E2/MPa44 0.005 29300 103 0.015 2000 表 5 特征荷载表(单位:千牛)

Table 5. Characteristic loads ( Unit : kN )

试件编号 屈服荷载 峰值荷载 极限荷载 RC 65.33 75.38 64.1 RRC 64.31 73.12 62.2 CRRC 70.5 86.88 73.85 C-3-1050 73.5 83.9 71.32 C-3-400 73.86 83.74 71.18 C-1-400 65.19 74.27 63.13 表 6 特征位移表(单位:毫米)

Table 6. Characteristic displacements( Unit : mm )

试件编号 屈服位移Δy 峰值位移Δmax 极限位移Δu RC 15.1 43.91 67.3 RRC 15.1 29.99 69.53 CRRC 17.18 54 78.35 表 7 位移延性系数与弹塑性极限位移角

Table 7. Displacement ductility coefficient and elastic-plastic ultimate displacement angle

试件编号 位移延性系数 弹塑性极限位移角 RC 4.60 1/18.57 RRC 4.46 1/17.98 CRRC 4.56 1/15.95 表 8 等价关系表

Table 8. Equivalence relation

单位材料/t 电能消耗/(kW·h) 煤消耗/kg 柴油消耗/L 水泥 40 96 — 再生粗骨料 — — 0.507 天然粗骨料 1.17 — 0.723 矿粉 76.93 21.66 0.12 减水剂 2.5 10 — 表 9 CO2总排放量(单位:千克)

Table 9. Total emissions of CO2 ( Unit : kg )

柱体类型 $ \mathop A\nolimits_{\mathop {{\mathrm{CO}}}\nolimits_{\text{2}} } $ $ \mathop B\nolimits_{\mathop {{\mathrm{CO}}}\nolimits_{\text{2}} } $ $ \mathop C\nolimits_{\mathop {{\mathrm{CO}}}\nolimits_{\text{2}} } $ $ \mathop T\nolimits_{\mathop {{\mathrm{CO}}}\nolimits_{\text{2}} } $ 约束再生柱 3762 296 33 4091 普通混凝土柱 3978 296 — 4274 -

薄景山,李平,孙有为等,2019. 中国城市抗御地震灾害研究的发展与实践. 震灾防御技术,14(2):259−268.Bo J. S., Li P., Sun Y. W., et al., 2019. The development and practice of the research on city resistance to earthquake disaster in China. Technology for Earthquake Disaster Prevention, 14(2): 259−268. (in Chinese) 贾晗曦,林均岐,刘金龙,2019. 全球地震灾害发展趋势综述. 震灾防御技术,14(4):821−828.Jia H. X., Lin J. Q., Liu J. L., 2019. The review of serious earthquake across the globe. Technology for Earthquake Disaster Prevention, 14(4): 821−828. (in Chinese) 贾俊峰,谭豫卿,白玉磊等,2022. 基于OpenSees仿真的自复位预制装配RC桥墩抗震性能分析. 应用基础与工程科学学报,30(2):328−340.Jia J. F., Tan Y. Q., Bai Y. L., et al., 2022. Seismic performance analysis of self-centering precast RC bridge columns based on OpenSees. Journal of Basic Science and Engineering, 30(2): 328−340. (in Chinese) 李贵乾,唐光武,郑罡,2016. 圆形钢筋混凝土桥墩等效塑性铰长度. 土木工程学报,49(2):87−97.Li G. Q., Tang G. W., Zheng G., 2016. Equivalent plastic hinge length of circular reinforced concrete bridge columns. China Civil Engineering Journal, 49(2): 87−97. (in Chinese) 李硕,赵作周,2023. 震损RC柱FRP加固后抗震性能数值模拟分析. 工程力学,40(10):89−98.Li S., Zhao Z. Z., 2023. Numerical simulation of seismic behavior of earthquake damaged RC columns strengthened with FRP. Engineering Mechanics, 40(10): 89−98. (in Chinese) 梁炯丰,刘大为,刘小娟等,2023. CFRP约束方钢管再生混凝土柱轴压性能研究. 混凝土,(5):21−26.Liang J. F. , Liu D. W. , Liu X. J. , et al. Study on axial compression performance of recycled concrete-filled CFRP confined square steel tubular columns. Concrete, (5): 21−26. (in Chinese) 刘瑾,张明,张淑斌,2022. 碳纤维复合材料风电叶片全生命周期内的碳排放分析. 合成纤维工业,45(3):41−44. doi: 10.3969/j.issn.1001-0041.2022.03.008Liu J., Zhang M., Zhang S. B., 2022. Carbon emission analysis of carbon fiber reinforced plastic wind turbine blades in life cycle. China Synthetic Fiber Industry, 45(3): 41−44. (in Chinese) doi: 10.3969/j.issn.1001-0041.2022.03.008 彭有开,2011. 再生混凝土框架柱抗震性能试验研究. 北京:北京建筑工程学院. 田甜,邱文亮,齐中新等,2017. 剪跨比对钢管混凝土组合桥墩抗震性能影响试验研究. 大连理工大学学报,57(2):133−141.Tian T., Qiu W. L., Qi Z. X., et al., 2017. Experimental study for effects of shear span ratio on seismic performance of concrete filled steel tube (CFST) composite bridge columns. Journal of Dalian University of Technology, 57(2): 133−141. (in Chinese) 肖建庄,黄一杰,2012. GFRP管约束再生混凝土柱抗震性能与损伤评价. 土木工程学报,45(11):112−120.Xiao J. Z., Huang Y. J., 2012. On the seismic behavior and damage assessment of recycled aggregate concrete filled GFRP tube column. China Civil Engineering Journal, 45(11): 112−120. (in Chinese) 肖建庄,黎骜,丁陶,2016. 再生混凝土生命周期CO2排放评价. 东南大学学报(自然科学版),46(5):1088−1092.Xiao J. Z., Li A., Ding T., 2016. Life cycle assessment on CO2 emission for recycled aggregate concrete. Journal of Southeast University (Natural Science Edition), 46(5): 1088−1092. (in Chinese) 谢礼立,2009. 汶川地震的教训. 南京工业大学学报(自然科学版),31(1):1−8. doi: 10.3969/j.issn.1671-7627.2009.01.002Xie L. L., 2009. Lessons learnt from Wenchuan earthquake. Journal of Nanjing Tech University (Natural Science Edition), 31(1): 1−8. (in Chinese) doi: 10.3969/j.issn.1671-7627.2009.01.002 杨刻亚,刘庆洋,2008. GFRP管混凝土圆形管柱抗震性能试验研究. 长春工程学院学报(自然科学版),9(1):29−31.Yang K. Y., Liu Q. Y., 2008. Seismic performance experimental research of GFRP-concrete circular tube columns. Journal of Changchun Institute of Technology (Natural Sciences Edition), 9(1): 29−31. (in Chinese) 袁泉,2021. 高轴压比下圆钢管再生混凝土柱抗震性能试验研究与有限元分析. 合肥:合肥工业大学.Yuan Q., 2021. Experimental study and finite element analysis on seismic performance of recycled concrete columns with circular steel tube under high axial compression ratio. Hefei:Hefei University of Technology. (in Chinese) 袁学良,杨月,盛雪柔等,2023. 碳达峰碳中和政策解析与对策建议. 山东大学学报(工学版),53(5):132−141.Yuan X. L., Yang Y., Sheng X. R., et al., 2023. Policy analysis and countermeasures for achieving carbon peak and carbon neutrality. Journal of Shandong University (Engineering Science), 53(5): 132−141. (in Chinese) 章雪峰,单鲁阳,郑曙光等,2018. GFRP管混凝土组合长柱的抗震性能研究. 建筑结构,48(9):78−82.Zhang X. F., Shan L. Y., Zheng S. G., et al., 2018. Analysis on seismic behaviors of long concrete-filled GFRP tube columns. Building Structures, 48(9): 78−82. (in Chinese) 张一伟,王章琼,石钊等,2022. 国内外建筑垃圾资源化利用现状及对策分析. 山西建筑, 48 (16):173−176,188.Zhang Y. W. , Wang Z. Q. , Shi Z. , et al. , 2022. Current situation and countermeasures of construction waste resource utilization at home and abroad. Shanxi Architecture, 48 (16): 173−179, 188. (in Chinese) 郑山锁,杨路,姬金铭等,2021. 冻融RC梁抗震性能与数值模拟方法. 振动工程学报,34(5):889−898.Zheng S. S., Yang L., Ji J. M., et al., 2021. Seismic behavior and numerical modelling method of RC beams subjected to freezing-thawing damage. Journal of Vibration Engineering, 34(5): 889−898. (in Chinese) 朱百峰,2016. 装配整体式建筑绿色度评价体系研究−−以沈阳名流印象项目为例. 沈阳:沈阳建筑大学.Zhu B. F., 2016. Research on evaluation index system of prefabricated building green degree based on MingLiu project in Shenyang. Shenyang:Shenyang Jianzhu University. (in Chinese) Ajdukiewicz A. B., Kliszczewicz A. T., 2007. Comparative tests of beams and columns made of recycled aggregate concrete and natural aggregate concrete. Journal of Advanced Concrete Technology, 5(2): 259−273. doi: 10.3151/jact.5.259 Bai Y. L., Mei S. J., Chan C. W., et al., 2021. Compressive behavior of large-size square PEN FRP-concrete-steel hybrid multi-tube concrete columns. Engineering Structures, 246: 113017. doi: 10.1016/j.engstruct.2021.113017 Chen G. M., He Y. H., Jiang T., et al., 2016. Behavior of CFRP-confined recycled aggregate concrete under axial compression. Construction and Building Materials, 111: 85−97. doi: 10.1016/j.conbuildmat.2016.01.054 Chen G. M., Zhang J. J., Lin G., et al., 2022. Behavior of different-sized FRP-confined square compound concrete columns containing recycled concrete lumps. Journal of Composites for Construction, 26(2): 04022003. doi: 10.1061/(ASCE)CC.1943-5614.0001192 Guo Y. C. , Xiao S. H. , Zeng J. J. , et al. 2022. Behavior of concrete-filled FRP tube columns internally reinforced with FRP-steel composite bars under axial compression. Construction and Building Materials, 315 : 125714. Lam L., Teng J. G., 2003. Design-oriented stress–strain model for FRP-confined concrete. Construction and Building Materials, 17(6-7): 471−489. doi: 10.1016/S0950-0618(03)00045-X Ozbakkaloglu T., Saatcioglu M., 2006. Seismic behavior of high-strength concrete columns confined by fiber-reinforced polymer tubes. Journal of Composites for Construction, 10(6): 538−549. doi: 10.1061/(ASCE)1090-0268(2006)10:6(538) Wu B., Yang X., Zhang J. J., et al., 2022. Recycled lump concrete-filled FRP tubular columns: axial compressive behavior and size effects. Construction and Building Materials, 352: 129000. doi: 10.1016/j.conbuildmat.2022.129000 Zeng J. J., Zhang X. W., Chen G. M., et al., 2020. FRP-confined recycled glass aggregate concrete: concept and axial compressive behavior. Journal of Building Engineering, 30: 101288. doi: 10.1016/j.jobe.2020.101288 -

下载:

下载: