Experimental Study on Small Strain Shear Modulus of Fine Grained Soil in the Yellow River Alluvial Plain

-

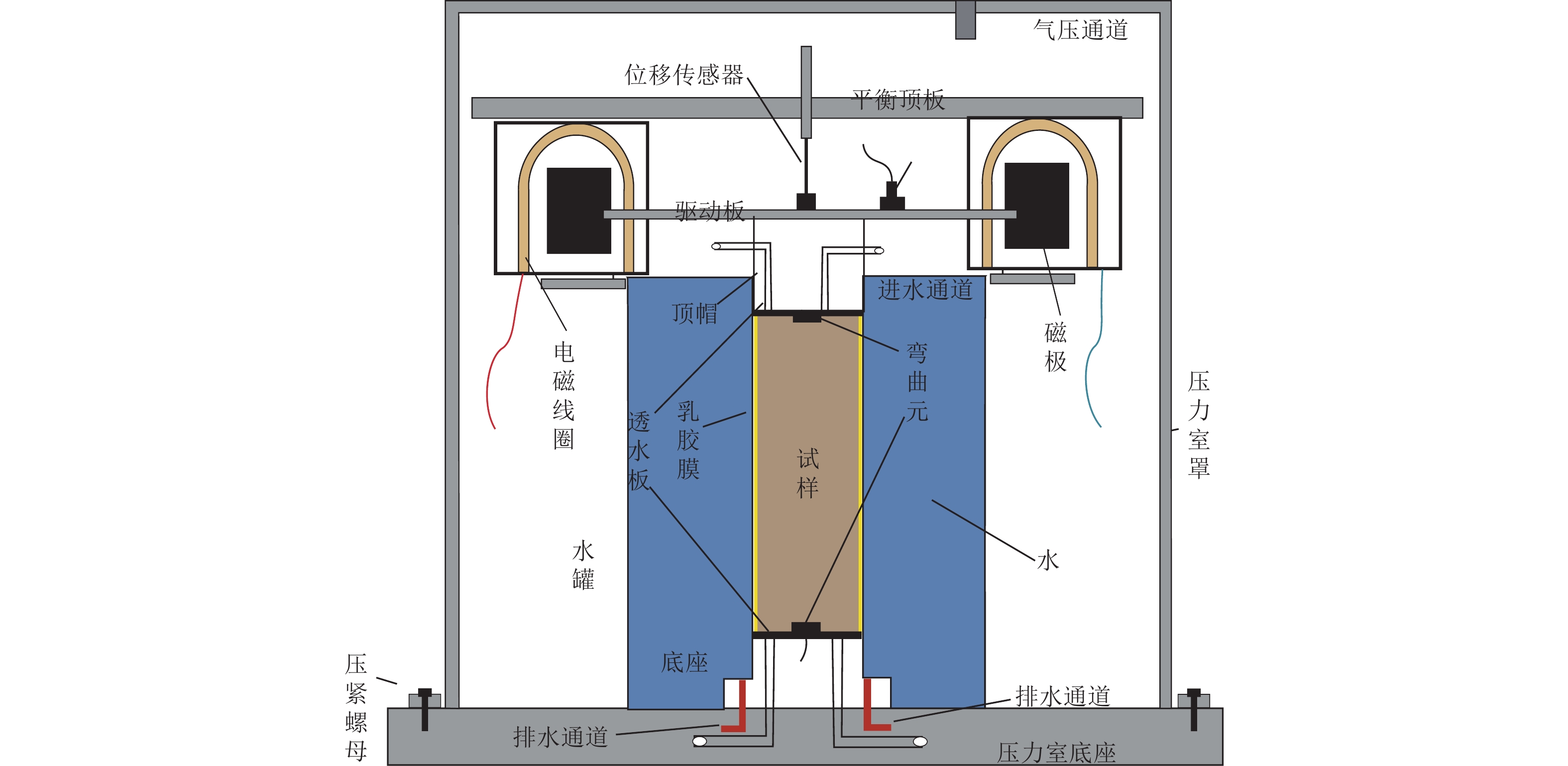

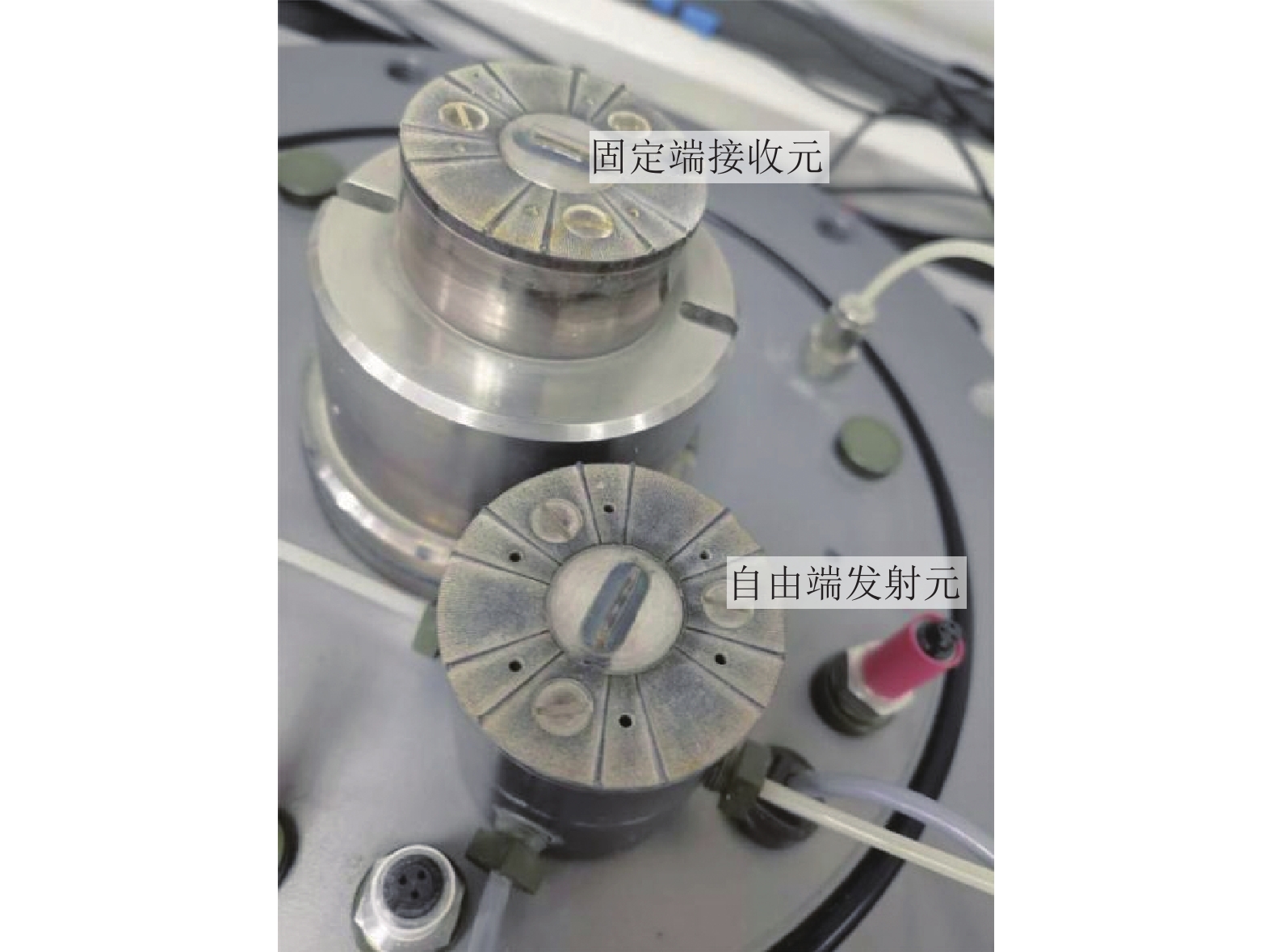

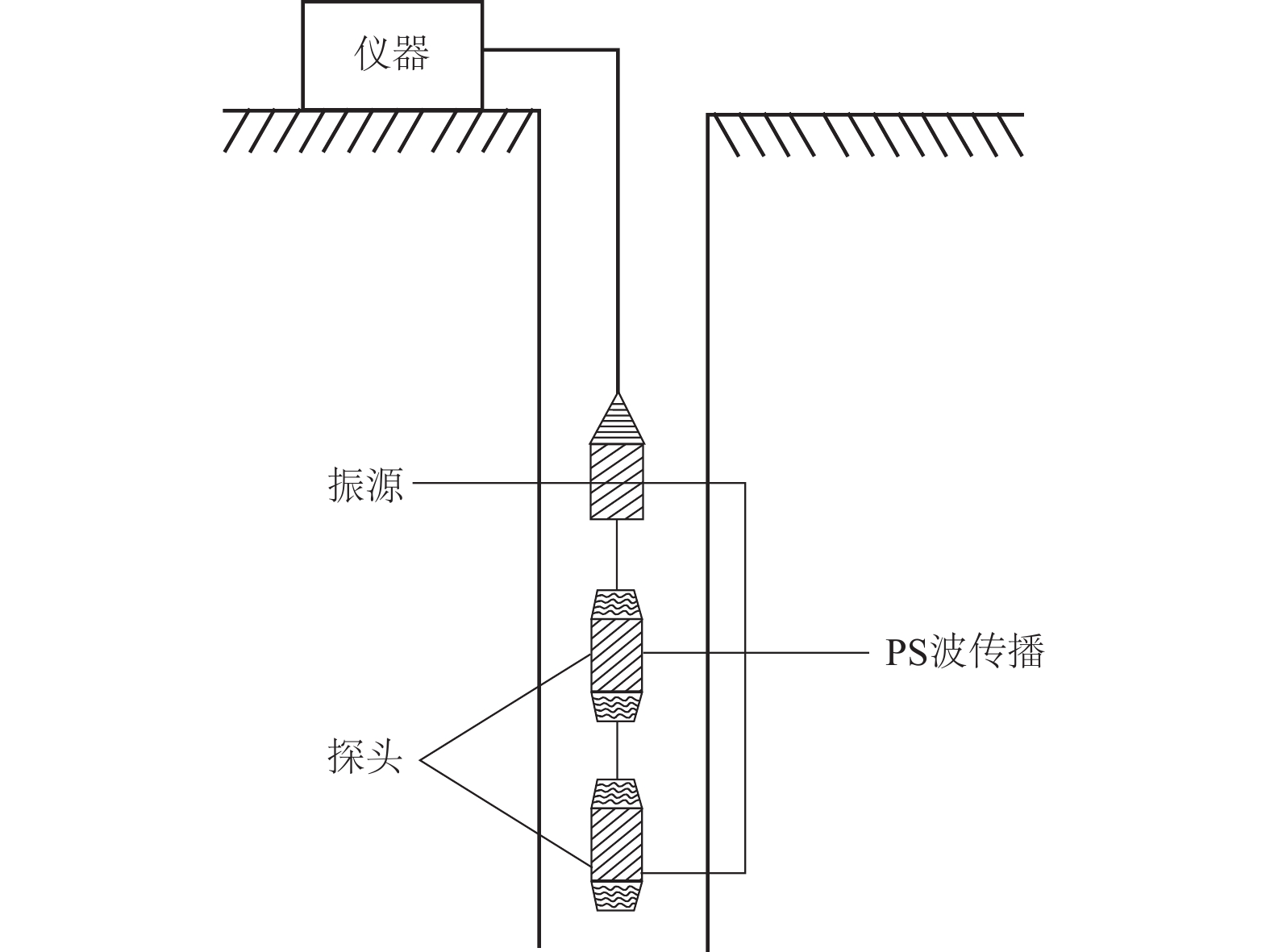

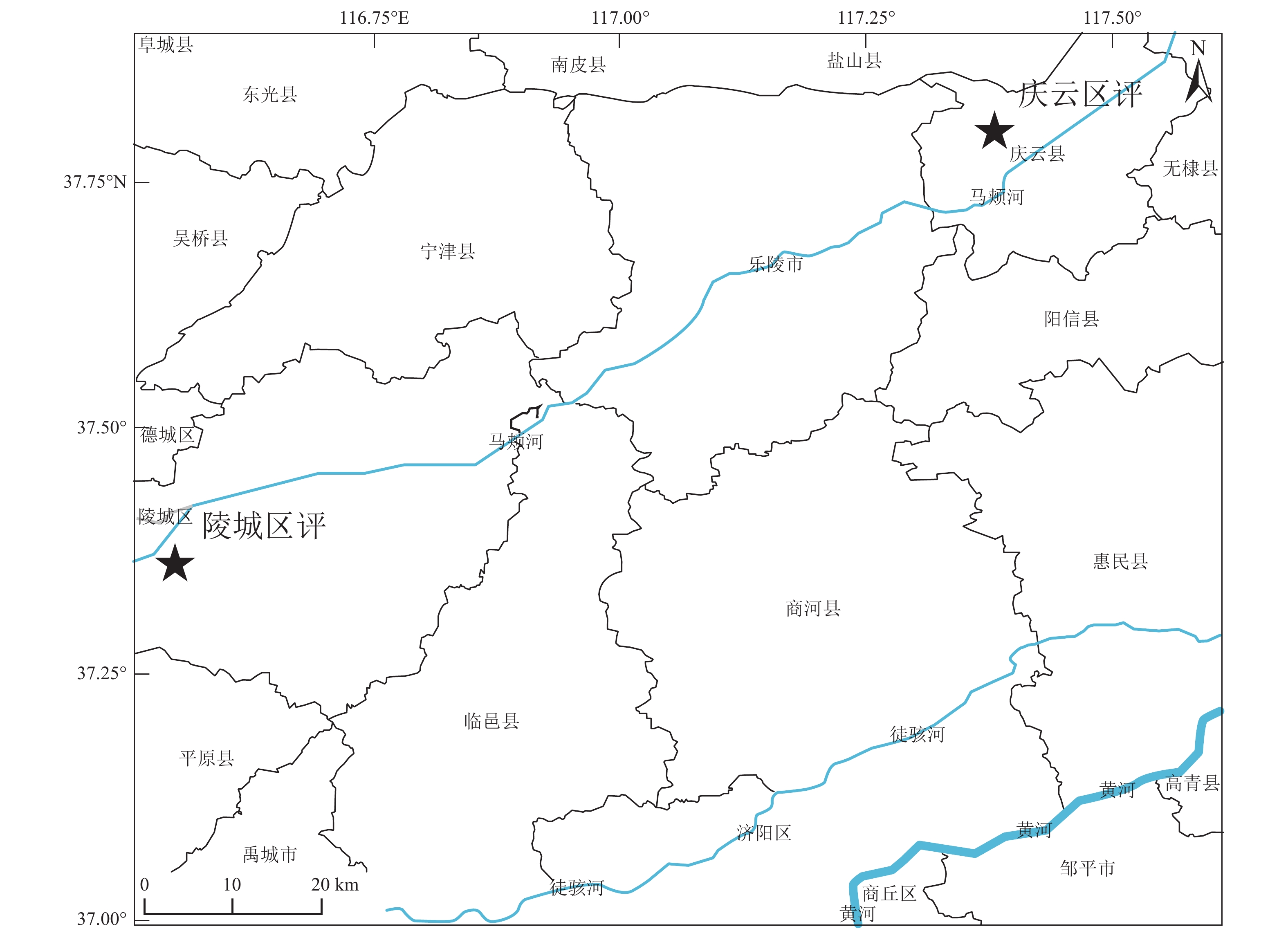

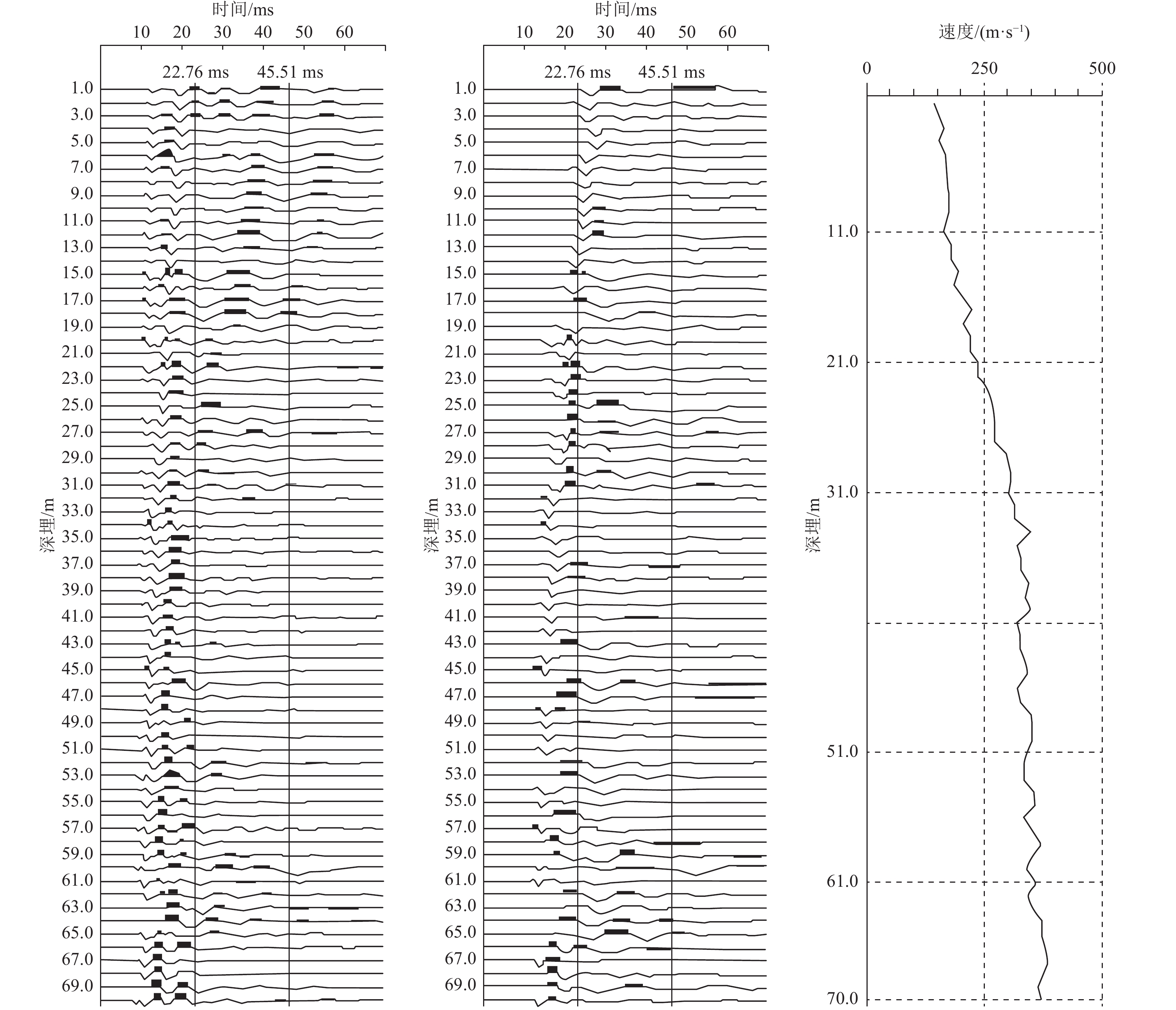

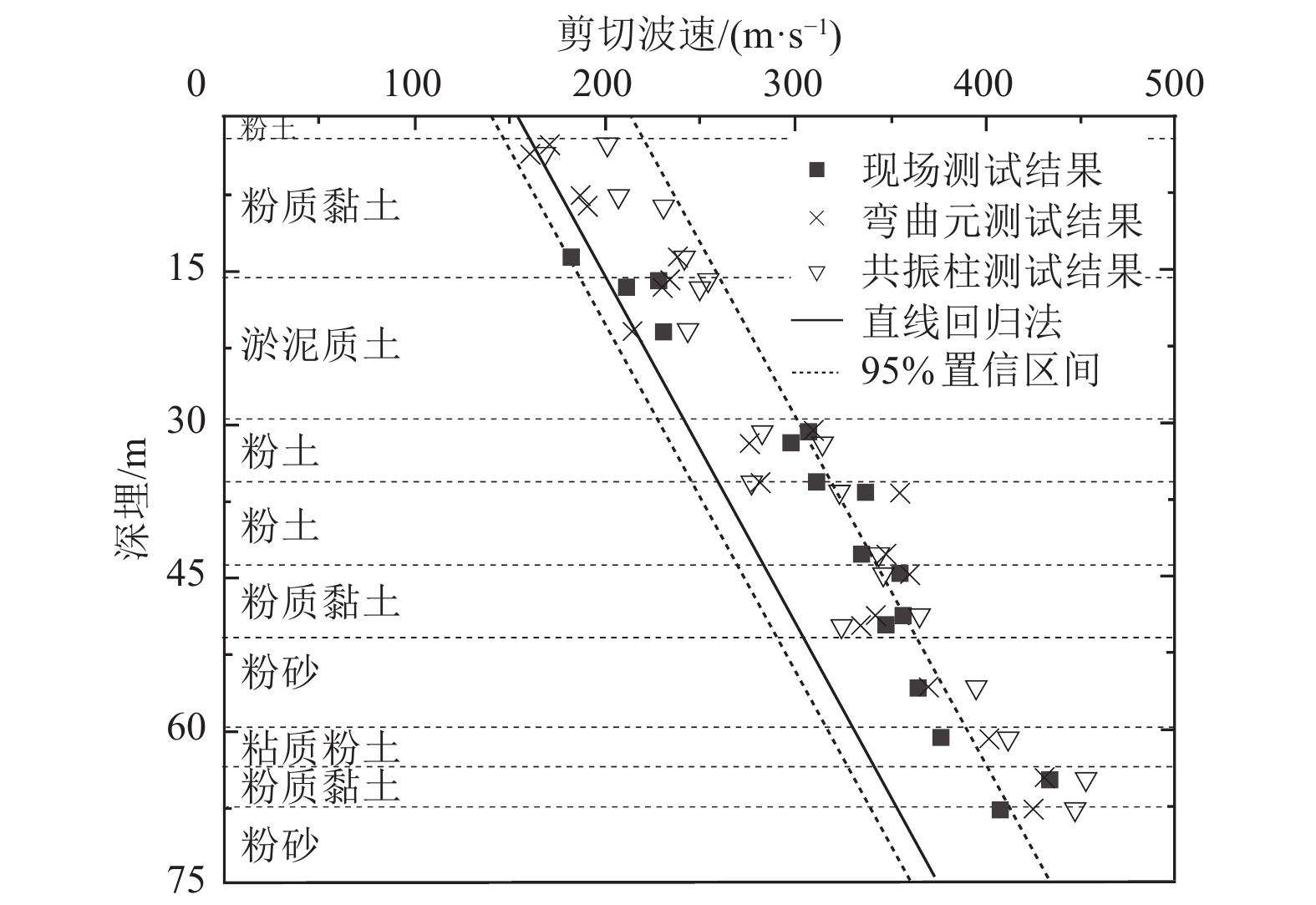

摘要: 本文通过采用原位波速法、弯曲元试验法和共振柱试验法,深入探讨了室内测试与原位波速法在小应变剪切模量试验中的差异。选取山东省境内黄河冲积平原典型场地细粒土钻孔资料,统计原位波速法和室内测试2种测试手段测得的剪切波速,并对测试结果进行对比分析。研究结果表明,在保持土的有效应力状态和减少土样扰动的基础上,原位波速法、弯曲元试验法和共振柱试验法测得的小应变剪切模量总体趋势一致,原位波速法的结果普遍小于室内测试的结果,但相对误差大多不超过10%。其中弯曲元试验法测试细粒土得到的小应变剪切模量与原位波速法的结果更为接近。建议工程实践中采用弯曲元试验法快速测得细粒土小应变剪切模量。将Rampello的经验公式描述的小应变剪切模量与实测结果进行对比,给出相关土层经验参数。研究结果可为该地区地下工程计算分析中小应变剪切模量的估算提供参考。Abstract: This study investigates the differences in small strain shear modulus (Gmax) measured using laboratory tests and the in-situ wave velocity method. The research utilizes data from a typical fine-grained soil site in the Yellow River alluvial plain, Shandong Province, China. The shear wave velocities measured by both in-situ wave velocity and laboratory methods (including bending element and resonant column tests) were compared. The results demonstrate a consistent trend in Gmax values across all methods, assuming the effective stress state of the soil is maintained and sample disturbance is minimized. While Gmax values from the in-situ wave velocity method tend to be lower than those from laboratory tests, the relative errors are generally less than 10%. The bending element test yields Gmax values that are closer to those obtained from the in-situ wave velocity method. It is suggested that, for engineering applications, the bending element test offers a quick and accurate means of determining the small strain shear modulus of fine-grained soils. Additionally, Rampello's empirical formula for Gmax is compared to the measured results, and the relevant empirical parameters for different soil layers are provided. These findings offer valuable insights for estimating the shear modulus at small and medium strains in underground engineering design and analysis in this region.

-

表 1 试样参数

Table 1. Specimen parameters

取土地点 土样编号 取样深度/m 天然含水率/% 天然重度/(g·cm−3) 固结压力/kPa 土类 颜色状态 陵城区 K23-1 2.8 24.3 2.0 50 粉土 褐黄色,中密 K23-2 3.8 37.3 1.9 50 粉质黏土 黄褐色,可塑 K23-3 8.8 30.4 2.0 100 粉质黏土 黄褐色,可塑 K23-4 16.0 35.1 2.0 160 淤泥质土 黑灰色,可塑~软塑 K23-6 30.8 24.5 2.1 300 粉质黏土 褐黄色,可塑 K23-7 36.8 22.9 2.1 370 粉土 褐黄色,中密 K23-9 44.8 27.9 2.0 450 粉质黏土 褐黄色,可塑 K23-10 49.8 20.0 2.1 500 粉砂 褐黄色,密实 K23-14 60.8 22.5 2.1 600 黏质粉土 褐黄色,可塑~硬塑 K23-16 64.8 20.4 2.1 650 粉质黏土 黄褐色,硬塑 K23-17 67.8 19.5 1.9 680 粉砂 褐黄色,密实 庆云县 K19-2 7.8 21.7 2.0 100 粉质黏土 黄褐色,可塑 K19-3 13.8 24.3 2.1 140 粉质黏土 褐黄色,可塑 K19-4 16.8 20.8 2.1 170 粉质黏土 褐黄色,可塑 K19-5 21.0 22.0 2.1 200 黏土 黄褐色,可塑~硬塑 K19-7 32.0 27.7 2.0 300 粉质黏土 褐色,可塑~硬塑 K19-8 35.8 20.1 2.1 350 粉土 黄色,中密 K19-9 42.8 27.3 2.0 450 粉质黏土 褐黄色,可塑~硬塑 K19-11 48.8 25.1 2.0 500 粉质黏土 黄褐色,硬塑 K19-12 55.8 37.5 2.0 550 黏土 褐色,硬塑 注:原位波速法钻孔为取样钻孔。 表 2 3种方法剪切波速测试结果对比

Table 2. Comparison of shear wave velocity test results from three methods

取土点 测试深度/m 土层性质 现场测试结果/

(m·s−1)弯曲元测试结果/

(m·s−1)共振柱测试结果/

(m·s−1)相对误差/% 现场与弯曲元 现场与共振柱 弯曲元与共振柱 陵城区 2.8 粉土 164.0 170.9 201.9 4.2 23.1 18.1 3.8 粉质黏土 164.0 161.1 169.17 1.7 3.2 5.0 8.8 粉质黏土 179.0 191.0 231.2 6.7 29.2 21.1 16.0 淤泥质土 229.0 234.0 254.6 2.2 11.2 8.8 30.8 黏质粉土 307.0 310.0 282.8 1.0 7.9 8.8 36.8 粉土 337.0 355.0 323.0 5.3 4.2 9.0 44.8 粉质黏土 355.0 360.0 345.9 1.4 2.6 3.9 49.8 粉砂 348.0 335.0 324.7 3.7 6.7 3.1 60.8 黏质粉土 377.0 402.0 412.0 6.6 9.3 2.5 64.8 粉质黏土 434.0 431.0 453.0 0.7 4.4 5.1 67.8 粉砂 408.0 425.3 446.9 4.2 9.5 5.1 庆云县 7.8 黏质粉土 168.0 187.5 207.3 11.6 23.4 10.6 13.8 粉质黏土 182.0 238.7 242.4 31.2 33.2 1.6 16.8 粉质黏土 211.0 230.8 250.6 9.4 18.8 8.6 21.0 黏土 231.0 214.8 243.7 −7.0 5.5 13.4 32.0 粉质黏土 298.0 276.3 315.0 −7.3 5.7 14.0 35.8 粉土 311.0 281.9 277.8 −9.4 −10.7 −1.4 42.8 粉质黏土 335.0 347.7 344.6 3.8 2.9 −0.9 48.8 粉质黏土 357.0 342.3 365.2 −4.1 2.3 6.7 55.8 黏土 365.0 370.8 395.1 1.6 8.3 6.6 表 3 3种测试手段得到的土体小应变剪切模量Gmax值

Table 3. The small strain shear modulus of soil mass obtained with three testing methods

取样点 测试深度/m 土层性质 弯曲元Gmax/MPa 共振柱Gmax/MPa 现场测试Gmax/MPa 陵城区 3.8 粉质黏土 51.4 49.6 54.7 8.8 粉质黏土 64.7 73.7 108.0 16.0 淤泥质土 102.8 107.3 127.0 30.8 黏质粉土 198.9 202.8 168.7 36.8 粉土 240.8 267.2 221.2 44.8 粉质黏土 254.6 261.8 241.7 49.8 粉砂 253.1 234.6 220.4 60.8 黏质粉土 298.5 339.4 356.5 64.8 粉质黏土 391.8 386.4 426.8 67.8 粉砂 322.9 350.9 387.5 7.8 黏质粉土 56.2 70.0 85.5 庆云县 13.8 粉质黏土 69.9 120.2 124.0 16.8 粉质黏土 94.8 113.4 133.7 21.0 黏土 113.7 98.3 126.5 32.0 粉质黏土 173.2 148.9 193.5 35.8 粉土 200.2 164.5 159.7 42.8 粉质黏土 226.7 244.2 239.9 48.8 粉质黏土 256.2 235.4 268.1 55.8 黏土 261.1 269.4 306.0 表 4 土体经验参数S、n取值

Table 4. Values of soil empirical parameters S and n

数据类别 试验方法 e f(e) S n 参考文献 经验值 三轴试验、共振柱试验 0.5~6.2 $ {\left(1+e\right)}^{-2.4} $ 15000 ~50000 0.5 Vardanega等(2013) 本次测试 单孔波速测试 0.7~1.13 $ {\left(1+e\right)}^{-2.4} $ 30000 ~45000 0.5 本文结果 -

柏立懂,项伟,Savidis A. S. 等,2012. 干砂最大剪切模量的共振柱与弯曲元试验. 岩土工程学报,34(1):184−188.Bai L. D., Xiang W., Savidis A. S., et al., 2012. Resonant column and bender element tests on maximum shear modulus of dry sand. Chinese Journal of Geotechnical Engineering, 34(1): 184−188. (in Chinese) 陈旭庚,田家勇,王恩福等,2007. 基于小波分析的场地波速测量方法. 地震工程与工程振动,27(1):159−163. doi: 10.3969/j.issn.1000-1301.2007.01.025Chen X. G., Tian J. Y., Wang E. F., et al., 2007. Wave-velocity logging based on wavelet analysis. Journal of Earthquake Engineering and Engineering Vibration, 27(1): 159−163. (in Chinese) doi: 10.3969/j.issn.1000-1301.2007.01.025 陈云敏,周燕国,黄博,2006. 利用弯曲元测试砂土剪切模量的国际平行试验. 岩土工程学报,28(7):874−880. doi: 10.3321/j.issn:1000-4548.2006.07.013Chen Y. M., Zhou Y. G., Huang B., 2006. International parallel test on the measurement of shear modulus of sand using bender elements. Chinese Journal of Geotechnical Engineering, 28(7): 874−880. (in Chinese) doi: 10.3321/j.issn:1000-4548.2006.07.013 董全杨,蔡袁强,徐长节等,2013. 干砂饱和砂小应变剪切模量共振柱弯曲元对比试验研究. 岩土工程学报,35(12):2283−2289.Dong Q. Y., Cai Y. Q., Xu C. J., et al., 2013. Measurement of small−strain shear modulus G max of dry and saturated sands by bender element and resonant column tests. Chinese Journal of Geotechnical Engineering, 35(12): 2283−2289. (in Chinese) 方怡,赵京轶,吕悦军等,2016. 唐山地区剪切波速现场测试和室内测试值差异研究. 工程勘察,44(8):7−10.Fang Y., Zhao J. Y., Lv Y. J., et al., 2016. Study on the difference of shear wave velocity values between field tests and laboratory tests in Tangshan area. Geotechnical Investigation & Surveying, 44(8): 7−10. (in Chinese) 冯志仁,郭德存,刘红帅等,2007. 最大剪切模量对土动力参数及地震反应的影响. 自然灾害学报,16(3):90−95. doi: 10.3969/j.issn.1004-4574.2007.03.017Feng Z. R., Guo D. C., Liu H. S., et al., 2007. Influence of maximum shear modulus on dynamic parameters and seismic response of soil layer. Journal of Natural Disasters, 16(3): 90−95. (in Chinese) doi: 10.3969/j.issn.1004-4574.2007.03.017 胡庆兴,刘雪珠,从卫民等,2003. 淮安市典型土动力特性的试验研究. 地震工程与工程振动,23(6):144−148. doi: 10.3969/j.issn.1000-1301.2003.06.023Hu Q. X., Liu X. Z., Cong W. M., et al., 2003. Experimental study on dynamic property of typical soils for Huaian City. Earthquake Engineering and Engineering Vibration, 23(6): 144−148. (in Chinese) doi: 10.3969/j.issn.1000-1301.2003.06.023 姬美秀,陈云敏,黄博,2003. 弯曲元试验高精度测试土样剪切波速方法. 岩土工程学报,25(6):732−736. doi: 10.3321/j.issn:1000-4548.2003.06.019Ji M. X., Chen Y. M., Huang B., 2003. Method for precisely determining shear wave velocity of soil from bender element tests. Chinese Journal of Geotechnical Engineering, 25(6): 732−736. (in Chinese) doi: 10.3321/j.issn:1000-4548.2003.06.019 汪云龙,袁晓铭,李晓飞,2014. GDS-RCA型共振柱仪常规实验可靠性研究. 地震工程与工程振动,34(1):95−99.Wang Y. L., Yuan X. M., Li X. F., 2014. Reliability analysis of the tests by GDS-RCA resonant column apparatus. Earthquake Engineering and Engineering Dynamics, 34(1): 95−99. (in Chinese) 尹松,孔令伟,张先伟,2017. 炎热多雨气候影响下残积土小应变刚度特性试验研究. 岩土工程学报,39(4):743−751. doi: 10.11779/CJGE201704021Yin S., Kong L. W., Zhang X. W., 2017. Experimental study on stiffness characteristics of residual soil at small strain under hot and rainy climate. Chinese Journal of Geotechnical Engineering, 39(4): 743−751. (in Chinese) doi: 10.11779/CJGE201704021 Brignoli E. G. M., Gotti M., Stokoe II K. H., 1996. Measurement of shear waves in laboratory specimens by means of piezoelectric transducers. Geotechnical Testing Journal, 19(4): 384−397. doi: 10.1520/GTJ10716J Burland J. B., Longworth T. I., Moore J. F. A., 1977. A study of ground movement and progressive failure caused by a deep excavation in Oxford clay. Géotechnique, 27(4): 557−591. Clayton C. , 1998. The stiffness of soils and weak rocks at very small strains. Guildford: University of Surrey. Imai T. , Tonouchi K. , 1982. Correlation of N value with S-wave velocity and shear modulus. In: Proceedings of 2nd European Symposium on Penetration Testing. Rotterdam: A. A. Balkema, 68−72. Rampello S., Viggiani G. M. B., Amorosi A., 1997. Small-strain stiffness of reconstituted clay compressed along constant triaxial effective stress ratio paths. Géotechnique, 47(3): 475−489. Seed H. B. , Idriss I. M. , 1970. Soil moduli and damping factors for dynamic response analyses. Berkeley: University of California. Shirley D. J., Hampton L. D., 1978. Shear-wave measurements in laboratory sediments. The Journal of the Acoustical Society of America, 63(2): 607−613. doi: 10.1121/1.381760 Vardanega P. J., Bolton M. D., 2013. Stiffness of clays and silts: normalizing shear modulus and shear strain. Journal of Geotechnical and Geoenvironmental Engineering, 139(9): 1575−1589. doi: 10.1061/(ASCE)GT.1943-5606.0000887 Yang J. , Gu X. Q. , 2013. Shear stiffness of granular material at small strains: does it depend on grain size? Géotechnique, 63 (2): 165−179. Youn J. U., Choo Y. W., Kim D. S., 2008. Measurement of small-strain shear modulus Gmax of dry and saturated sands by bender element, resonant column, and torsional shear tests. Canadian Geotechnical Journal, 45(10): 1426−1438. doi: 10.1139/T08-069 -

下载:

下载: