Numerical Simulation Analysis of Seismic Damage Characteristics of Typical Overhead Oil Pipeline

-

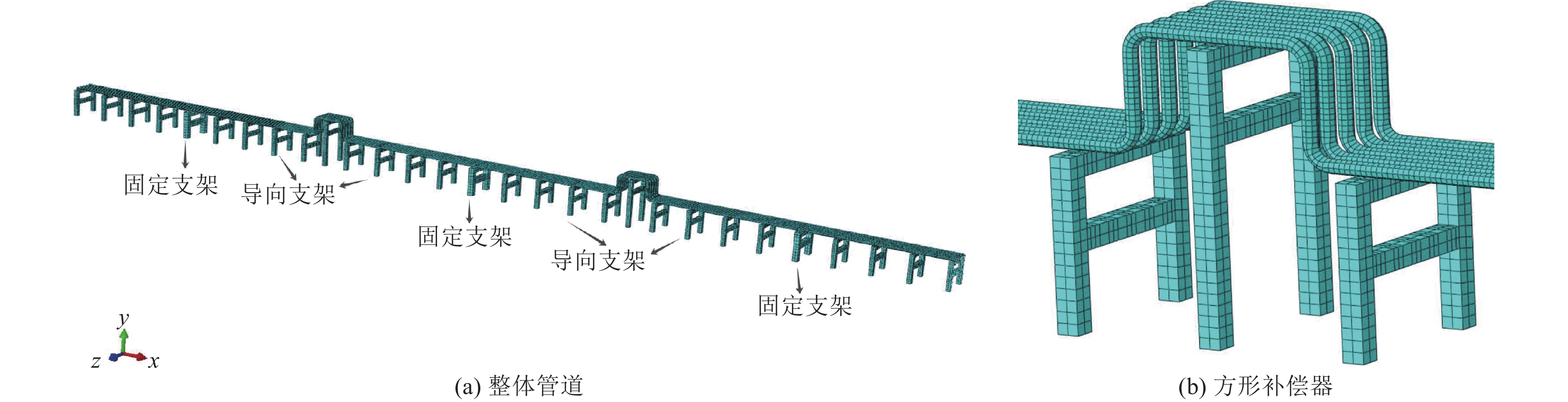

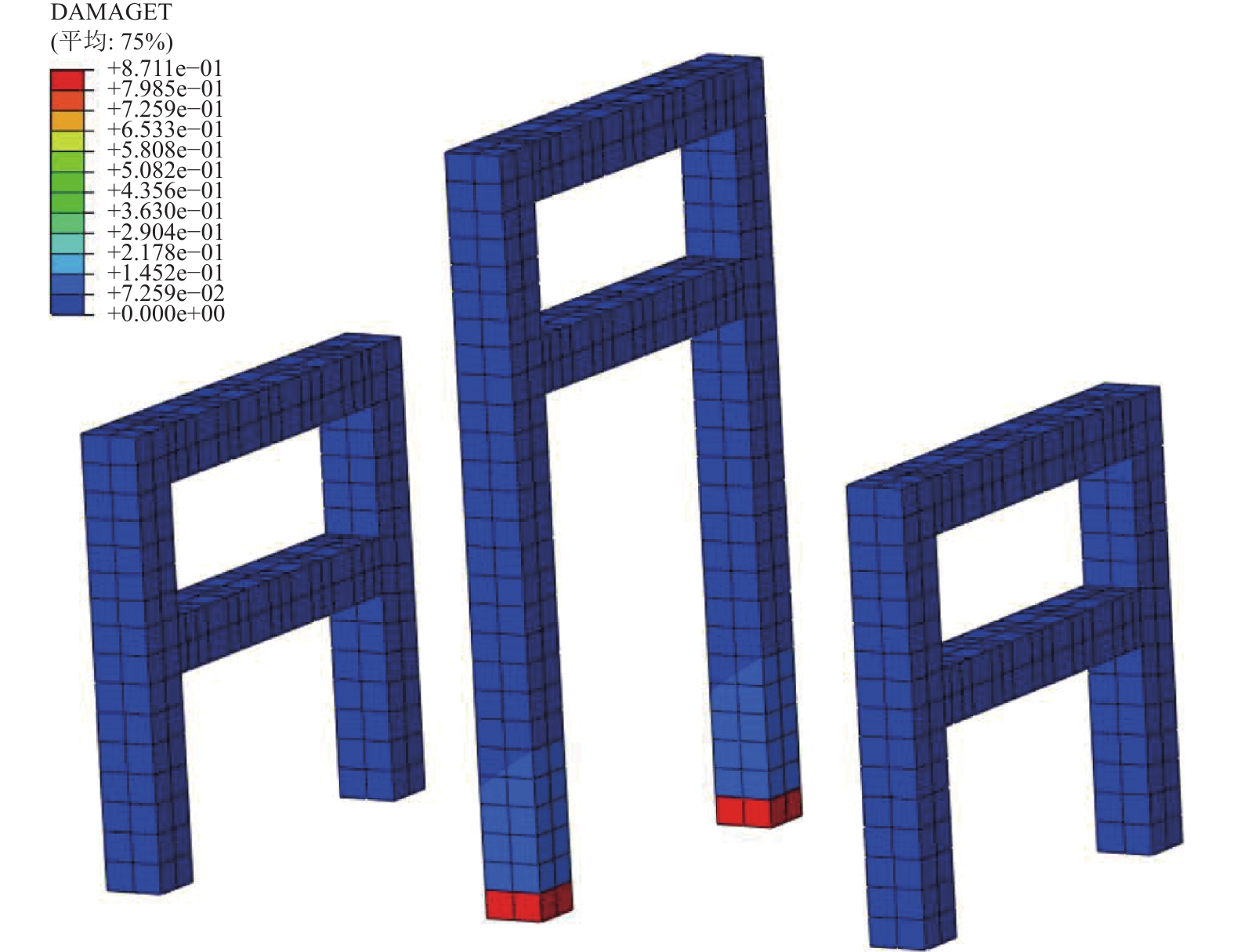

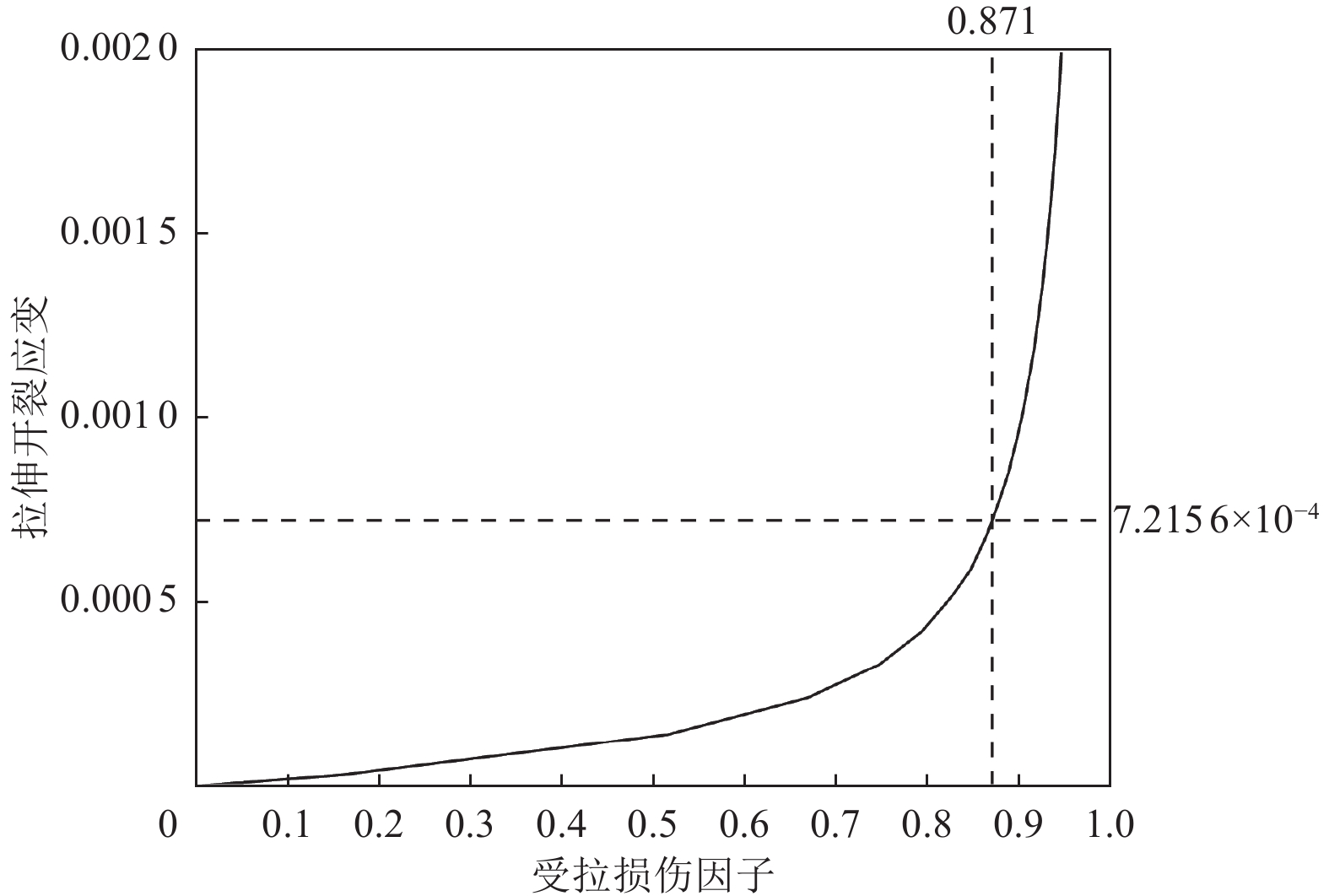

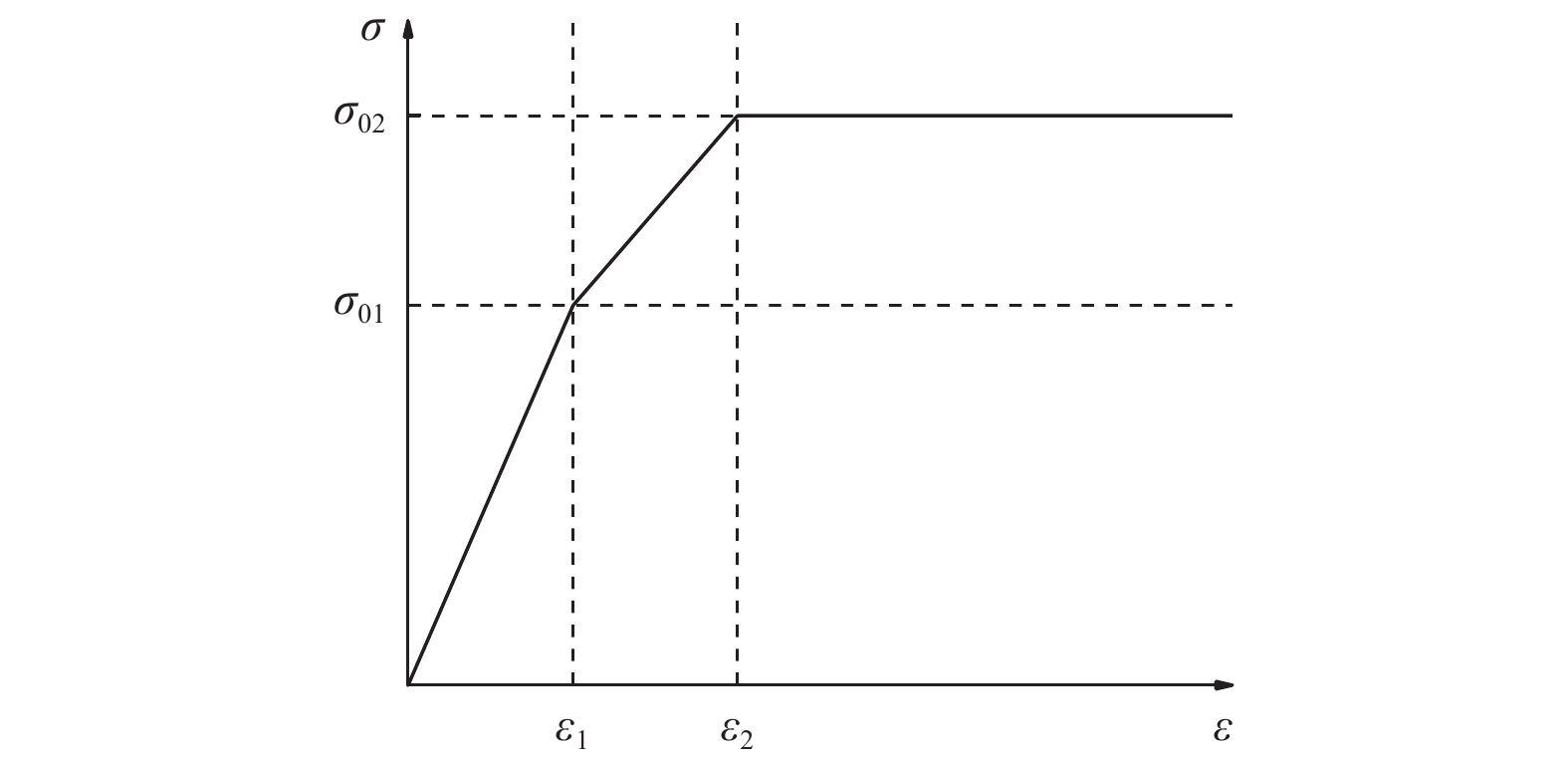

摘要: 近年来国内外时常发生地震对石油天然气管道的破坏事件,而架空管道是油气管线输送工程的薄弱环节,为保证架空管道在地震作用下的安全性,采用数值模拟方法建立架空输油管道有限元模型,研究架空管道地震破坏特征,分析架空管道典型破坏模式。研究结果表明,在地震作用下,较高的活动支架可能会发生倒塌,管道弯折处为较易发生破坏的部位。管道与管架之间的相对滑动也可能造成管道掉落,设计时应同时考虑管道及管架抗震问题。Abstract: In recent years, earthquakes both domestically and internationally have frequently caused damage to oil and gas pipelines, with overhead pipelines identified as critical vulnerabilities within pipeline transportation systems. To ensure the seismic safety of overhead pipelines, this study employs numerical simulation methods to develop a finite element model of overhead oil pipelines. The seismic failure characteristics of these pipelines are investigated, and several typical failure modes are analyzed in detail. The results indicate that during seismic events, higher movable supports are susceptible to collapse, and bending sections of the pipeline are particularly prone to failure. Additionally, relative sliding between the pipeline and the supporting pipe rack can lead to pipeline detachment. Therefore, it is essential to address seismic considerations for both the pipeline and its supports concurrently during the design process.

-

Key words:

- Overhead pipeline /

- Time history analysis /

- Failure grade /

- Pipe support /

- Seismic performance

-

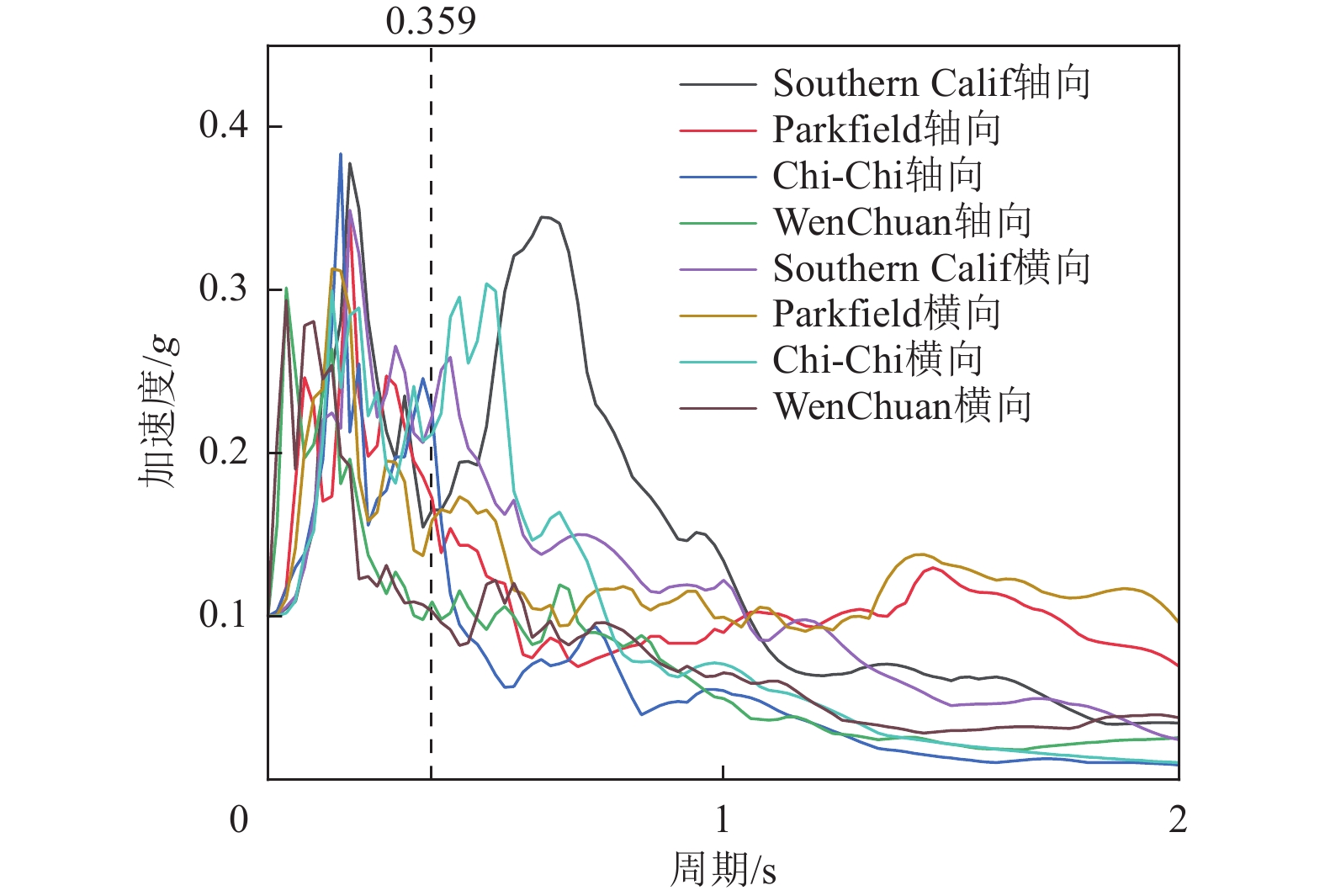

表 1 地震动参数

Table 1. Ground motion parameters

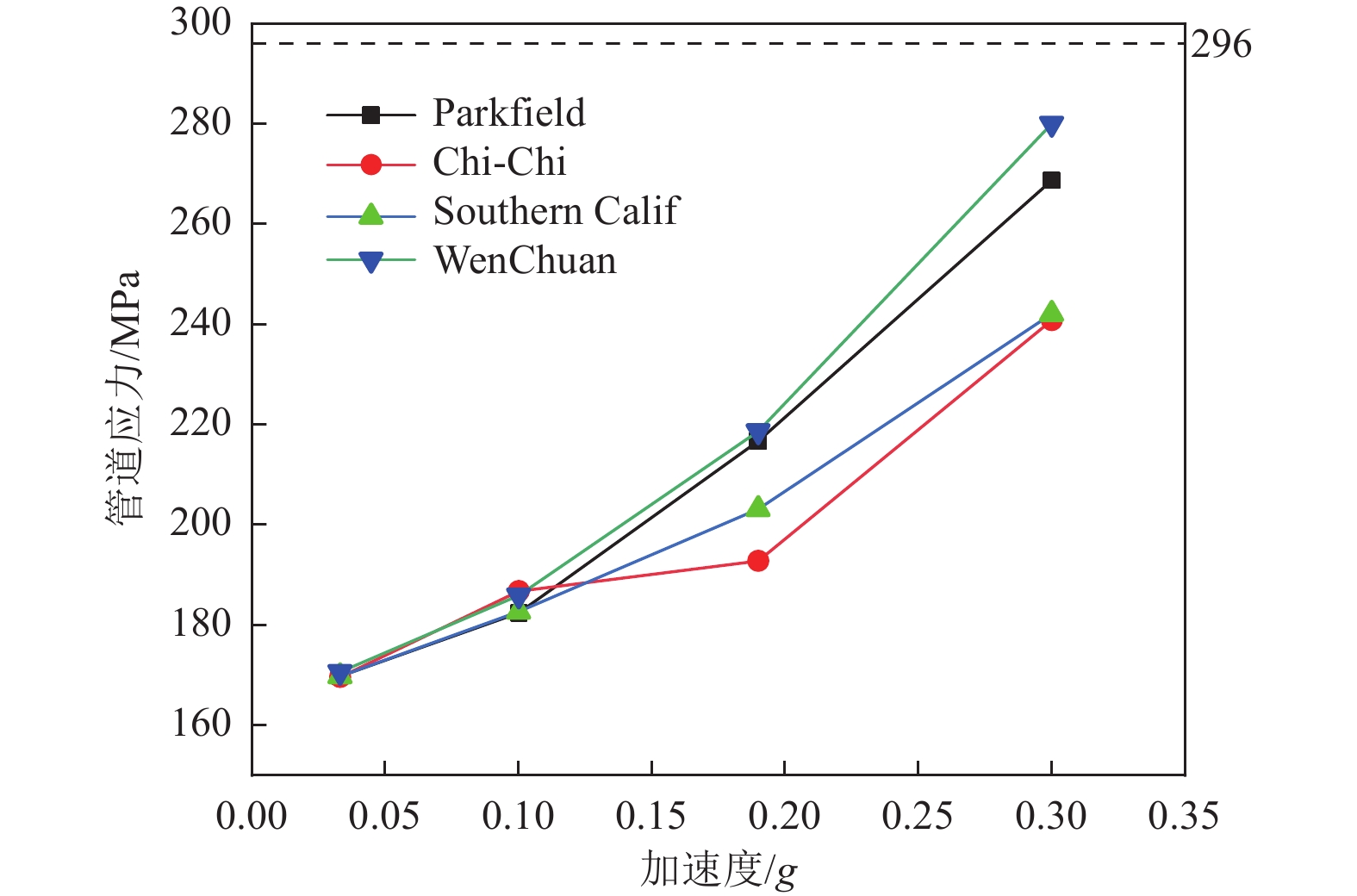

地震动 台站 震中距/km 震级 Parkfield Cholame-Shandon Array #12 17.64 6.19 Chi-Chi TCU049 3.76 7.62 Southern Calif San Luis Obispo 73.41 6.00 WenChuan 51 MZQ 87.4 8.00 表 2 管道最大应力

Table 2. Maximum pipe stress

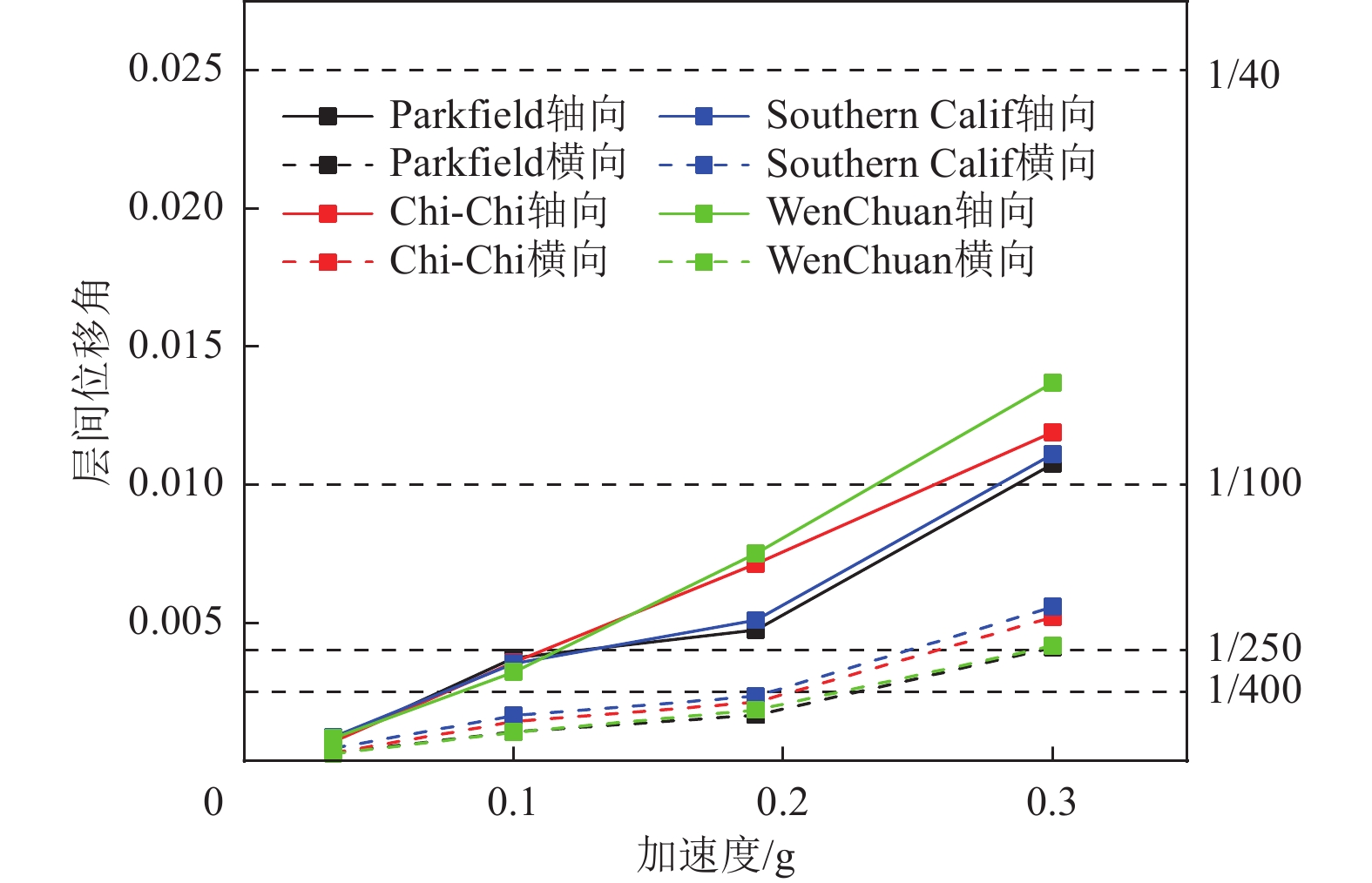

峰值加速度/g Mises应力/MPa Parkfield Chi-Chi Southern Calif WenChuan 0.033 169.8 169.6 169.7 170.6 0.100 182.4 186.8 182.7 185.9 0.190 216.7 192.8 203.1 218.6 0.300 268.7 240.9 242.1 280.1 表 3 管架最大层间位移角

Table 3. The maximum interlayer displacement angle of the pipe support

峰值加速度/g Parkfield Chi-Chi Southern Calif WenChuan 轴向 横向 轴向 横向 轴向 横向 轴向 横向 0.033 1/1 362 1/3 412 1/1 439 1/3 445 1/1 147 1/2 132 1/1 212 1/3 738 0.100 1/268 1/939 1/279 1/701 1/283 1/605 1/311 1/959 0.190 1/211 1/601 1/140 1/468 1/196 1/425 1/133 1/541 0.300 1/93 1/243 1/84 1/192 1/90 1/179 1/73 1/240 表 4 管道与管架间最大相对位移(单位:毫米)

Table 4. Maximum relative displacement(Unit: mm)

峰值加速度/g Parkfield Chi-Chi Southern Calif WenChuan 轴向 横向 轴向 横向 轴向 横向 轴向 横向 0.033 3.82 1.13 3.09 1.41 4.14 1.38 3.22 0.89 0.100 15.30 5.62 14.51 7.67 14.16 9.59 13.30 3.73 0.190 19.84 12.03 25.63 12.35 22.33 17.31 32.35 10.53 0.300 46.58 33.15 45.12 27.84 48.20 34.15 58.41 25.80 表 5 管道地震破坏等级判定标准

Table 5. The criterion for determining the earthquake damage grade of pipeline

破坏等级 判定标准 基本完好 $ \sigma < 0.8\sigma_{\mathrm{s}} $ 中等破坏 $ 0.8\sigma_{\mathrm{s}}\leqslant\sigma\leqslant0.8\sigma\mathrm{_b} $ 毁坏 $ \sigma < 0.8\sigma_{\mathrm{s}} $ 表 6 管道地震破坏等级及宏观现象

Table 6. Pipeline seismic damage level and macroscopic phenomenon

破坏等级 宏观现象 基本完好 管道无破损、渗漏,无须修复即可正常运行。 中等破坏 管道发生较大变形或屈曲,或有轻度破坏、渗

漏,须采取修理措施才能正常运行。毁坏 管道破裂、漏气,须更换管道。 表 7 管架地震破坏等级的判定标准

Table 7. Criterion for classifying seismic damage grade of pipe support

破坏等级 判定标准 基本完好 α<1/400 轻微破坏 1/400≤α<1/250 中等破坏 1/250≤α<1/100 严重破坏 1/100≤α<1/40 毁坏 α≥1/40 表 8 管架地震破坏等级及宏观现象

Table 8. Seismic damage grade and macroscopic phenomenon of pipe frame

破坏等级 宏观现象 基本完好 承重构件无损伤。 轻微破坏 承重部分仍保持弹性范围内,抗力水平未显著降低。 中等破坏 管架梁及柱出现不断扩展裂缝,结构抗力水平有所降低。 严重破坏 多数梁、柱端混凝土剥落、主筋外露,个别柱主筋压屈,多数梁柱节点、

柱与基础连接处破坏。毁坏 管架大部分塌落或全部塌落;大部分柱破坏处混凝土酥碎,钢筋严重弯曲;

产生较大变位或已折断;整体结构濒于倒毁或已倒毁,无修复可能。 -

格赫曼A. C. ,扎伊涅特季诺夫X. X. ,1992. 管道的抗震设计施工与监护. 刘昆,张宗理,译. 北京:地震出版社. 梁继淦,1992. 石油化工厂架空管道的抗震设计. 石油炼制与化工,(10):5−10.Liang J. G., 1992. The antiseisemic design of overhead pipelines in petrochemical plants. Petroleum Processing and Petrochemicals, (10): 5−10. (in Chinese) 柳春光,孙平,宋伟庆,1999. 架空管道的地震破坏及其分析方法研究. 世界地震工程,15(3):69−73.Liu C. G., Sun P., Song W. Q., 1999. The earthquake damage to overad pipe and its analysis methods. World Information on Earthquake Engineering, 15(3): 69−73. (in Chinese) 孙健,2014. 基于ABAQUS的悬空管道地震响应分析. 石油和化工设备,17(7):30−33. doi: 10.3969/j.issn.1674-8980.2014.07.012 孙建刚,薛景宏,王振,2000. 架空输液管道系统动力反应分析. 地震工程与工程振动,20(2):129−133. doi: 10.3969/j.issn.1000-1301.2000.02.022Sun J. G., Xue J. H., Wang Z., 2000. Dynamic response analysis of pipeline systems conveying fluid and supported above the ground. Earthquake Engineering and Engineering Vibration, 20(2): 129−133. (in Chinese) doi: 10.3969/j.issn.1000-1301.2000.02.022 项忠权,孙家孔,1995. 石油化工设备抗震. 北京:地震出版社. 谢礼立,翟长海,2003. 最不利设计地震动研究. 地震学报,25(3):250−261. doi: 10.3321/j.issn:0253-3782.2003.03.003Xie L. L., Zhai C. H., 2003. Study on the severest real ground motion for seismic design and analysis. Acta Seismologica Sinica, 25(3): 250−261. (in Chinese) doi: 10.3321/j.issn:0253-3782.2003.03.003 许萍,李著信,高松竹,2006. 悬空输油管道的地震动力反应分析. 管道技术与设备,(4):11−12,15.Xu P., Li Z. X., Gao S. Z., 2006. Dynamic response analysis of suspended oil-conveying pipe under earthquake load. Pipeline Technique and Equipment, (4): 11−12,15. (in Chinese) 钟旻,缪昇,秦云,等,2013. “3·10”盈江地震管道节点破坏机理及抗震对策研究. 自然灾害学报,22(2):221−228.Zhong M., Miu S., Qin Y., et al., 2013. Study on damage mechanism of pipe's joints in "3·10"Yingjiang earthquake and seismic countermeasures. Journal of Natural Disasters, 22(2): 221−228. (in Chinese) 朱健,2010. 钢筋混凝土结构易损性分析与地震风险研究. 西安:西安建筑科技大学.Zhu J., 2010. Seismic fragility and risk analysis of RC buildings. Xi'an:Xi'an University of Architecture and Technology. (in Chinese) Liu W., Wu Q. X., 2020. Comparison between the seismic performance of buried pipes and pipes in a utility tunnel. Computer Modeling in Engineering & Sciences, 123(2): 661−690. -

下载:

下载: