Study on Seismic Interaction of Non-safety and Safety Pipeline Items in Nuclear Power Plants

-

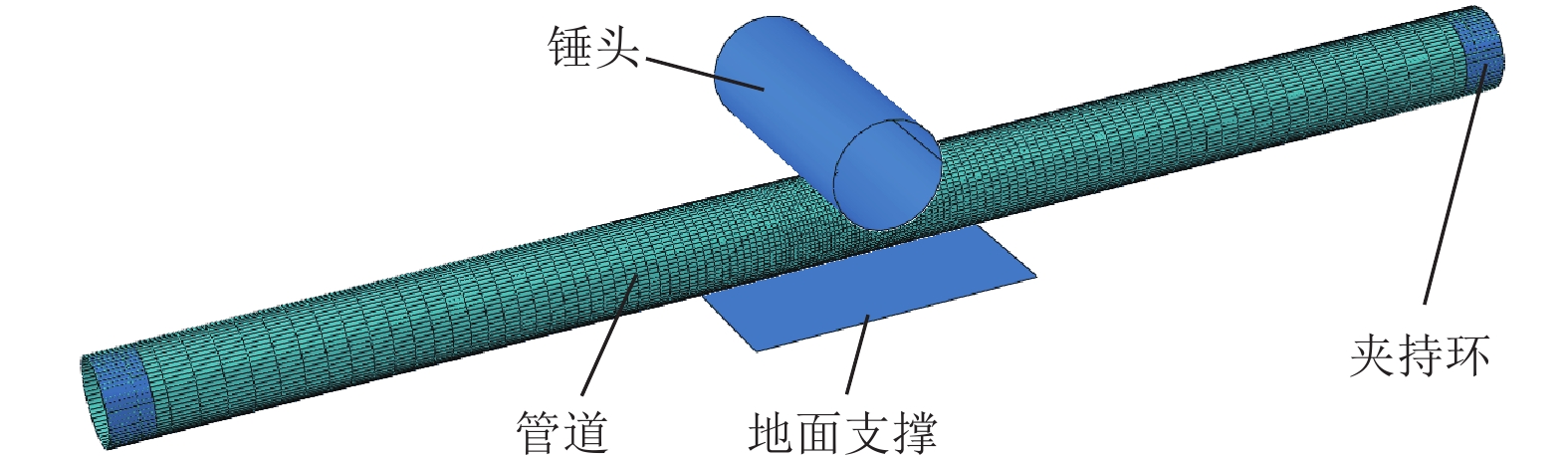

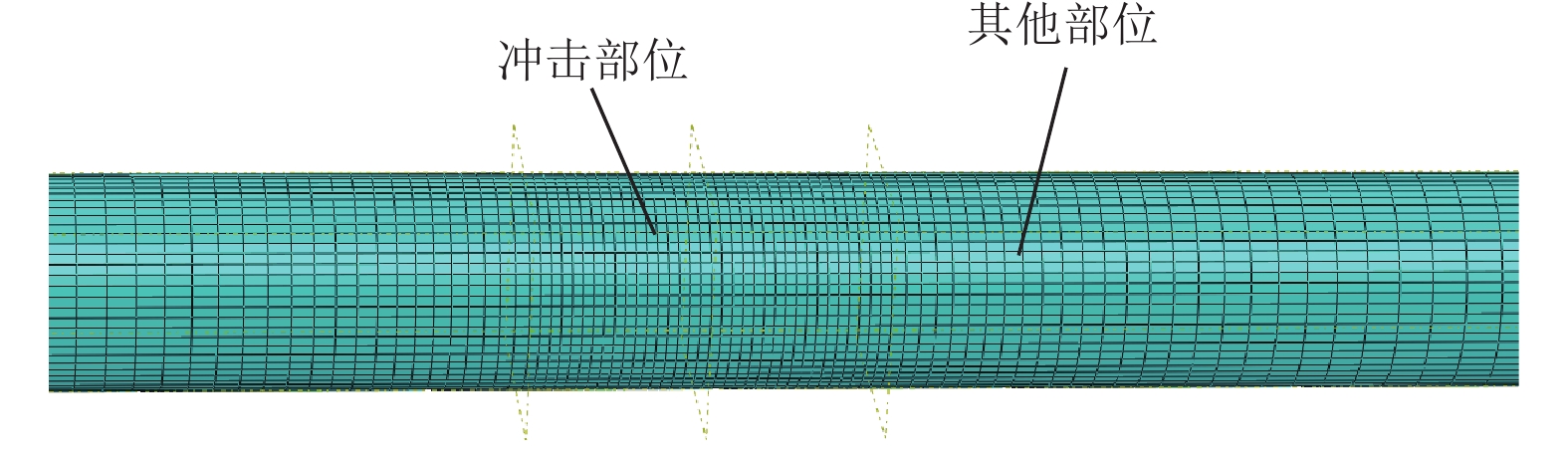

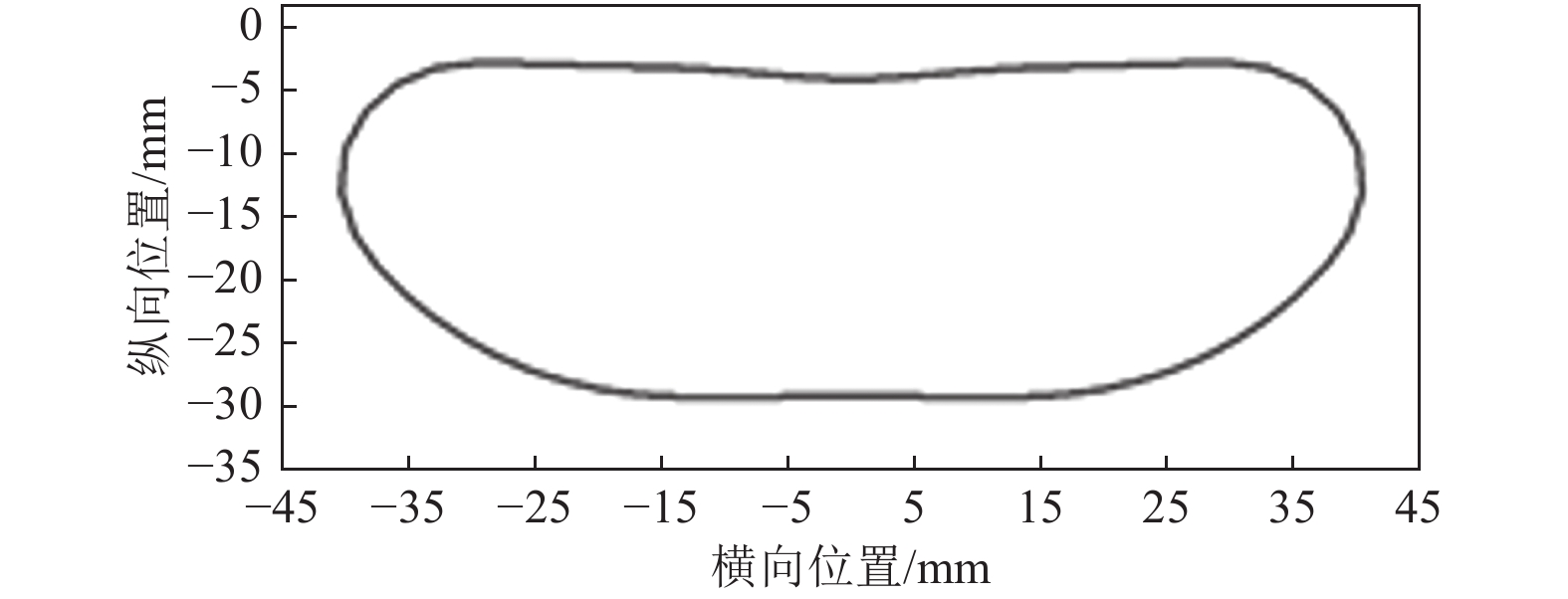

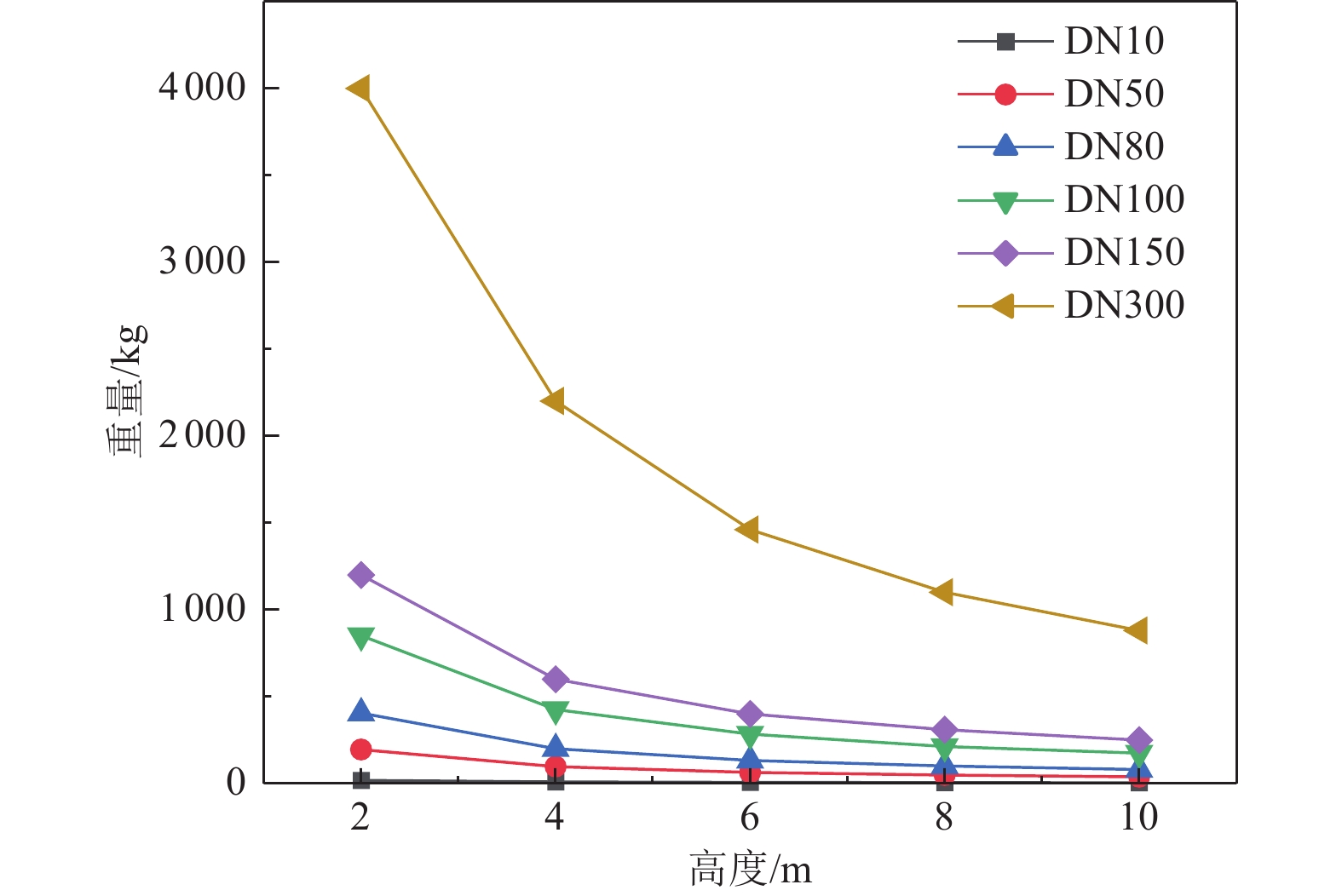

摘要: 为评估地震灾害中核电厂非安全级管道物项跌落对安全级管道物项的交互作用影响,采用模拟仿真分析与试验验证相结合的方法对管道物项间的冲击过程进行研究。本文建立了管道冲击有限元仿真模型,采用ABAQUS有限元分析软件对核电厂常用安全级管道进行冲击仿真,将管道内截面通流面积减小至50%~55%作为损伤极限,得到不同高度下的冲击极限质量,并采用冲击试验对模拟仿真结果进行验证。研究结果表明,当管道型号规格一定时,其损伤极限主要取决于下落物体的能量,受到高度的影响较小;进行核电厂安全级管道设计布局时,应保证挂在上方的非安全级管道冲击能量小于其能够承受的极限能量。Abstract: To assess the interaction effects of non-safety pipeline components falling onto safety-grade pipelines in nuclear power plants during an earthquake, this study investigates the impact process through a combination of simulation analysis and experimental validation. A finite element model of pipeline impact is developed, and impact simulations of common safety-level nuclear power pipelines are conducted using ABAQUS software. The damage threshold is defined as a reduction of 50%~55% in the cross-sectional flow area, and the critical impact mass at different heights is determined. The simulation results are validated through impact tests, confirming that for a given pipeline model, the damage threshold is primarily governed by the energy of the falling object, with only a minor influence from height. These findings highlight the importance of ensuring that the impact energy from non-safety pipelines suspended above safety-grade pipelines remains below the structural energy tolerance during the design and layout of nuclear power plant piping systems.

-

Key words:

- Nuclear power plants /

- Seismic interaction /

- Pipeline items /

- Simulation /

- Impact energy

-

表 1 仿真与试验结果对比

Table 1. Comparison of simulation and test results

尺寸类型 仿真 试验 最小宽度/mm 27.17 28.60 最大宽度/mm 78.91 78.22 通流面积/% 52.6 53.5 表 2 DN100-S40管道变形

Table 2. Deformation data of DN100-S40 pipeline

锤头高度/m 锤头质量/kg 变形后高度/mm 变形后宽度/mm 内截面面积比/% 2 850 43.64 156.68 52.49 4 425 45.17 155.90 53.36 6 284 45.74 155.61 54.04 8 213 46.18 155.36 54.58 10 175 45.35 155.84 53.57 表 3 不同型号管道承受的极限能量

Table 3. Ultimate energy withstood by different types of pipelines

管道规格 极限能量/J 2 m 4 m 6 m 8 m 10 m DN10 353 353 353 353 343 DN50 3 822 3 802 3 763 3 763 3 724 DN80 7 938 7 840 7 820 7 840 7 840 DN100 16 660 16 660 16 699 16 699 17 150 DN150 23 520 23 520 23 520 24 304 24 500 DN300 78 400 86 240 85 848 86 240 86 240 注:计算时,取g=9.8 m/s2。 表 4 不同型号管道拟合结果

Table 4. Fitting data of different types of pipelines

圆管类型 W/(N·m) δ R2 DN10-S40 392 0.008 0.992 3 DN50-S40 3 824 0.110 0.997 8 DN80-S40 7 928 0.170 0.995 8 DN100-S40 16 635 −0.320 0.994 3 DN150-S40 23 448 −0.980 0.998 8 DN300-S40 79 168 −158.000 0.996 5 -

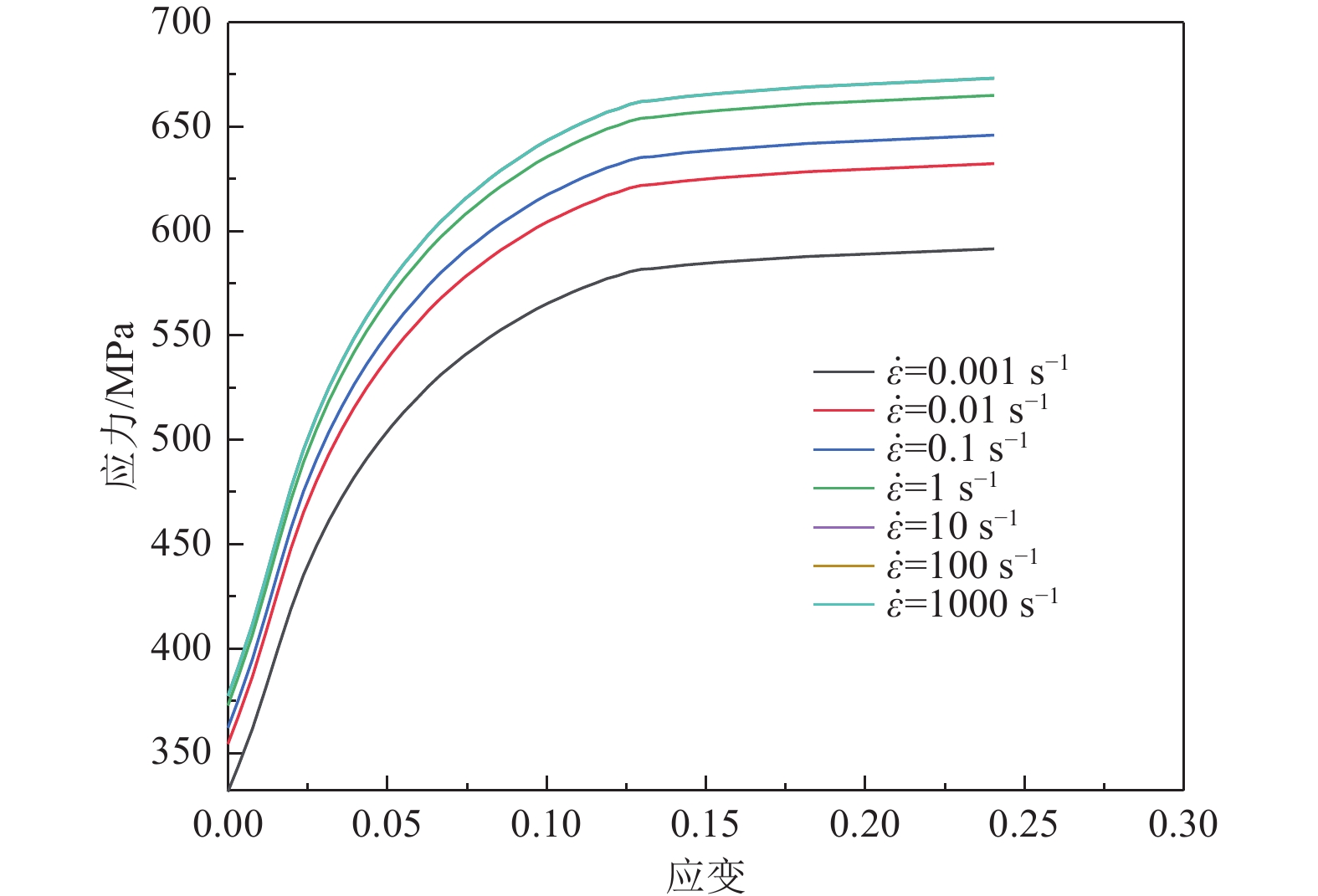

艾红雷,刘文进,2008. 管道布置对核电站主系统抗震性能的影响. 原子能科学技术,42(S):397−400.Ai H. L., Liu W. J., 2008. Effect of piping layout on aseismatic performance of reactor coolant system. Atomic Energy Science and Technology, 42(S): 397−400. (in Chinese) 戴颖楠,闫维明,陈适才,2017. 某核电站结构-设备相互作用的地震反应分析. 震灾防御技术,12(3):655−666. doi: 10.11899/zzfy20170321Dai Y. N., Yan W. M., Chen S. C., 2017. Seismic response analysis of structures in a nuclear power plant-equipment interaction. Technology for Earthquake Disaster Prevention, 12(3): 655−666. (in Chinese) doi: 10.11899/zzfy20170321 郭婧,方火浪,张轶群等,2016. 强震作用下核电厂反应堆厂房结构的抗震性能分析. 地震工程与工程振动,36(6):11−21.Guo J., Fang H. L., Zhang Y. Q., et al., 2016. Seismic performance analyses of reactor building structures in nuclear power plant under strong earthquake motions. Earthquake Engineering and Engineering Dynamics, 36(6): 11−21. (in Chinese) 冀珩,2012. 考虑设备−结构相互作用的大型变电站主厂房系统抗震性能研究. 西安:西安建筑科技大学.Ji H., 2012. Study on seismic performance of large transformer substation main power house system with equipment-structure interaction. Xi'an:Xi'an University of Architecture and Technology. (in Chinese) 金煜皓,赵杰,尹训强,2016. 山东海阳核电厂一期取水沟道抗震性能分析. 水利与建筑工程学报,14(1):132−138. doi: 10.3969/j.issn.1672-1144.2016.01.025Jin Y. H., Zhao J., Yin X. Q., 2016. Analysis of earthquake resistant behavior of water channel in Shandong Haiyang nuclear power project. Journal of Water Resources and Architectural Engineering, 14(1): 132−138. (in Chinese) doi: 10.3969/j.issn.1672-1144.2016.01.025 李伟正,郭石永,2022. 核电厂抗震仪表支架应力分析及结构优化. 科学技术与工程,22(16):6530−6536. doi: 10.3969/j.issn.1671-1815.2022.16.019Li W. Z., Guo S. Y., 2022. Stress analysis and structural optimization of seismic instrument support in nuclear power plant. Science Technology and Engineering, 22(16): 6530−6536. (in Chinese) doi: 10.3969/j.issn.1671-1815.2022.16.019 李英,颜星晗,2022. 海洋双金属复合管的冲击荷载响应. 中国海洋平台,37(3):28−32. doi: 10.12226/j.issn.1001-4500.2022.03.20220305Li Y., Yan X. H., 2022. Structure response of submarine bimetallic lined pipe under impact. China Offshore Platform, 37(3): 28−32. (in Chinese) doi: 10.12226/j.issn.1001-4500.2022.03.20220305 刘明星,杨静远,王东伟等,2021. 核电厂安全级DCS机柜结构抗震分析及试验研究. 重庆理工大学学报(自然科学),35(10):224−232.Liu M. X., Yang J. Y., Wang D. W., et al., 2021. Seismic analysis and experimental study of safety-related DCS cabinet structure in nuclear power plant. Journal of Chongqing University of Technology (Natural Science), 35(10): 224−232. (in Chinese) 马铭辉,余毅磊,蒋招绣等,2022. 675装甲钢的静动态力学行为与J-C模型参数拟合确定. 北京理工大学学报,42(6):596−603.Ma M. H., Yu Y. L., Jiang Z. X., et al., 2022. Static and dynamic mechanical properties of 675 armor steel and determination of J-C model parameters. Transactions of Beijing Institute of Technology, 42(6): 596−603. (in Chinese) 彭建,刘浪,石媛媛,2023. 核电厂高能管道冲击过程数值模拟研究. 哈尔滨工程大学学报,44(2):307−313.Peng J., Liu L., Shi Y. Y., 2023. Numerical simulation of the high-energy piping impact process in a nuclear power plant. Journal of Harbin Engineering University, 44(2): 307−313. (in Chinese) 谭勇,张亮,彭俊等,2022. 秦山核电厂设冷水大厅安全级与非安全级物项地震交互作用影响研究. 核动力工程,43(S1):80−85.Tan Y., Zhang L., Peng J., et al., 2022. Study on earthquake interaction between safety-related and non-safety-related items in equipment cooling water system room of Qinshan nuclear power plant. Nuclear Power Engineering, 43(S1): 80−85. (in Chinese) 滕振超,赵誉翔,滕云超等,2021. 冲击荷载作用下冻土区埋地管道动力响应试验研究. 地震工程与工程振动,41(6):168−176.Teng Z. C., Zhao Y. X., Teng Y. C., et al., 2021. Dynamic response test of buried pipeline in frozen soil area under impact load. Earthquake Engineering and Engineering Dynamics, 41(6): 168−176. (in Chinese) 尹训强,孙华跃,2023. 复杂非均质场地条件下核电厂联合泵房抗震安全性评价分析. 地震工程与工程振动,43(4):226−234.Yin X. Q., Sun H. Y., 2023. Seismic safety evaluation analysis of pumping station of nuclear power plant under complex heterogeneous site condition. Earthquake Engineering and Engineering Dynamics, 43(4): 226−234. (in Chinese) 张虎,邵磊,余成等,2022. 冲击荷载对埋地管道影响的试验与数值模拟研究. 地震工程与工程振动,42(3):243−252.Zhang H., Shao L., Yu C., et al., 2022. Experimental and numerical simulation study of impact loading on buried pipeline. Earthquake Engineering and Engineering Dynamics, 42(3): 243−252. (in Chinese) 赵杰,甘长江,兰雯竣,2023. 考虑土结相互作用下核电厂海域沉管隧道三维抗震分析. 核科学与工程,43(2):402−411. doi: 10.3969/j.issn.0258-0918.2023.02.023Zhao J., Gan C. J., Lan W. J., 2023. Three dimensional seismic analysis of immersed tunnel in sea area of nuclear power plant considering soil structure interaction. Nuclear Science and Engineering, 43(2): 402−411. (in Chinese) doi: 10.3969/j.issn.0258-0918.2023.02.023 Shubham, Yerramalli C. S., Sumant C., et al., 2022. Finite element modelling and experimentation of plain weave glass/epoxy composites under high strain-rate compression loading for estimation of Johnson-Cook model parameters. International Journal of Impact Engineering, 167: 104262. doi: 10.1016/j.ijimpeng.2022.104262 Stevenson and Associates, 1990. Procedure for seismic evaluation and design of small bore piping (NCIG-14). Palo Alto: EPRI. Wu Q., Wu J., Gao M. T., 2020. Correlation analysis of earthquake impacts on a nuclear power plant cluster in Fujian province, China. Environmental Research, 187: 109689. doi: 10.1016/j.envres.2020.109689 -

下载:

下载: