Study on Seismic Performance of Pile Foundation in Loess Engineering Site Based on Lignin Reinforcement

-

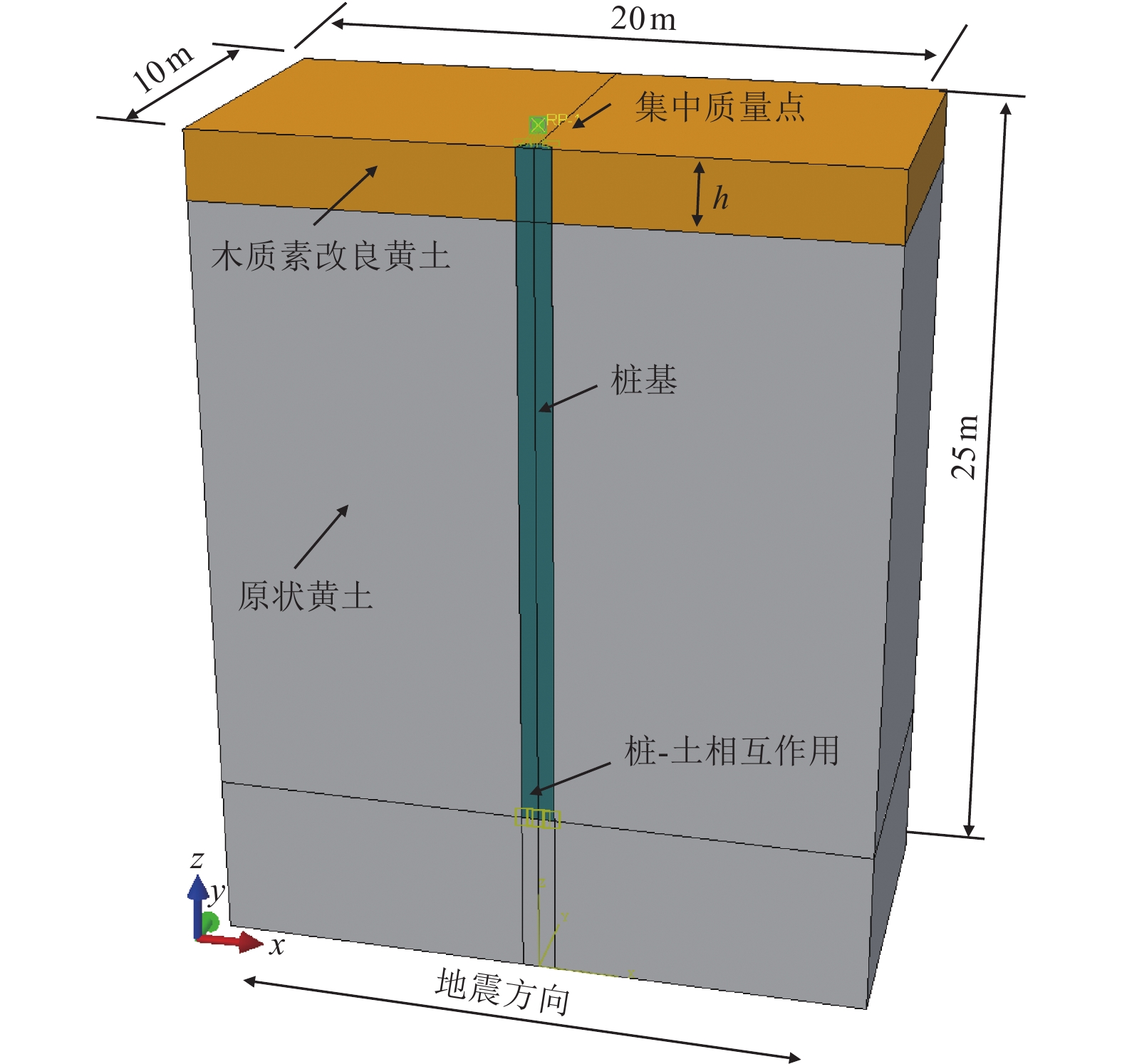

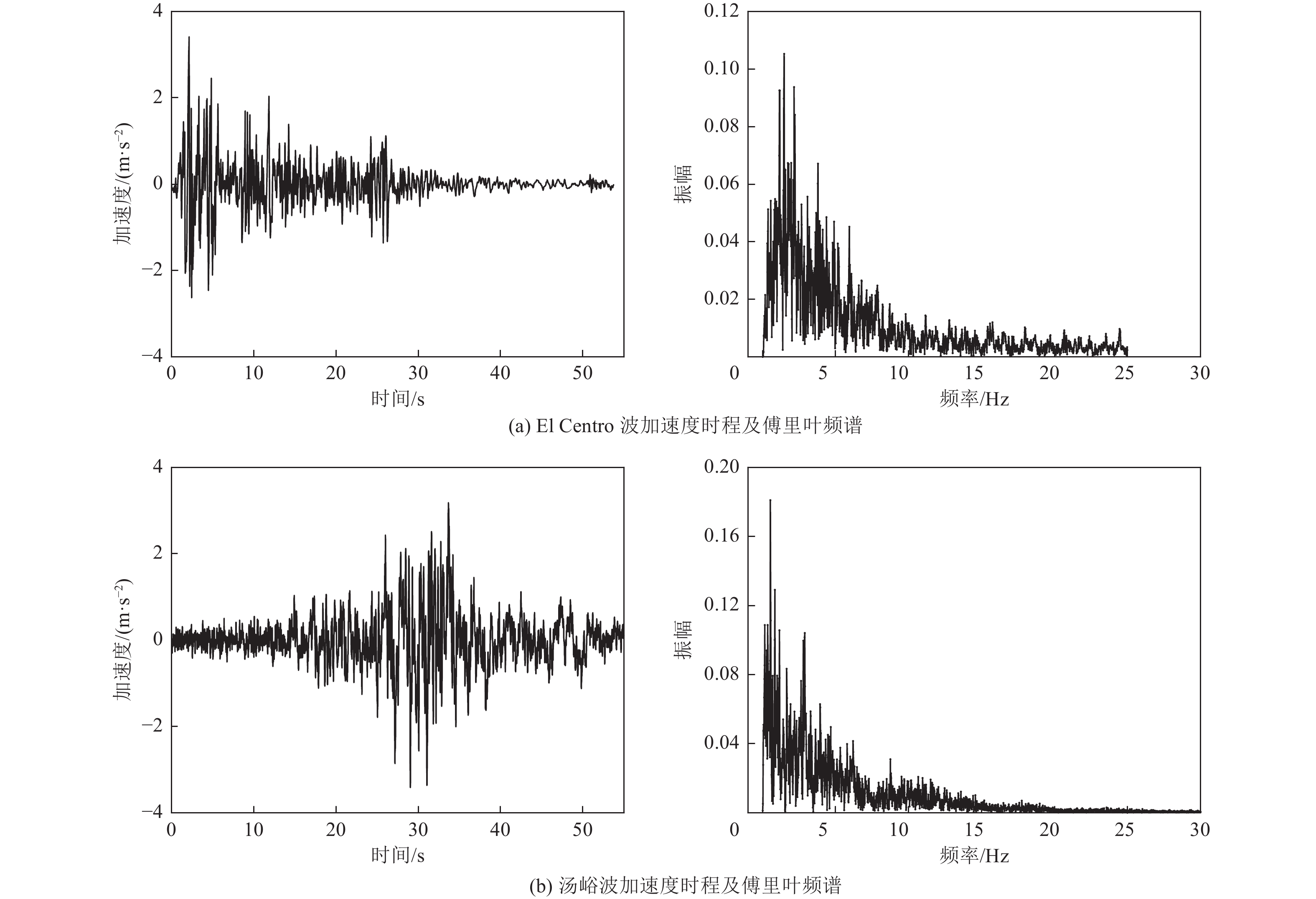

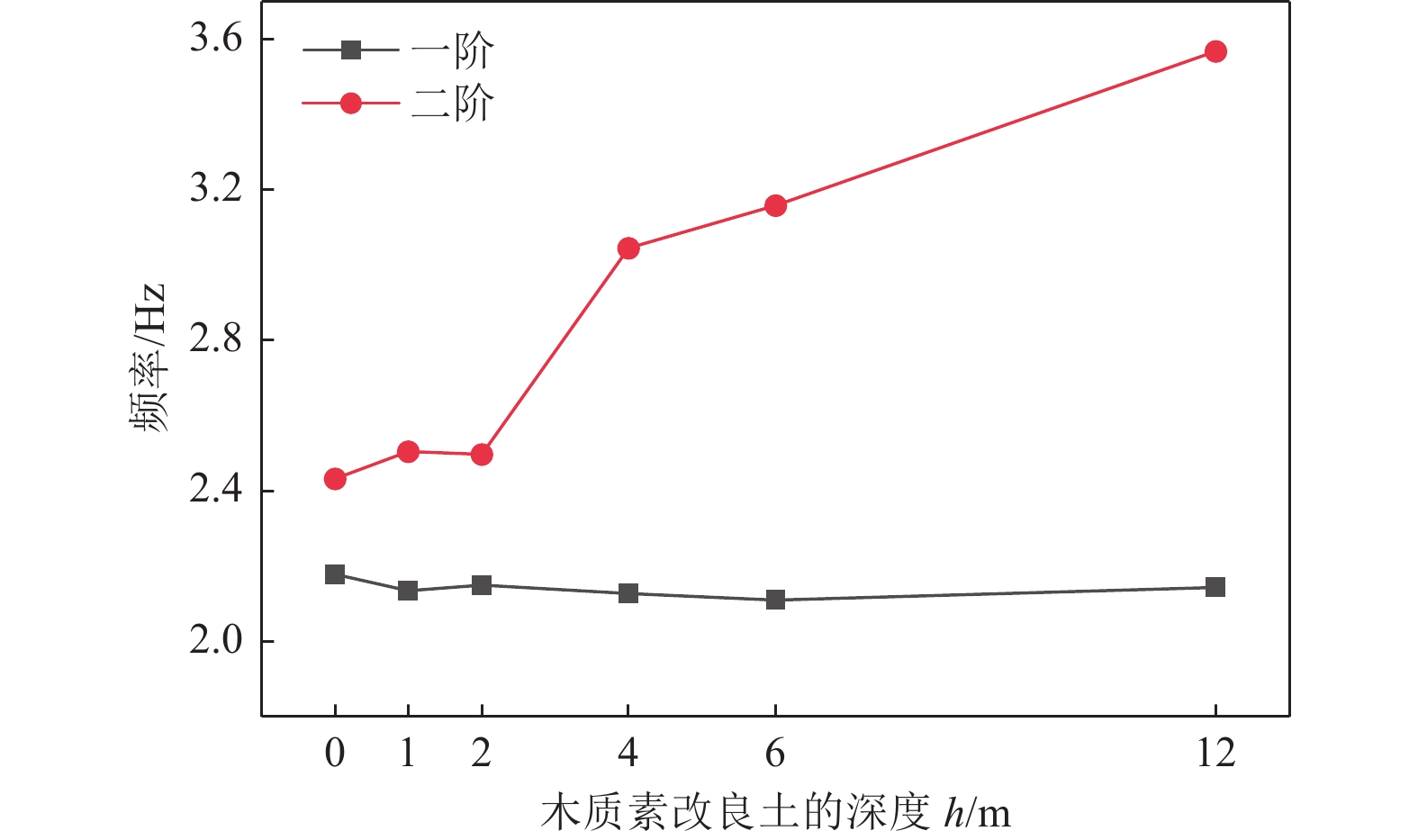

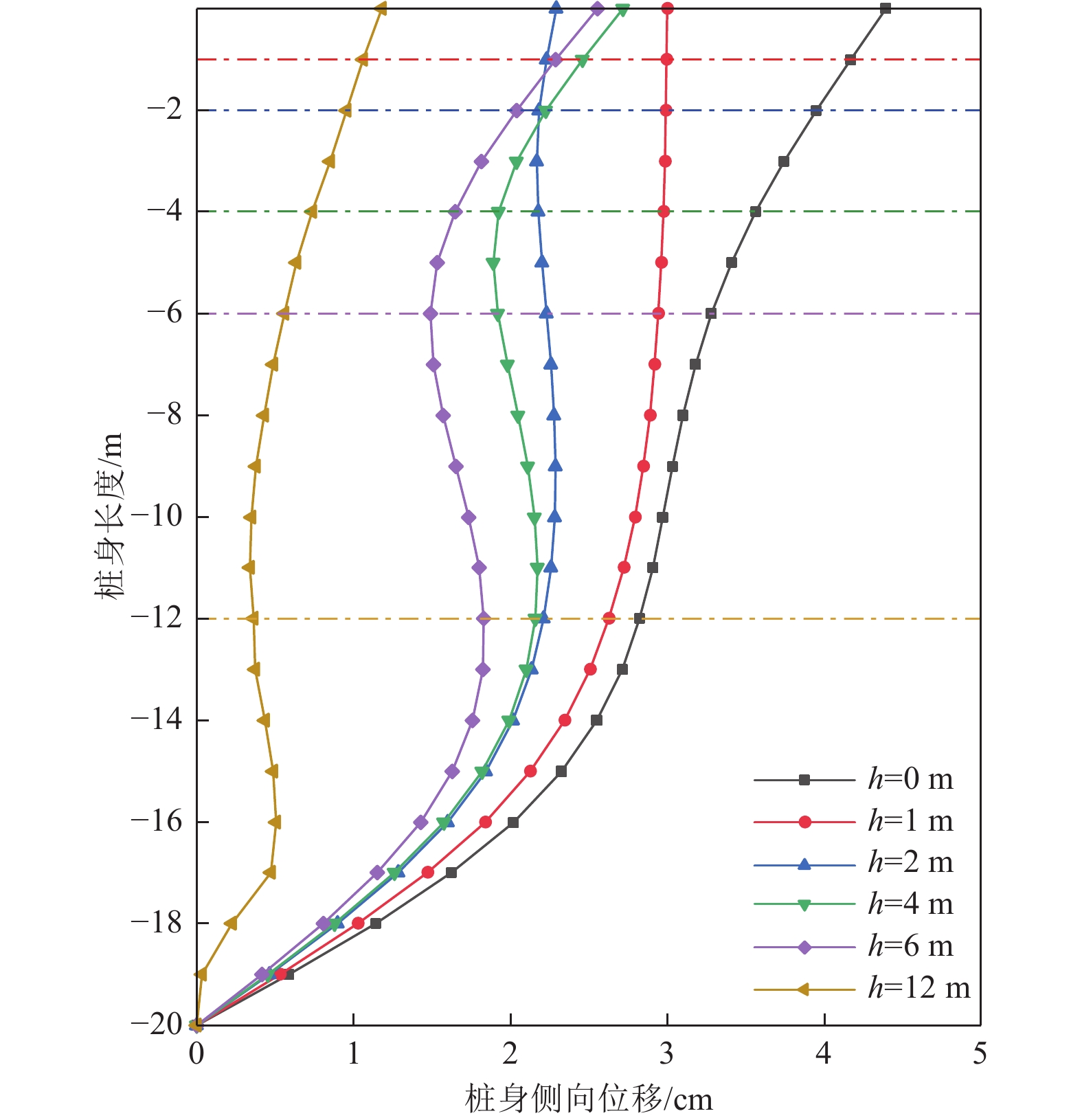

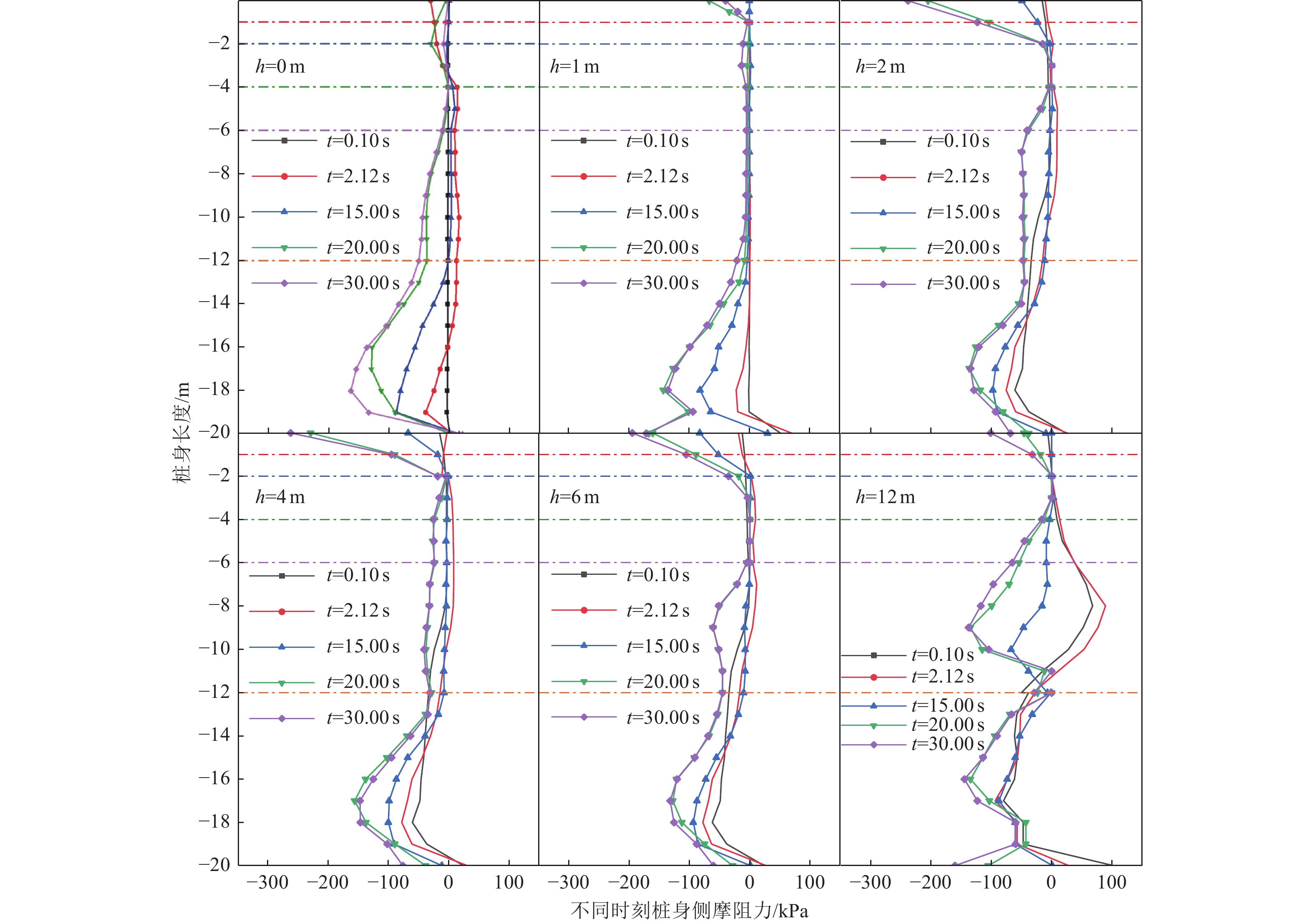

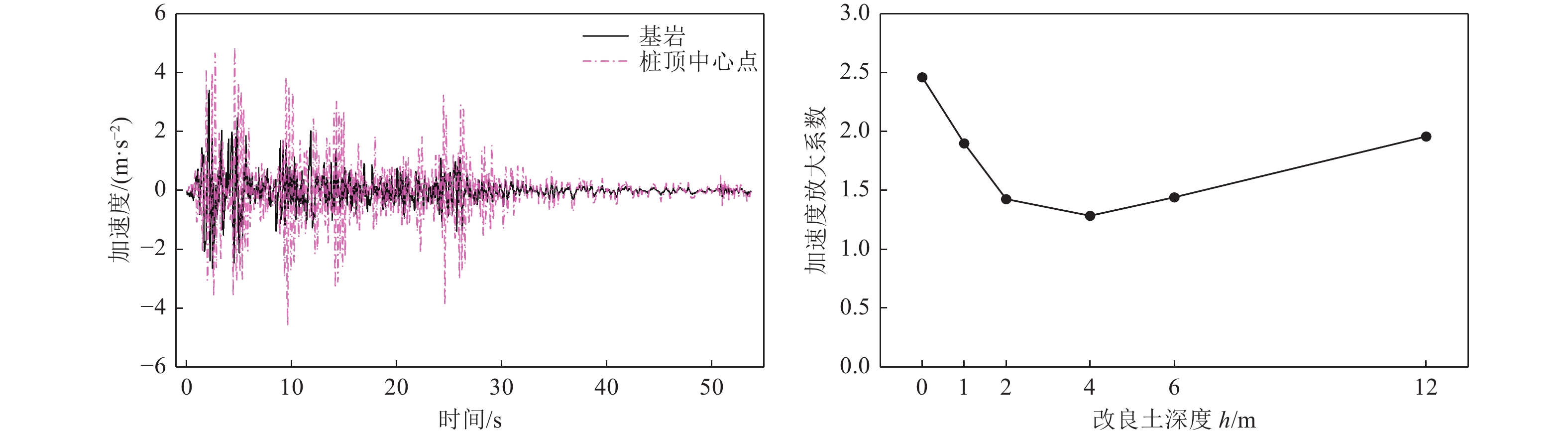

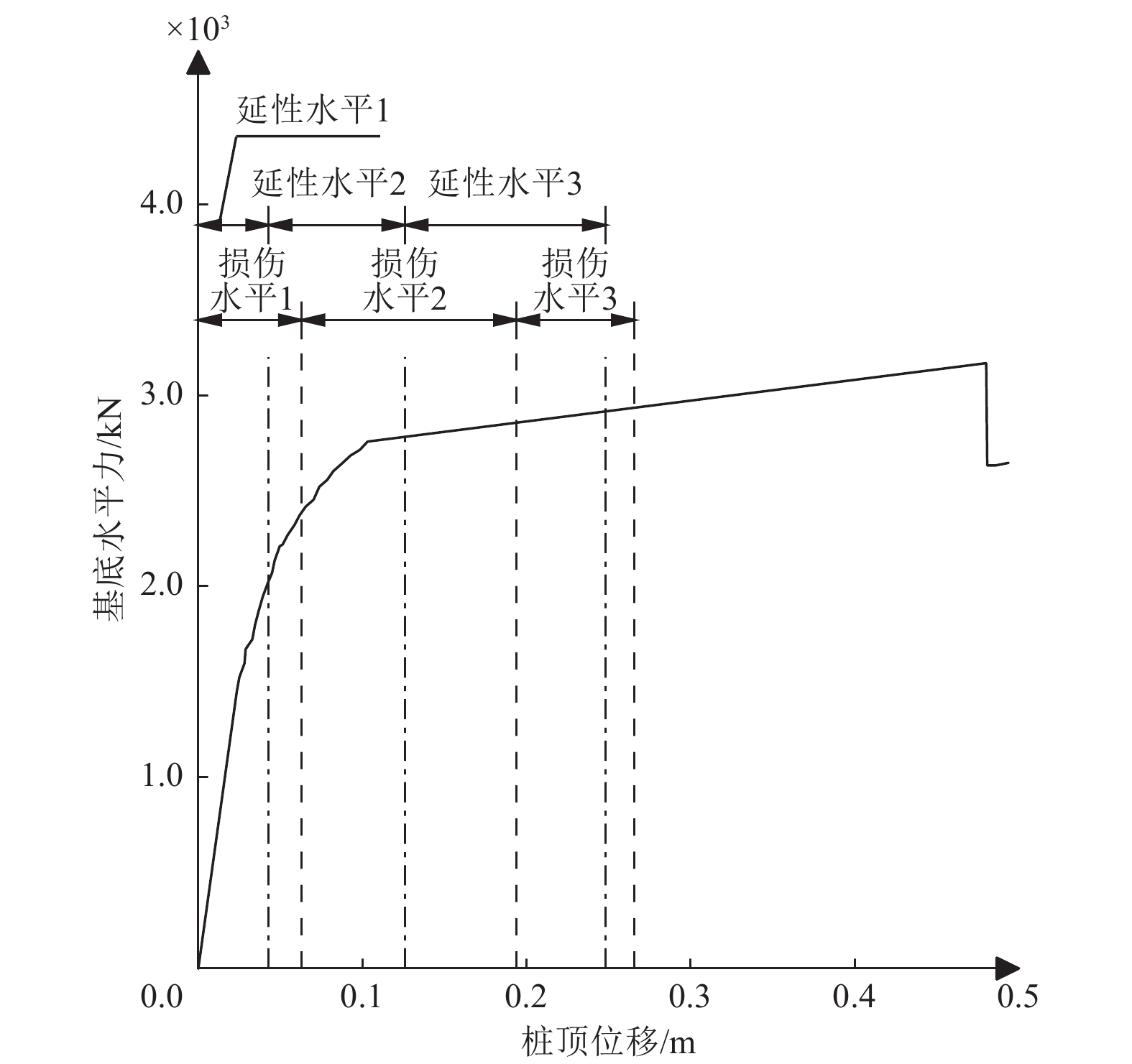

摘要: 针对地震引起的地基土变形失效导致的桩-土脱空及桩基产生较大侧向变形问题,使用环境友好的新型绿色材料木质素对黄土工程场地的地基土进行加固。基于室内试验和数值模拟,考虑桩-土相互作用和改良黄土的加固深度,对木质素加固黄土工程场地的桩基抗震性能进行了研究。结果表明:(1)改良土层显著提高了桩周土体的横向约束刚度,增强了桩-土体系的整体动力刚度,从而提升了桩基抵抗高阶振动的能力,导致高阶频率向高频偏移,整体表现为频率上升。(2)改良土层可改变桩身反弯点位置,且两侧正负弯矩极值的绝对差值随改良深度h的增加先减后增;随h增大桩身位移整体呈减小模式,h=12 m时的桩头位移仅为h=0 m的27%。(3)改良土层可减弱桩-土相互作用系统的加速度响应,h=4 m时桩顶中心点的加速度放大系数最小,桩周土对桩基的支撑最强。(4)改良深度超过1 m即可将桩基的抗震性能从中等损伤Ⅱ类水平改善至基本弹性Ⅰ类水平;h=4 m时桩-土相互作用体系在震后的损伤及位移较小,综合考虑桩身震后的损伤、位移及地基土加固的经济性,可认为针对类似本文桩的桩长径比为20、配筋率为2%的模型,最优加固深度为4 m。(5)地震波的频谱特性对桩身弯矩的影响主要体现在桩身最大弯矩的最大值及反弯点位置,对桩身位移的影响表现在其沿桩身分布曲线的拐点数量及同一高度处桩身位移的数值差上,低频越突出,高频成分越丰富的地震波对桩身弯矩的影响越大,对桩身位移的影响反而较小。相关结论可为类似桩基加固的抗震性能提供参考。Abstract: To address the problems of pile–soil separation and large lateral deformation of piles caused by foundation soil failure under seismic loading, this study explores the use of lignin, an environmentally friendly reinforcement material, to improve the foundation soil of loess engineering sites. Laboratory tests and numerical simulations were conducted to investigate the seismic performance of piles in lignin-modified loess, considering pile–soil interaction and reinforcement depth. The main findings are as follows: (1) Soil improvement significantly enhances the lateral confinement stiffness of the surrounding soil, increases the overall dynamic stiffness of the pile–soil system, and improves the pile foundation’s resistance to higher-order vibrations, resulting in a frequency elevation of the system. (2) The improved soil layer modifies the location of inflection points along the pile shaft. The difference between extreme bending moments on opposite sides of the pile decreases and then increases with reinforcement depth (h). Pile displacement generally decreases with increasing h, with pile head displacement at h=12 m reduced to 27% of that at h=0 m. (3) Soil improvement weakens the acceleration response of the pile–soil system, with the minimum acceleration amplification factor at the pile top center observed at h=4 m. (4) Seismic performance can be upgraded from moderate damage (Class II) to essentially elastic behavior (Class I) when h>1 m. At h= 4 m, post-earthquake damage and displacement of the pile–soil system are minimal. Considering seismic damage, displacement control, and economic feasibility, the optimal reinforcement depth for piles with a slenderness ratio of 20 and reinforcement ratio of 2% is determined to be 4 m. (5) The spectral characteristics of seismic waves influence pile bending moments through maximum and inflection point positions, while their effects on displacement are reflected in the number and magnitude of inflection points in displacement profiles. Seismic waves with prominent low-frequency and rich high-frequency components exert stronger effects on bending moments but relatively weaker effects on displacements. These findings provide a useful reference for improving the seismic performance of pile foundations in loess regions.

-

Key words:

- Lignin /

- Loess engineering site /

- Pile foundation /

- Seismic dynamic response /

- Pile-soil interaction

-

表 1 试验所用黄土力学特性参数

Table 1. The mechanical property parameters of tested loess

ρ/(g·cm−3) wop/% Ip ρd/(g·cm−3) E/MPa c/kPa φ/(°) υ 1.59 12.25 9.80 1.375 55 23 26 0.3 表 2 试验所用木质素的工程性能参数

Table 2. Engineering performance parameters of lignin used in this study

长度 平均直径 体积密度 含水率 含灰量 耐热性能 pH <1 mm 40 μm 27 g/L <5% 18% 230 ℃ 7.0 表 3 木质素改良黄土的力学特性参数

Table 3. Mechanical propertiy parameters of lignin modified loess

ma/% Ed/MPa υ cd/kPa φd/(°) ξ 0 116.99 0.29 44.80 32.1 0.16 1 215.16 0.29 64.10 32.8 0.14 2 164.72 0.29 73.80 32.4 0.15 表 4 有限元模型的基本力学参数

Table 4. Basic properties of the 3D finite element model

类别 ρ/(kg·m−3) E/Pa υ c/Pa φ/(°) ξ σf/Pa 桩基 2500 3.00×1010 0.20 — — 0.05 1.53×107 原状黄土 1590 5.50×107 0.30 2.30×103 26.00 0.09 — 改良黄土 1 932 2.15×108 0.29 6.41×104 32.80 0.14 — 表 5 h对桩-土相互作用体系动力特性的影响

Table 5. Effect of h on dynamic characteristics of pile-soil interaction system

h/m 一阶 二阶 频率/HZ 特征值 $ \Delta_f $/% 频率/Hz 特征值 $ \Delta_f $/% 0 2.1783 187.33 — 2.4329 233.67 — 1 2.1354 180.03 −1.97 2.5052 247.76 2.97 2 2.1502 182.52 0.69 2.4973 246.20 −0.31 4 2.1279 178.75 −1.04 3.0451 366.07 21.93 6 2.1099 175.75 −0.85 3.1587 393.88 3.73 12 2.1437 181.42 1.62 3.5674 502.42 12.94 表 6 桩基内力特征值

Table 6. Internal force characteristic value of pile foundation

h/m 最大轴力响应特征 最大弯矩响应特征 FZmax/kN k/m γF MYmax/(kN·m) k/m 反弯点/m γM 0 1311 −11 1 638.91 −15 −10 1 1 1498 −10 1.14 560.60 −15 −3 0.88 2 1332 −11 1.02 546.80 −15 −4 0.86 4 1394 −11 1.06 539.20 −14 −7 0.84 6 1405 −10 1.07 552.70 −15 −8 0.87 12 1642 −12 1.25 529.00 −14 −13 0.83 表 7 桩头侧向位移值

Table 7. The lateral displacement value of pile head

项目 深度h/m 0 1 2 4 6 12 Ux/cm 4.39 3.00 2.30 2.72 2.55 1.18 γU 1 0.68 0.52 0.62 0.58 0.27 表 8 桩基础抗震性能与评价指标

Table 8. Seismic performance and evaluation index of pile foundations

抗震性能 整体位移延性水平 桩构件损伤水平 等级 判断依据 等级 判断依据 抗震性能Ⅰ 1 δ≤δy 1 μφ≤1.0 抗震性能Ⅱ 2 δy<δ≤δy2 2 μφ>1.0且εc≤0.004 抗震性能Ⅲ 3 δy2<δ≤δy3 3 0.004<εc≤0.006 -

陈育民, 周晓智, 徐君, 2017. 土工格栅控制液化土体流动变形的试验研究. 岩土工程学报, 39(10): 1922−1929.Chen Y. M., Zhou X. Z., Xu J., 2017. Experimental investigation on flow deformation of liquefiable soil reinforced with geogrids. Chinese Journal of Geotechnical Engineering, 39(10): 1922−1929. (in Chinese) 董超凡, 张吾渝, 张瑞星等, 2022. 冻融作用下木质素纤维改良黄土力学与热学特性试验研究. 冰川冻土, 44(2): 612−622.Dong C. F., Zhang W. Y., Zhang R. X., et al., 2022. Experimental study of the mechanical and thermal properties of lignin fiber-stabilized loess under freeze-thaw cycles. Journal of Glaciology and Geocryology, 44(2): 612−622. (in Chinese) 蒋挺大, 2009. 木质素. 2版. 北京: 化学工业出版社. 蒋应军, 王翰越, 乔怀玉等, 2020. 水、干湿及冻融循环作用下水泥改良黄土路基稳定性. 科学技术与工程, 20(35): 14592−14599.Jiang Y. J., Wang H. Y., Qiao H. Y., et al., 2020. Stability of cement-modified loess subgrade under water, wet-dry and freezing-thawing cycles. Science Technology and Engineering, 20(35): 14592−14599. (in Chinese) 李驰, 史冠宇, 武慧敏等, 2021. 基于脲酶诱导碳酸钙沉积的微生物矿化技术在分散性土改良中应用的试验研究. 岩土力学, 42(2): 333−342.Li C., Shi G. Y., Wu H. M., et al., 2021. Experimental study on bio-mineralization for dispersed soil improvement based on enzyme induced calcite precipitate technology. Rock and Soil Mechanics, 42(2): 333−342. (in Chinese) 陆飞云, 2020. 地下结构动力计算中地层弹簧参数和地层边界研究. 杭州: 浙江大学.Lu F. Y., 2020. Research on stratum spring parameters and stratum boundary in dynamic calculation of underground structure. Hangzhou: Zhejiang University. (in Chinese) 王兰民, 石玉成, 刘旭等, 2003. 黄土动力学. 北京: 地震出版社, 85−143.Wang L. M. , Shi Y. C. , Liu X. , et al. , 2003. Loess dynamics. Beijing: Seismological Press, 85−143. (in Chinese) 王谦, 刘钊钊, 王兰民等, 2023. 木质素改良黄土动本构关系研究. 岩土工程学报, 45(S2): 235−240.Wang Q., Liu Z. Z., Wang L. M., et al., 2023. Dynamic constitutive relationship of lignin−modified loess. Chinese Journal of Geotechnical Engineering, 45(S2): 235−240. (in Chinese) 张斌, 郑文杰, 薛中飞等, 2023. 微生物诱导碳酸盐沉淀修复铅(Pb)污染黄土的试验研究. 土木工程学报, 56(11): 114−123.Zhang B., Zheng W. J., Xue Z. F., et al., 2023. Experimental study on remediation of lead(Pb) contaminated loess using microbial-induced carbonate precipitation. China Civil Engineering Journal, 56(11): 114−123. (in Chinese) 张磊, 许徐晗, 陈成等, 2022. 地震作用下软土中桩承桥墩系统响应特性分析. 振动工程学报, 35(6): 1530−1540.Zhang L., Xu X. H., Chen C., et al., 2022. Seismic response characteristics of clay-pile-pier systems. Journal of Vibration Engineering, 35(6): 1530−1540. (in Chinese) 张永亮, 宁贵霞, 陈兴冲等, 2016. 考虑桩-土相互作用效应的高速铁路桥梁桩基础抗震设计方法研究. 冰川冻土, 38(4): 1003−1011.Zhang Y. L., Ning G. X., Chen X. C., et al., 2016. Study on seismic design method for high-speed railway bridge pile foundations considering soil-pile interaction effect. Journal of Glaciology and Geocryology, 38(4): 1003−1011. (in Chinese) 钟秀梅, 王谦, 刘钊钊等, 2020. 干湿循环作用下粉煤灰改良黄土路基的动强度试验研究. 岩土工程学报, 42(S1): 95−99.Zhong X. M., Wang Q., Liu Z. Z., et al., 2020. Dynamic strength of fly ash-modified loess subgrade under influences of drying-wetting cycle. Chinese Journal of Geotechnical Engineering, 42(S1): 95−99. (in Chinese) 邹佑学, 王睿, 张建民, 2019. 可液化场地碎石桩复合地基地震动力响应分析. 岩土力学, 40(6): 2443−2455.Zou Y. X., Wang R., Zhang J. M., 2019. Analysis on the seismic response of stone columns composite foundation in liquefiable soils. Rock and Soil Mechanics, 40(6): 2443−2455. (in Chinese) Adalier K., Elgamal A., Meneses J., et al., 2003. Stone columns as liquefaction countermeasure in non-plastic silty soils. Soil Dynamics and Earthquake Engineering, 23(7): 571−584. doi: 10.1016/S0267-7261(03)00070-8 Bhattacharya S., Tokimatsu K., Goda K., et al., 2014. Collapse of Showa Bridge during 1964 Niigata earthquake: a quantitative reappraisal on the failure mechanisms. Soil Dynamics and Earthquake Engineering, 65: 55−71. doi: 10.1016/j.soildyn.2014.05.004 Calvi G. M., 1999. A displacement-based approach for vulnerability evaluation of classes of buildings. Journal of Earthquake Engineering, 3(3): 411−438. Das R., Muthukkumaran K., 2024. Enhancing sand liquefaction resistance through microbial-induced partial saturation: an experimental study. Transportation Geotechnics, 48: 101337. doi: 10.1016/j.trgeo.2024.101337 Guo D., Shao S. J., Guo R. F., 2024. Experimental study on the dynamic behavior of lignin-amended loess. Scientific Reports, 14(1): 17404. doi: 10.1038/s41598-024-68505-5 Han Z. G., Cheng X. H., Ma Q., 2016. An experimental study on dynamic response for MICP strengthening liquefiable sands. Earthquake Engineering and Engineering Vibration, 15(4): 673−679. doi: 10.1007/s11803-016-0357-6 Mylonakis G., Syngros C., Gazetas G., et al., 2006. The role of soil in the collapse of 18 piers of Hanshin Expressway in the Kobe earthquake. Earthquake Engineering & Structural Dynamics, 35(5): 547−575. Pitilakis K., Tsinidis G., Leanza A., et al., 2014. Seismic behaviour of circular tunnels accounting for above ground structures interaction effects. Soil Dynamics and Earthquake Engineering, 67: 1−15. doi: 10.1016/j.soildyn.2014.08.009 Song J., Ma J. X., Li F. Y., et al., 2021. Study on fractal characteristics of mineral particles in undisturbed loess and lime-treated loess. Materials, 14(21): 6549. doi: 10.3390/ma14216549 Tsinidis G., Pitilakis K., Trikalioti A. D., 2014. Numerical simulation of round robin numerical test on tunnels using a simplified kinematic hardening model. Acta Geotechnica, 9(4): 641−659. doi: 10.1007/s11440-013-0293-9 -

下载:

下载: