Seismic Performance of Fuel Assembly under Mixed Core Condition of Nuclear Power Plant

-

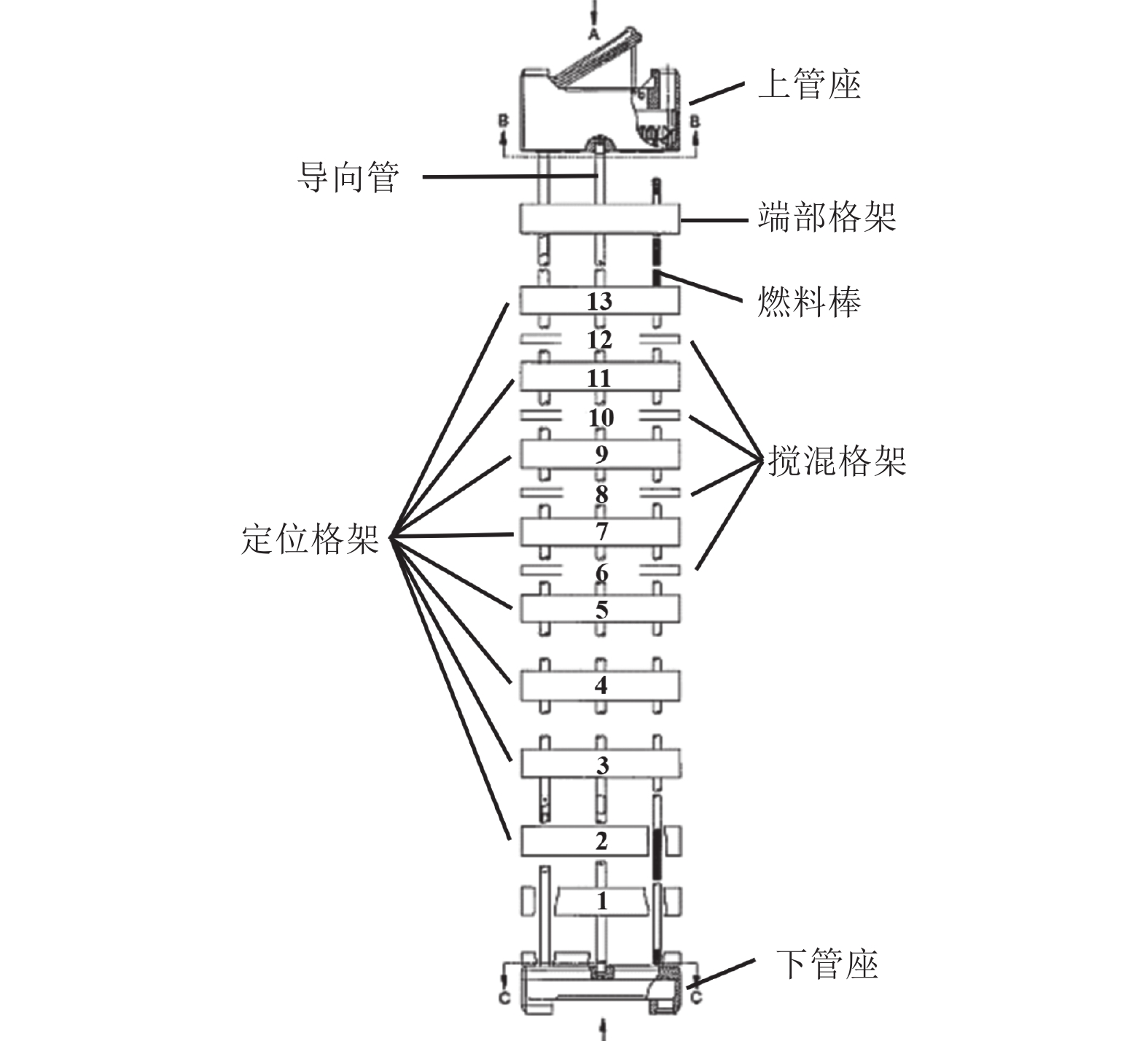

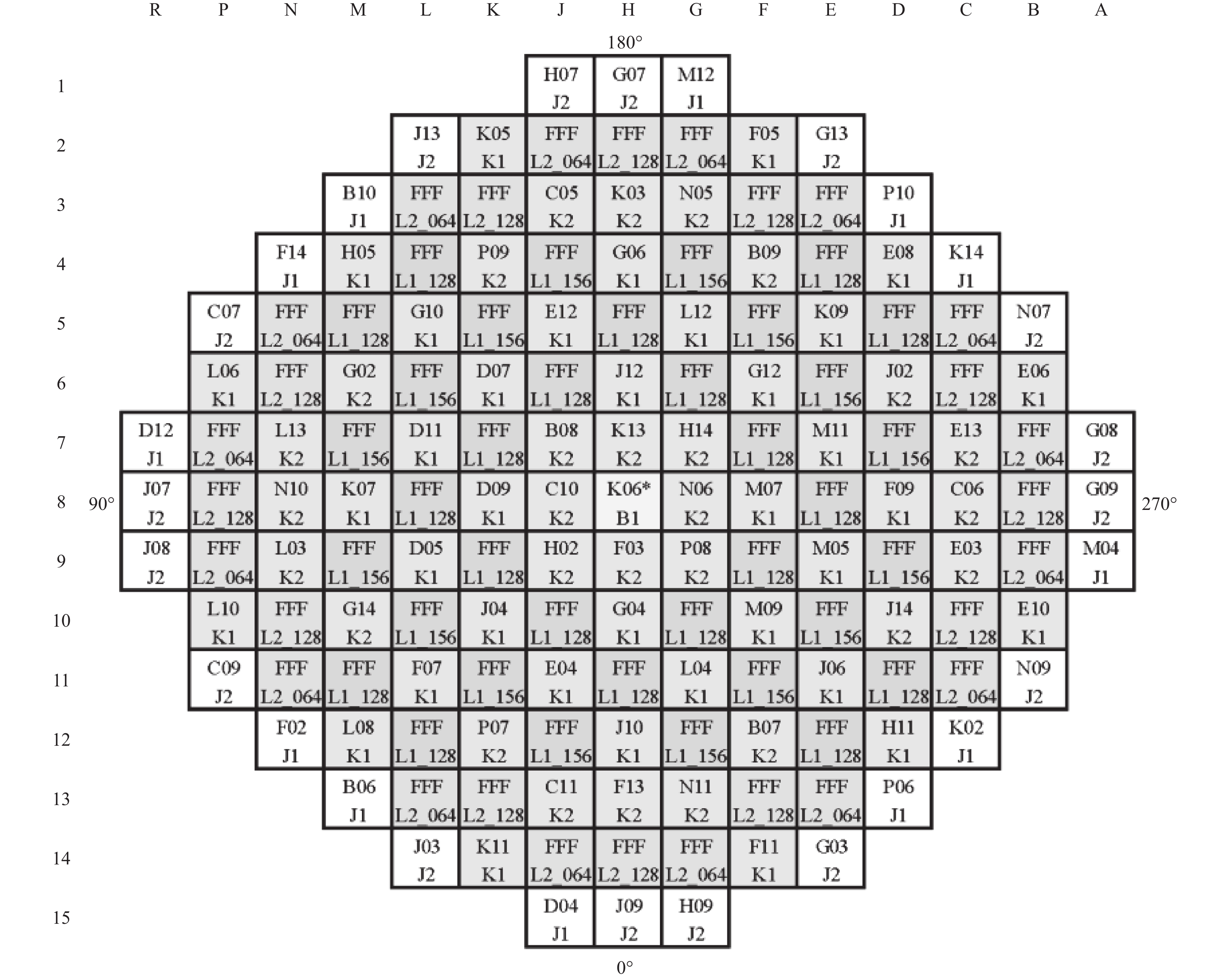

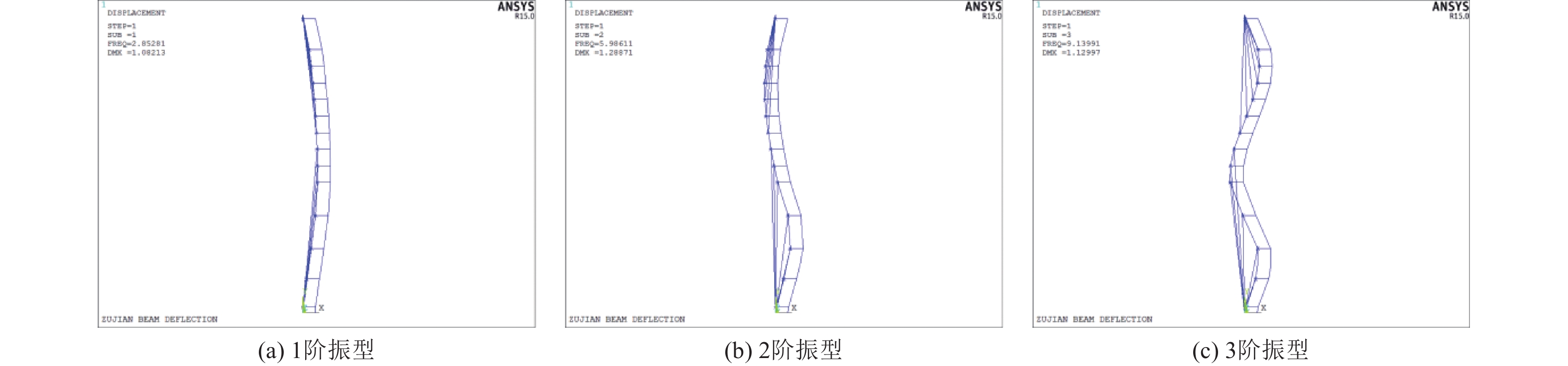

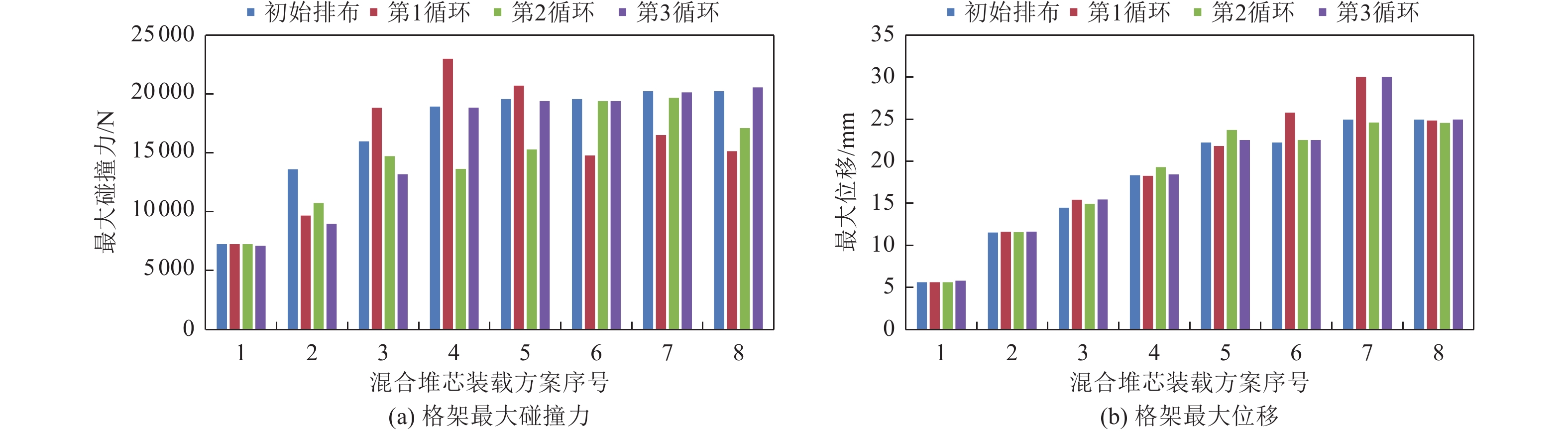

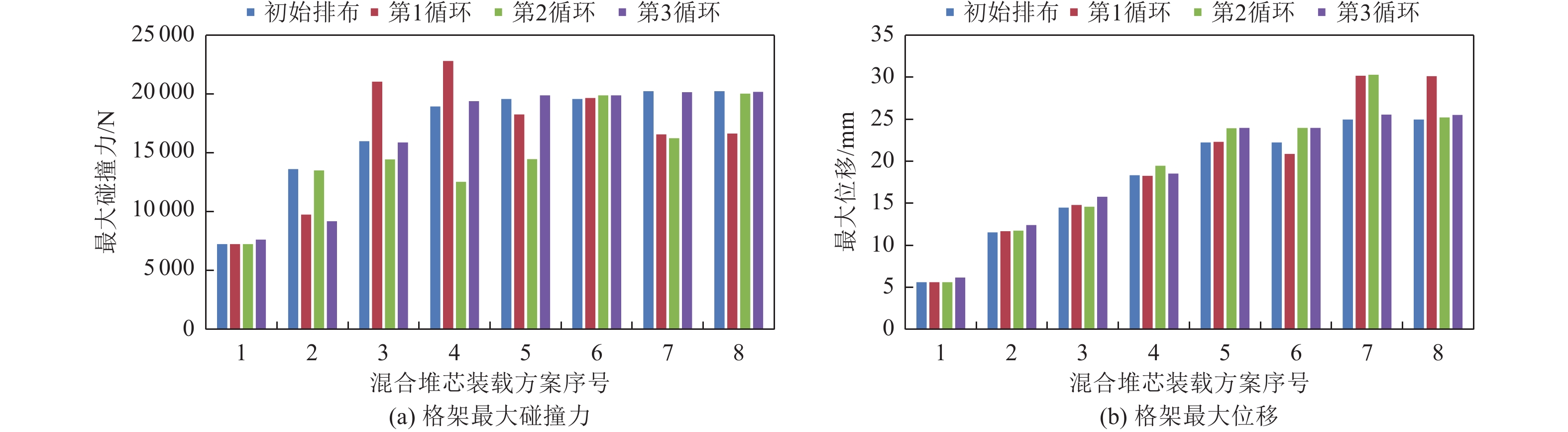

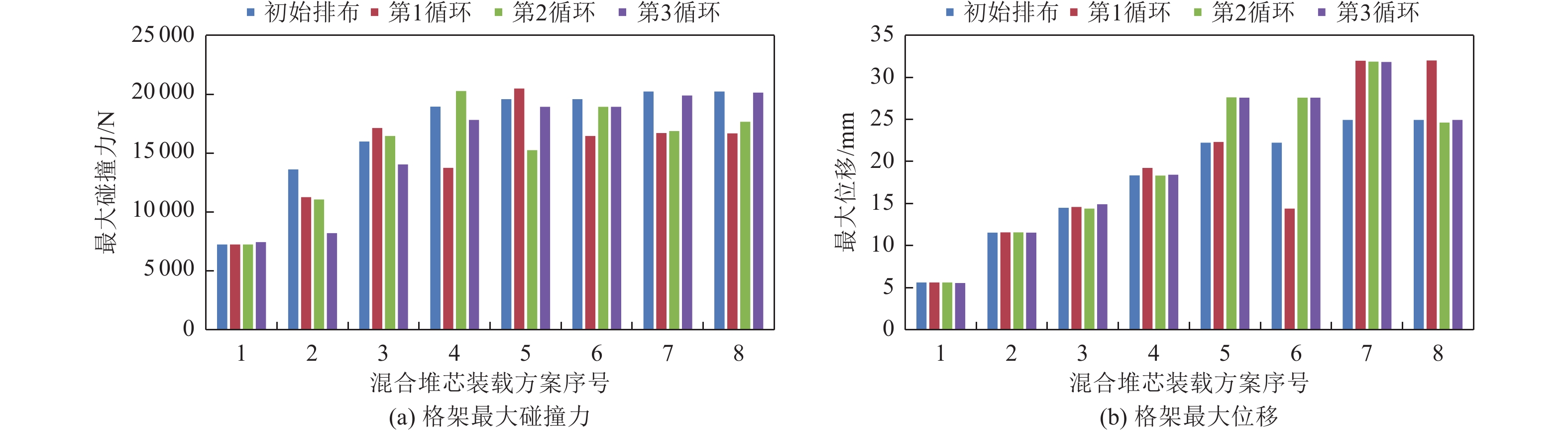

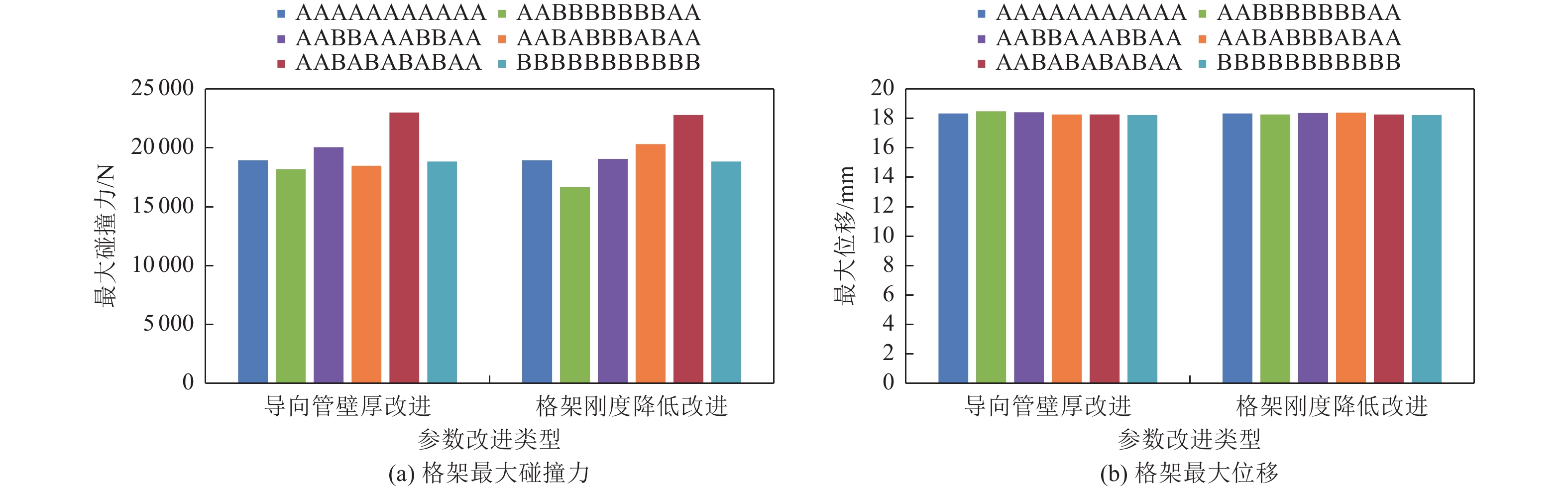

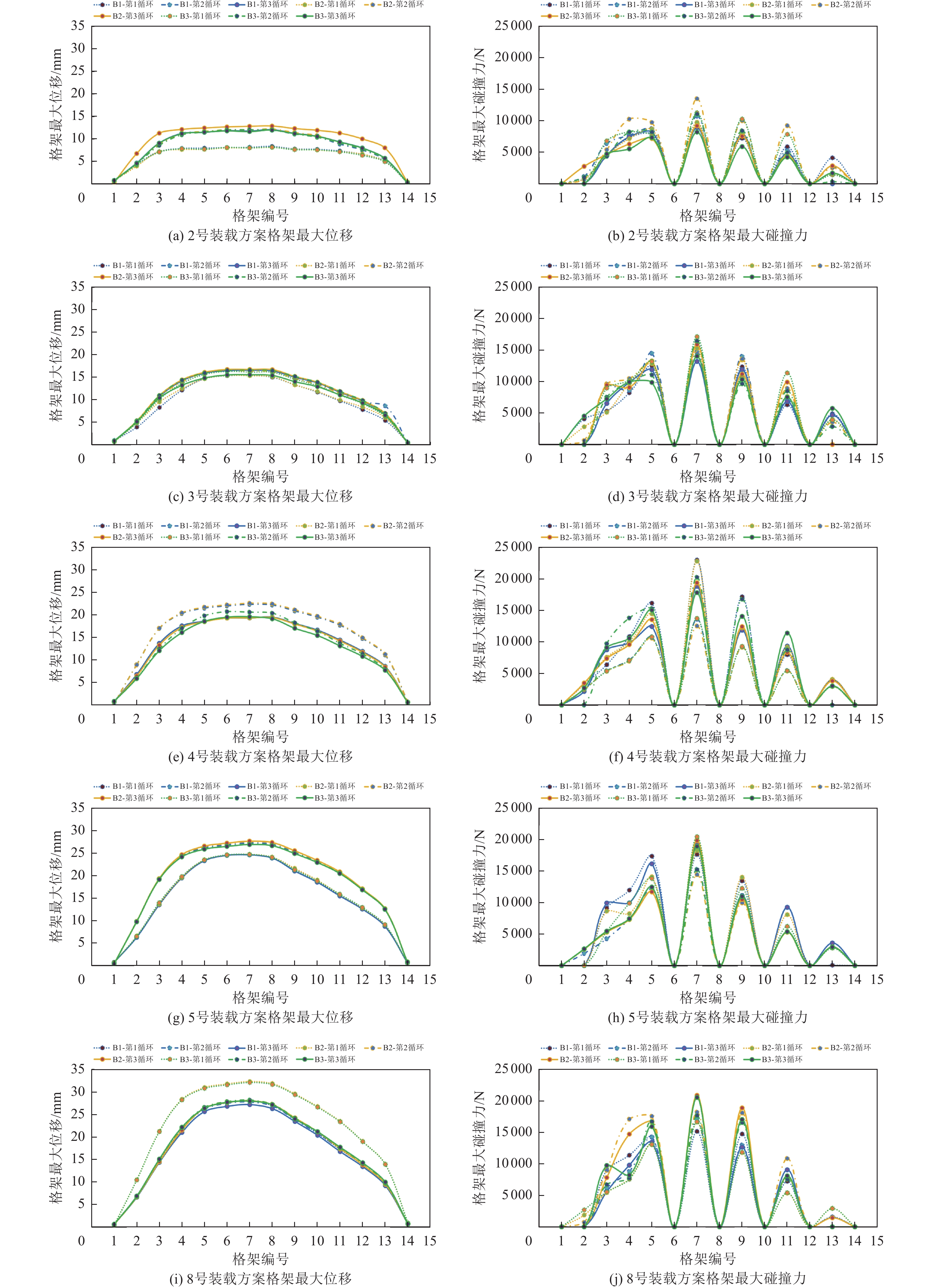

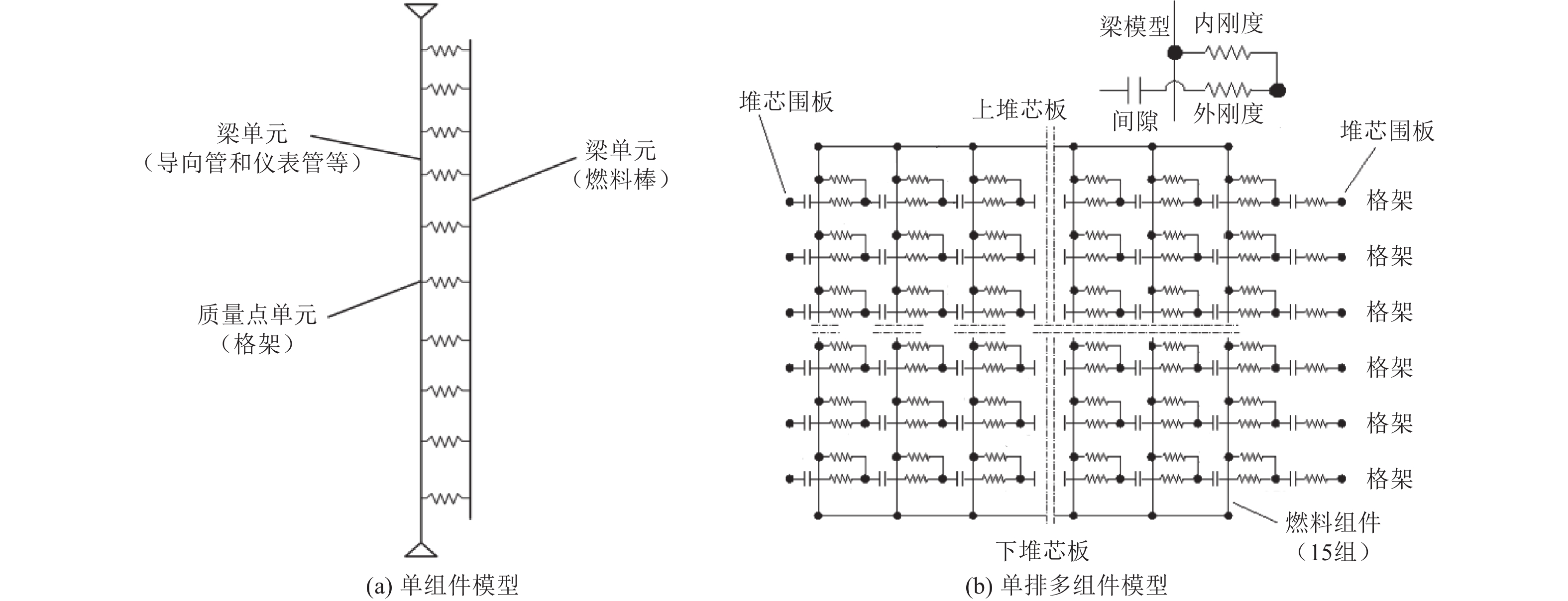

摘要: 我国先进燃料组件的自主研发将有助于提升核电厂的经济性和安全性。在新型燃料组件入堆形成混合堆芯时,需要开展燃料组件相容性、中子学特性及抗震性能等方面的安全评价。针对新型燃料组件入堆换料方案中出现的混合堆芯条件,结合自主化新型燃料组件设计改进特点,开展堆芯燃料组件抗震分析,研究不同设计改进和不同装载方案对燃料组件抗震性能的影响。结果表明:均质堆芯条件下,随着单排组件数量的增多,组件格架的最大碰撞力和最大位移逐渐增大,选择单排15个组件开展抗震分析具有一定的保守性。混合堆芯条件下,格架刚度参数变化对入堆第1和第2循环格架最大位移影响较大,导向管壁厚增加和格架刚度减小等参数改进会引起第1循环边缘对称AA组件装载方案格架最大碰撞力的大幅增长,可能超过单排15个组件成为整个堆芯组件格架的最大碰撞力,需要在混合堆芯燃料组件安全评价中重点关注。Abstract: The independent development of advanced fuel assemblies in China is expected to enhance both the economic efficiency and safety of nuclear power plants. When a new fuel assembly is introduced into a reactor to form a hybrid core, it is essential to evaluate fuel assembly compatibility, neutronic characteristics, and seismic performance. Considering the mixed-core conditions under the new fuel assembly refueling scheme and the design improvements of the self-developed fuel assembly, this study conducts seismic analyses of the core fuel assemblies and investigates the effects of different design modifications and loading schemes on their seismic performance. The results indicate that, under homogeneous core conditions, as the number of single-row assemblies increases, both the maximum collision force and maximum displacement of the assembly grid gradually rise, making the selection of 15 single-row assemblies a conservative choice for seismic analysis. Under mixed-core conditions, variations in grid stiffness parameters have a significant impact on the maximum displacement of grids during the first and second reactor cycles. Specifically, increasing the guide tube wall thickness and reducing grid stiffness can substantially increase the maximum collision force of the first-cycle edge symmetrical AA assembly loading scheme, potentially exceeding the maximum collision force of a 15-assembly single-row configuration. These findings highlight critical factors that must be addressed in the safety evaluation of mixed-core fuel assemblies.

-

Key words:

- Fuel assembly /

- Mixed core /

- Seismic analysis

-

表 1 新型燃料组件结构设计改进参数

Table 1. Improved parameters of new fuel assembly structure design

组件类型 改进参数描述 入堆方式 A 参照组件 已在堆 B B1 参照组件导向管壁厚增加0.1 mm 新入堆 B2 参照组件格架刚度减小5% B3 参照组件格架刚度增大5% 表 2 混合堆芯燃料组件分批次入堆装载方案

Table 2. Mixed core fuel assembly batch loading scheme

序号 组件数量 新组件入堆第1循环 新组件入堆第2循环 新组件入堆第3循环(B组件均质堆芯) 1 3 AAA AAA BBB 2 7 A(A)B(B)B(A)A A(B)B(B)B(B)A B(B)B(B)B(B)B 3 9 A(B)B(A)A(A)B(B)A A(B)B(B)B(B)B(B)A B(B)B(B)B(B)B(B)B 4 11 A(A)B(A)B(A)B(A)B(A)A A(B)B(B)B(B)B(B)B(B)A B(B)B(B)B(B)B(B)B(B)B 5 13 A(B)B(A)B(A)B(A)B(A)B(B)A A(B)B(B)B(B)B(B)B(B)B(B)A B(B)B(B)B(B)B(B)B(B)B(B)B 6 (A)B(A)B(A)B(A)B(A)B(A)B(A) (B)B(B)B(B)B(B)B(B)B(B)B(B) (B)B(B)B(B)B(B)B(B)B(B)B(B) 7 15 AB(A)B(A)B(A)A(A)B(A)B(A)BA AB(B)B(B)B(B)B(B)B(B)B(B)BA BB(B)B(B)B(B)B(B)B(B)B(B)BB 8 A(B)A(A)B(A)A(A)A(A)B(A)A(B)A A(B)B(B)B(B)B(A)B(B)B(B)B(B)A B(B)B(B)B(B)B(A)B(B)B(B)B(B)B 注:括号表示堆芯控制棒位置 表 3 燃料组件前7阶模态计算结果(单位:赫兹)

Table 3. The seven order modal calculation results of fuel assembly (Unit:Hz)

组件类型 阶数 1 2 3 4 5 6 7 A 2.85 5.98 9.14 13.10 17.01 22.49 25.75 B1 2.88 6.04 9.25 13.25 17.22 22.73 26.09 B2 2.83 5.87 9.02 12.98 16.87 22.21 25.52 B3 2.86 6.01 9.19 13.21 17.14 22.53 25.91 -

杜修力, 陈厚群, 2000. 核电厂堆芯燃料组件地震反应分析. 地震工程与工程振动, 20(2): 57−60. doi: 10.13197/j.eeev.2000.02.010Du X. L., Chen H. Q., 2000. Seismic response analysis of fuel assembly in nuclear power station. Earthquake Engineering and Engineering Vibration, 20(2): 57−60. (in Chinese) doi: 10.13197/j.eeev.2000.02.010 冯英杰, 邱斌, 2023. 不同混合堆芯方案对压水堆CIPS风险的影响研究. 核科学与工程, 43(1): 7−11.Feng Y. J., Qiu B., 2023. Study on the influence of different hybrid core schemes on the PWR CIPS risk. Nuclear Science and Engineering, 43(1): 7−11. (in Chinese) 傅先刚, 周洲, 2002. 混合堆芯的热工水力设计. 核动力工程, 23(2): 17−20.Fu X. G., Zhou Z., 2002. Thermal and hydraulic analysis of mixed core. Nuclear Power Engineering, 23(2): 17−20. (in Chinese) 龚曙光, 谢桂兰, 黄云清, 2009. ANSYS参数化编程与命令手册. 北京: 机械工业出版社. 焦拥军, 肖忠, 李云等, 2017. “华龙一号”燃料组件设计研究及验证. 中国核电, 10(4): 478−482, 488.Jiao Y. J., Xiao Z., Li Y., et al., 2017. R&D and validation of HPR1000 fuel assembly. China Nuclear Power, 10(4): 478−482,488. (in Chinese) 林诚格, 2010. 非能动安全先进压水堆核电技术. 北京: 原子能出版社. 齐欢欢, 沈平川, 吴万军等, 2016. 燃料组件导向管事故工况应力计算方法研究. 应用数学和力学, 37(5): 534−541.Qi H. H., Shen P. C., Wu W. J., et al., 2016. A stress calculation method for guide thimbles in fuel assemblies under accident conditions. Applied Mathematics and Mechanics, 37(5): 534−541. (in Chinese) 邱斌, 毛玉龙, 严亚伦等, 2023. 混合堆芯中腐蚀产物沉积和一回路放射性水平的影响研究. 核科学与工程, 43(1): 25−29.Qiu B., Mao Y. L., Yan Y. L., et al., 2023. Study of corrosion products deposition and primary circuit source term levels in hybrid core. Nuclear Science and Engineering, 43(1): 25−29. (in Chinese) 魏超, 宋辰宁, 郭超等, 2023. 堆芯燃料组件抗震计算关键参数的敏感性分析. 地震工程与工程振动, 43(5): 232−239. doi: 10.13197/j.eeed.2023.0523Wei C., Song C. N., Guo C., et al., 2023. Sensitivity analysis of key parameters in seismic calculation of core fuel assembly. Earthquake Engineering and Engineering Dynamics, 43(5): 232−239. (in Chinese) doi: 10.13197/j.eeed.2023.0523 肖忠, 2000. 秦山二期工程燃料组件LOCA和SSE下的事故分析. 核动力工程, 21(6): 511−514.Xiao Z., 2000. Fuel assembly accident analysis under LOCA and SSE for Qinshan phase-Ⅱ project. Nuclear Power Engineering, 21(6): 511−514. (in Chinese) 谢永诚, 姚伟达, 姜南燕, 2002. 燃料组件在地震和失水工况下的结构动力反应分析. 核动力工程, 23(S1): 139−147.Xie Y. C., Yao W. D., Jiang N. Y., 2002. Dynamic response analysis for fuel assemblies under earthquake and LOCA accidents. Nuclear Power Engineering, 23(S1): 139−147. (in Chinese) 杨晓东, 2003. AFA 3G及其它高性能燃料组件. 原子能科学技术, 37(S1): 15−20.Yang X. D., 2003. AFA 3G and other designs of high performance fuel assemblies. Atomic Energy Science and Technology, 37(S1): 15−20. (in Chinese) 周云清, 刘家正, 朱丽兵, 2011. 地震加LOCA下的燃料组件安全分析研究. 核动力工程, 32(S1): 83−86.Zhou Y. Q., Liu J. Z., Zhu L. B., 2011. Safety analysis of fuel assembly for combined seismic and loss-of-coolant accident. Nuclear Power Engineering, 32(S1): 83−86. (in Chinese) Fritz R. J., 1972. The effect of liquids on the dynamic motions of immersed solids. Journal of Engineering for Industry, 94(1): 167−173. doi: 10.1115/1.3428107 Shan S. J. , Brenneman B. , Strumpell J. H. , et al. , 2005. Improved fuel assembly dynamic model. In: Proceedings of the 18th International Conference on Structural Mechanics in Reactor Technology. Beijing: IASMiRT, 413−421. Snyder M. D. , 2001. Parametric studies of the dynamic impact of fuel assemblies in PWR cores. In: Proceedings of the 16th International Conference on Structural Mechanics in Reactor Technology. Washington: IASMiRT, 1078−1085. -

下载:

下载: