The Design and Shaking Table Test Verification of a Dynamic Model Box for Tunnels Crossing Multi-rupture Surface Fault

-

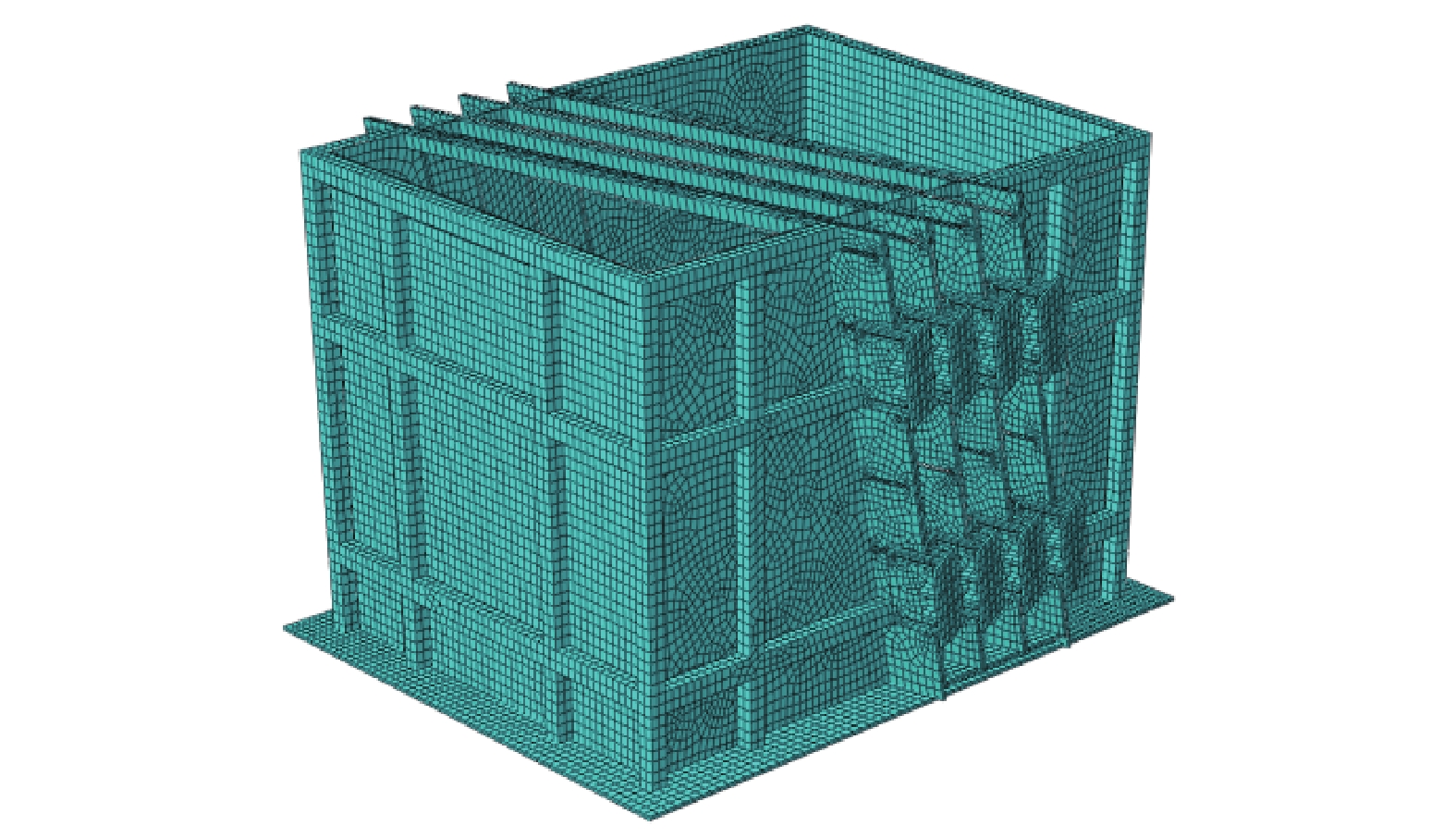

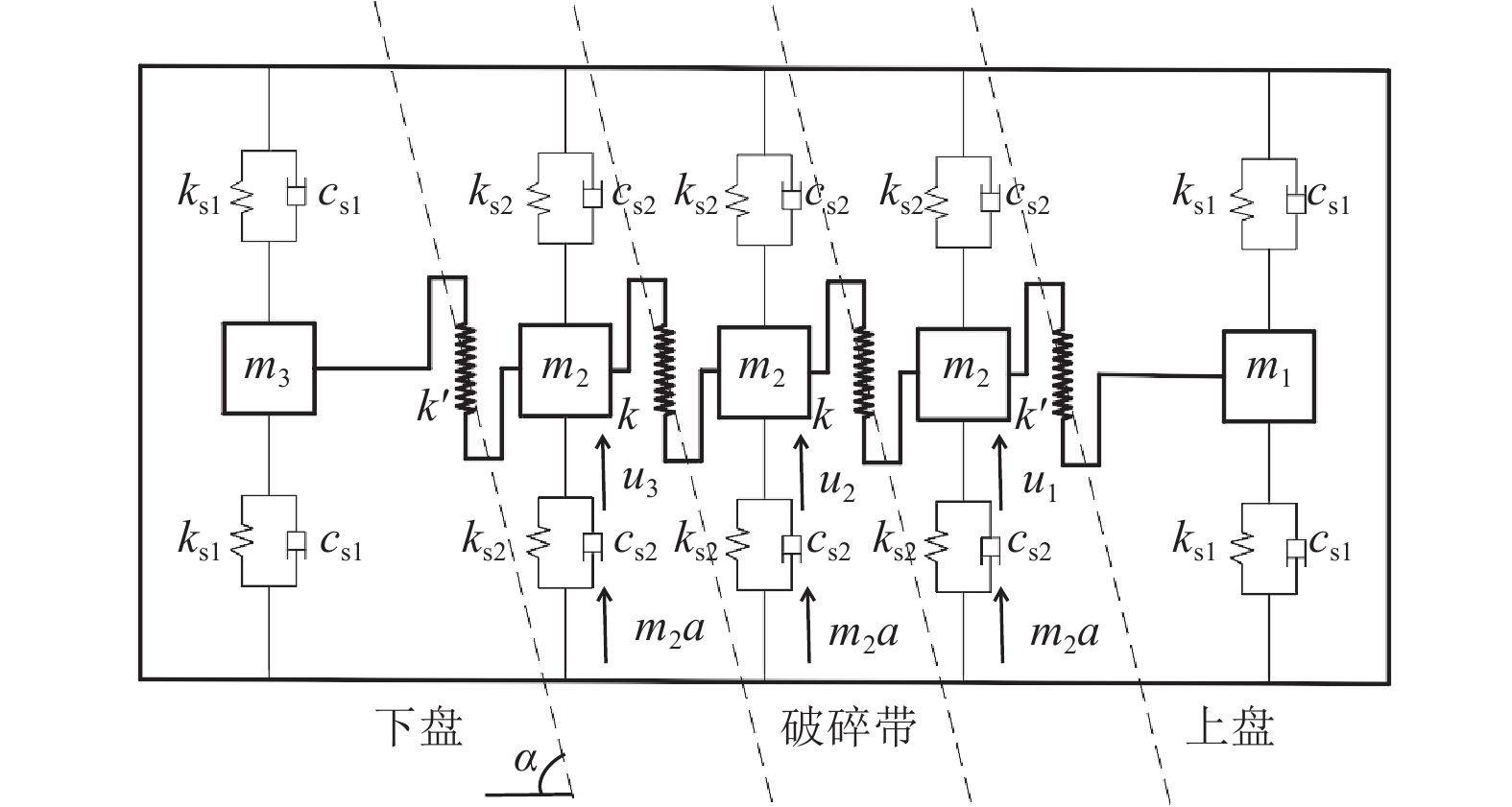

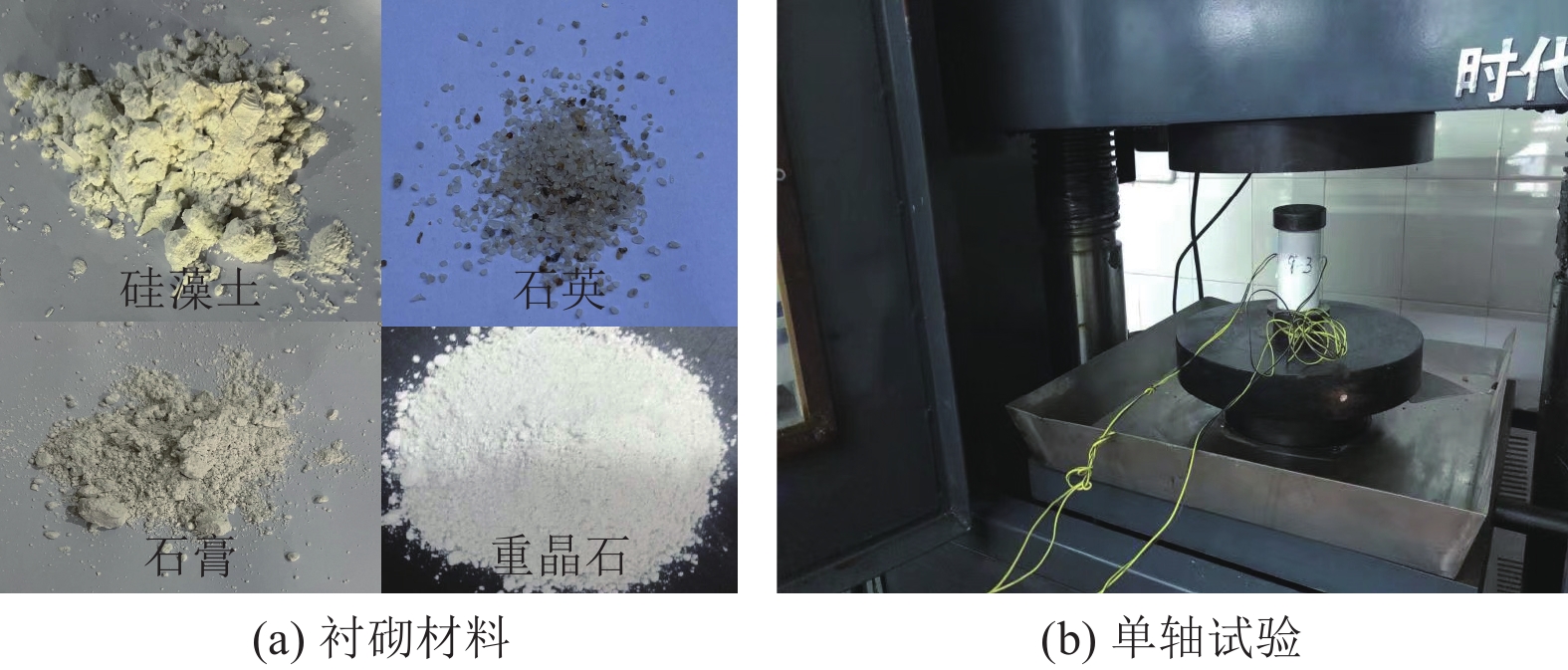

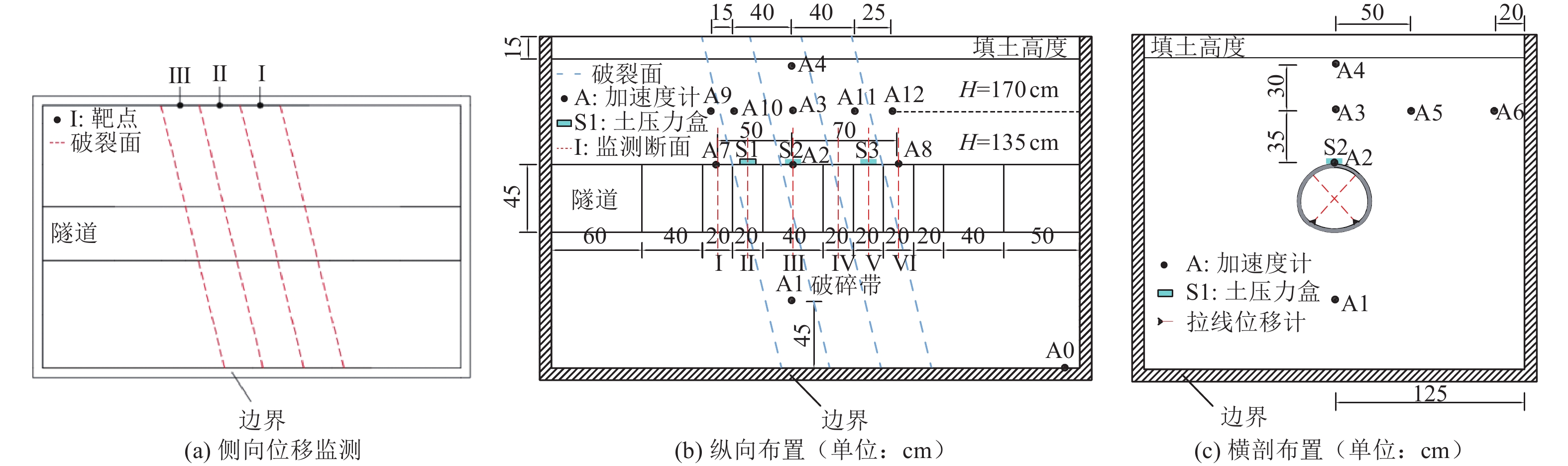

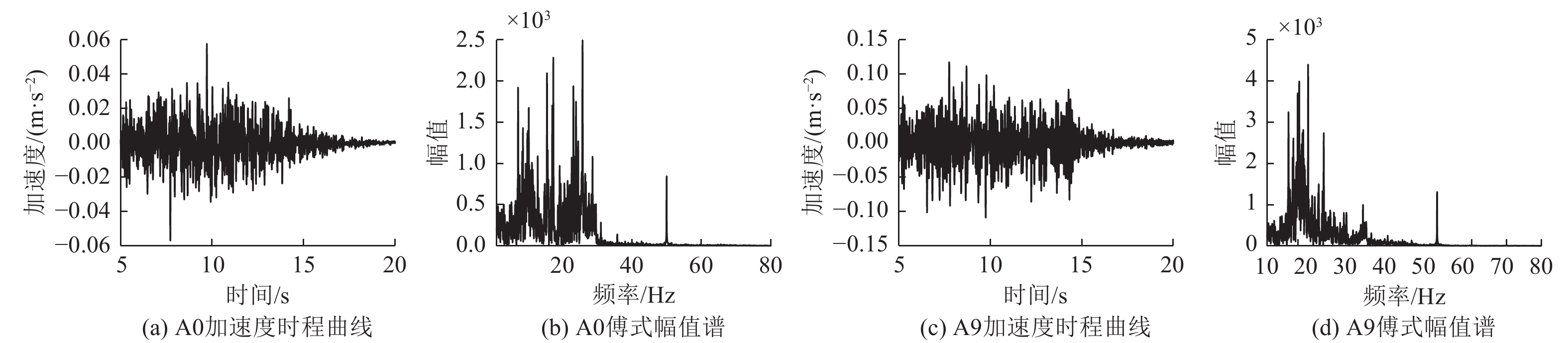

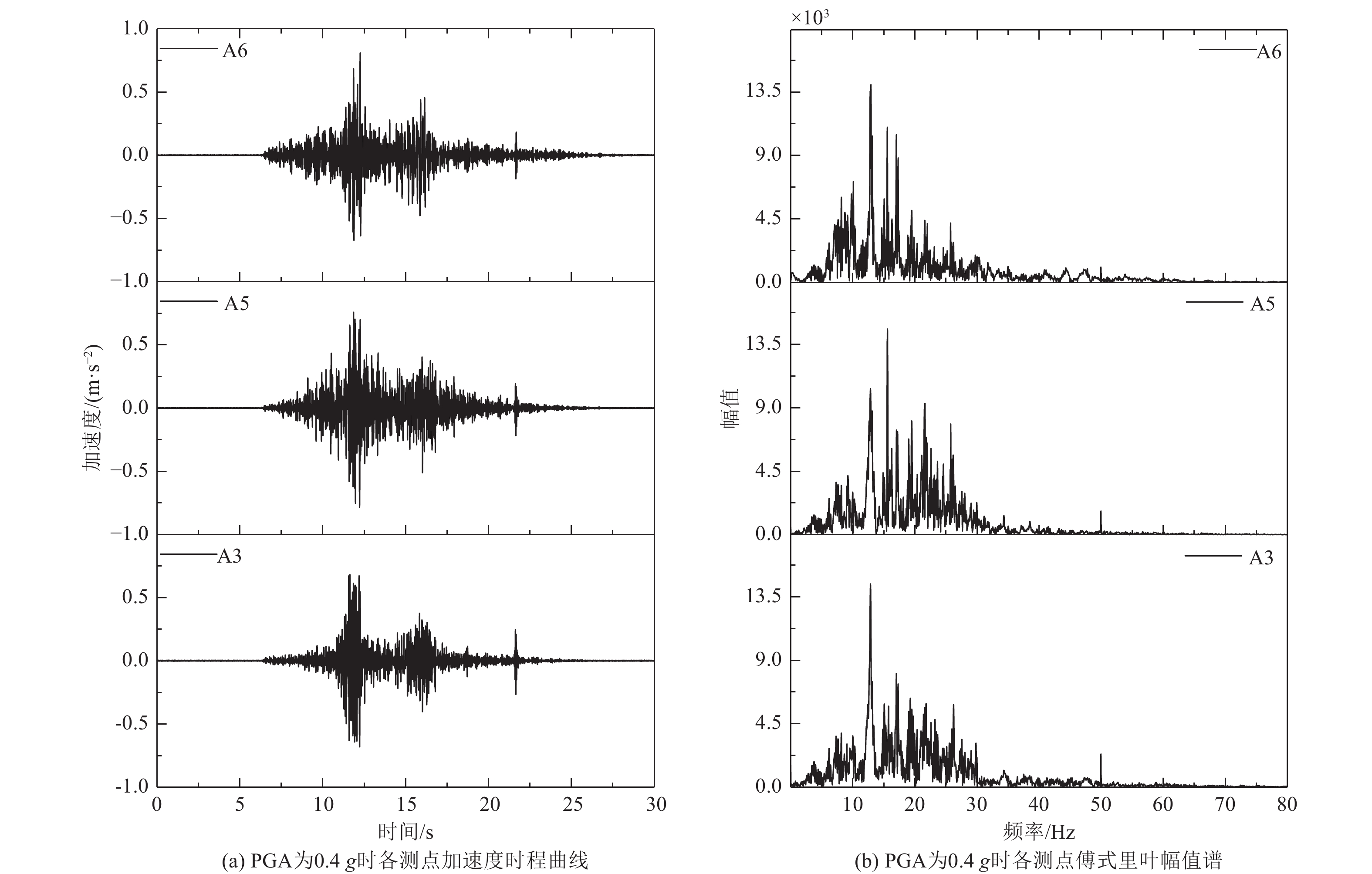

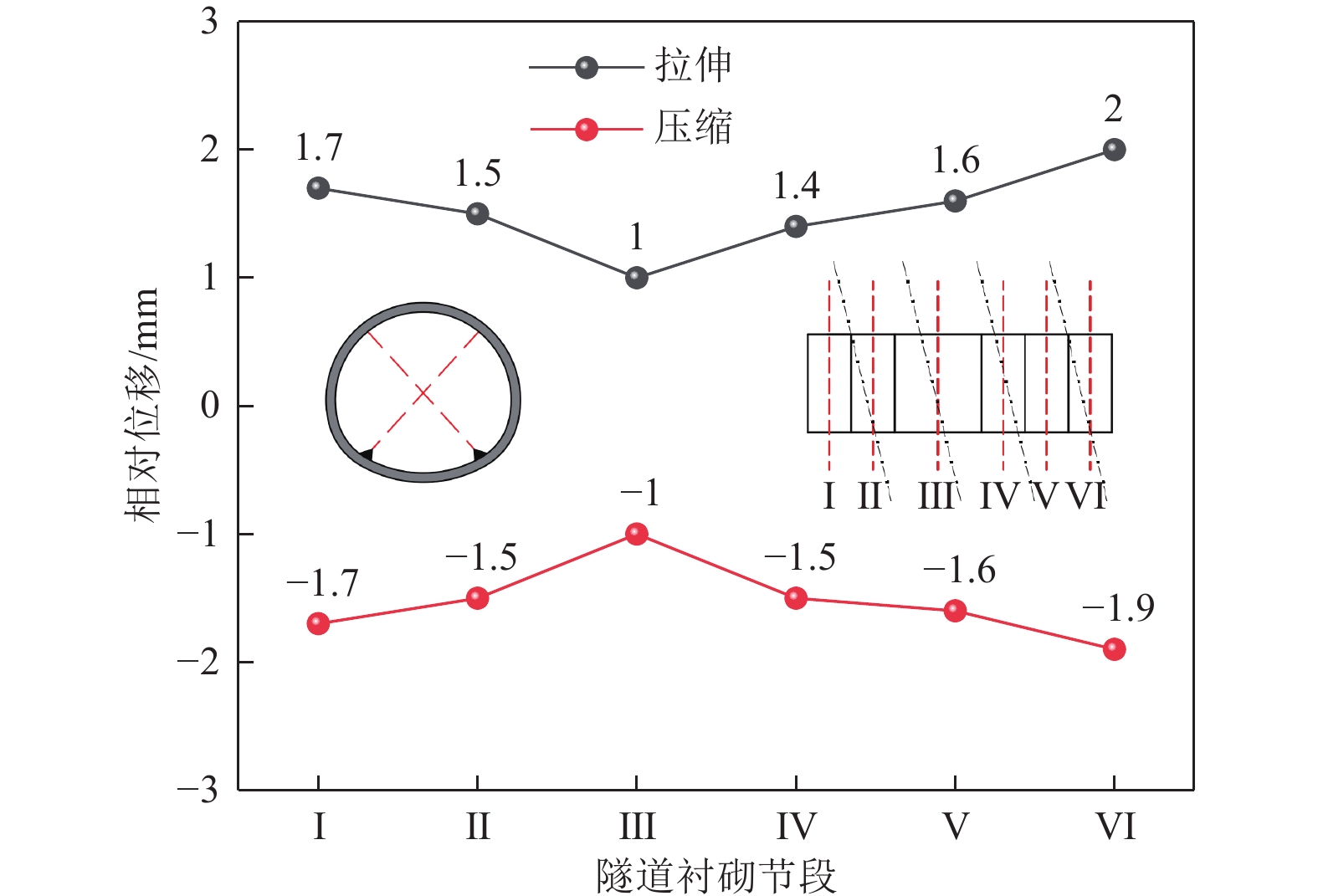

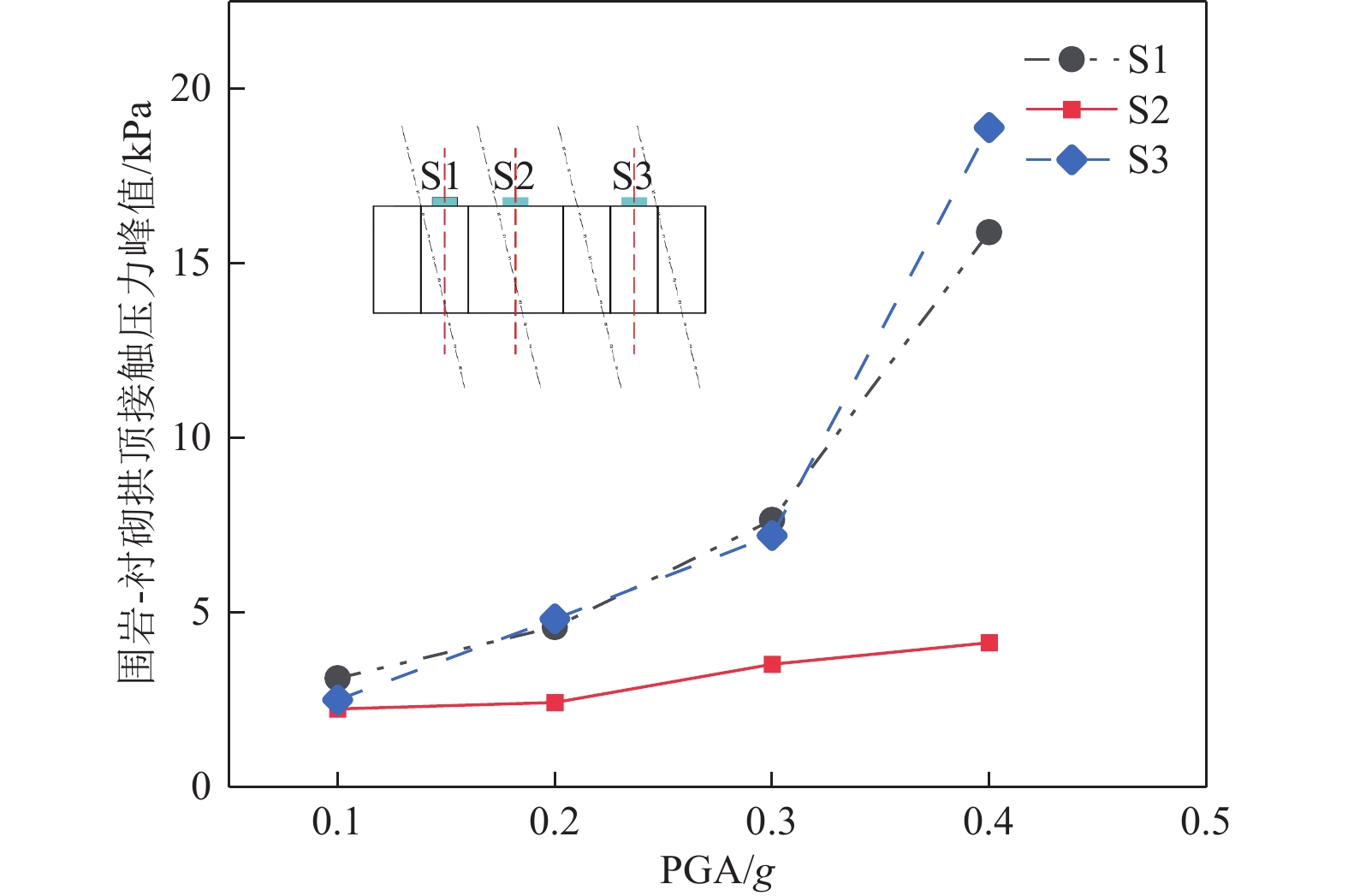

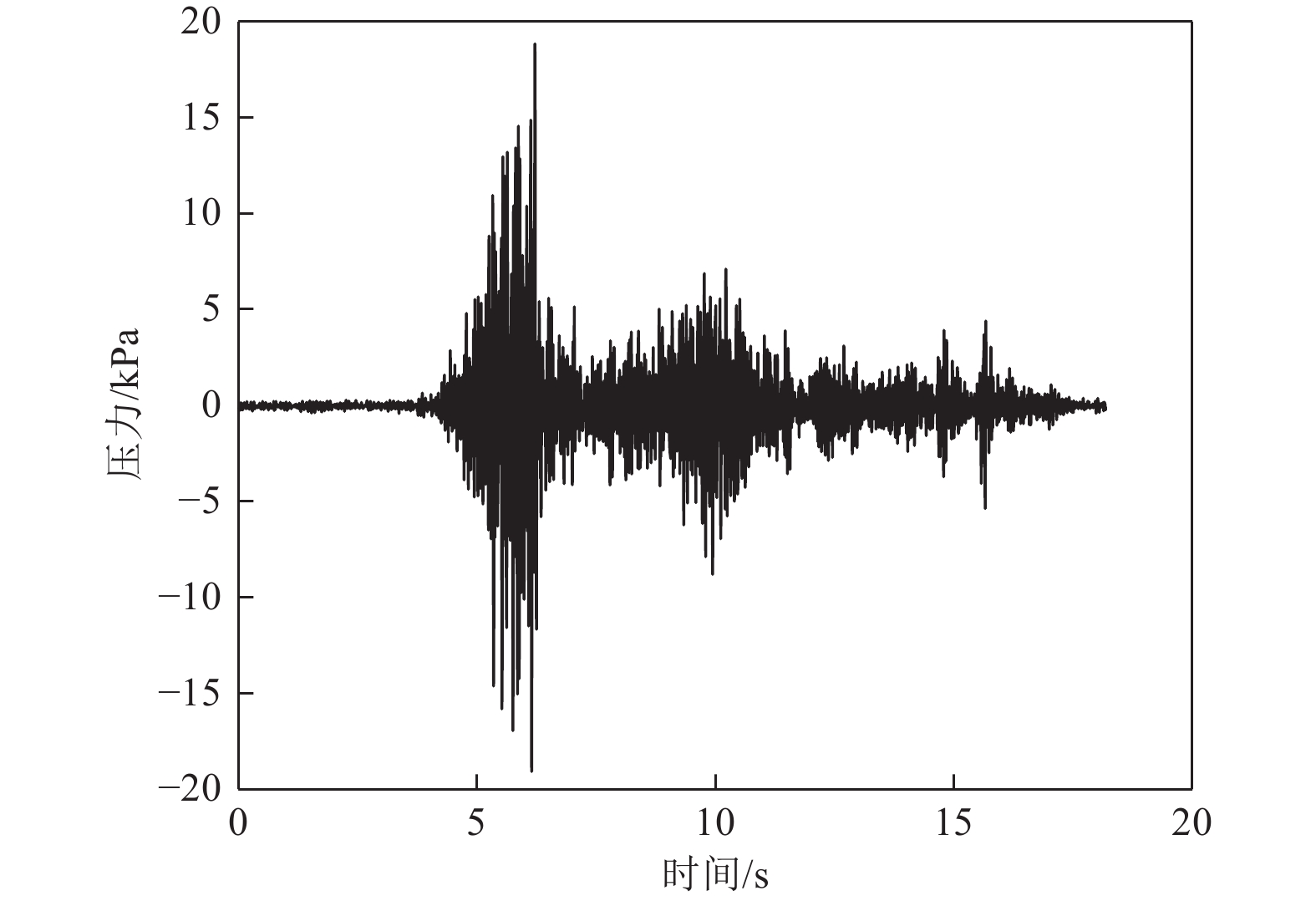

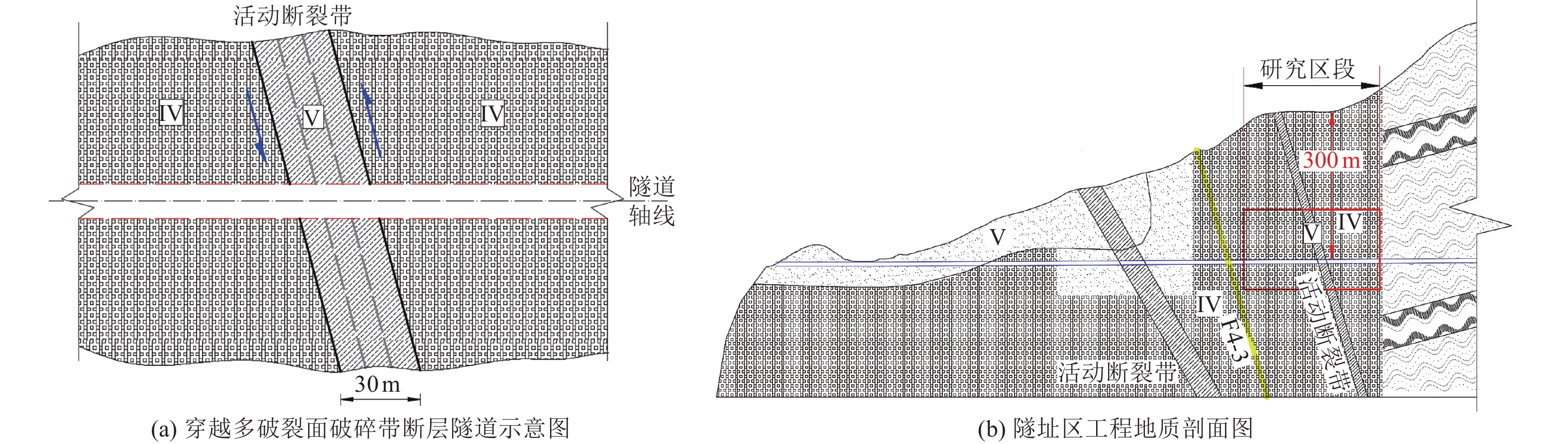

摘要: 振动台模型试验是研究工程结构动力响应的重要手段,模型箱作为隧道工程振动台模型试验的关键因素,其设计的合理性成为确保振动台试验准确的关键。本文依托某高烈度地震区穿越大型断裂带隧道工程,以穿越多破裂面断层隧道为对象,根据多破裂断层相互作用力学机理,基于弹性地基理论构建了集中质量力学模型,并设计了针对穿越多破裂面断层隧道的动力模型箱。利用有限元软件对模型箱进行模态频响分析,得出模型箱-围岩-衬砌在地震动作用下不发生共振,各阶振型之间不会产生影响。运用该模型箱进行振动台试验并验证合理性,结果表明,围岩纵向范围同高度处,破碎带与上下盘交界处附近土体加速度峰值最大,显示出在地震作用下穿越多破裂面断层隧道与围岩的加速度响应特性;隧道衬砌共轭45°相对位移及围岩-衬砌拱顶接触应力峰值最大值出现在破碎带与上下盘交界处附近,最小值出现在破碎带内部破裂面处,破碎带边缘所受地震力最大;力学模型理论与试验的应力释放量相对差值仅为6.7%、0.5%,位移相差均在10%以内,验证了模型箱能较好地模拟穿越多破裂面断层隧道的错震特性;采用2-范数偏差μ对边界效应进行量化,μ总体小于0.2,并随着PGA的增大先增加后减小并趋于稳定,说明模型箱边界效应影响较小,能够模拟地震时多破裂面断层运动特性,验证了试验结果的可靠性,研究结果可为此类模型箱设计提供参考。Abstract: Shaking table model testing is a crucial method for investigating the dynamic response of engineering structures. In the context of tunnel engineering, the design of the model box plays a pivotal role in ensuring the accuracy and reliability of shaking table tests. This study focuses on a tunnel project located in a high-intensity seismic zone traversing a large fracture zone, where the tunnel intersects multiple fault surfaces. Based on the mechanics of multi-fault rupture interaction and employing elastic foundation theory, a concentrated mass mechanical model is developed to support the design of a dynamic model box tailored for tunnels crossing multiple fractured faults. A modal and frequency response analysis of the model box is conducted using finite element software, confirming that the model box–surrounding rock–lining system does not exhibit resonance under seismic excitation and that there is no coupling between different vibration modes. The designed model box is subsequently used in shaking table tests, validating its structural and dynamic rationality. The test results indicate that the peak acceleration of the soil near the junction between the fracture zone and the upper and lower rock plates is the highest at the same longitudinal elevation of the surrounding rock. This reveals the characteristic acceleration response of both the surrounding rock and the tunnel structure when subjected to seismic loading across a complex fracture zone. Additionally, the maximum relative displacement (along the 45° conjugate plane) of the tunnel lining and the peak contact stress between the surrounding rock and the lining vault occur near the interface of the fracture zone and the upper/lower planes. Conversely, the minimum values are observed within the interior of the fracture zone. The outer edges of the fracture zone experience the largest seismic forces. The relative error between the theoretical mechanical model and the experimental results is 6.7% for stress and 0.5% for stress release, while displacement discrepancies remain within 10%, confirming the model box’s capability to realistically simulate the seismic dislocation behavior of tunnels intersecting multiple fault surfaces. To assess boundary effects, the 2-norm deviation (μ) is introduced as a quantitative metric. The results show that μ generally remains below 0.2, and exhibits a trend of increasing, then decreasing, and stabilizing with rising peak ground acceleration (PGA). This behavior indicates minimal boundary effects, and demonstrates that the model box can accurately reproduce the kinematic characteristics of multi-fault rupture under seismic excitation. Overall, the model box design proves reliable and provides a practical reference for the development of similar shaking table testing systems for tunnel engineering in complex fault zones.

-

表 1 断层错断模型箱类型及尺寸

Table 1. Type and dimensions of existing fault dislocation model box

单位 类型 错断形式 尺寸 破裂面 西南交通大学(仇文革等,2016) 刚性 无 1.0 m×0.5 m×1.0 m 无 西南交通大学(闫高明等,2019) 刚性 无 3.7 m×1.5 m×1.8 m 无 同济大学(Yan等,2016) 刚性 走滑断层 4 m×6 m×4.5 m 单 西南交通大学(杨长卫等,2023) 刚性 正/逆断层 8.3 m×3.1 m×2.5 m 单 中国地震局(孙海峰等,2012) 剪切 无 3.7 m×2.4 m×1.7 m 无 同济大学(伍小平等,2002) 剪切 无 2.0 m×1.5 m×2.0 m 无 西南交通大学(崔光耀等,2013,2018) 刚性 正/逆断层 2.5 m×2.5 m×2.0 m 单 西南交通大学(耿萍等,2020) 刚性 无 3.75 m×1.75 m×1.5 m 无 西南交通大学(赵建沣等,2019) 刚性 正/逆断层 2.5 m×2.5 m×1.5 m 单 表 2 模型箱材料与参数

Table 2. Materials and parameters of model boxes

动力模型箱 材料 规格/mm 侧壁 钢板 10 底板 钢板 16 外伸钢板 钢板 2 框架 H型钢 100×100×8×8 侧板连结 Π字型钢版 24×34.8×2 表 3 模型箱材料参数

Table 3. Model box material parameters

材料 密度/(kg·m−3) 弹性模量/GPa 泊松比 Q345钢 7850 210 0.3 表 4 模型箱各部频率表

Table 4. Model box frequency

类别 基频/Hz 位移图例(归一化) 一阶模态位移云图 二阶模态位移云图 模态分析曲线 下盘模型 28.07

断层模型 19.56

上盘模型 19.56

整体模型 28.00

——

围岩+隧道 11.74

——

表 5 模型相似比量纲

Table 5. Model similarity ratios for the shaking table tests

物理量 量纲 相似比 泊松比μ 1 1.00 应力σ L−1MT−2 45.00 应变ε 1 1.00 时间t T 5.48 加速度a LT−2 1.00 频率f T −1 0.18 表 6 围岩模型材料参数

Table 6. Material parameters of surrounding rocks model

弹性模量/GPa 密度/(kg·m−3) 黏聚力/kPa 摩擦角/° 上下盘(Ⅳ) 原型值 4 2200 400 33 模型值 0.089 1466.67 8.89 33 试验值 0.09 1467 11.7 32.3 断层破碎带(Ⅴ) 原型值 1 1800 100 24 模型值 0.022 1200.00 2.22 24 试验值 0.025 1200 4 25 表 7 衬砌模型材料参数

Table 7. Material parameters of lining model

弹性模量/GPa 密度/(kg·m−3) 抗压强度/MPa 衬砌 原型值 32.5 2.3 26 模型值 0.72 1.53 0.58 试验型 1.16 1.48 1.18 表 8 基于加速度时程计算的μ值

Table 8. μ-value distribution calculated based on acceleration time histories

偏差 PGA/g 0.1 0.2 0.3 0.4 μ5/3/% 11.76 12.73 10.75 11.00 表 9 H=135 cm时各测点加速度峰值表

Table 9. Peak acceleration at measurement points at H=135 cm

工况 下盘 破碎带 上盘 A7 A2 A8 0.1 g 0.21 0.30 0.26 0.4 g 0.67 0.82 0.70 表 10 H=170 cm时各测点加速度峰值表

Table 10. Peak acceleration at measurement points at H=170 cm

工况 下盘 破碎带 上盘 A9 A10 A3 A11 A12 0.1 g 0.20 0.23 0.22 0.23 0.23 0.4 g 0.61 0.67 0.68 0.71 0.64 表 11 PGA为0.4 g时错动位移与应力降

Table 11. Misalignment displacement and stress drop at 0.4 g

项目 错动位移/cm 应力降/MPa u2 u3 u4 Δσ(U4-U3) Δσ(U3-U2) 试验 2.53 3.00 3.43 0.542 0.557 理论 2.42 2.8 3.17 0.508 0.560 相对差值/% 4.5 7.1 8.2 6.7 0.5 -

常铭宇,申玉生,张熙等,2024. 基于数字图像技术振动台试验结构位移信息捕捉技术研究. 振动与冲击,43(5):139−148,158.Chang M. Y., Shen Y. S., Zhang X., et al., 2024. Capturing technology for displacement information of shaking table test structure based on digital image technique. Journal of Vibration and Shock, 43(5): 139−148,158. (in Chinese) 陈跃庆,吕西林,黄炜,2000. 结构-地基相互作用振动台试验中土体边界条件的模拟方法. 结构工程师,(3):25−30. doi: 10.3969/j.issn.1005-0159.2000.03.007Chen Y. Q., Lv X. L., Huang W., 2000. Simulation method of soil boundary condition in shaking table tests of soil structure interaction. Structural Engineers, (3): 25−30. (in Chinese) doi: 10.3969/j.issn.1005-0159.2000.03.007 陈运泰,林邦慧,林中洋等,1975. 根据地面形变的观测研究1966年邢台地震的震源过程. 地球物理学报,18(3):164−182.Chen Y. T., Lin B. H., Lin Z. Y., et al., 1975. The focal mechanism of the 1966 Hsingtai (邢台) earthquake as inferred from the ground deformation observations. Chinese Journal of Geophysics, 18(3): 164−182. (in Chinese) 崔光耀,王明年,于丽等,2013. 断裂黏滑隧道减震缝减震技术模型试验研究. 岩石力学与工程学报,32(8):1603−1609.Cui G. Y., Wang M. N., Yu L., et al., 2013. Model test study of shock absorption joint damping technology of crossing stick-slip fracture tunnel. Chinese Journal of Rock Mechanics and Engineering, 32(8): 1603−1609. (in Chinese) 崔光耀,孟令瀚,张军徽等,2018. 隧道洞口软硬围岩交接段地震响应大型振动台模型试验研究. 工程科学与技术,50(6):84−90.Cui G. Y., Meng L. H., Zhang J. H., et al., 2018. Study on large-scale shaking table model test for seismic response of soft and hard surrounding rock interface section of tunnel portal part. Advanced Engineering Sciences, 50(6): 84−90. (in Chinese) 范凯祥,申玉生,高波等,2019. 穿越软硬围岩隧道设置减震层振动台试验研究. 土木工程学报,52(9):109−120,128.Fan K. X. , Shen Y. S. , Gao B. , 2019, et al. Shaking table test on damping layer applied in tunnel crossing soft and hard surrounding rock. China Civil Engineering Journal, 52(9): 109−120, 128. (in Chinese) 耿萍,杨琪,何悦等,2020. 盾构隧道联络横通道的振动台试验与数值模拟. 西南交通大学学报,55(6):1215−1223. doi: 10.3969/j.issn.0258-2724.20180982Geng P., Yang Q., He Y., et al., 2020. Shaking table test and numerical simulation of shield tunnel connecting cross passage. Journal of Southwest Jiaotong University, 55(6): 1215−1223. (in Chinese) doi: 10.3969/j.issn.0258-2724.20180982 李霞,许成顺,杜修力,2016. 悬挂式层状多向剪切变形模型箱的研制. 地震工程与工程振动,36(1):118−126.Li X., Xu C. S., Du X. L., 2016. Development of suspension laminar multidirectional shear box. Earthquake Engineering and Engineering Dynamics, 36(1): 118−126. (in Chinese) 仇文革,段东亚,李冰天等,2016. 隧道地震响应模型试验箱体设计与合理性验证. 现代隧道技术,53(6):129−136.Qiu W. G., Duan D. Y., Li B. T., et al., 2016. Design and verification of a model test box for tunnel seismic response. Modern Tunnelling Technology, 53(6): 129−136. (in Chinese) 孙海峰,景立平,孟宪春等,2012. 振动台试验三维叠层剪切箱研制. 振动与冲击,31(17):26−32. doi: 10.3969/j.issn.1000-3835.2012.17.005Sun H. F., Jing L. P., Meng X. C., et al., 2012. A three-dimensional laminar shear soil container for shaking table test. Journal of Vibration and Shock, 31(17): 26−32. (in Chinese) doi: 10.3969/j.issn.1000-3835.2012.17.005 伍小平,孙利民,胡世德等,2002. 振动台试验用层状剪切变形土箱的研制. 同济大学学报,30(7):781−785.Wu X. P., Sun L. M., Hu S. D., et al., 2002. Development of laminar shear box used in shaking table test. Journal of Tongji University,30(7):781−785. (in Chinese) 闫高明,申玉生,信春雷等,2019. 衬砌背后空洞对隧道地震响应影响的振动台试验研究. 岩石力学与工程学报,38(12):2491−2501.Yan G. M., Shen Y. S., Xin C. L., et al., 2019. Shaking table test research of the influence of voids on seismic responses of tunnel structures. Chinese Journal of Rock Mechanics and Engineering, 38(12): 2491−2501. (in Chinese) 杨长卫,张良,张凯文等,2023. 山岭隧道跨断裂带段及洞口段地震响应大型振动台模型试验研究. 岩石力学与工程学报,42(4):993−1002.Yang C. W., Zhang L., Zhang K. W., et al., 2023. Large scale shaking table model test on seismic response of mountain tunnel portal section passing through fault zone. Chinese Journal of Rock Mechanics and Engineering, 42(4): 993−1002. (in Chinese) 禹海涛,卫一博,2023. 穿断层分段柔性接头隧道纵向地震响应解析解. 岩土工程学报,45(5):912−920. doi: 10.11779/CJGE20220315Yu H. T., Wei Y. B., 2023. Analytical solution for longitudinal seismic response of tunnels with segmental flexible joints crossing faults. Chinese Journal of Geotechnical Engineering, 45(5): 912−920. (in Chinese) doi: 10.11779/CJGE20220315 袁勇,黄伟东,禹海涛,2014. 地下结构振动台试验模型箱应用现状. 结构工程师,30(1):38−45. doi: 10.3969/j.issn.1005-0159.2014.01.007Yuan Y., Huang W. D., Yu H. T., 2014. Status of model container applications in shaking table test for underground structures. Structural Engineers, 30(1): 38−45. (in Chinese) doi: 10.3969/j.issn.1005-0159.2014.01.007 张涛,高波,范凯祥等,2018. 地震作用下振动台试验刚性模型箱侧壁柔性材料研究. 岩石力学与工程学报,37(10):2415−2424.Zhang T., Gao B., Fan K. X., et al., 2018. Study on flexible material in the sidewall of rigid model box in shaking table test. Chinese Journal of Rock Mechanics and Engineering, 37(10): 2415−2424. (in Chinese) 张涛,2018. 地下结构振动台试验刚性模型箱边界效应研究. 成都:西南交通大学.Zhang T., 2018. Study on boundary effect of rigid model box in shaking table test of underground structure. Chengdu:Southwest Jiaotong University. (in Chinese) 赵建沣,高波,范凯祥等,2019. 穿越不良地质段山岭隧道动力模型箱设计及其试验验证. 振动与冲击,38(8):80−87.Zhao J. F., Gao B., Fan K. X., et al., 2019. The design and verification test of dynamic model boxes for mountain tunnels crossing a bad geology region. Journal of Vibration and Shock, 38(8): 80−87. (in Chinese) 郑森,李伟华,崔杰等,2022. 刚度可调层状多向剪切模型箱的研制及性能测试. 岩土力学,43(S2):616−625.Zheng S., Li W. H., Cui J., et al., 2022. Development and performance test of a stiffness-variable multidirectional laminar shear model container. Rock and Soil Mechanics, 43(S2): 616−625. (in Chinese) Alaie R., Chenari R. J., 2018. Design and performance of a single axis shake table and a laminar soil container. Civil Engineering Journal, 4(6): 1326−1337. doi: 10.28991/cej-0309176 Bandini V. , Cascone E. , Biondi G. , et al. , 2019. The shaking table with laminar box of the university of Messina. In: Silvestri F. , Moraci N. , eds. , Earthquake Geotechnical Engineering for Protection and Development of Environment and Constructions. London: CRC Press, 1289−1296. Li Y. D., Zheng S., Luo W. L., et al., 2020. Design and performance of a laminar shear container for shaking table tests. Soil Dynamics and Earthquake Engineering, 135: 106157. doi: 10.1016/j.soildyn.2020.106157 Meymand P. , 1998. Shaking table scale model tests of nonlinear soil-pile-superstructure interaction in soft clay. Berkeley: University of California. Shi W. D., Chen W. E., Lin Y. Q., et al., 2021. Fabrication and testing of a laminar shear soil box for a shaking-table test. Practice Periodical on Structural Design and Construction, 26(4): 04021030. doi: 10.1061/(ASCE)SC.1943-5576.0000600 Yan X., Yuan J. Y., Yu H. T., et al., 2016. Multi-point shaking table test design for long tunnels under non-uniform seismic loading. Tunnelling and Underground Space Technology, 59: 114−126. doi: 10.1016/j.tust.2016.07.002 Zhang X., Shen Y. S., Zhou P. F., et al., 2023. Partitions of seismic affected zone and characteristics of segmental lining based on energy principle. Journal of Central South University, 30(1): 227−242. doi: 10.1007/s11771-022-5008-7 -

下载:

下载: