Impact of Hybrid Fibers on the Fault-resistance Performance of Tunnel Linings Crossing Creeping Reverse Faults

-

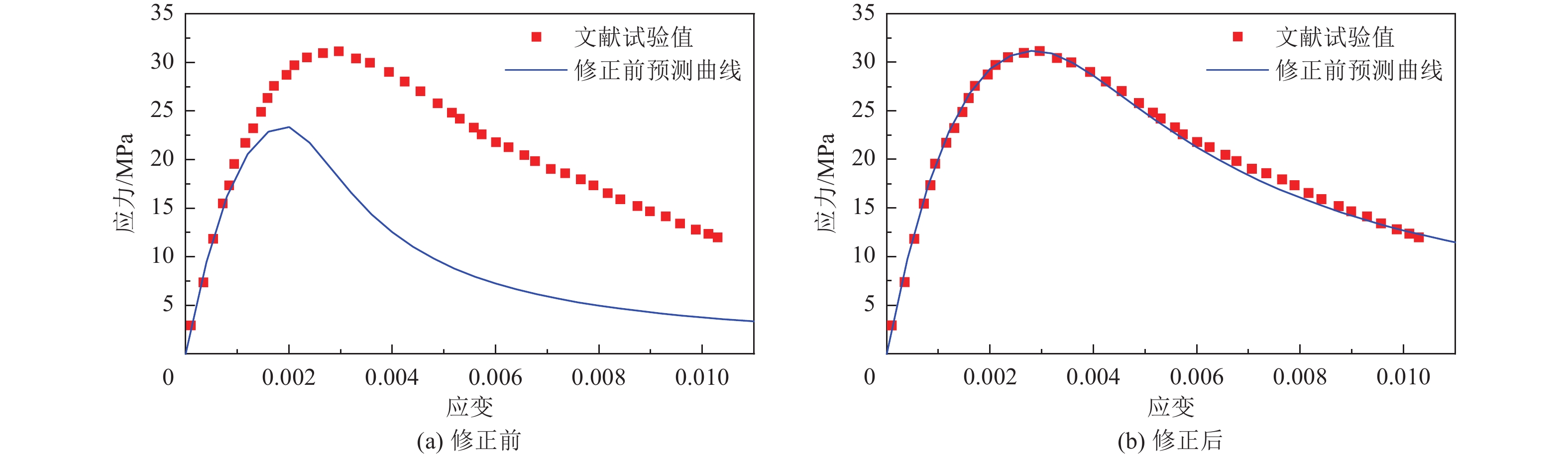

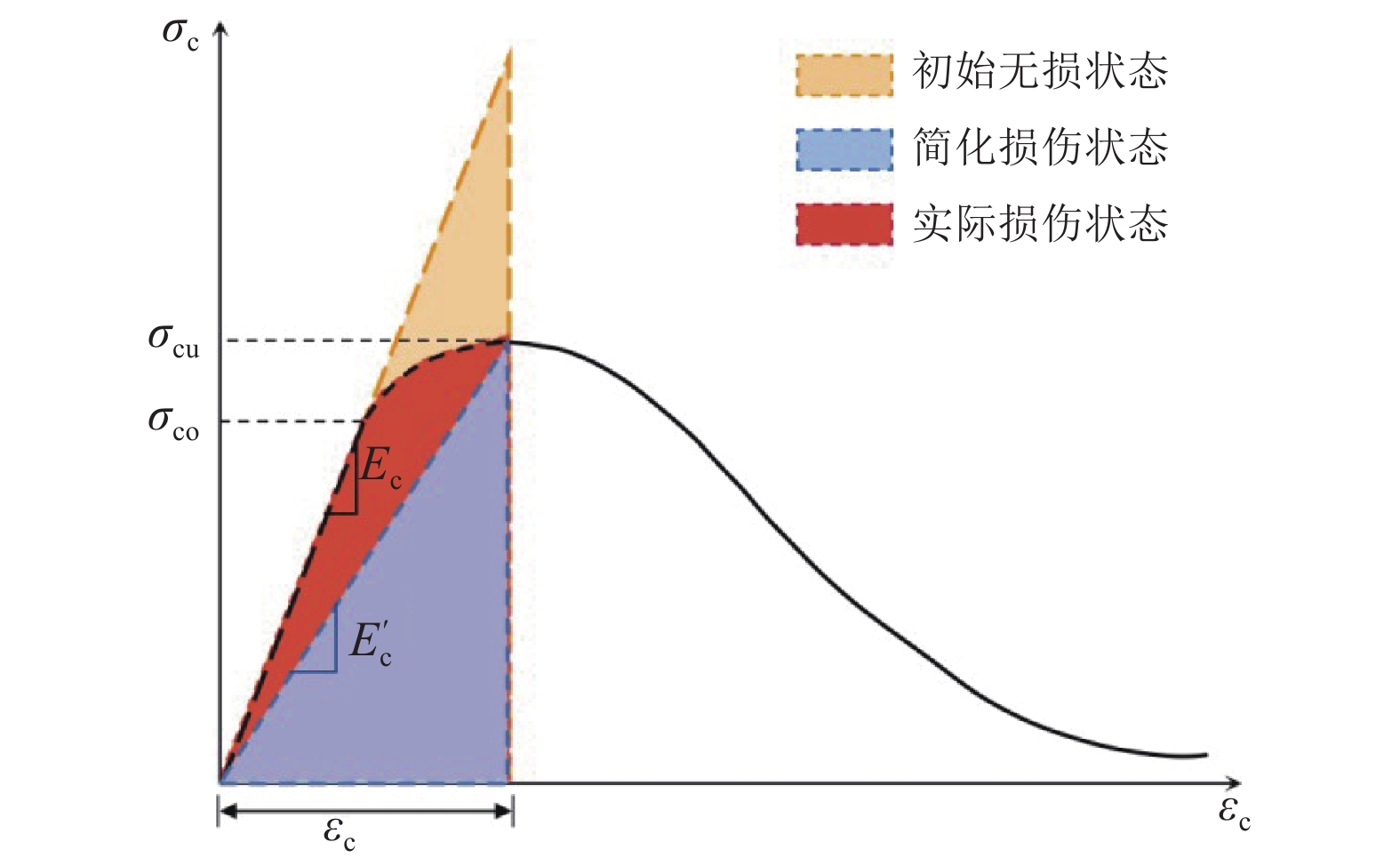

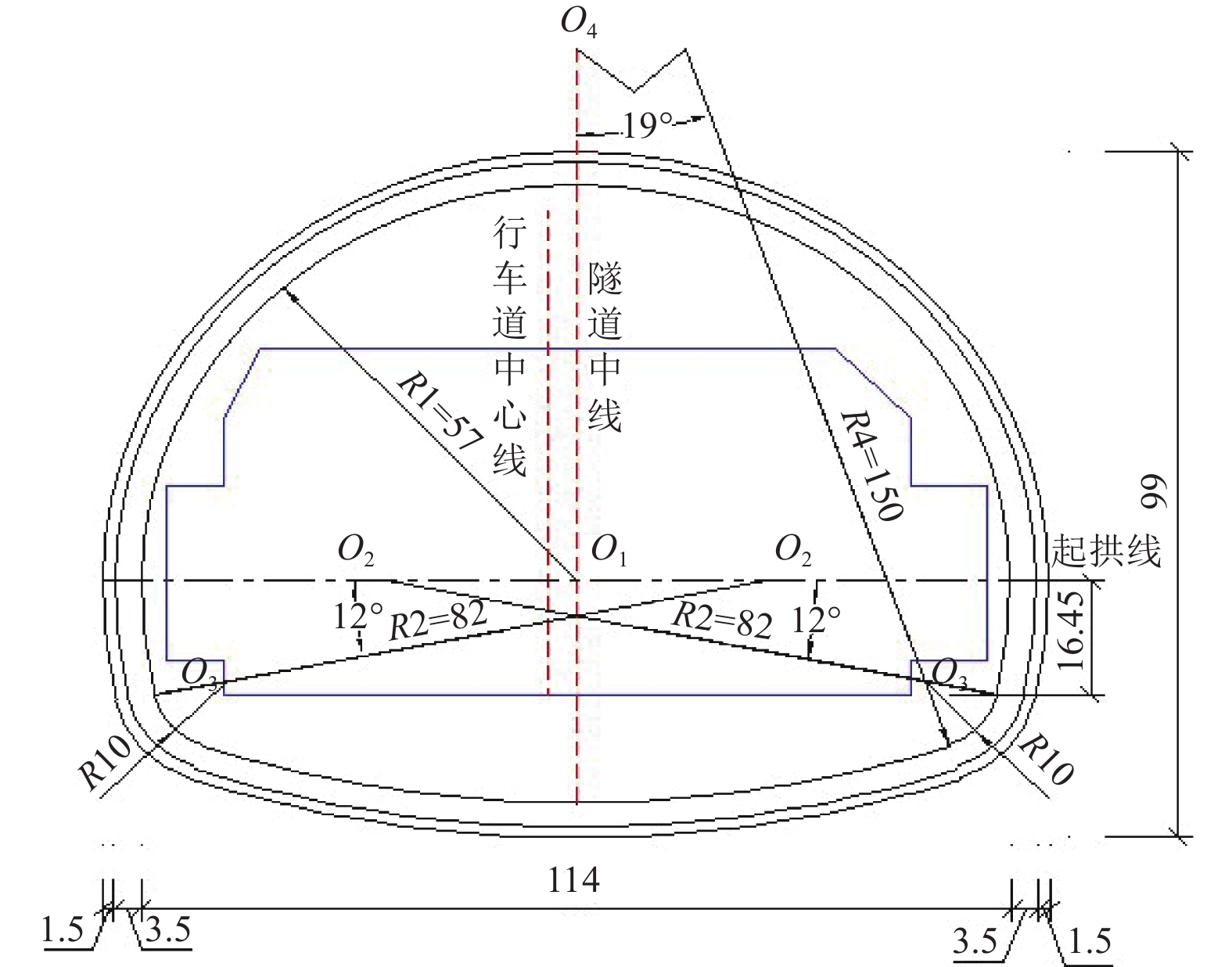

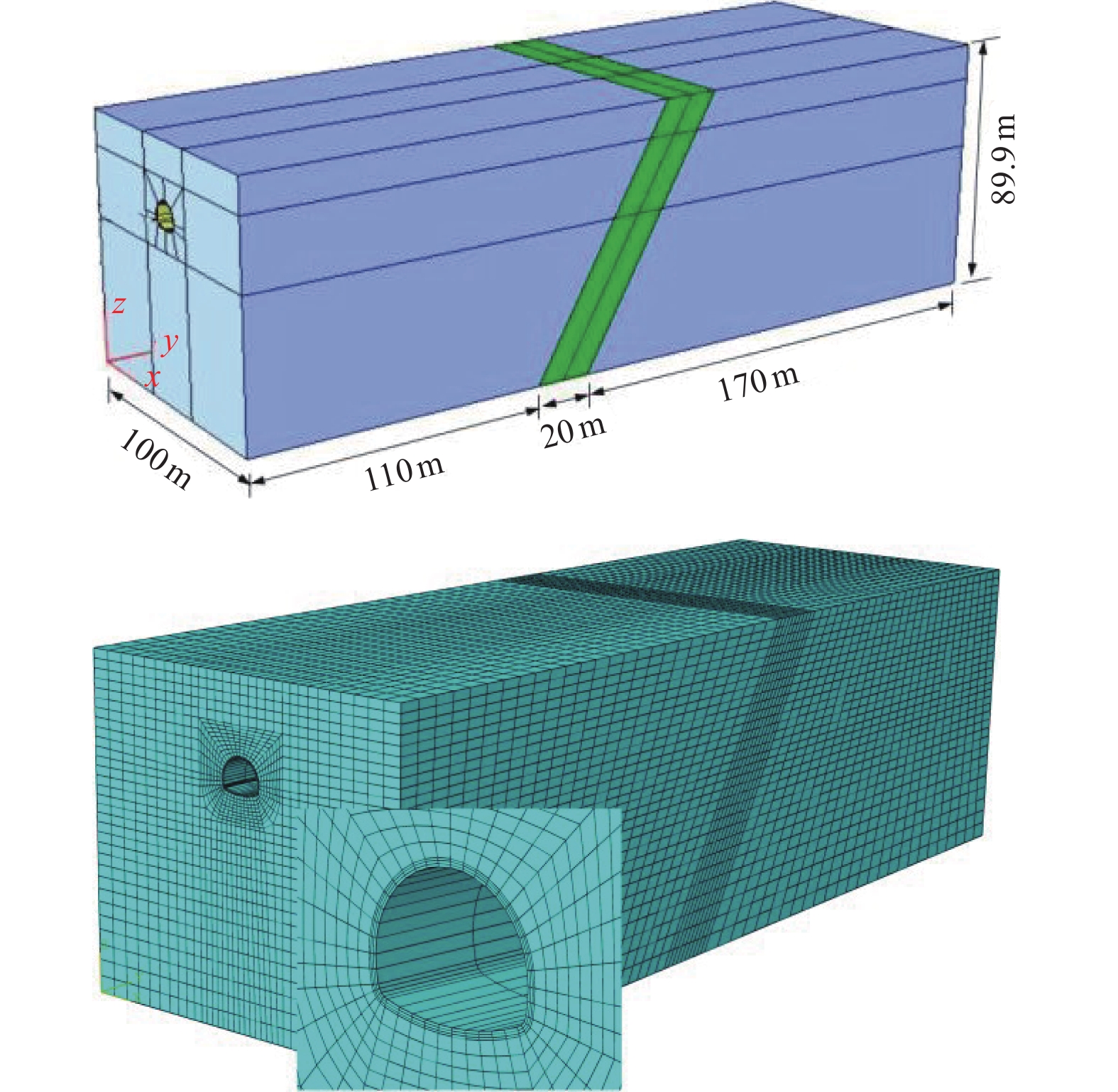

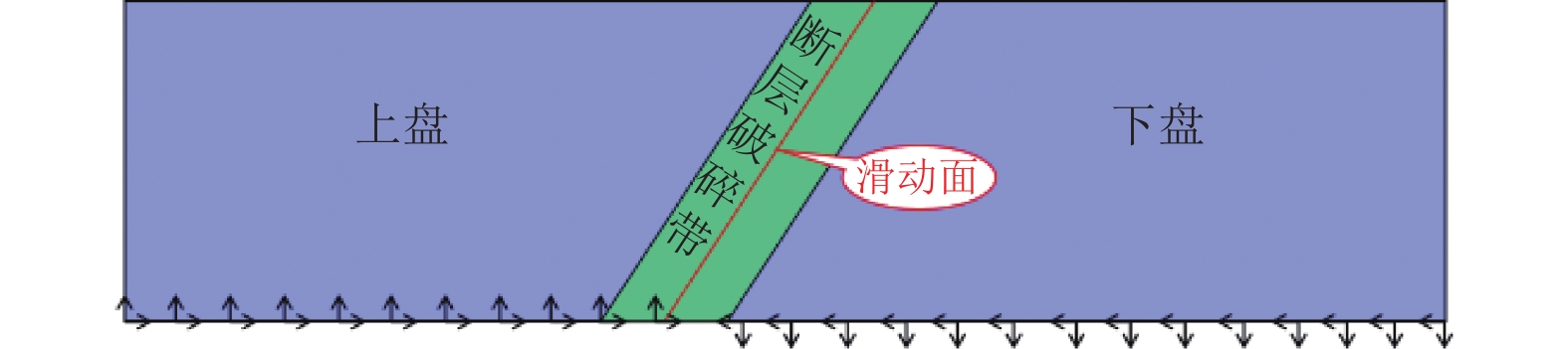

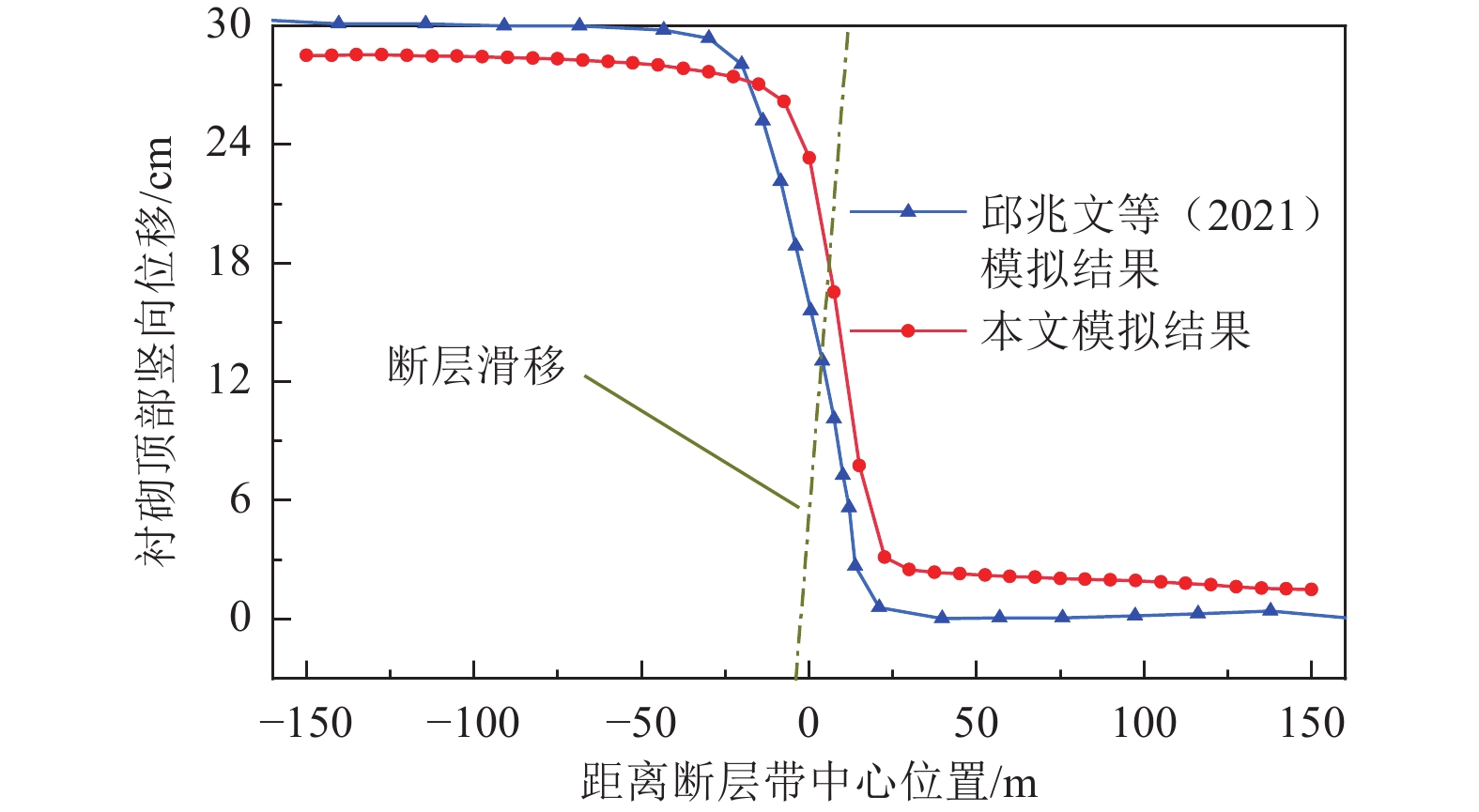

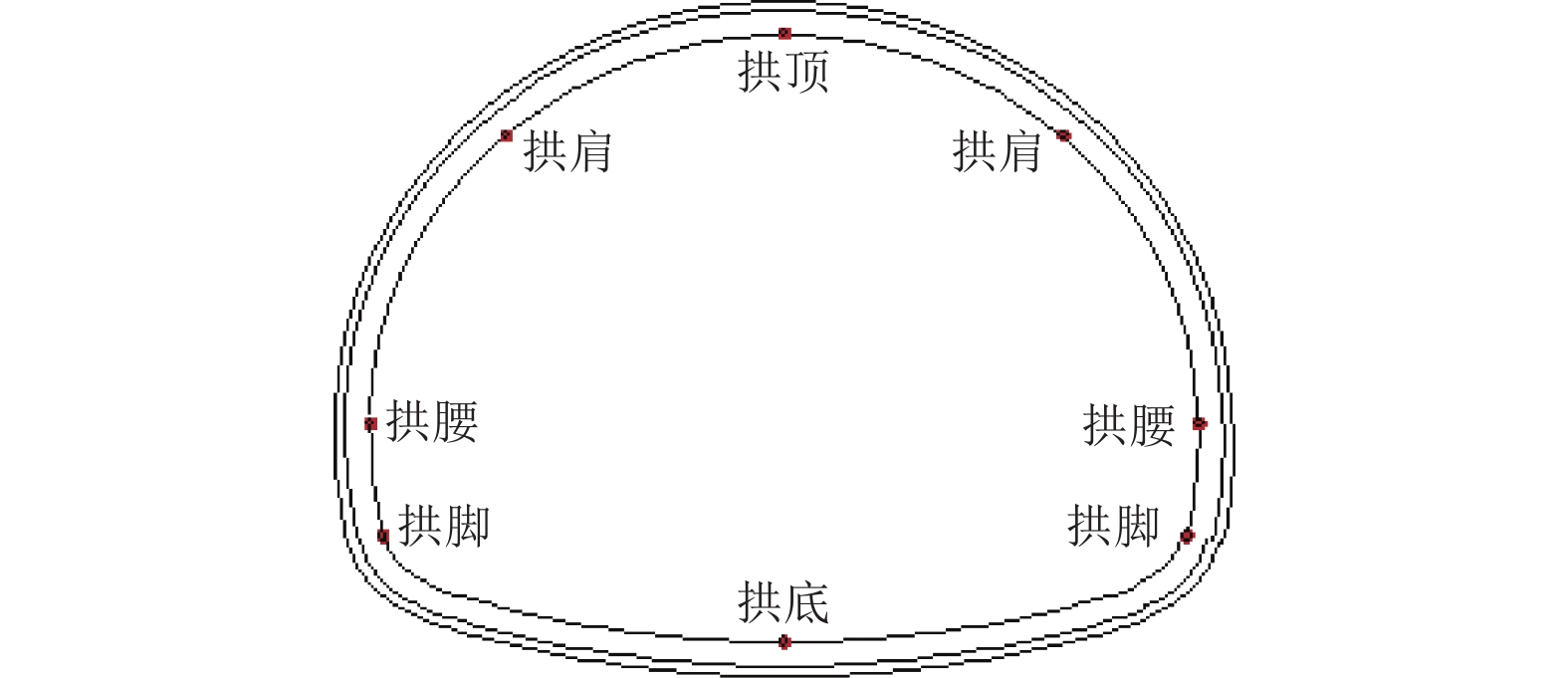

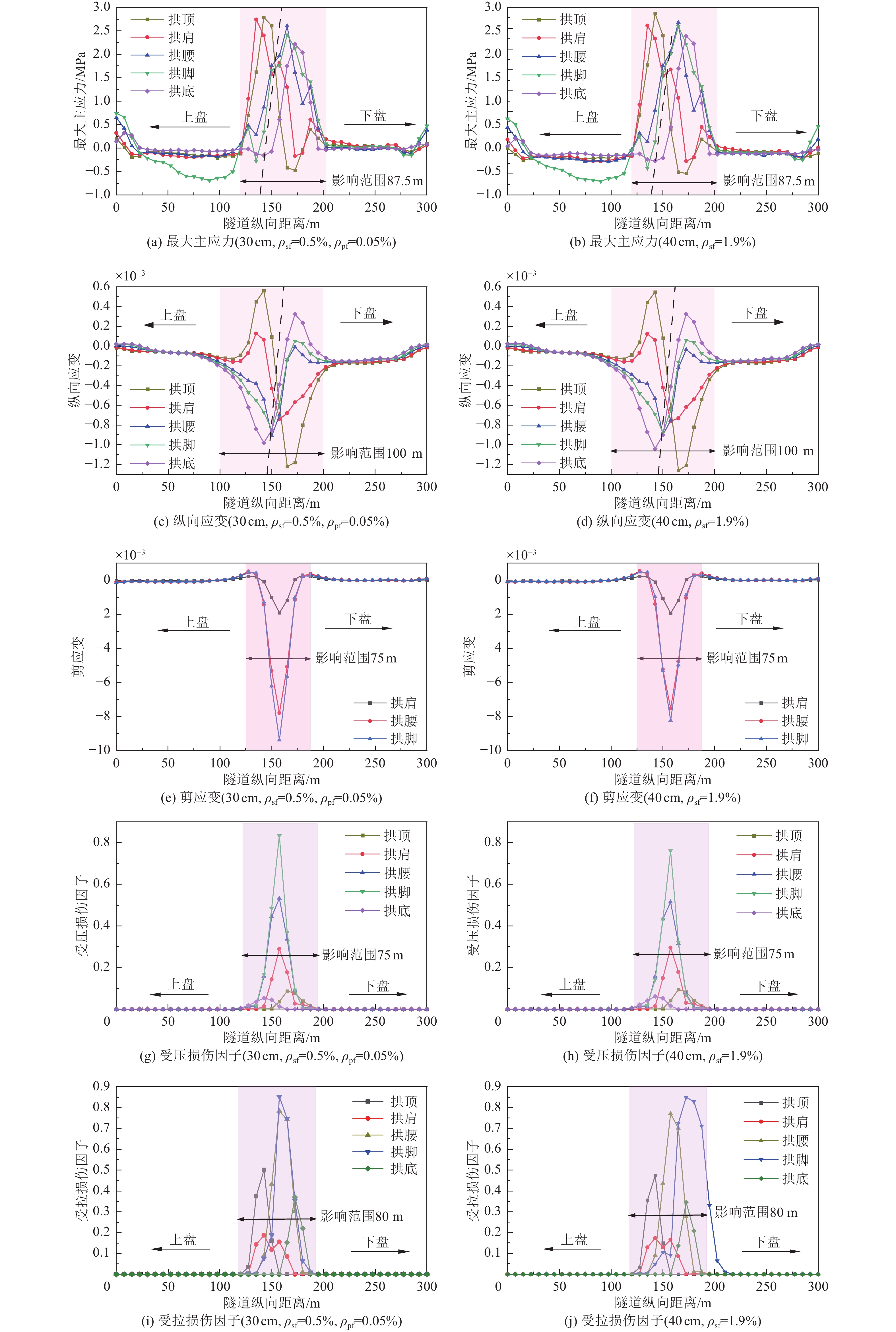

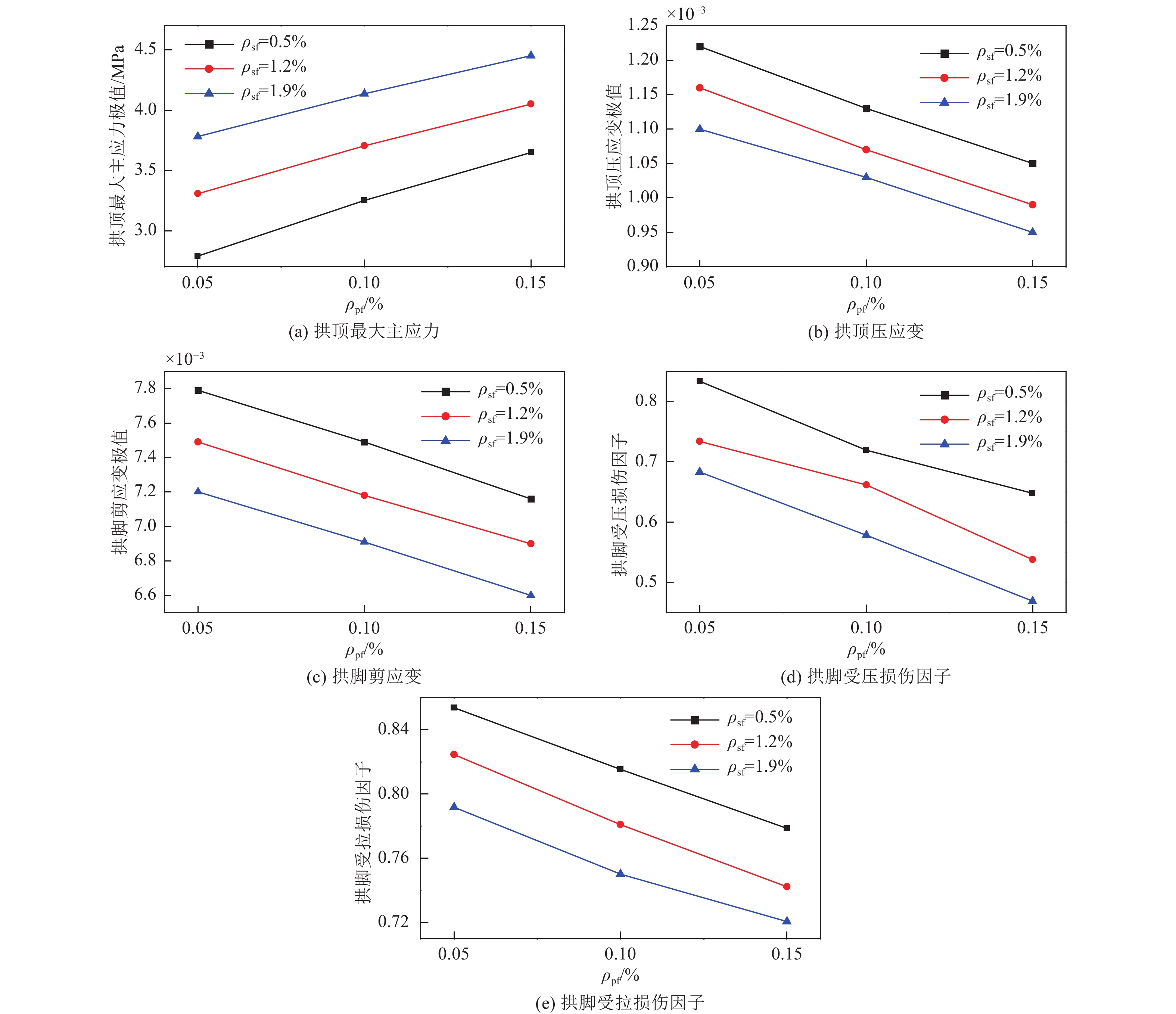

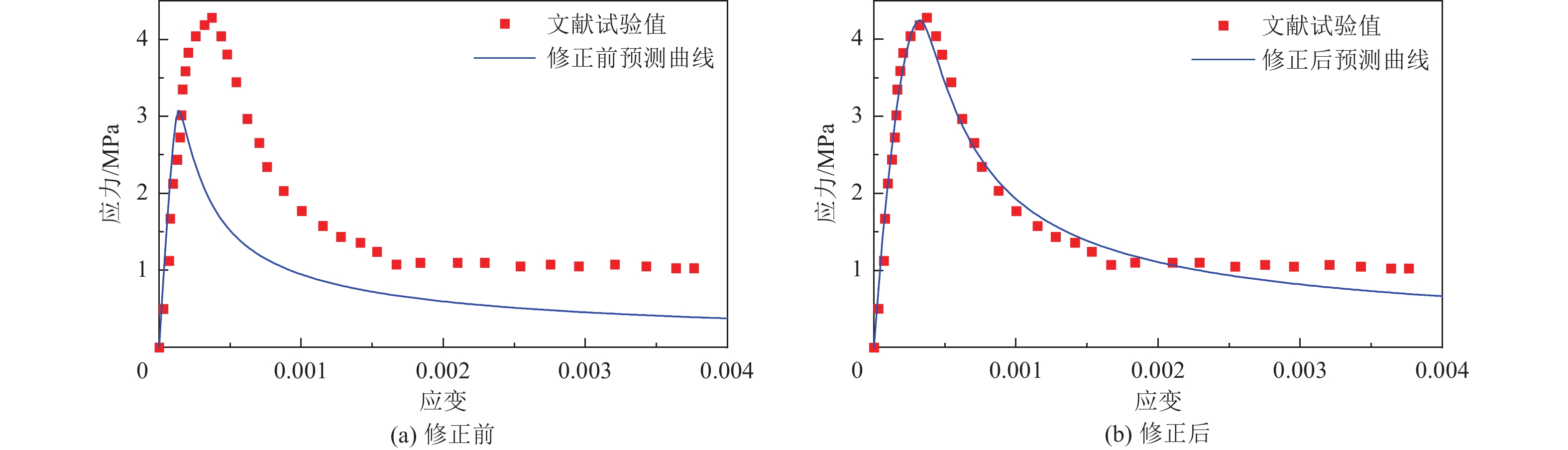

摘要: 位于断层蠕滑错动地段的隧道存在结构破坏风险,钢-聚丙烯混杂纤维能显著改善混凝土韧性,有效减缓断层错动带来的衬砌裂缝延展,但相关研究较少。在修正既有钢-聚丙烯混杂纤维混凝土本构模型基础上,基于Najar公式计算损伤变量,使用ABAQUS建立跨蠕滑逆断层隧道三维模型,对不同断层错动量下,不同纤维类型、掺量的混凝土衬砌力学性能和损伤开展研究。结果表明,断层倾角为60°时,不同错动量和纤维参数下隧道衬砌的受影响范围均为以错动带为中心的100 m,拱顶最大主应力和纵向应变极值、拱脚剪应变和拉压损伤极值最大;掺入适量纤维能明显增强衬砌力学性能并减少损伤,且混掺效果较单掺更优;混掺纤维时,在一定范围内提高某种纤维掺量能更有效地改善衬砌力学性能和损伤,并削弱拱顶最大主应力、加强拱脚受压损伤对另一种纤维掺量的敏感性;断层竖向错动不超过30 cm时,掺入适量混杂纤维可较好地满足衬砌受力变形及损伤需求,超过30 cm后可结合其他防错断措施。Abstract: Tunnels located in fault creep zones are prone to structural damage. The incorporation of steel–polypropylene hybrid fibers can significantly enhance concrete toughness, thereby mitigating lining cracks in fault-affected areas. However, research on this topic remains limited. In this study, the existing constitutive model of steel–polypropylene hybrid fiber concrete was modified, and the Najar formula was applied to calculate damage variables. A three-dimensional tunnel model crossing a creeping reverse fault was then developed in ABAQUS. The mechanical behavior and damage patterns of linings with different fiber types and dosages were examined under varying fault displacements. Results indicate that for a fault dip of 60°, the affected lining length is approximately 80 m. Maximum principal stress and longitudinal strain concentrate at the arch crown, whereas shear strain and tension–compression damage are most pronounced at the arch foot. Adding fibers significantly improves lining mechanical performance and reduces damage, with hybrid fibers outperforming single-fiber reinforcement. Within a certain range, increasing the dosage of one fiber type in hybrid systems more effectively enhances lining performance and reduces damage, while decreasing the sensitivity of arch crown stresses to the other fiber type and increasing the sensitivity of arch foot compressive damage. For fault displacements up to 30 cm, hybrid fiber reinforcement is sufficient; beyond 30 cm, additional mitigation measures are required.

-

表 1 材料参数

Table 1. Material parameters

材料 密度/(kg·m−3) 弹性模量/GPa 泊松比 黏聚力/MPa 摩擦角/(°) Ⅳ级围岩 2200 7 0.3 0.5 35 断层破碎带 2000 5 0.3 0.25 25 初期支护C25 2400 27.5 0.2 12.5 31 二次衬砌C30 2500 29 0.25 — — 表 2 纤维参数取值表

Table 2. Fiber parameter values

纤维类型 掺量 钢纤维 0.5% 1.2% 1.9% 聚丙烯纤维 0.05% 0.1% 0.15% 表 3 单掺、混掺相较于素混凝土的指标变化幅度

Table 3. The index change range of single blending and mixed blending compared with plain concrete

力学性能及损伤情况 S-P S P 最大主应力 378.6% 275.6% 303.8% 纵向应变 −45.5% −41.5% −42.9% 剪应变 −23.5% −11.3% −14.4% 受压损伤 −9.9% −4.4% −5.5% 受拉损伤 −7.8% −4.2% −5.7% 表 4 纤维掺量变化时指标变化幅度

Table 4. The magnitude of the index change when the fiber content changes

力学性能及损伤情况 $ {\rho }_{\mathrm{p}\mathrm{f}} $由0.05%增至0.15%时对应变化幅度 $ {\rho }_{\mathrm{s}\mathrm{f}} $由0.5%增至1.9%时对应变化幅度 $ {\rho }_{\mathrm{s}\mathrm{f}} $=0.5% $ {\rho }_{\mathrm{s}\mathrm{f}} $=1.2% $ {\rho }_{\mathrm{s}\mathrm{f}} $=1.9% $ {\rho }_{\mathrm{p}\mathrm{f}} $=0.05% $ {\rho }_{\mathrm{p}\mathrm{f}} $=0.10% $ {\rho }_{\mathrm{p}\mathrm{f}} $=0.15% 拱顶最大主应力 30.8% 22.4% 17.7% 35.5% 27.4% 21.9% 拱顶压应变 −13.9% −14.7% −13.6% −9.8% −8.8% −9.5% 拱脚剪应变 −8.1% −7.9% −8.3% −7.6% −7.7% −7.8% 拱脚受压损伤因子 −22.3% −26.7% −31.3% −18.1% −19.6% −27.6% 拱脚受拉损伤因子 −8.8% −10.1% −8.96% −7.3% −8.1% −7.4% -

白晓玮, 2017. 混凝土损伤本构关系的研究与应用. 郑州: 郑州大学.Bai X. W., 2017. Study and application on the damage constitutive law for concrete. Zhengzhou: Zhengzhou University. (in Chinese) 程卓群, 彭刚, 孙尚鹏等, 2019. 基于Najar能量法的混凝土动态双轴受压损伤特性分析. 水利水运工程学报, (4): 100−106.Cheng Z. Q., Peng G., Sun S. P., et al., 2019. Analysis of dynamic biaxial compression damage characteristics of concrete based on Najar energy method. Hydro-Science and Engineering, (4): 100−106. (in Chinese) 崔光耀, 蒋梦新, 王明胜, 2022. 高烈度地震区隧道洞口段纤维混凝土衬砌抗震效果分析. 现代隧道技术, 59(1): 207−213.Cui G. Y., Jiang M. X., Wang M. S., 2022. Anti-seismic effect of fiber-reinforced concrete lining at tunnel portals in high-intensity seismic areas. Modern Tunnelling Technology, 59(1): 207−213. (in Chinese) 丁一宁, 董香军, 王岳华, 2005. 混杂纤维自密实混凝土的强度和抗弯韧性. 建筑材料学报, 8(3): 294−298.Ding Y. N., Dong X. J., Wang Y. H., 2005. Strength and flexural toughness of hybrid fiber reinforced self-compacted concrete. Journal of Building Materials, 8(3): 294−298. (in Chinese) 刘伟, 2019. 地下隧道钢纤维混凝土衬砌抗爆性能研究. 淮南: 安徽理工大学.Liu W., 2019. Study on anti-explosion performance of steel fiber reinforced concrete lining in underground tunnel. Huainan: Anhui University of Science and Technology. (in Chinese) 梅国栋, 2014. 钢−聚丙烯混杂纤维混凝土单轴受拉性能与本构关系研究. 武汉: 武汉大学.Mei G. D., 2014. Study on uniaxial tensile properties and constitutive relation of steel-polypropylene hybrid fiber reinforced concrete. Wuhan: Wuhan University. (in Chinese) 倪亮, 2020. 钢纤维混凝土单轴受压性能及本构关系研究. 武汉: 湖北工业大学.Ni L., 2020. Research on uniaxial compression performance and constitutive relationship of steel fiber reinforced concrete. Wuhan: Hubei University of Technology. (in Chinese) 邱兆文, 喻烟, 杜义等, 2021. 逆断层错动对隧道工程影响的数值模拟. 地震学报, 43(2): 237−244.Qiu Z. W., Yu Y., Du Y., et al., 2021. Numerical analysis of effect of reverse fault dislocation on tunnel engineering. Acta Seismologica Sinica, 43(2): 237−244. (in Chinese) 王红喜, 陈友治, 丁庆军等, 2004. 混杂纤维对高性能混凝土力学性能与抗渗性能的影响. 混凝土与水泥制品, (1): 38−40.Wang H. X., Chen Y. Z., Ding Q. J., et al., 2004. Effact of hybrid fibers on mechanical properties and impermeability of high performance concrete. China Concrete and Cement Products, (1): 38−40. (in Chinese) 王耀达, 2023. 走滑断层错动与地震动作用隧道力学响应及减震层措施研究. 成都: 西南交通大学.Wang Y. D., 2023. Study on mechanical response and damping layer measures of tunnels under the strike-slip fault and earthquake. Chengdu: Southwest Jiaotong University. (in Chinese) 徐礼华, 梅国栋, 黄乐等, 2014. 钢-聚丙烯混杂纤维混凝土轴心受拉应力-应变关系研究. 土木工程学报, 47(7): 35−45.Xu L. H., Mei G. D., Huang L., et al., 2014. Study on uniaxial tensile stress-strain relationship of steel-polypropylene hybrid fiber reinforced concrete. China Civil Engineering Journal, 47(7): 35−45. (in Chinese) 杨萌, 黄承逵, 2006. 钢纤维高强混凝土轴拉性能试验研究. 土木工程学报, 39(3): 55−61.Yang M., Huang C. K., 2006. Study on stress-strain curve of high strength steel fiber reinforced concrete under uniaxial tension. China Civil Engineering Journal, 39(3): 55−61. (in Chinese) 张恒, 2023. 跨蠕滑断层隧道精细化建模及力学分析. 哈尔滨: 中国地震局工程力学研究所.Zhang H., 2023. Fine modeling and mechanical analysis of tunnel across creep fault. Harbin: Institute of Engineering Mechanics, China Earthquake Administration. (in Chinese) 张雨童, 2020. 西安地裂缝活动环境下综合管廊结构变形规律及安全预警方法研究. 西安: 西安建筑科技大学.Zhang Y. T., 2020. Research on structure deformation regularity and safety early warning method of integrated pipe gallery in active environment of Xi’an ground fissure. Xi'an: Xi'an University of Architecture and Technology. (in Chinese) 张元元, 2010. 钢-聚丙烯混杂纤维混凝土单轴受压本构关系与受拉性能研究. 武汉: 武汉大学.Zhang Y. Y., 2010. Study on uniaxial compressive constitutive relationship and uniaxial tensile behavior of steel-polypropylene hybrid fiber reinforced concrete. Wuhan: Wuhan University. (in Chinese) An S., Tao L. J., Han X. C., et al., 2021. Application of two-level design method on subway tunnel crossing active fault: a case study on Urumqi subway tunnel intersected by reverse fault dislocation. Bulletin of Engineering Geology and the Environment, 80(5): 3871−3884. doi: 10.1007/s10064-021-02164-y Pul S., Ghaffari A., Öztekin E., et al., 2017. Experimental determination of cohesion and internal friction angle on conventional concretes. ACI Materials Journal, 114(3): 407−416. Wang D. Y., Qi J. S., Cui G. Y., et al., 2020. Model test on bearing characteristics of basalt fiber-reinforced concrete lining. Advances in Materials Science and Engineering, 2020(1): 3891343. doi: 10.1155/2020/3891343 -

下载:

下载: