Mechanics Characteristics of Clay Improved by Rubber Particles

-

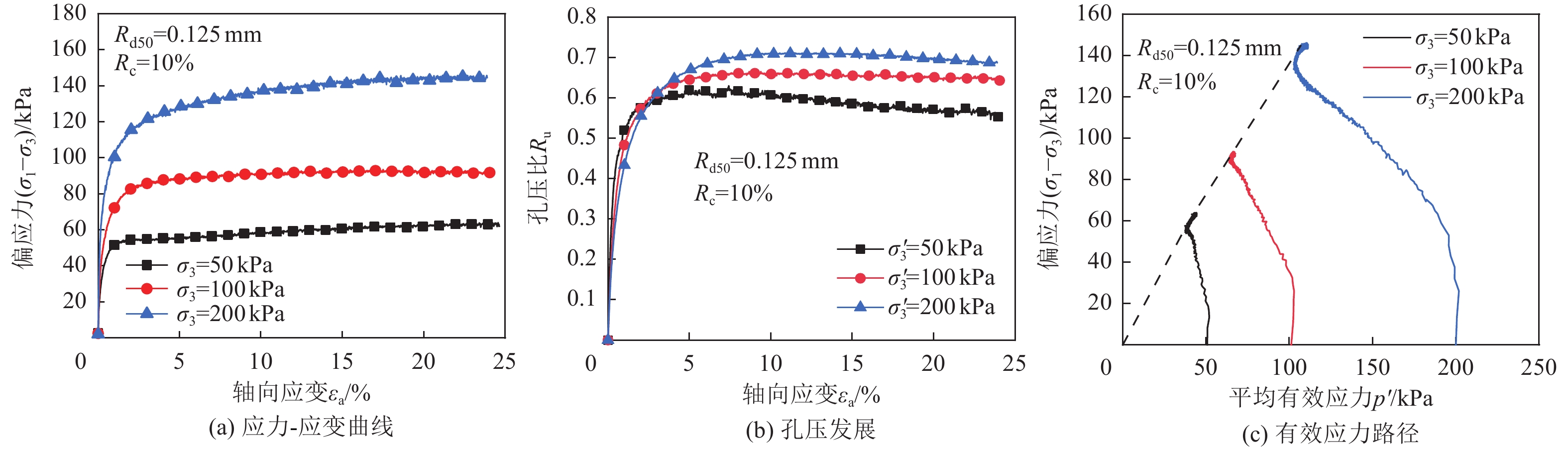

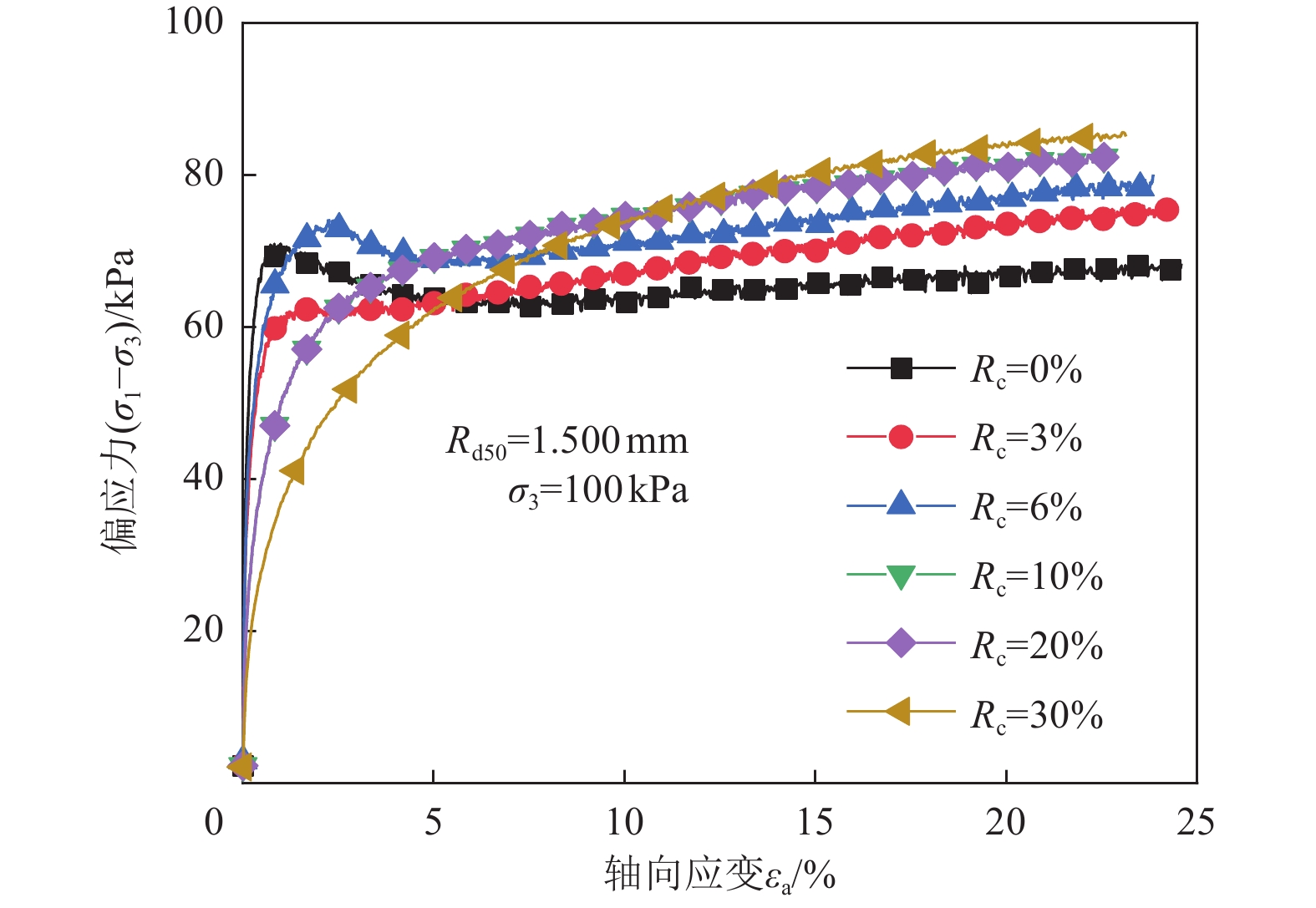

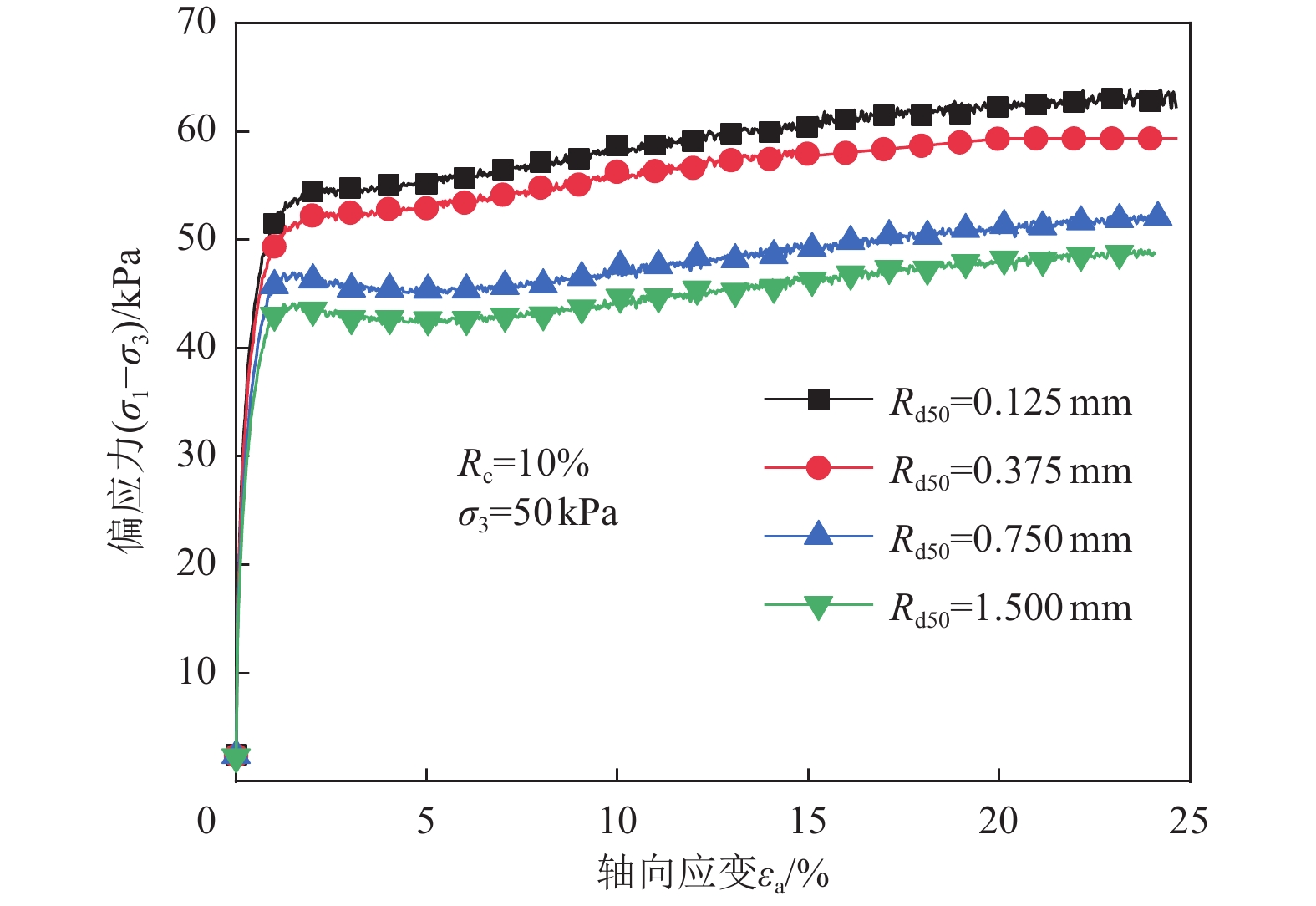

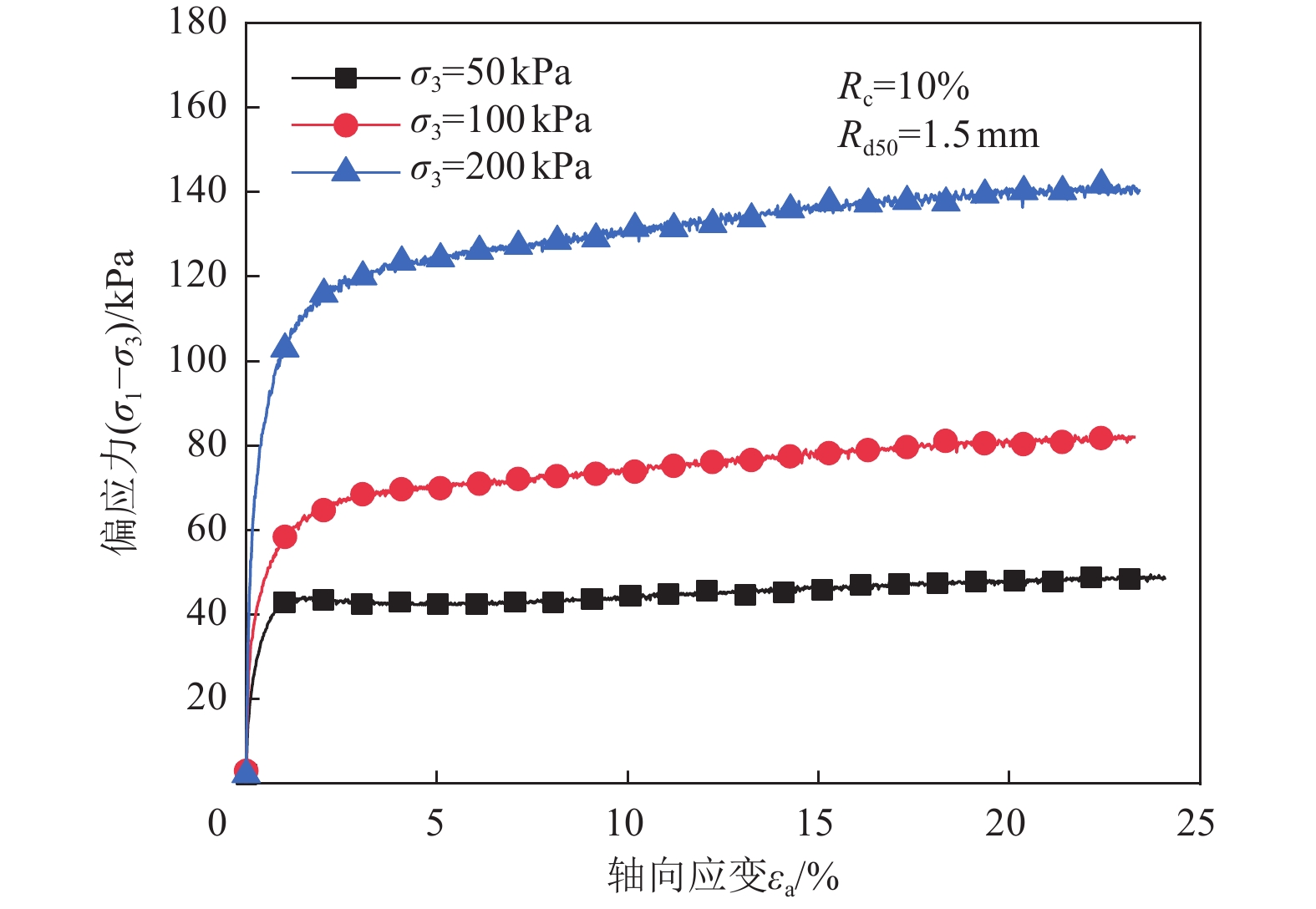

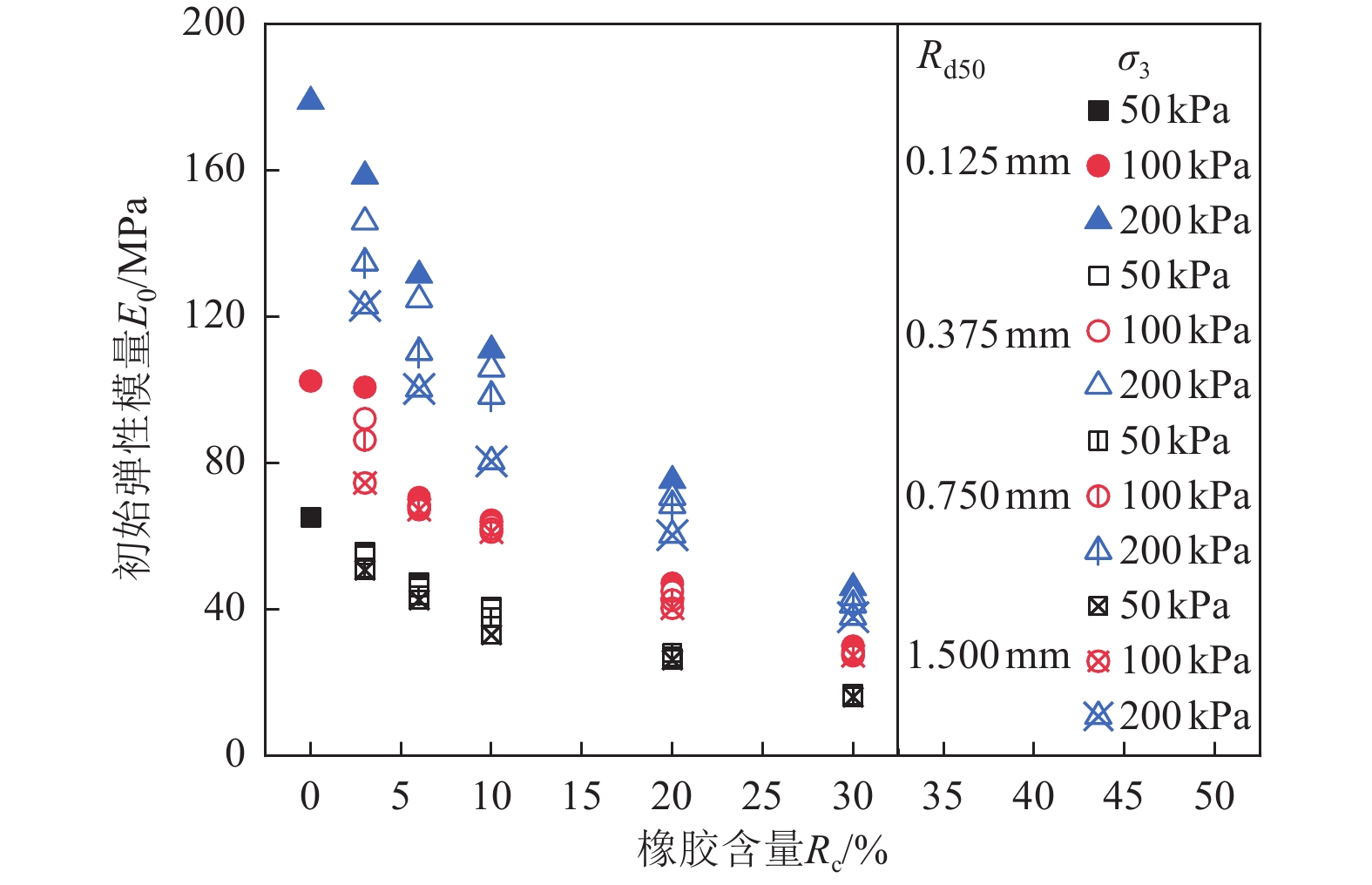

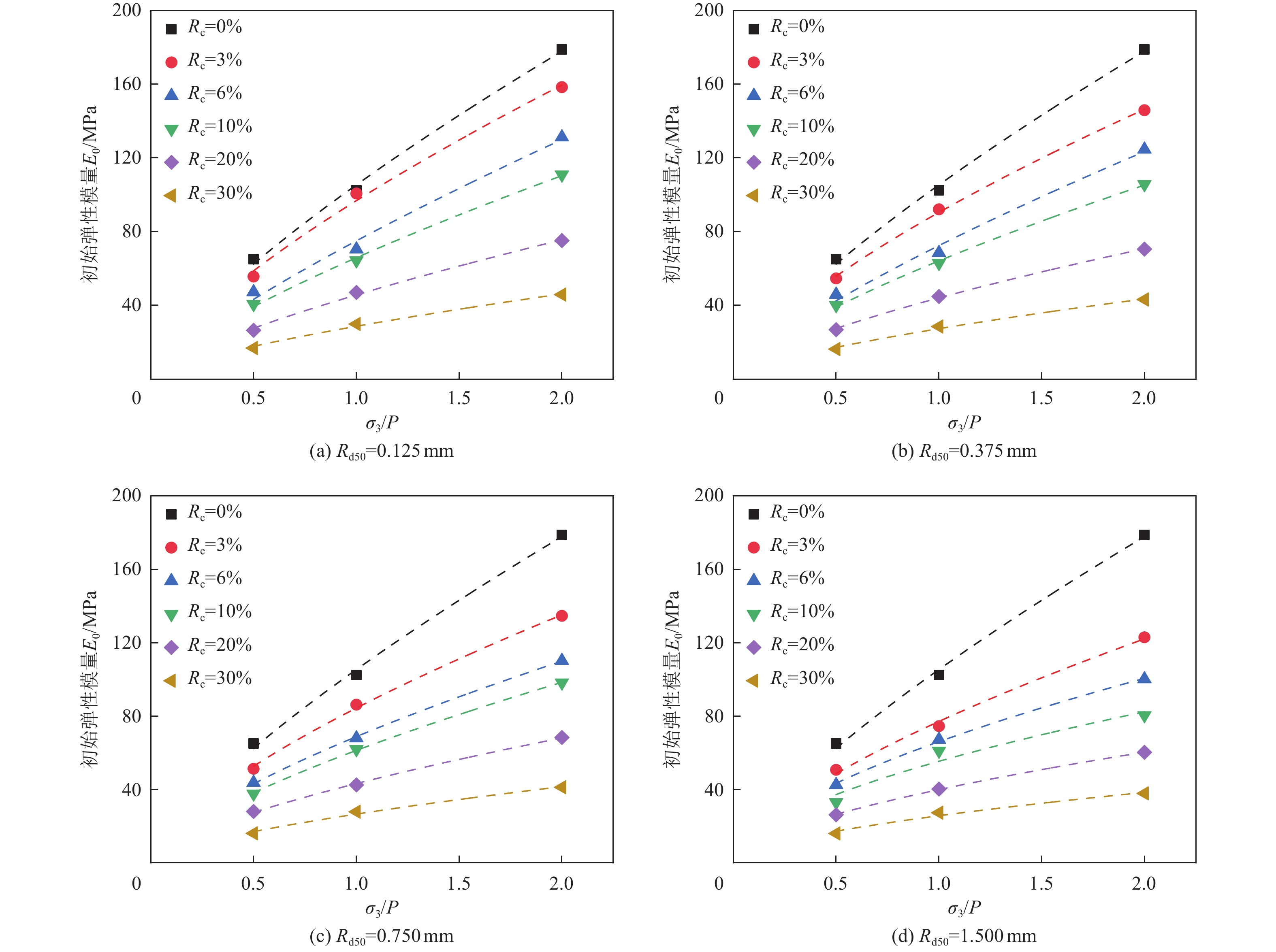

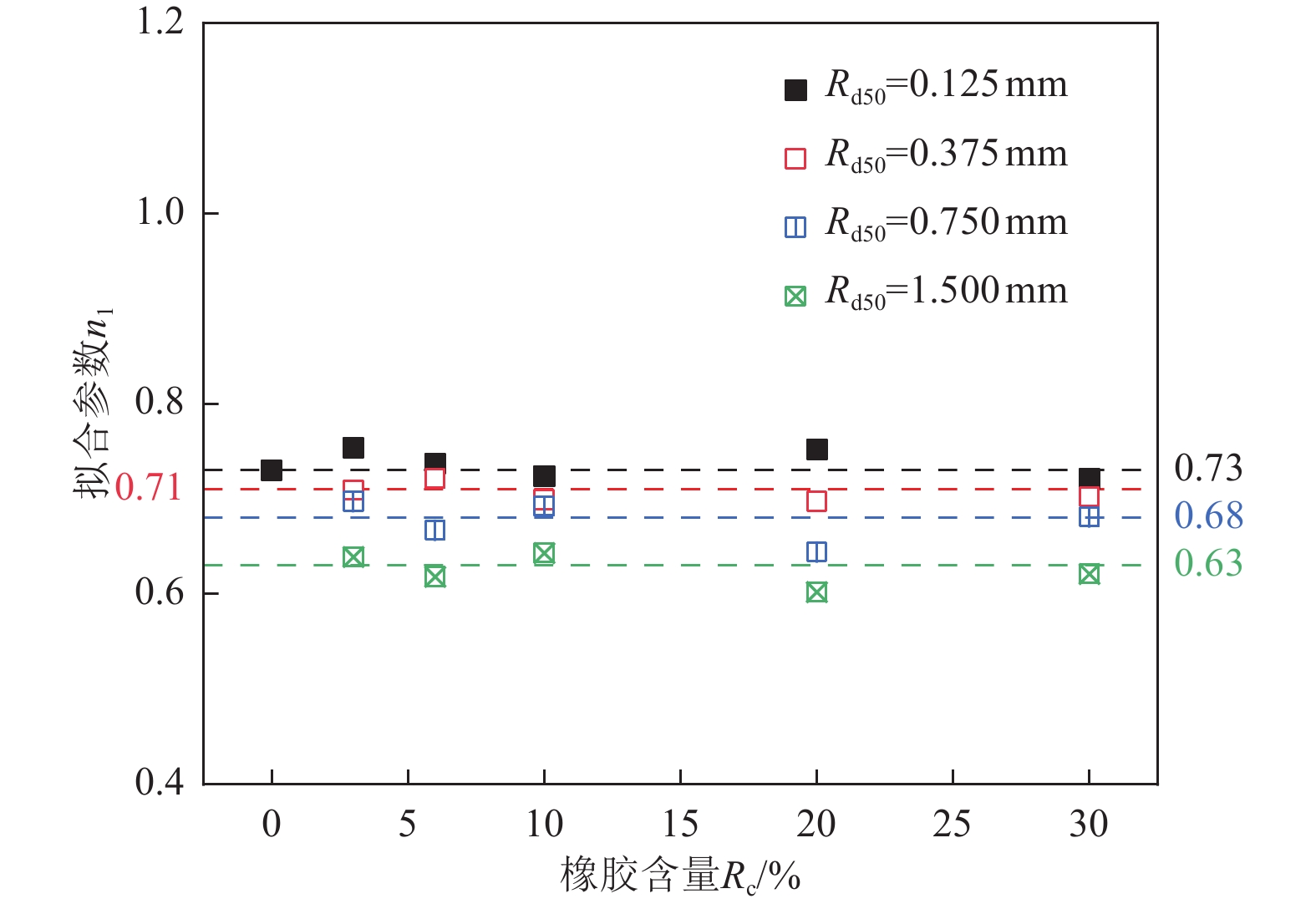

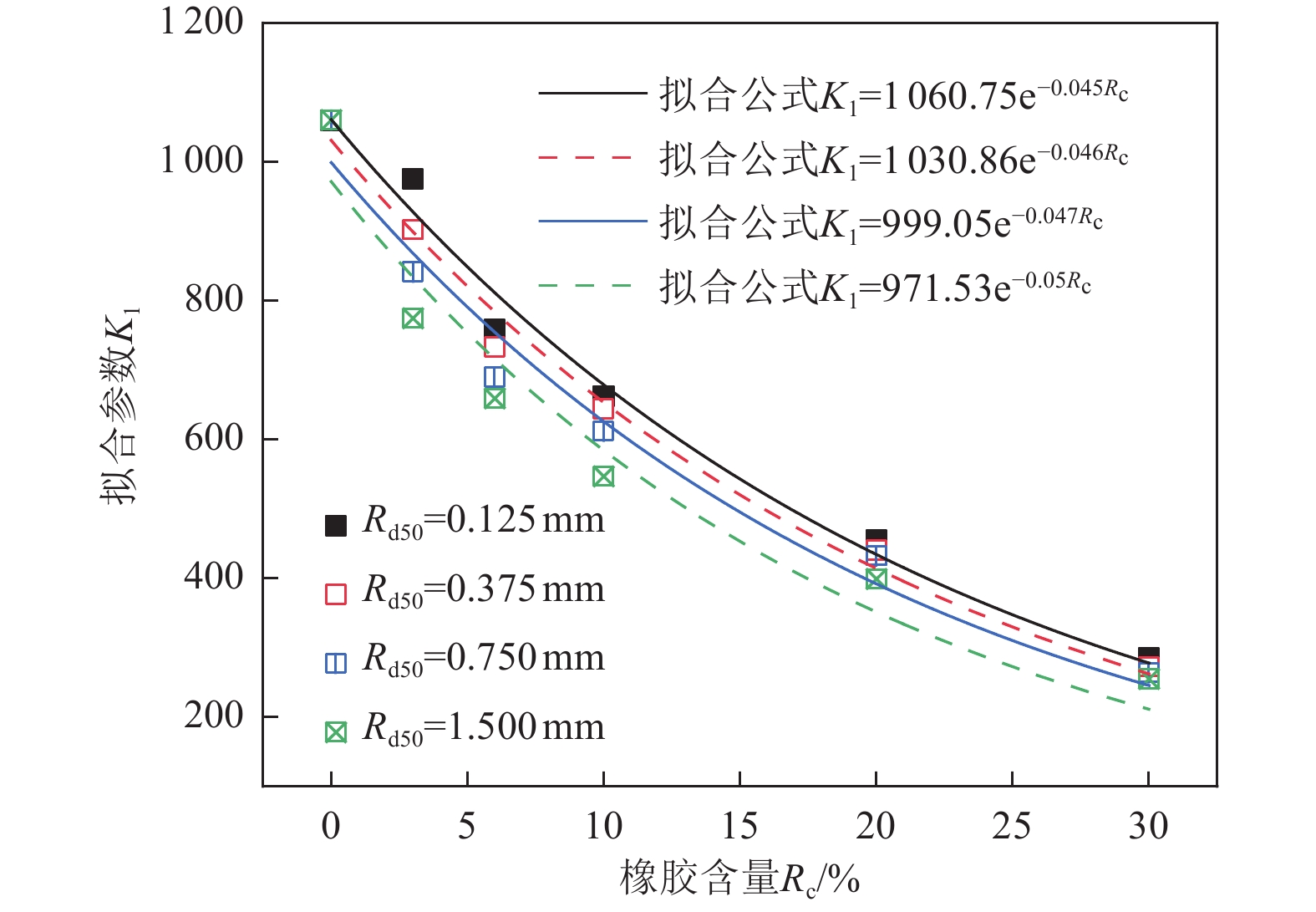

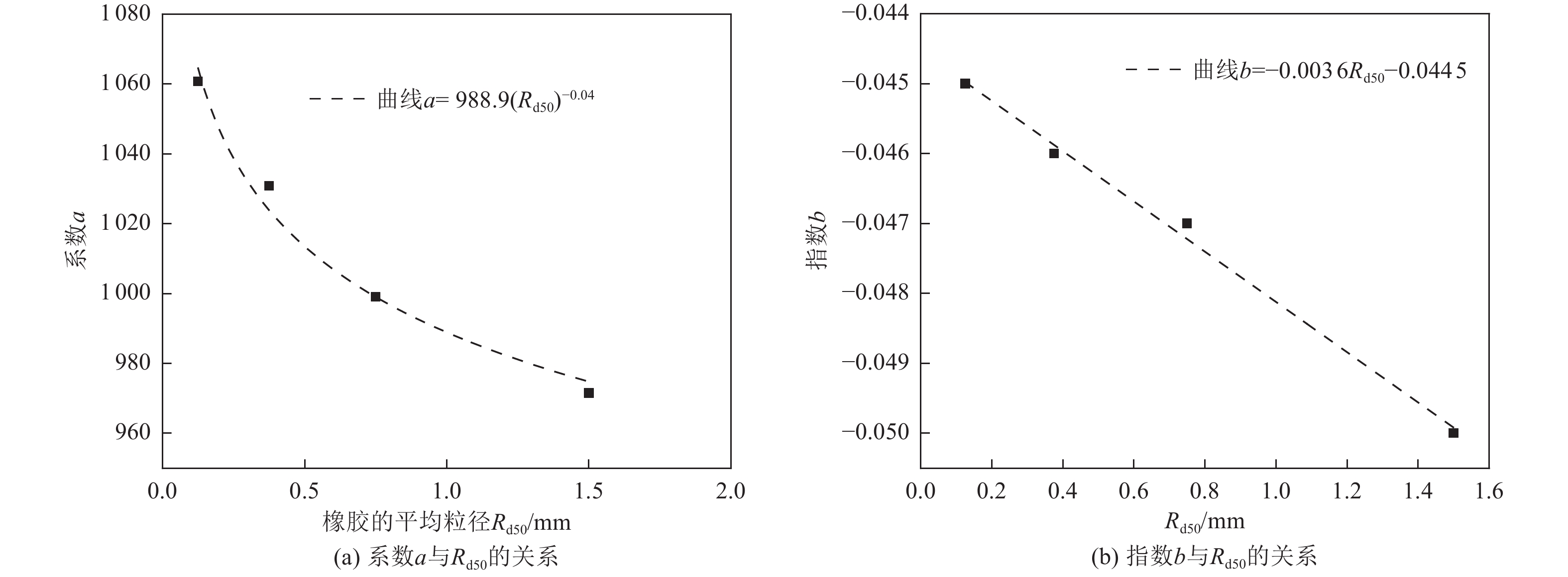

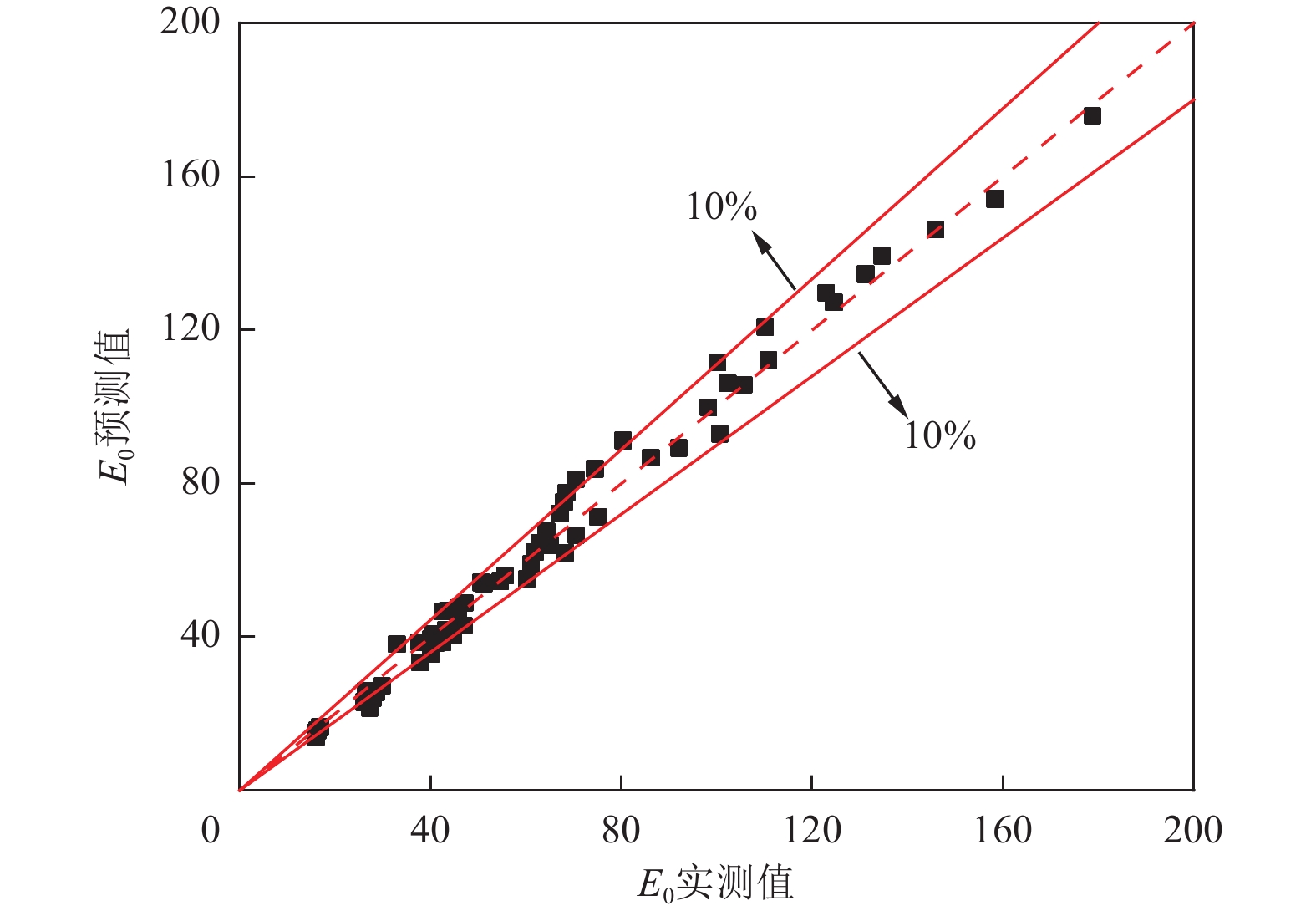

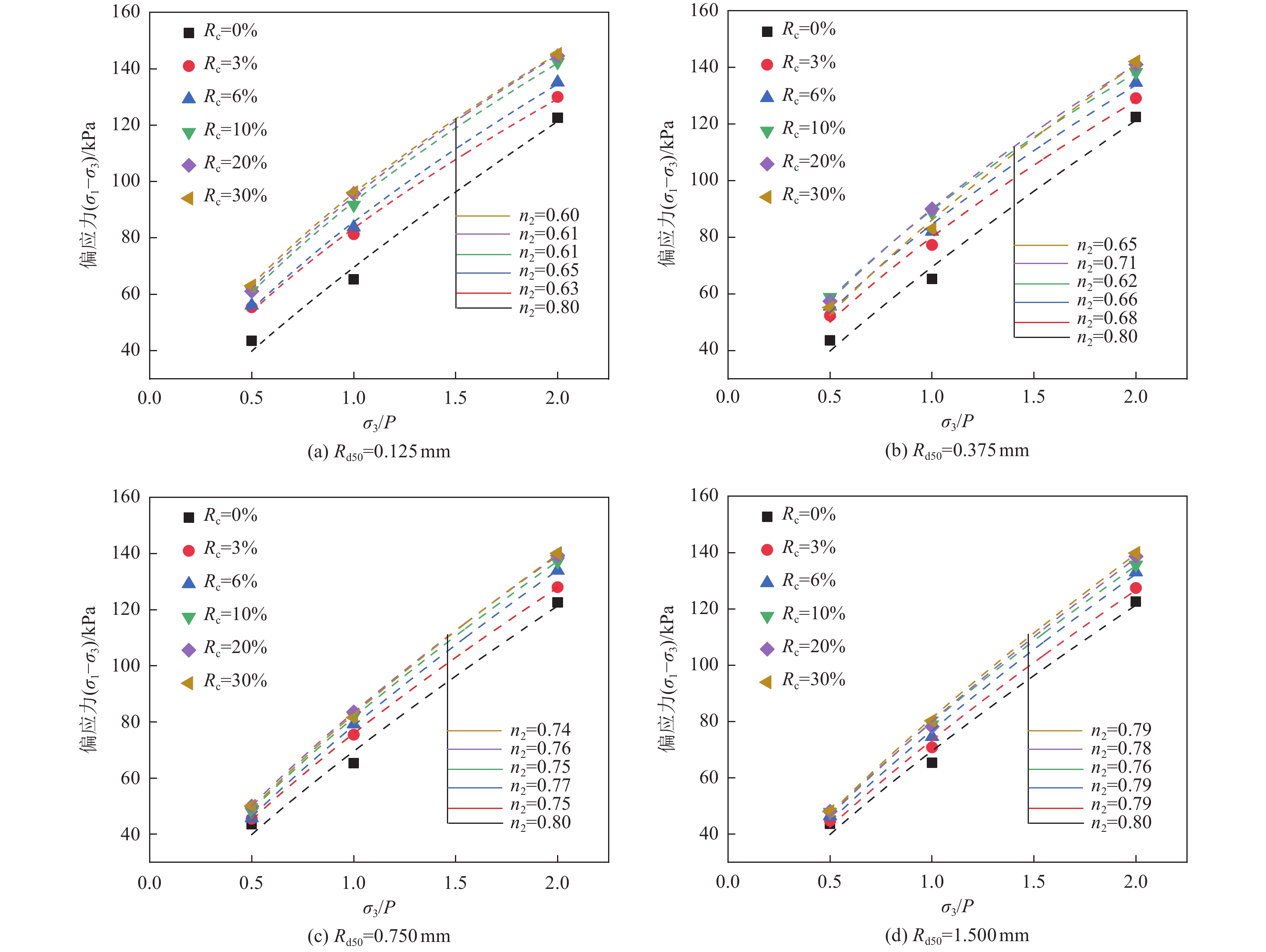

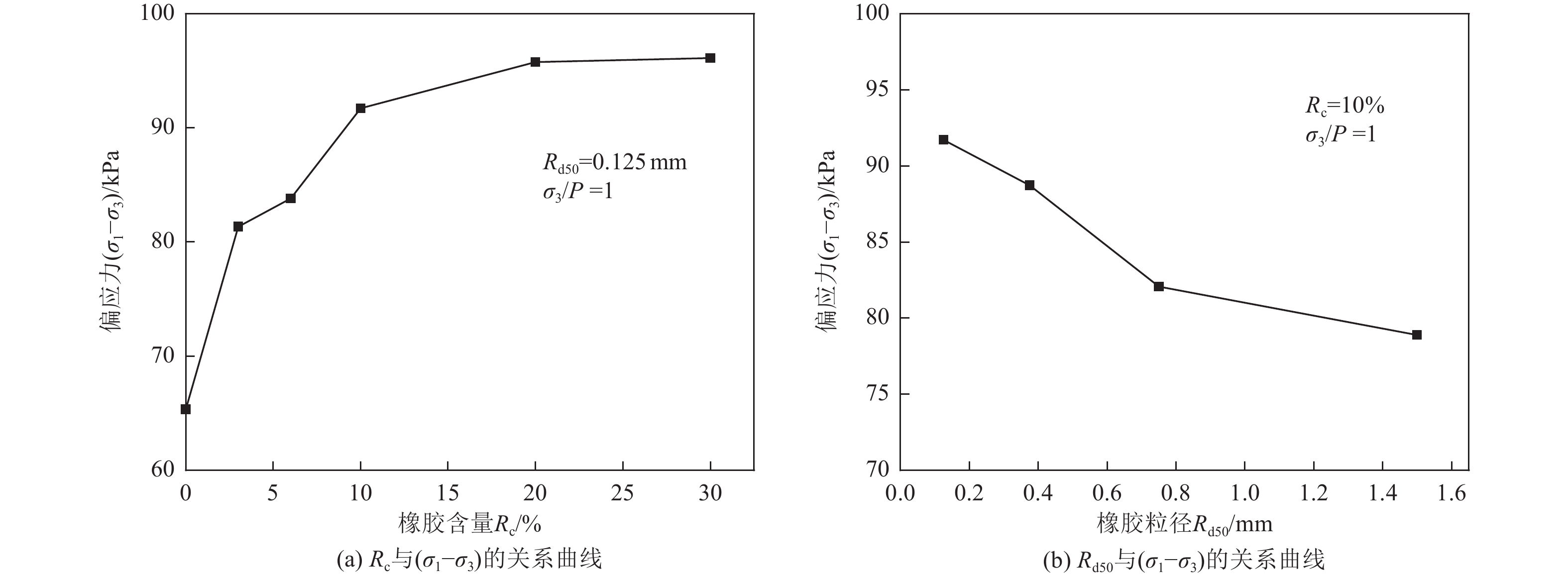

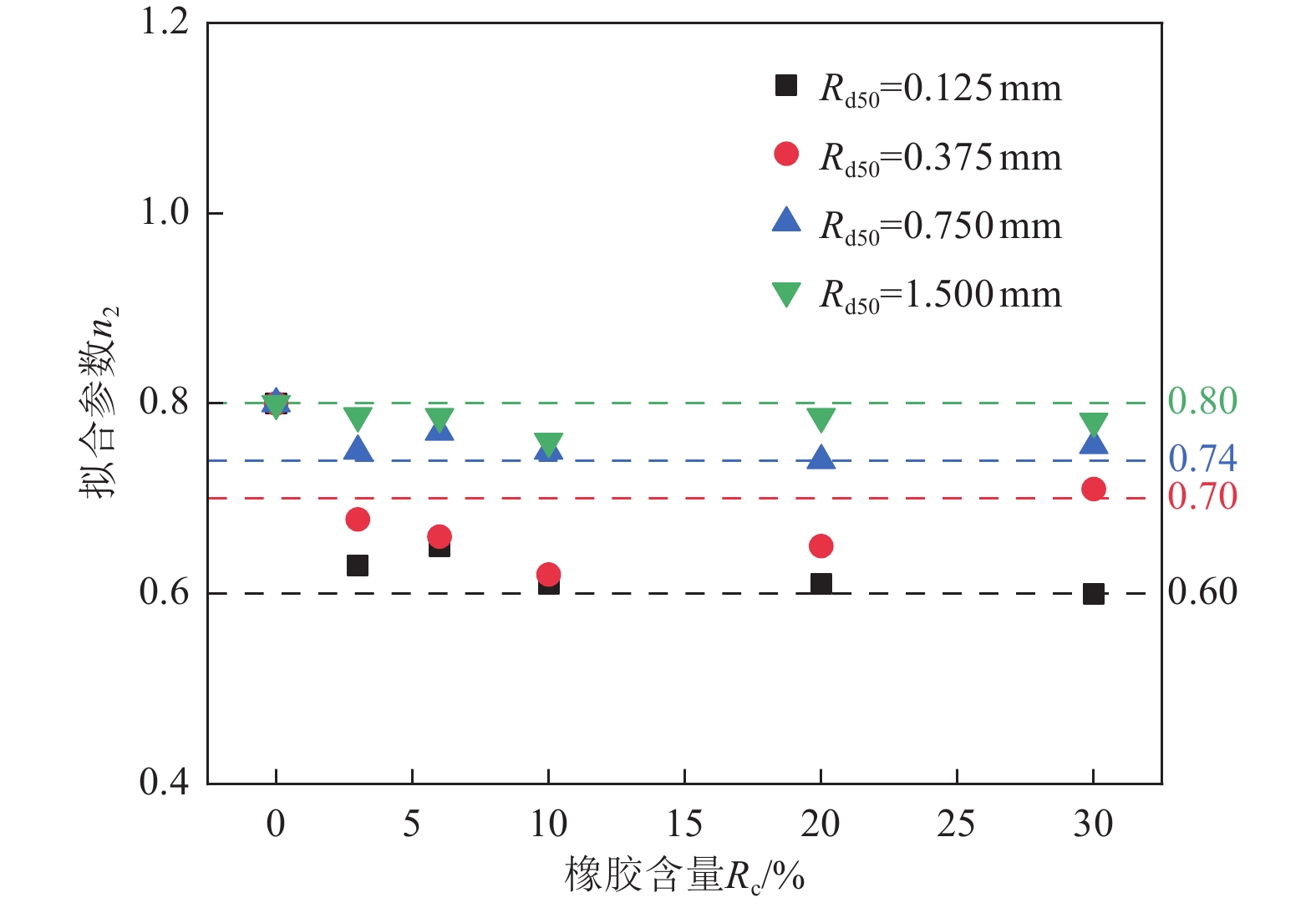

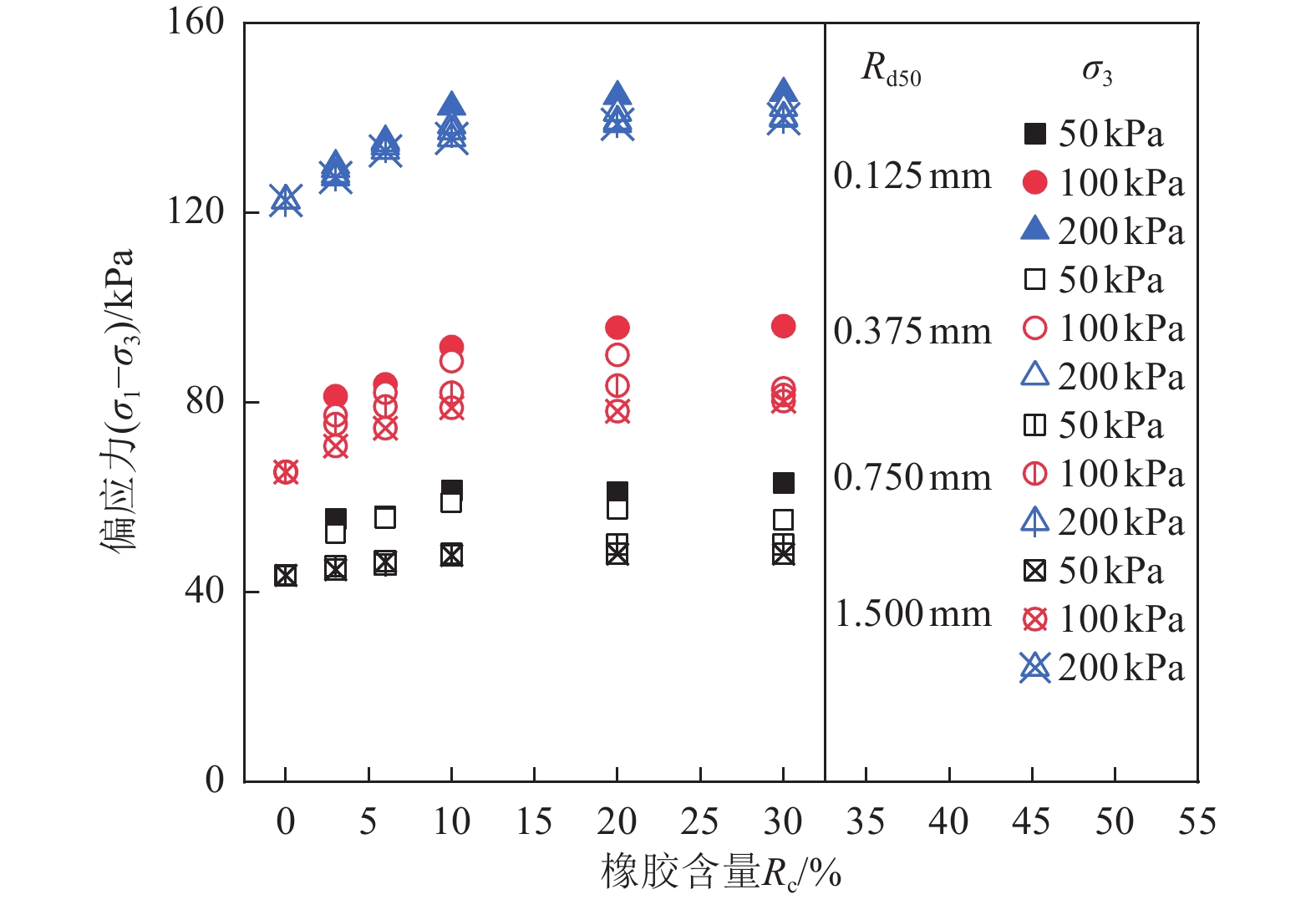

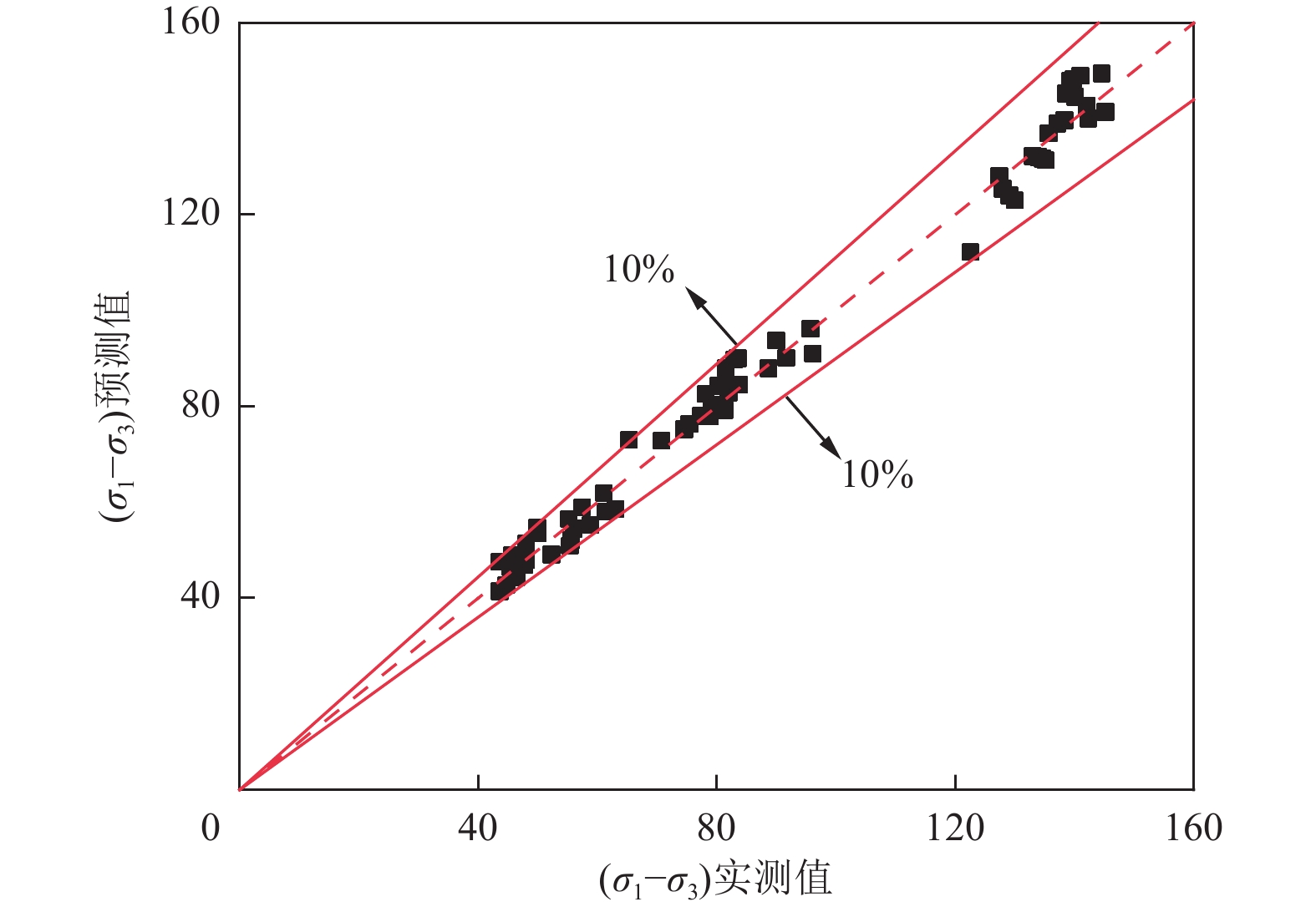

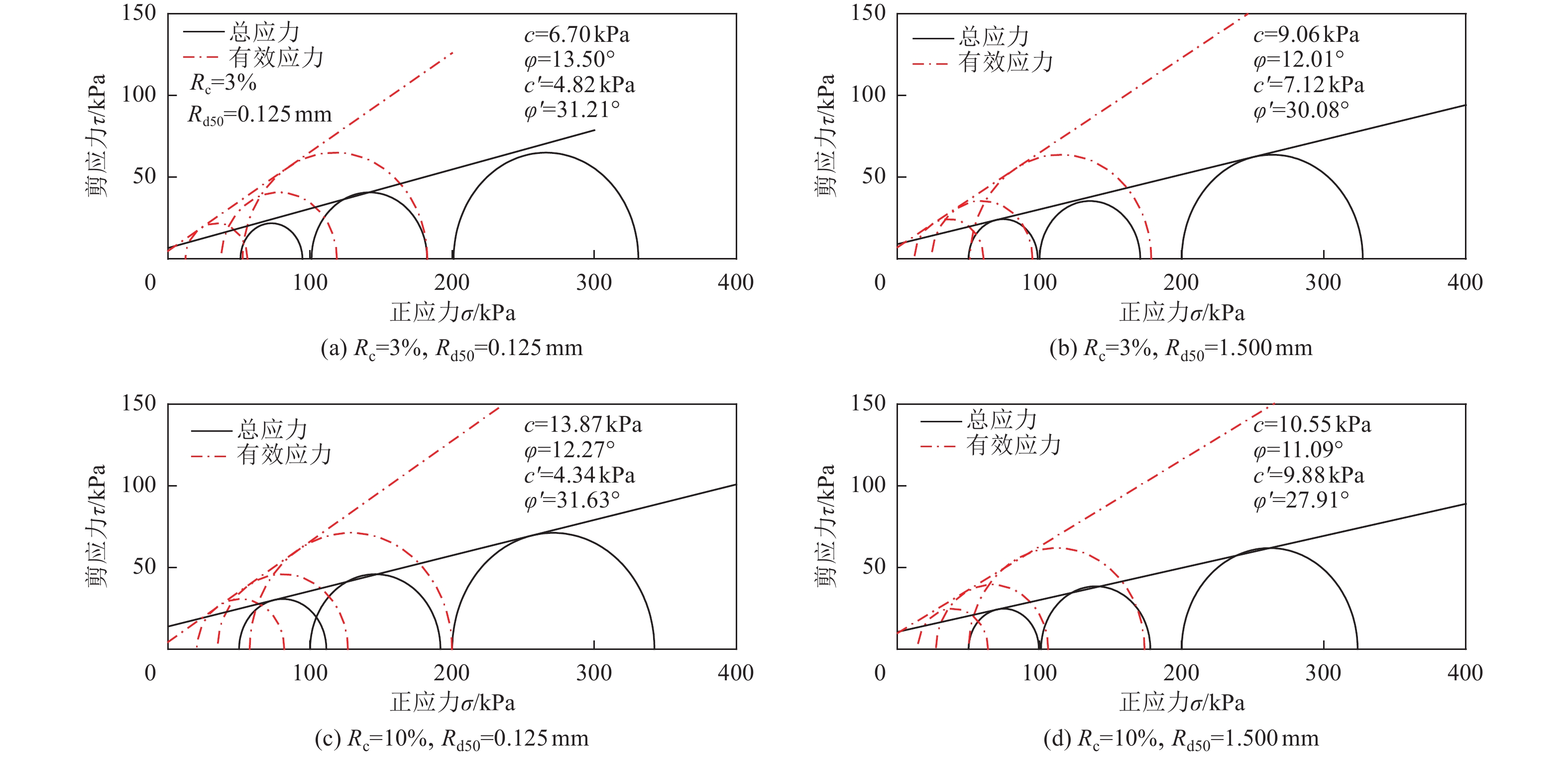

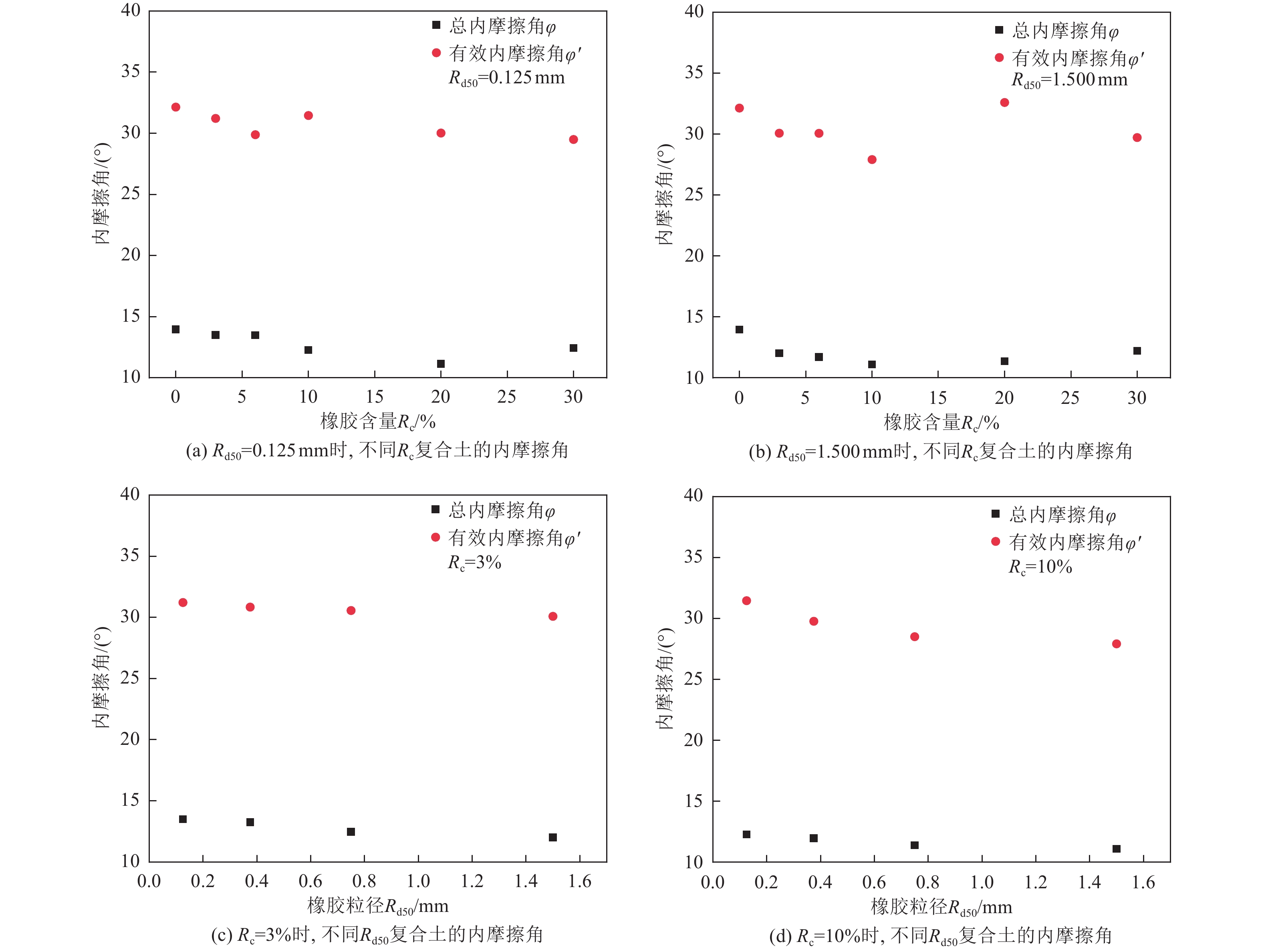

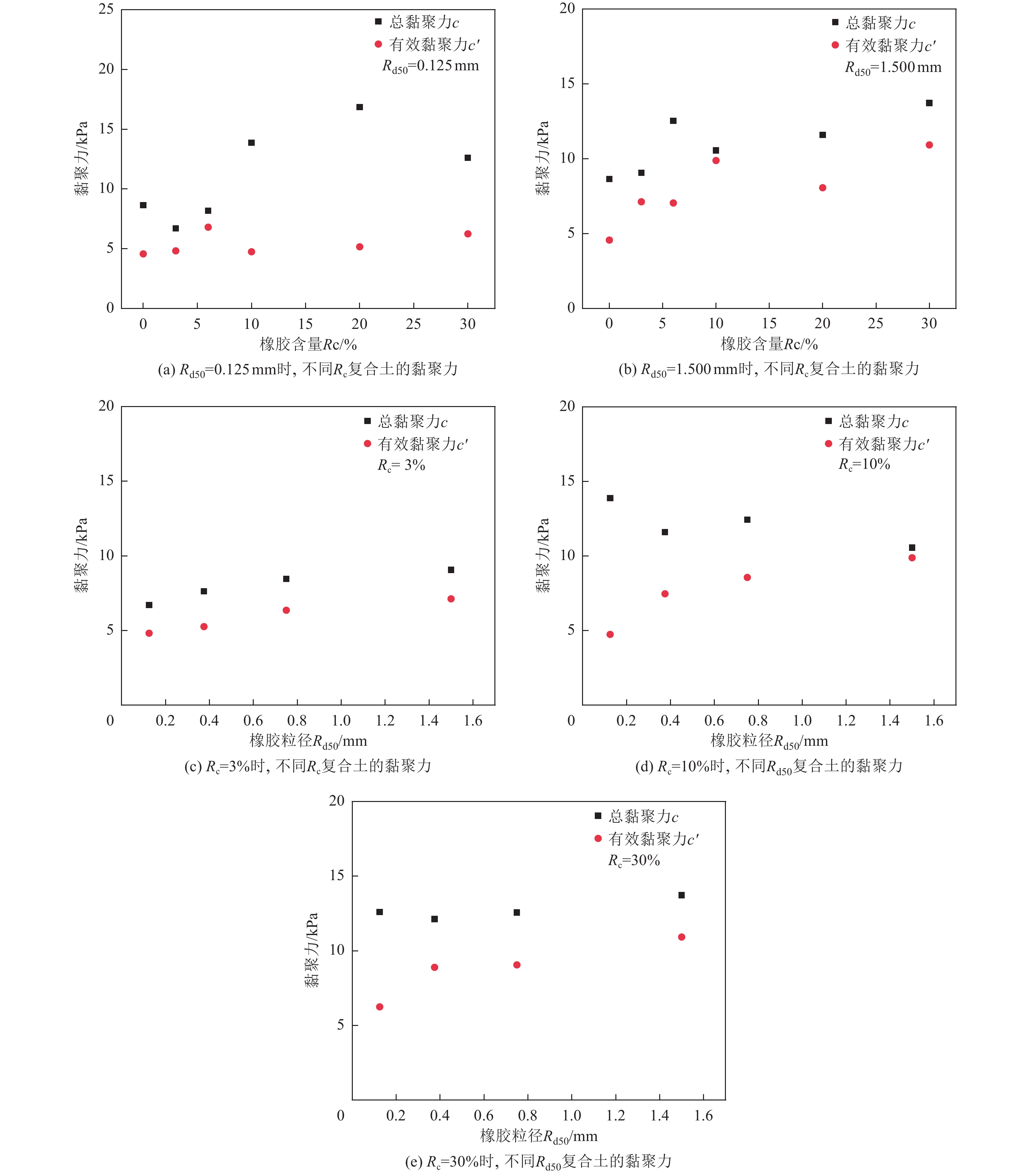

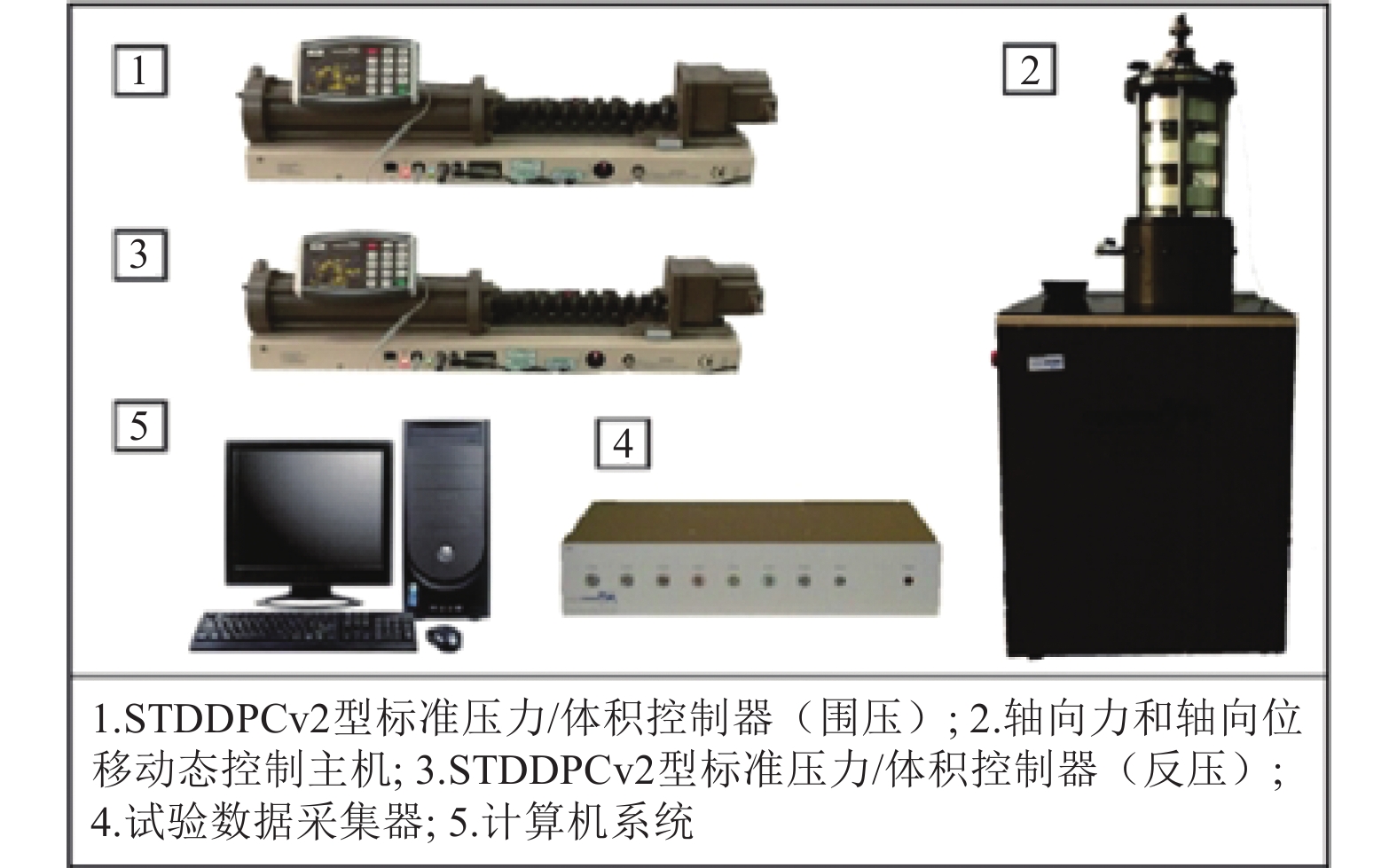

摘要: 随着乡村振兴的提出,诸多建(构)筑物建于地质条件较差的软弱地基上,为满足工程抗震需要,对这类地基土进行改良很有必要。为了探究橡胶颗粒的掺入对黏性土抗剪强度的影响规律,本文对橡胶颗粒复合土进行室内固结不排水三轴压缩试验,分析了橡胶含量、橡胶粒径、固结围压等因素对橡胶颗粒复合土力学特性的影响规律。试验结果表明,在黏土中加入橡胶颗粒会在一定程度上增加黏性土的抗剪强度,使其黏聚力稍有增加,但复合土的内摩擦角基本不变;同时加入橡胶颗粒会使复合土的初始弹性模量E0显著降低,E0受橡胶含量Rc和固结围压σ3的影响较大,受橡胶颗粒平均粒径Rd50影响较小。本文得出了不同Rc和Rd50下橡胶颗粒复合土E0在Janbu拟合公式中参数K1、n1的经验公式及建议值,以及抗剪强度(σ1−σ3)在不同Rc 和Rd50下的经验公式。Abstract: With the implementation of rural revitalization, many structures are being built on soft foundations with poor geological conditions. To address the challenges of low bearing capacity and significant settlement deformation in these soft soils, foundation improvement is essential. This study investigates the use of waste tire rubber particles to strengthen soft clay foundations. The objective is to enhance the performance of these foundations and mitigate engineering problems. To examine the influence of rubber particles on the shear strength of rubber-particle composite soil, an indoor consolidated undrained triaxial compression test was conducted. The impact of various factors, including rubber content, rubber particle size, and consolidation confining pressure, on the static properties of rubber-particle composite soil was analyzed. The test results indicate that the addition of rubber particles alters the shear strength of clay to some extent. Specifically, rubber addition significantly reduces the initial shearing modulus of the composite soil and slightly increases its cohesion, while the internal friction angle remains relatively unchanged. The initial shearing modulus (E0) of the composite soil is primarily influenced by the rubber content (Rc) and consolidation confining pressure (σ3), with less impact from the average rubber particle size (Rd50). This paper presents empirical formulas and recommended values for the parameters K1 and n1 in the Janbu fitting formula for E0 under varying Rc and Rd50 conditions. Additionally, empirical formulas for the shear strength (σ1−σ3) of rubber-particle composite soil are provided based on different Rc and Rd50 values.

-

表 1 不同配比复合土的压实特性

Table 1. Compaction characteristics of composite soil

橡胶含量 Rc/% 橡胶颗粒平均粒径Rd50/mm 最优含水率/% 最大干密度/(g·cm−3) 0 — 16.00 1.839 3 0.125 15.72 1.781 6 18.85 1.715 10 19.92 1.672 20 19.39 1.520 30 20.44 1.366 3 0.375 16.30 1.776 6 18.76 1.710 10 19.90 1.674 20 19.50 1.519 30 20.20 1.374 3 0.75 16.80 1.768 6 18.90 1.703 10 19.50 1.677 20 19.55 1.517 30 19.50 1.386 3 1.5 17.18 1.753 6 18.99 1.689 10 18.44 1.683 20 19.60 1.514 30 18.79 1.410 表 2 橡胶颗粒复合土的试验工况

Table 2. Test conditions of rubber particle composite soil

橡胶含量Rc/% 橡胶颗粒平均粒径Rd50/mm 压实度/% 固结围压σ3/kPa 0 — 90 50, 100, 200 3 0.125,0.375,0.75,1.5 90 50, 100, 200 6 0.125,0.375,0.75,1.5 90 50, 100, 200 10 0.125,0.375,0.75,1.5 90 50, 100, 200 20 0.125,0.375,0.75,1.5 90 50, 100, 200 30 0.125,0.375,0.75,1.5 90 50, 100, 200 表 3 不同围压下抗剪强度最大的最优橡胶颗粒含量Rc

Table 3. The optimal Rc that maximizes the shear strength under different confining pressures

橡胶粒径Rd50/mm Rc/% σ3=50 kPa σ3=100 kPa σ3=200 kPa 0.125 10 20 10 0.375 10 10 20 0.75 20 20 20 1.5 30 20 30 表 4 不同工况下橡胶颗粒复合土的抗剪强度指标

Table 4. Shear strength index of rubber particle composite soil under different working conditions

橡胶含量Rc/% 橡胶颗粒粒径Rd50/mm 总黏聚力 c/kPa 总内摩擦角φ/(g·cm−3) 有效黏聚力c'/kPa 有效内摩擦角φ/(g·cm−3) 0 8.64 13.96 4.56 32.14 3 0.125 6.7 13.5 4.82 31.21 6 8.17 13.47 6.8 29.88 10 13.87 12.27 4.74 31.45 20 19.91 11.13 5.15 30.02 30 11.9 12.44 6.24 29.49 3 0.375 7.89 13.12 4.98 31.57 6 9.53 12.86 5.32 30.94 10 9.95 12.78 7.55 30.24 20 12.69 12.62 6.62 29.76 30 10.22 13.02 7.21 28.88 3 0.75 8.42 12.36 6.78 31.05 6 9.86 12.15 7.05 30.45 10 10.79 11.78 8.63 29.76 20 12.78 11.06 7.08 29.02 30 12.46 11.95 8.96 28.07 3 1.5 9.06 12.01 7.12 30.08 6 12.53 11.7 7.04 30.07 10 10.55 11.09 9.88 27.91 20 11.58 11.36 4.16 32.6 30 13.72 12.2 10.92 29.72 -

李朝晖,2011. 废轮胎颗粒与黄土混合物岩土工程特性研究. 兰州:兰州大学.Li Z. H., 2011. Geotechnical properties of granulated rubber and loess soil mixtures. Lanzhou:Lanzhou University. (in Chinese) 庞邦辉,2020. 废旧轮胎橡胶颗粒改良桂林红黏土工程特性研究. 桂林:桂林理工大学.Pang B. H., 2020. Study on engineering characteristics of Guilin red clay improved by waste tire rubber particles. Guilin:Guilin University of Technology. (in Chinese) 孙树林,魏永耀,张鑫,2009. 废弃轮胎胶粉改良膨胀土的抗剪强度研究. 岩石力学与工程学报,28(S1):3070−3075.Sun S. L., Wei Y. Y., Zhang X., 2009. Research on shear strength of expansive soils reinforced with waste tire powders. Chinese Journal of Rock Mechanics and Engineering, 28(S1): 3070−3075. (in Chinese) 殷宗泽,2004. 土工原理. 北京:清华大学出版社.Yin Z. Z., 2004. Tugongyuanli. Beijing:Tsinghua University Press. (in Chinese) 宗佳敏,宋迎俊,鲁洋等,2017. 冻融循环下废旧轮胎颗粒改性膨胀土无侧限抗压强度试验. 长江科学院院报,34(9):110−114. doi: 10.11988/ckyyb.20160511Zong J. M., Song Y. J., Lu Y., et al., 2017. Unconfined compressive strength test on expansive soil improved by waste tire rubber particles under freeze-thaw cycles. Journal of Yangtze River Scientific Research Institute, 34(9): 110−114. (in Chinese) doi: 10.11988/ckyyb.20160511 Akbarimehr D., Eslami A., Aflaki E., 2020. Geotechnical behaviour of clay soil mixed with rubber waste. Journal of Cleaner Production, 271: 122632. doi: 10.1016/j.jclepro.2020.122632 Lu Y., Zhang Y. G., Liu S. H., et al., 2022. Mechanical behaviour and permeability of expansive soils mixed with scrap tire rubbers subjected to freeze-thaw cycles. Cold Regions Science and Technology, 199: 103580. doi: 10.1016/j.coldregions.2022.103580 Marefat V., Soltani-Jigheh H., 2011. Laboratory behavior of clay-tire mixtures. World Applied Sciences Journal, 13(5): 1035−1041. Ramirez G. G. D., Casagrande M. D. T., Folle D., et al., 2015. Behavior of granular rubber waste tire reinforced soil for application in geosynthetic reinforced soil wall. Revista IBRACON de Estruturas e Materiais, 8(4): 567−576. doi: 10.1590/S1983-41952015000400009 Sellaf H. , Trouzine H. , Hamhami M. , et al. , 2014. Geotechnical properties of rubber tires and sediments mixtures. Engineering, Technology & Applied Science Research, 4 (2): 618−624. Shibuya S., Tatsuoka F., Teachavorasinskun S., et al., 1992. Elastic deformation properties of geomaterials. Soils and Foundations, 32(3): 26−46. doi: 10.3208/sandf1972.32.3_26 Soltani A., Deng A., Taheri A., et al., 2019. Swell–shrink behavior of rubberized expansive clays during alternate wetting and drying. Minerals, 9(4): 224. doi: 10.3390/min9040224 Srivastava A., Pandey S., Rana J., 2014. Use of shredded tyre waste in improving the geotechnical properties of expansive black cotton soil. Geomechanics and Geoengineering, 9(4): 303−311. doi: 10.1080/17486025.2014.902121 Valipour M., Shourijeh P. T., Mohammadinia A., 2021. Application of recycled tire polymer fibers and glass fibers for clay reinforcement. Transportation Geotechnics, 27: 100474. doi: 10.1016/j.trgeo.2020.100474 Xia P. X., Shao L. T., Deng W., 2021. Mechanism study of the evolution of quasi-elasticity of granular soil during cyclic loading. Granular Matter, 23(4): 84. doi: 10.1007/s10035-021-01157-8 Xin L., He J., Liu H. L., et al., 2015. Potential of using cemented soil-tire chips mixture as construction fill: a laboratory study. Journal of Coastal Research, 73(S1): 564−571. -

下载:

下载: