Study on Mechanical Properties of Buried Steel Pipelines Strengthened with Carbon Fiber Reinforced Polymer under Reverse Fault

-

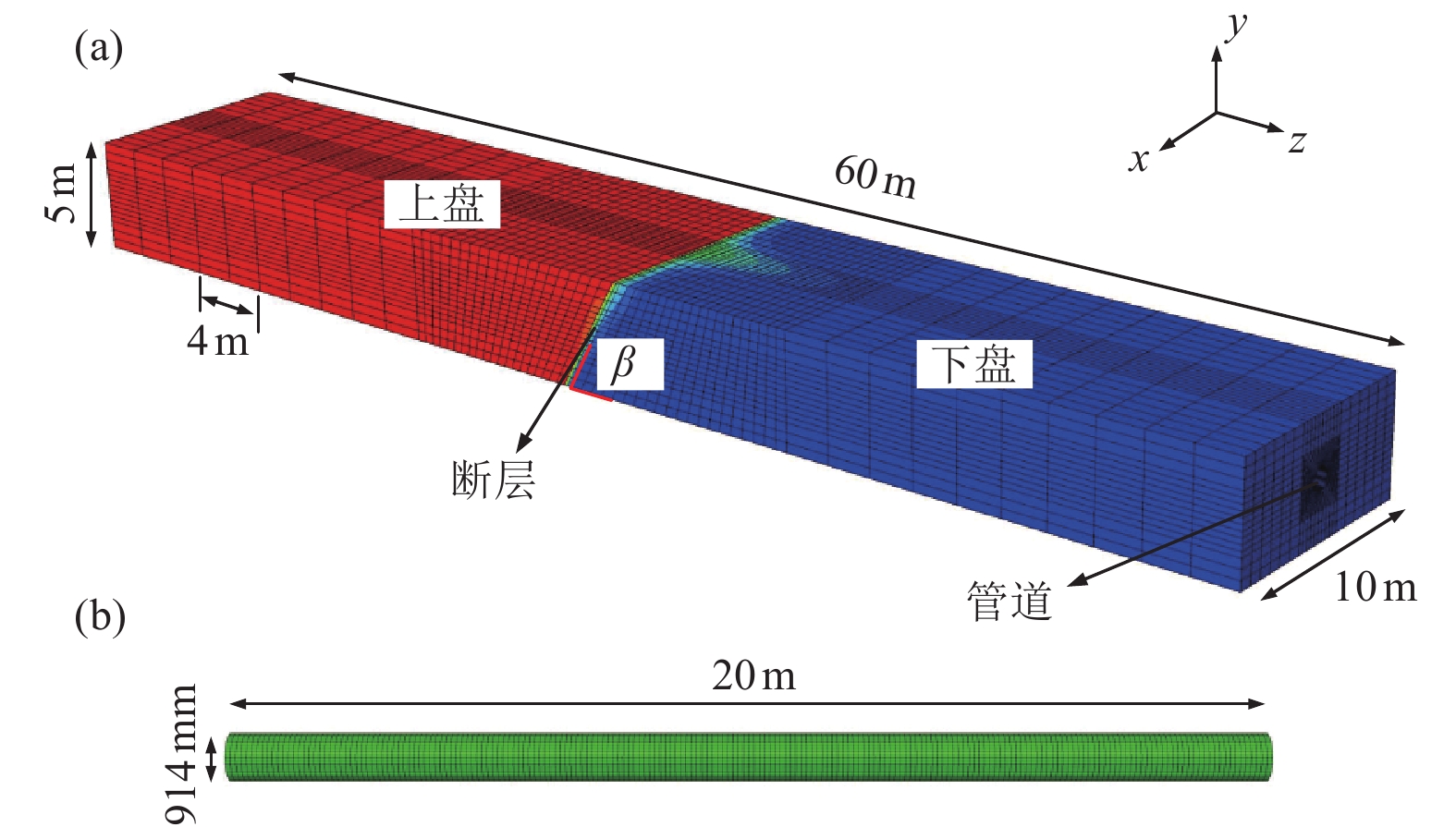

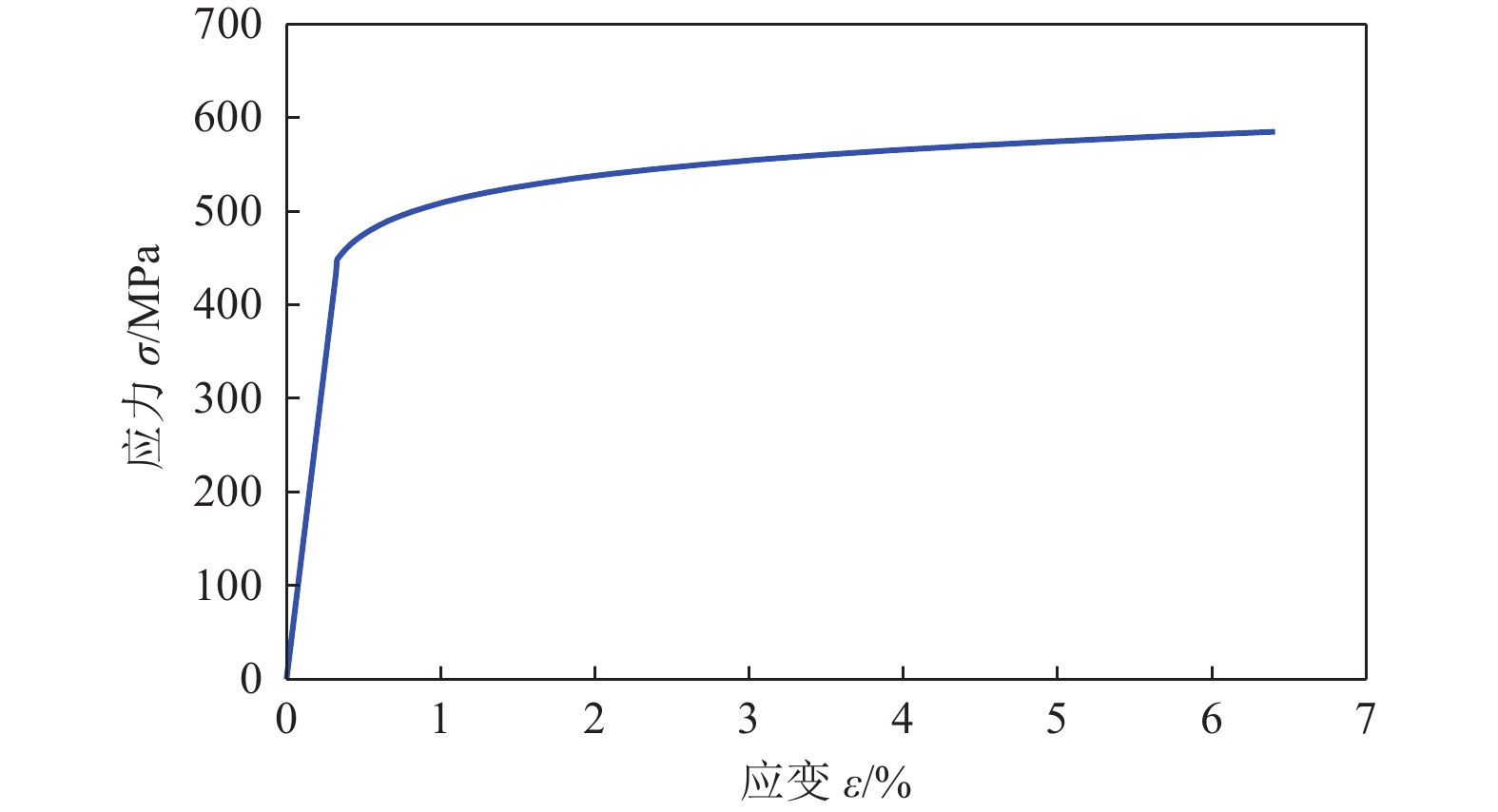

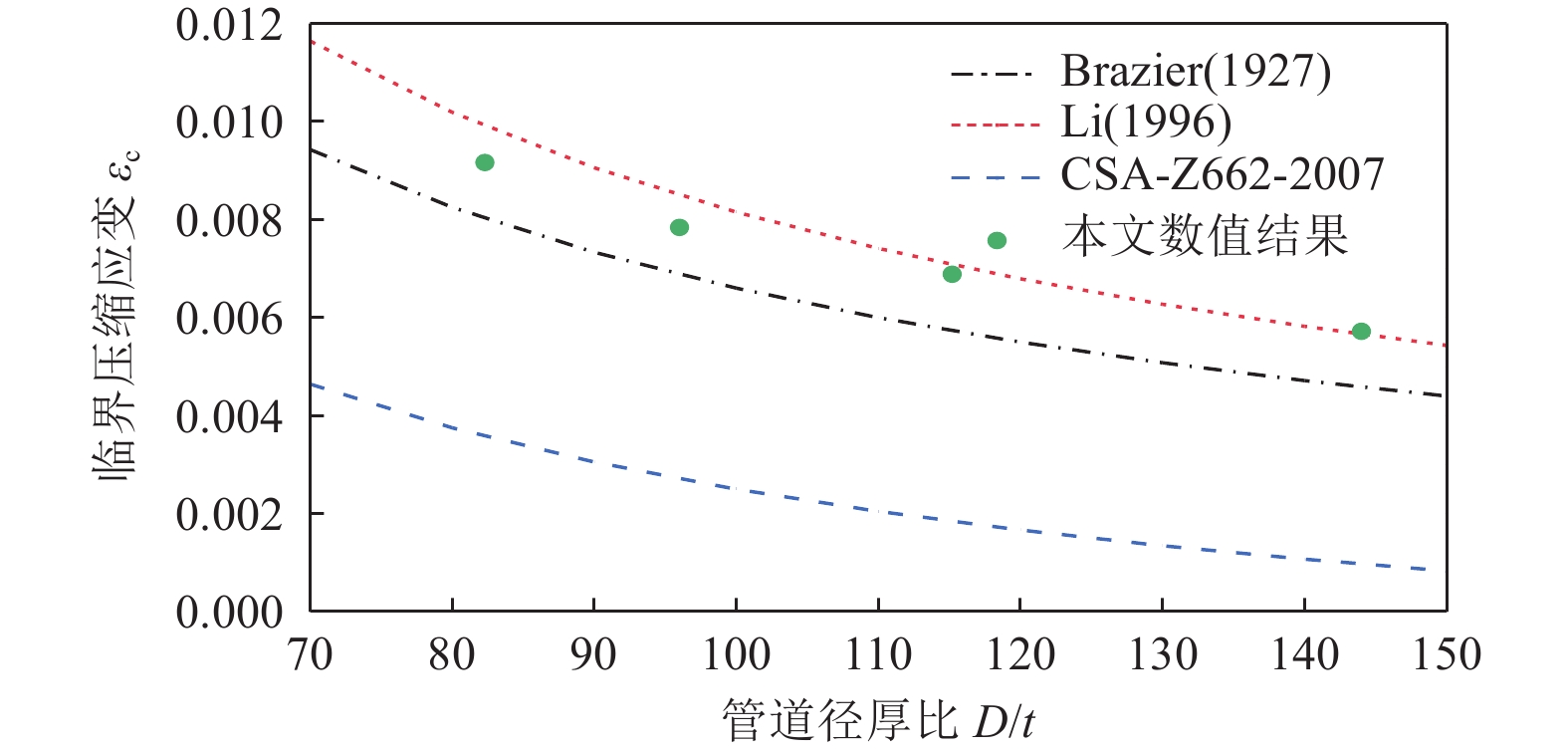

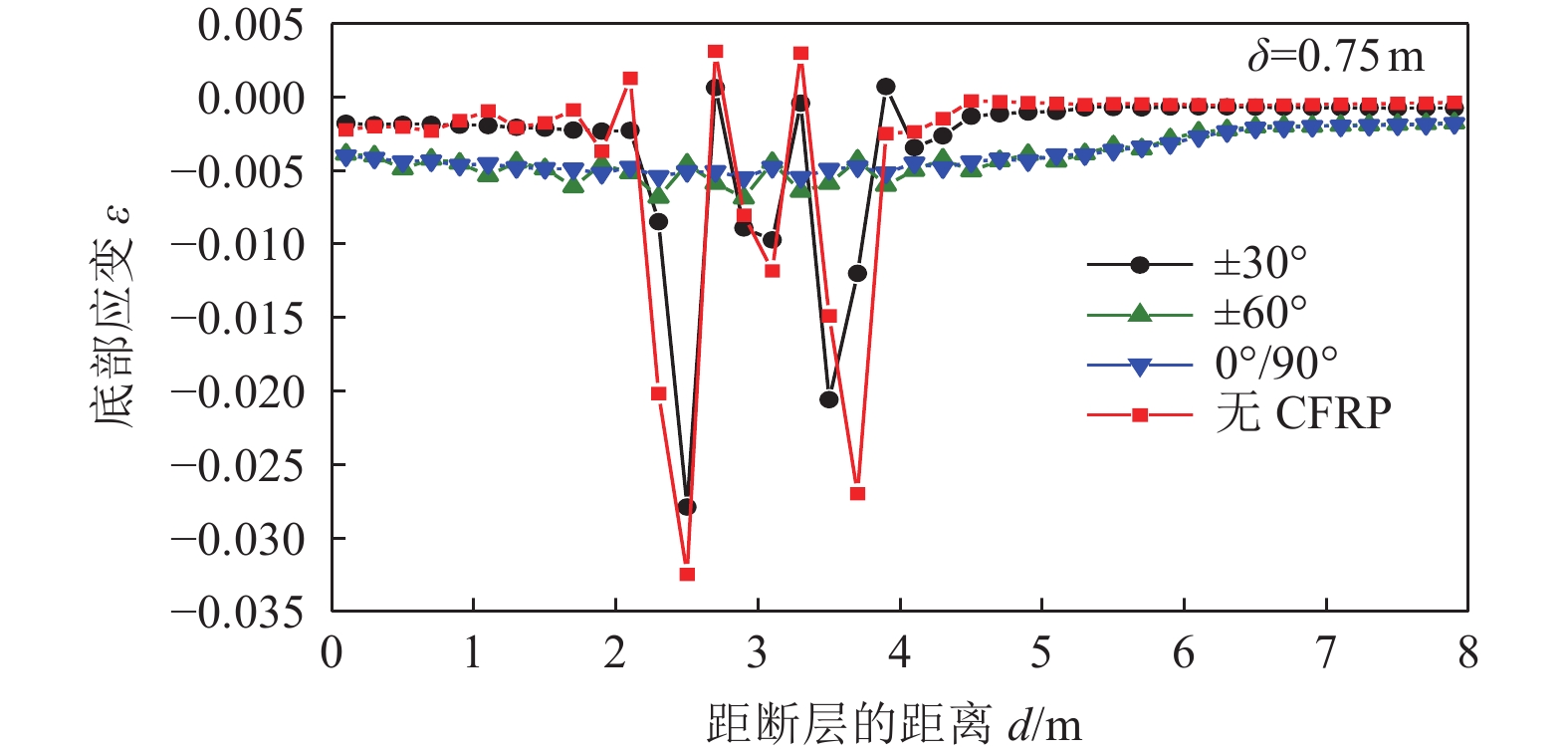

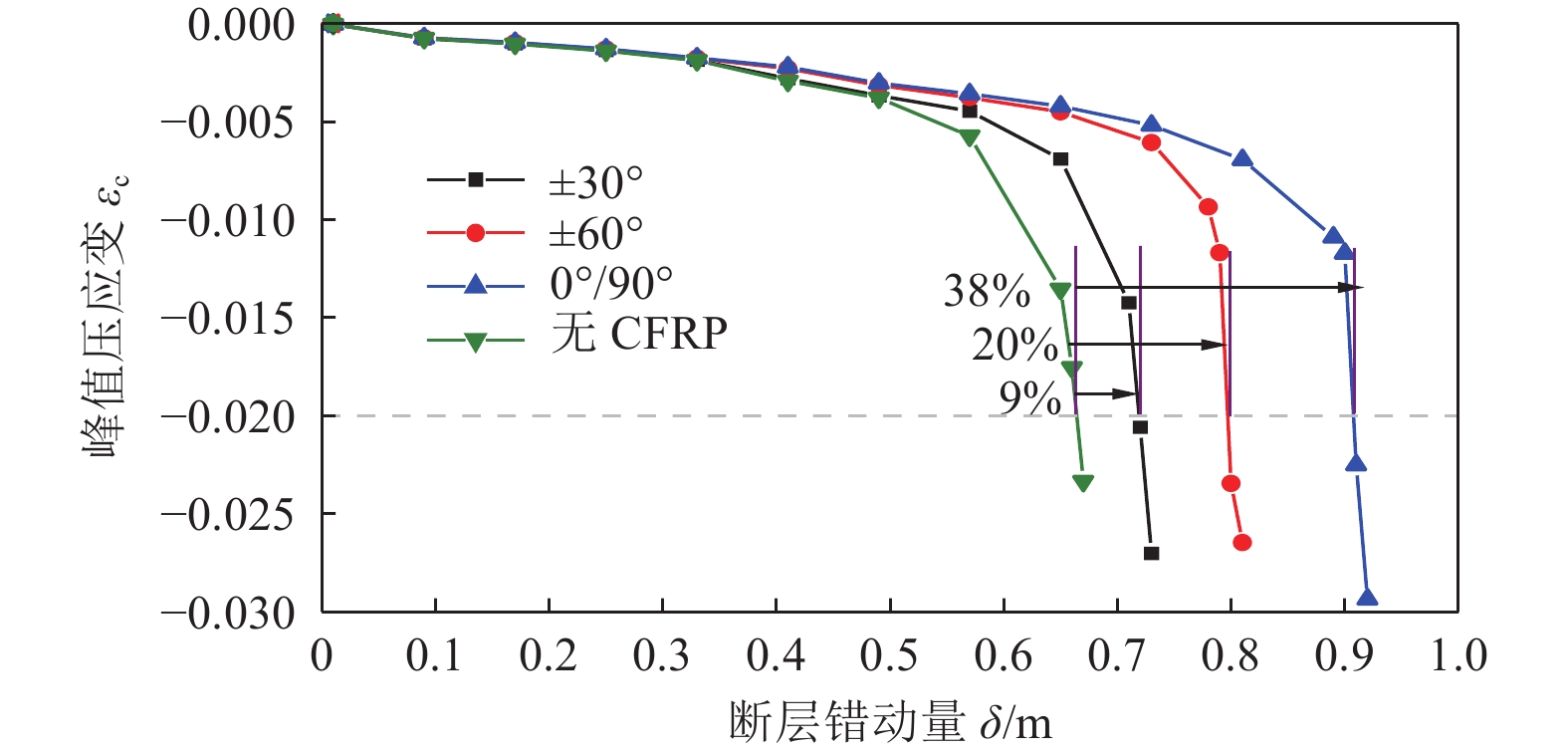

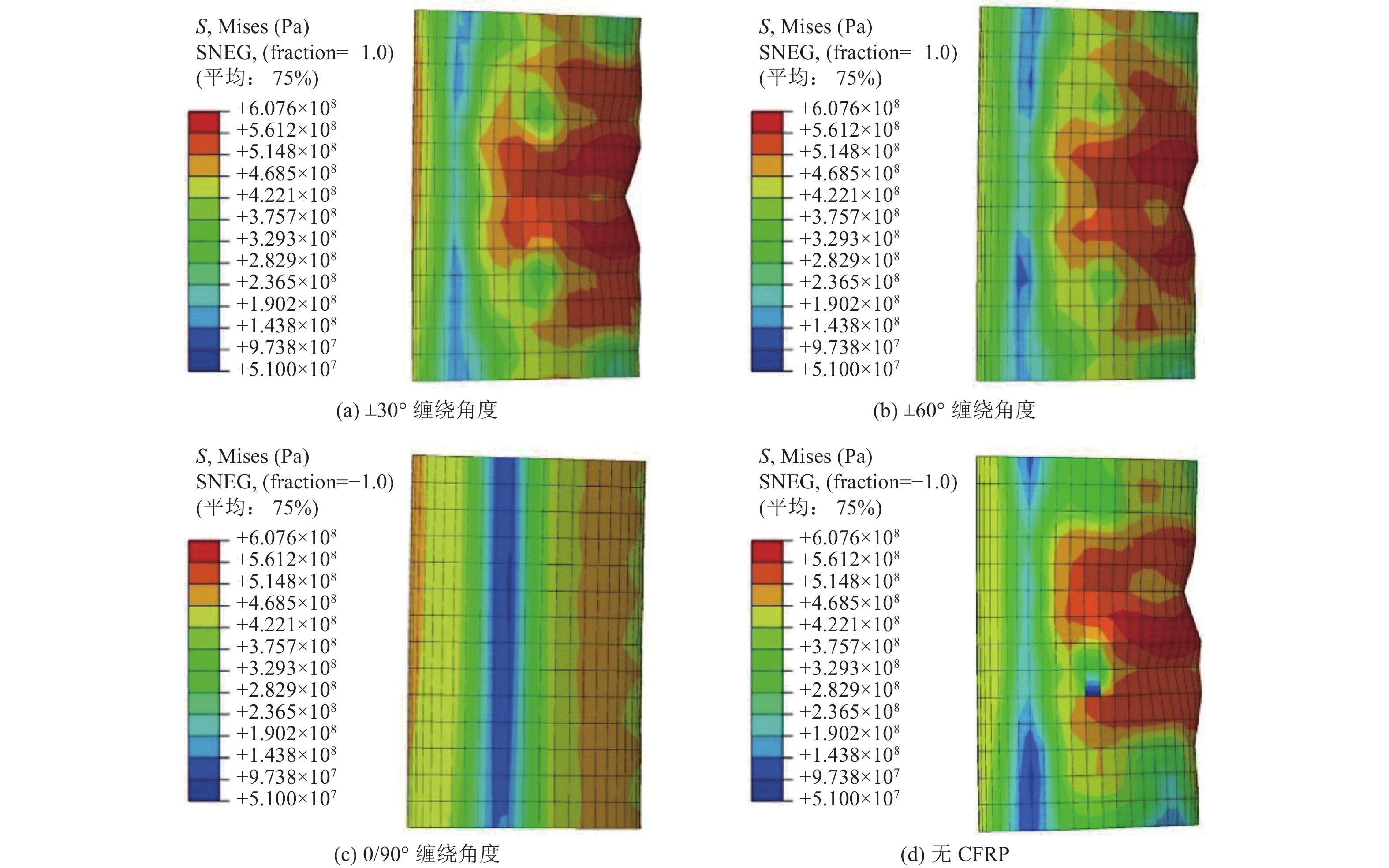

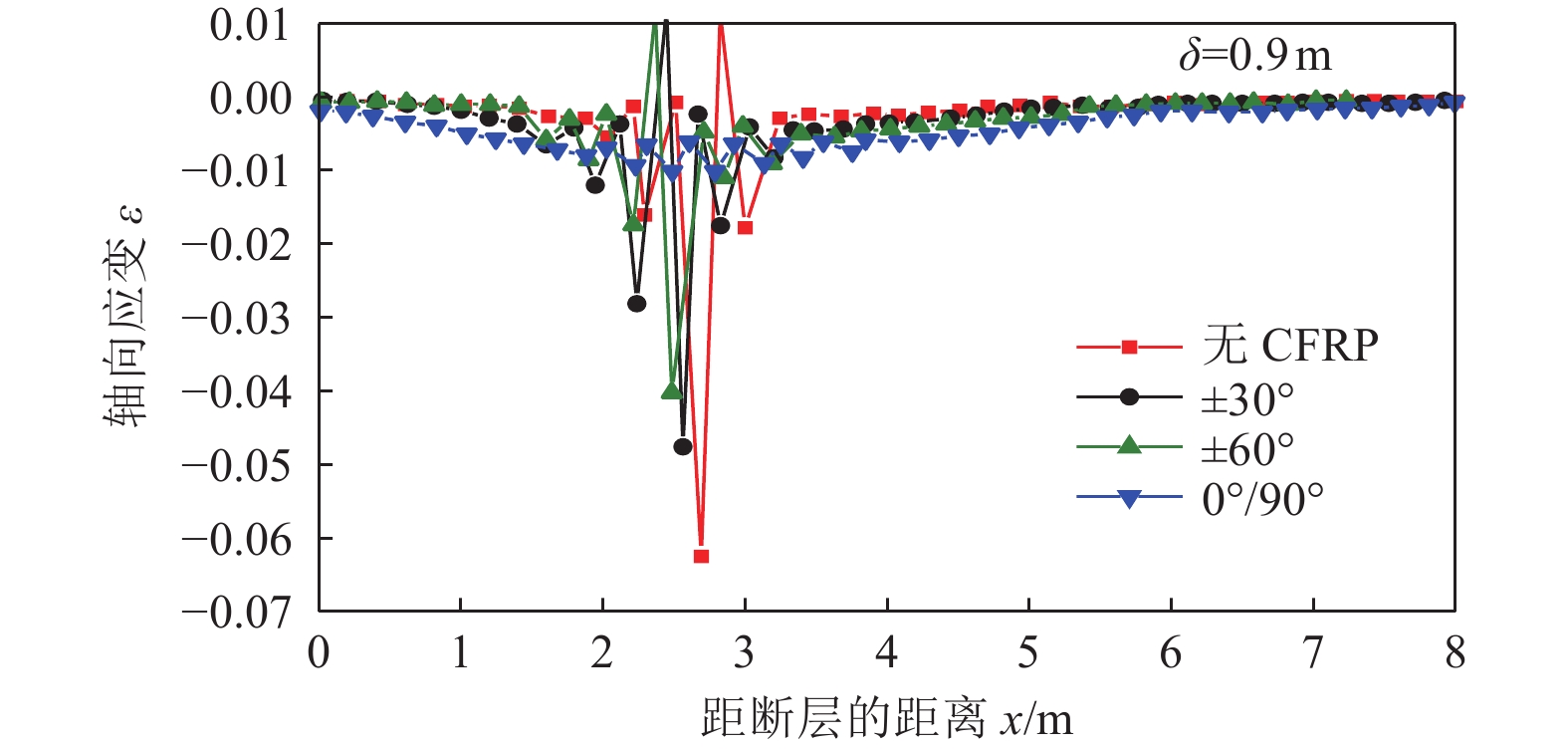

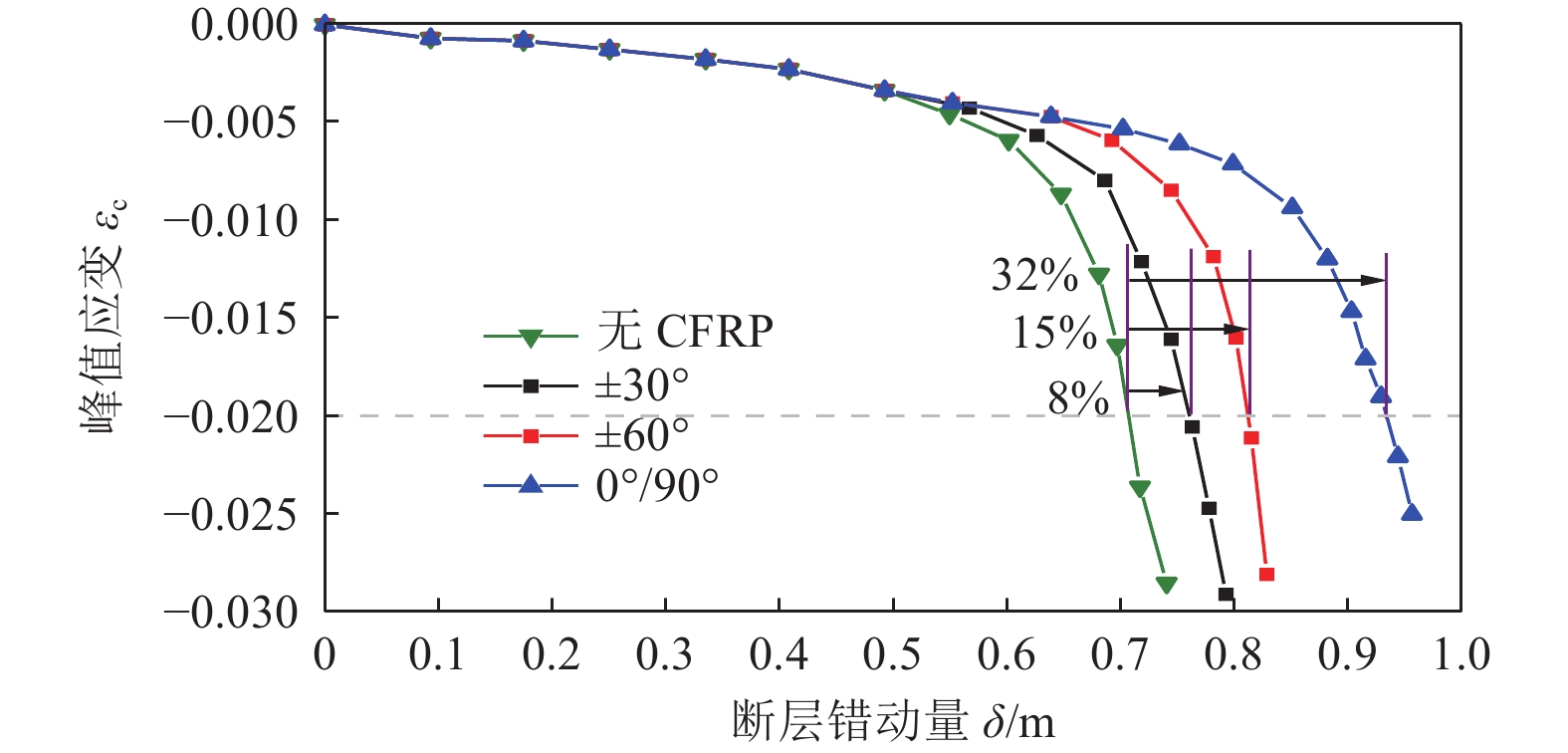

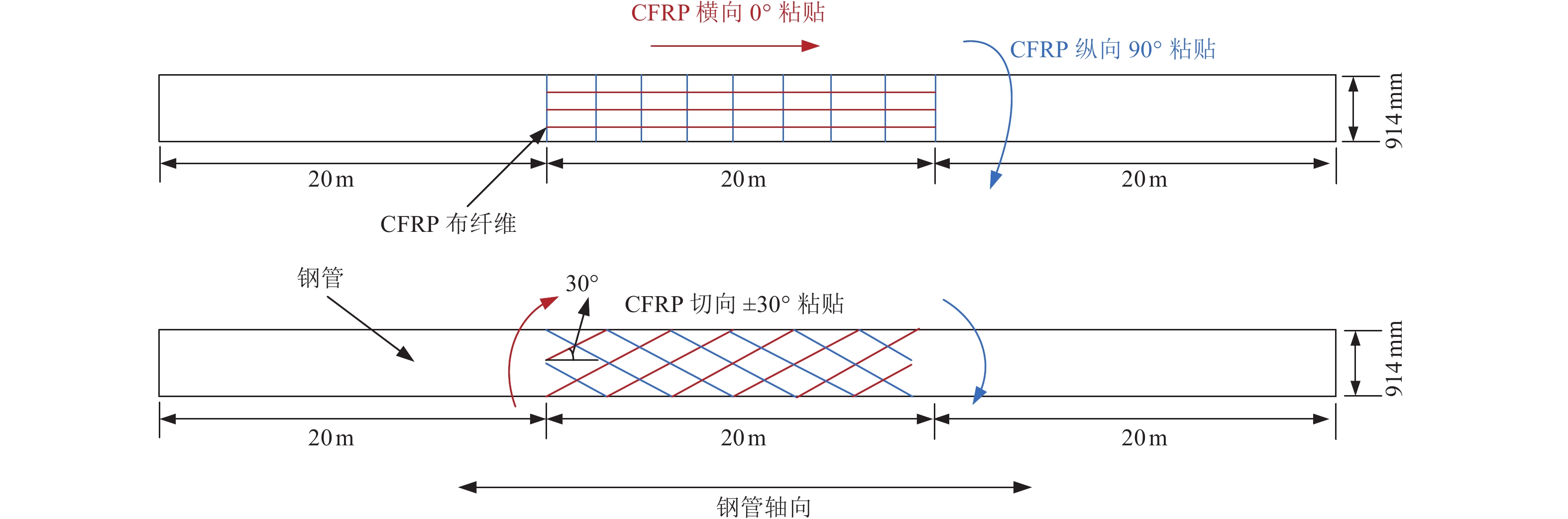

摘要: 碳纤维增强复合材料(CFRP)被广泛应用于工程结构加固领域,以提高结构抵抗变形的能力。基于管道-土体相互作用三维非线性有限元分析方法,研究逆断层作用下埋地油气钢管经外包CFRP加固后的非线性响应规律和破坏模式。基于Hashin失效准则模拟CFRP受力破坏过程,与相关理论公式进行对比验证,并对加固前后逆断层错动连续埋地钢管力学响应进行分析。研究结果表明,CFRP加固钢管可显著提高其抵抗逆断层错动的能力,0°/90°为最佳缠绕角度;管道内压的施加虽抑制了管道轴向应变的增加,但当管道发生局部屈曲后,管道内压会导致管道屈曲集中于应力最大处;管道内压的施加不仅增强了CFRP加固钢管的抗变形能力,还抑制了CFRP加固钢管发生局部屈曲后应变的发展。Abstract: CFRP is widely used in the field of engineering structures to improve the ability of structures to resist deformation. This paper investigates the possibility of wrapping FRP around steel pipelines to improve the resistance of cross-fault oil and gas pipelines to large ground deformation. Based on the Hashin failure criterion, the damage process of FRP materials is simulated, and a three-dimensional numerical analysis model was established and compared with the relevant equations to verify the equations, and analyze the mechanical response of continuous buried steel pipelines with reverse fault movement before and after reinforcement. The results show that: the FRP-reinforced steel pipeline can significantly improve its resistance to fault misalignment, where the wrapping angle of 0/90° is the best wrapping angle; although the internal pressure of the pipeline suppresses the increase in pipeline strain, when the pipeline undergoes local buckling, the internal pressure of the pipeline causes the pipeline buckling to concentrate at the maximum stress; the application of internal pressure not only increases the resistance to deformation of the CFRP-reinforced steel pipeline, but also The application of internal pressure not only increases the resistance to deformation of the CFRP reinforced steel pipeline, but also inhibits the development of strain after local buckling of the CFRP reinforced steel pipeline.

-

Key words:

- Cross-fault /

- Pressure pipelines /

- CFRP /

- Reinforcement efficiency /

- Numerical simulation

-

表 1 土体物理力学参数

Table 1. Physical and mechanical parameters of soil

名称 ρ/(kg·m−3) E/MPa μ c/MPa ϕ/(°) ψ/(°) 黏土 1 900 33 0.27 35 22 0 表 2 CFRP材料力学性能

Table 2. Mechanical properties of CFRP materials

沿纤维方向的

弹性模量E1/MPa垂直于纤维方向的

弹性模量E2/MPa泊松比Nu 纤维-树脂方向的

剪切模量G12/MPa垂直于纤维-树脂方向的

剪切模量G13/MPa树脂自身的剪切

模量G23/MPaCFRP的单层厚度

tCFRP/mm230 000 1 900 0.3 3 387 3 387 3 387 0.176 表 3 Hashin失效参数

Table 3. Hashin failure parameters

方向 参数 数值/MPa 方向 参数 数值/MPa x向 拉伸强度XT 1 830 y向 拉伸强度YT 31.3 压缩强度XC 895 压缩强度YC 124.5 剪切强度SL 72 剪切强度ST 62.3 -

刘爱文, 胡聿贤, 赵凤新等, 2004. 地震断层作用下埋地管线壳有限元分析的等效边界方法. 地震学报, 26(S1): 141—147Liu A. W. , Hu Y. X. , Zhao F. X. , et al. , 2004. An equivalent-boundary method for the shell analysis of buried pipelines under fault movement. Acta Seismologica Sinica, 26(S1): 141—147. (in Chinese) 邵永波, 朱红梅, 杨冬平, 2020. 轴压作用下CFRP加固圆钢管短柱的静力承载力分析. 西南交通大学学报, 55(1): 167—174 doi: 10.3969/j.issn.0258-2724.20180527Shao Y. B. , Zhu H. M. , Yang D. P. , 2020. Static bearing capacity analysis of CFRP-reinforced short CHS steel tubular columns under axial compression. Journal of Southwest Jiaotong University, 55(1): 167—174. (in Chinese) doi: 10.3969/j.issn.0258-2724.20180527 赵旭, 崔建阳, 钟紫蓝等, 2022. 逆断层作用下埋地连续钢管的力学性能. 北京工业大学学报, 48(7): 729—738 doi: 10.11936/bjutxb2021030013Zhao X. , Cui J. Y. , Zhong Z. L. , et al. , 2022. Mechanical properties of buried continuous steel pipe under reverse fault. Journal of Beijing University of Technology, 48(7): 729—738. (in Chinese) doi: 10.11936/bjutxb2021030013 中华人民共和国住房和城乡建设部, 中华人民共和国国家质量监督检验检疫总局, 2017. GB/T 50470—2017 油气输送管道线路工程抗震技术规范. 北京: 中国计划出版社.Ministry of Housing and Urban-Rural Development of the People's Republic of China, General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, 2017. GB/T 50470—2017 Seismic technical code for oil and gas transmission pipeline engineering. Beijing: China Planning Press. (in Chinese) Ariman T., 1983. A review of buckling and rupture failures in pipelines due to large ground deformations. In: American Society of Mechanical Engineers Pressure Vessel and Piping Conference. Portland: American Society of Mechanical Engineers. Betts D. , Sadeghian P. , Fam A. , 2019. Investigation of the stress-strain constitutive behavior of ±55° filament wound GFRP pipes in compression and tension. Composites Part B: Engineering, 172: 243—252. doi: 10.1016/j.compositesb.2019.05.077 Brazier L. G., 1927. On the flexure of thin cylindrical shells and other “thin” sections. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, 116(773): 104—114. Canadian Standards Association, 2007. CSA—Z662—2007 Oil and gas pipeline systems. Toronto: CSA. Chen W. W., Shih B. J., Chen Y. C., et al., 2002. Seismic response of natural gas and water pipelines in the Ji-Ji earthquake. Soil Dynamics and Earthquake Engineering, 22(9—12): 1209—1214. Cheng X. D. , Ma C. , Huang R. K. , et al. , 2019. Failure mode analysis of X80 buried steel pipeline under oblique-reverse fault. Soil Dynamics and Earthquake Engineering, 125: 105723. doi: 10.1016/j.soildyn.2019.105723 Gawande K. , Kiran R. , Cherukuri H. P. , 2019. A numerical study of the response of buried steel pipelines undergoing strike-slip fault. Engineering Failure Analysis, 102: 203—218. doi: 10.1016/j.engfailanal.2019.04.026 Kaya E. S. , Uçkan E. , O'Rourke M. J. , et al. , 2017. Failure analysis of a welded steel pipe at Kullar fault crossing. Engineering Failure Analysis, 71: 43—62. doi: 10.1016/j.engfailanal.2016.10.004 Li L. Y. , 1996. Approximate estimates of dynamic instability of long circular cylindrical shells under pure bending. International Journal of Pressure Vessels and Piping, 67(1): 37—40. doi: 10.1016/0308-0161(94)00073-5 Lim K. S. , Azraai S. N. A. , Yahaya N. , et al. , 2019. Behaviour of steel pipelines with composite repairs analysed using experimental and numerical approaches. Thin-Walled Structures, 139: 321—333. doi: 10.1016/j.tws.2019.03.023 Liu X. B. , Zhang H. , Li M. , et al. , 2016. Effects of steel properties on the local buckling response of high strength pipelines subjected to reverse faulting. Journal of Natural Gas Science and Engineering, 33: 378—387. doi: 10.1016/j.jngse.2016.05.036 Mahdi E. , Eltai E. , 2018. Development of cost-effective composite repair system for oil/gas pipelines. Composite Structures, 202: 802—806. doi: 10.1016/j.compstruct.2018.04.025 Melissianos V. E. , Vamvatsikos D. , Gantes C. J. , 2017. Performance-based assessment of protection measures for buried pipes at strike-slip fault crossings. Soil Dynamics and Earthquake Engineering, 101: 1—11. doi: 10.1016/j.soildyn.2017.07.004 Mokhtari M. , Nia A. A. , 2015. The influence of using CFRP wraps on performance of buried steel pipelines under permanent ground deformations. Soil Dynamics and Earthquake Engineering, 73: 29—41. doi: 10.1016/j.soildyn.2015.02.014 Ni P. P. , Moore I. D. , Take W. A. , 2018. Numerical modeling of normal fault-pipeline interaction and comparison with centrifuge tests. Soil Dynamics and Earthquake Engineering, 105: 127—138. doi: 10.1016/j.soildyn.2017.10.011 O'Rourke T. D. , Palmer M. C. , 1996. Earthquake performance of gas transmission pipelines. Earthquake Spectra, 12(3): 493—527. doi: 10.1193/1.1585895 Shamsuddoha M. , Islam M. M. , Aravinthan T. , et al. , 2013. Effectiveness of using fibre-reinforced polymer composites for underwater steel pipeline repairs. Composite Structures, 100: 40—54. doi: 10.1016/j.compstruct.2012.12.019 Soveiti S. , Mosalmani R. , 2020. Mechanical behavior of buried composite pipelines subjected to strike-slip fault movement. Soil Dynamics and Earthquake Engineering, 135: 106195. doi: 10.1016/j.soildyn.2020.106195 Trifonov O. V. , Cherniy V. P. , 2014. Analysis of stress–strain state in a steel pipe strengthened with a composite wrap. Journal of Pressure Vessel Technology, 136(5): 051202. doi: 10.1115/1.4027229 Valsamis A. I. , Bouckovalas G. D. , Gantes C. J. , 2020. Alternative design of buried pipelines at active fault crossings using flexible joints. International Journal of Pressure Vessels and Piping, 180: 104038. doi: 10.1016/j.ijpvp.2019.104038 Vazouras P. , Karamanos S. A. , Dakoulas P. , 2012. Mechanical behavior of buried steel pipes crossing active strike-slip faults. Soil Dynamics and Earthquake Engineering, 41: 164—180. doi: 10.1016/j.soildyn.2012.05.012 Zhang J. , Chen Y. , Zhang H. , 2020. Local buckling evolution mechanism of a buried steel pipe under fault movements. Energy Science & Engineering, 8(2): 412—425. Zhang L. S. , Zhao X. B. , Yan X. Z. , et al. , 2016. A new finite element model of buried steel pipelines crossing strike-slip faults considering equivalent boundary springs. Engineering Structures, 123: 30—44. doi: 10.1016/j.engstruct.2016.05.042 -

下载:

下载: