Numerical Analysis of the Mechanical Performance of the CFST Column-RC Beam Joint Connected by the Steel Plate-Stud at the Plastic Hinge Zone of the Beam End

-

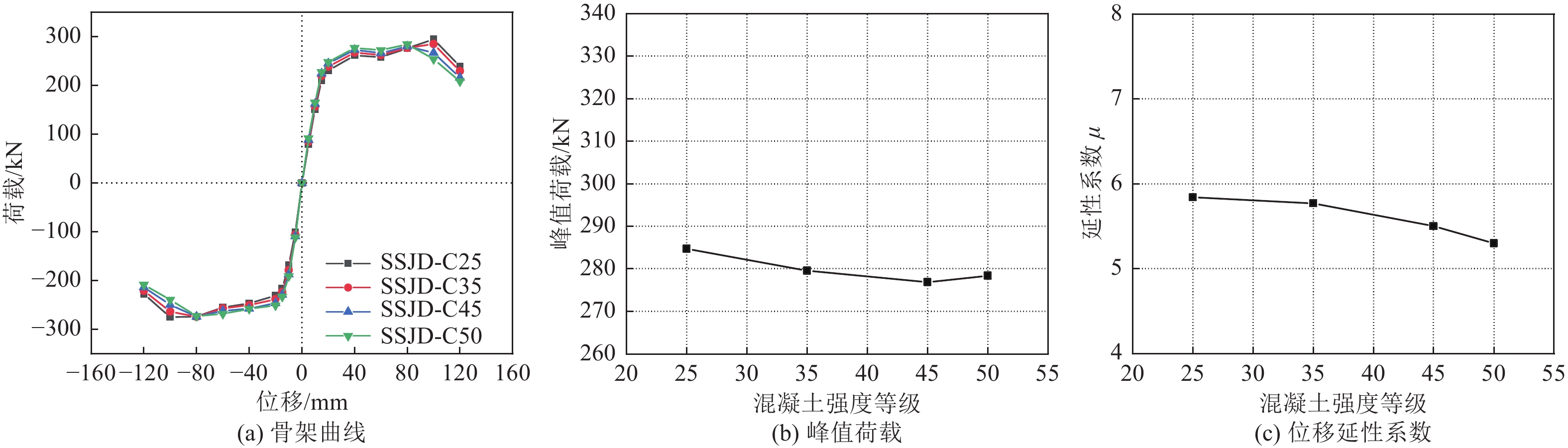

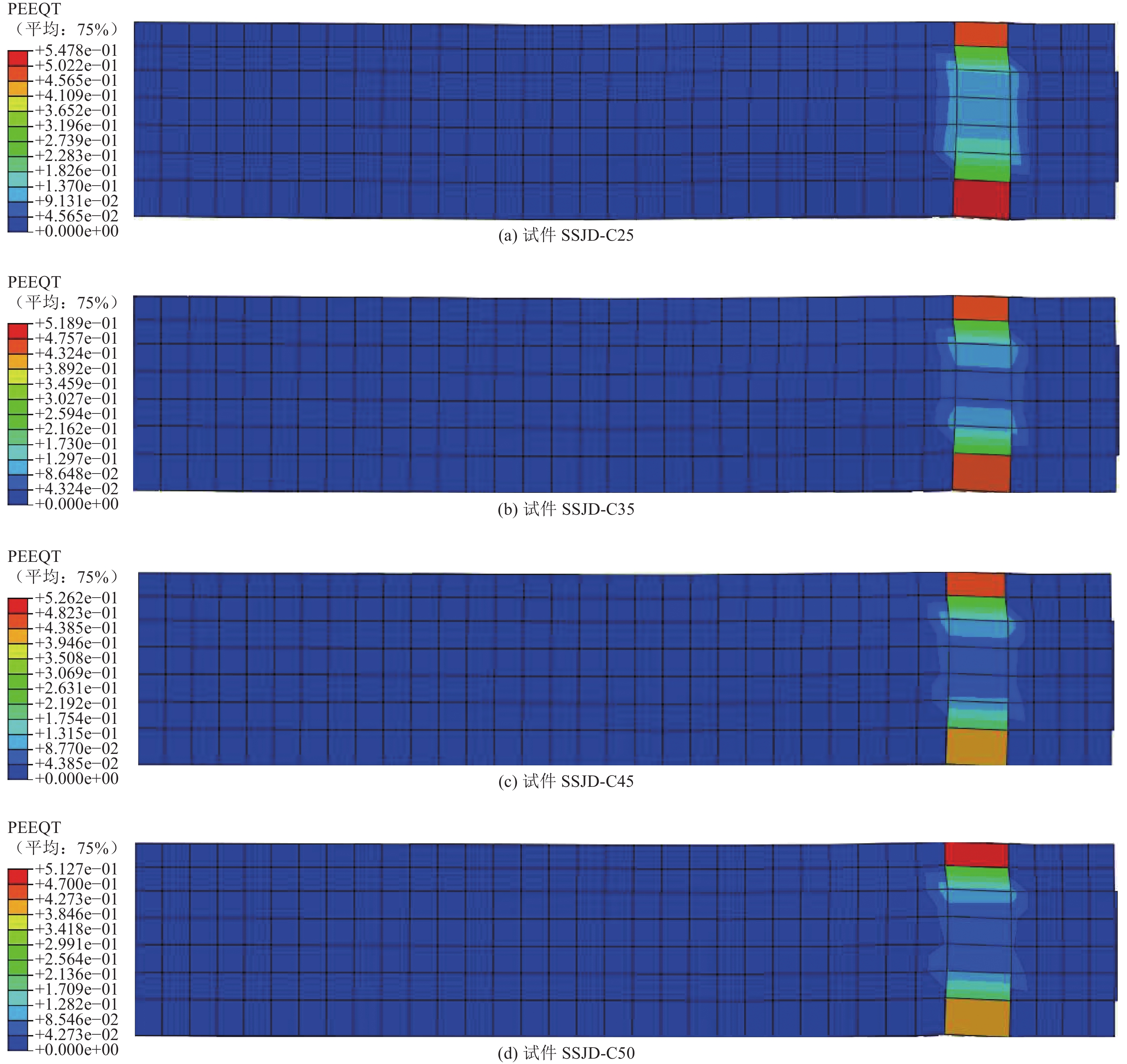

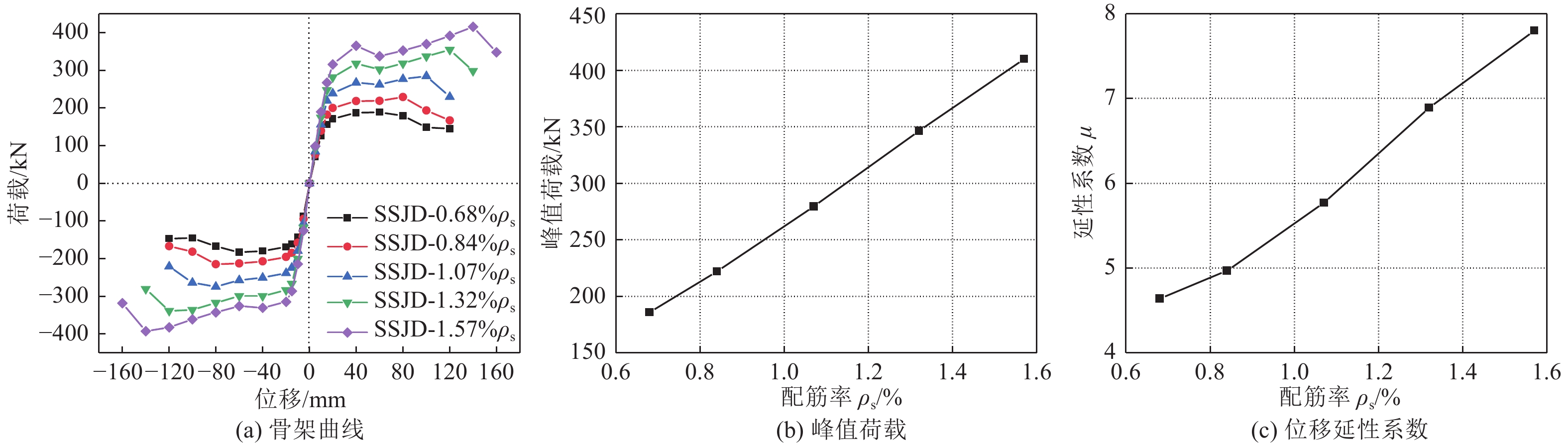

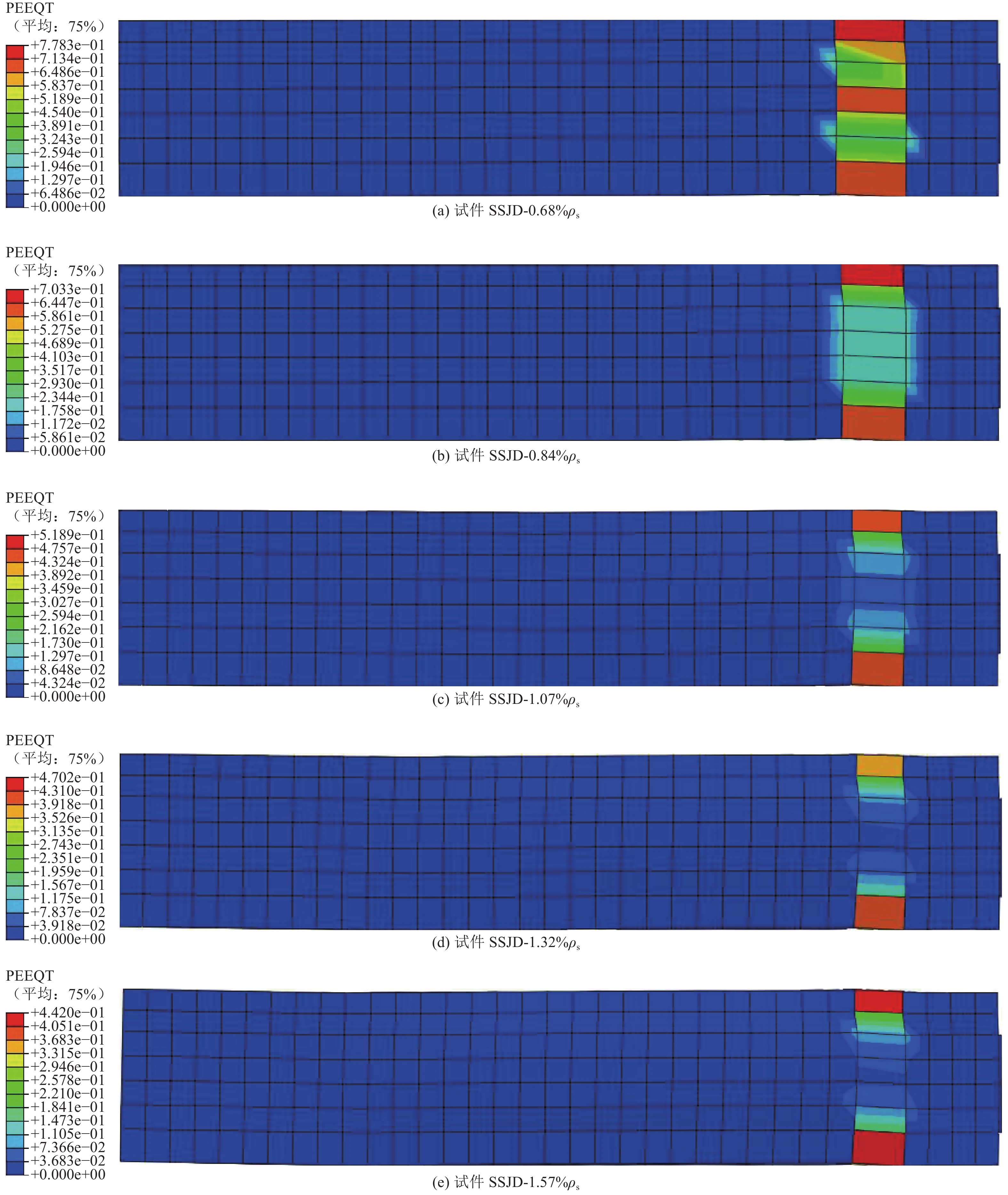

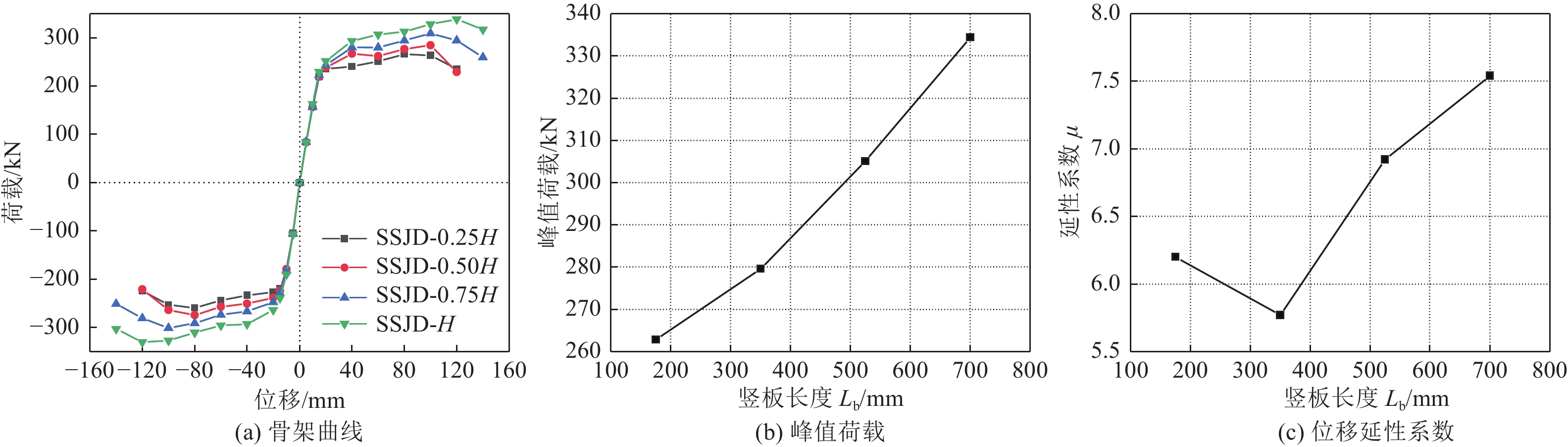

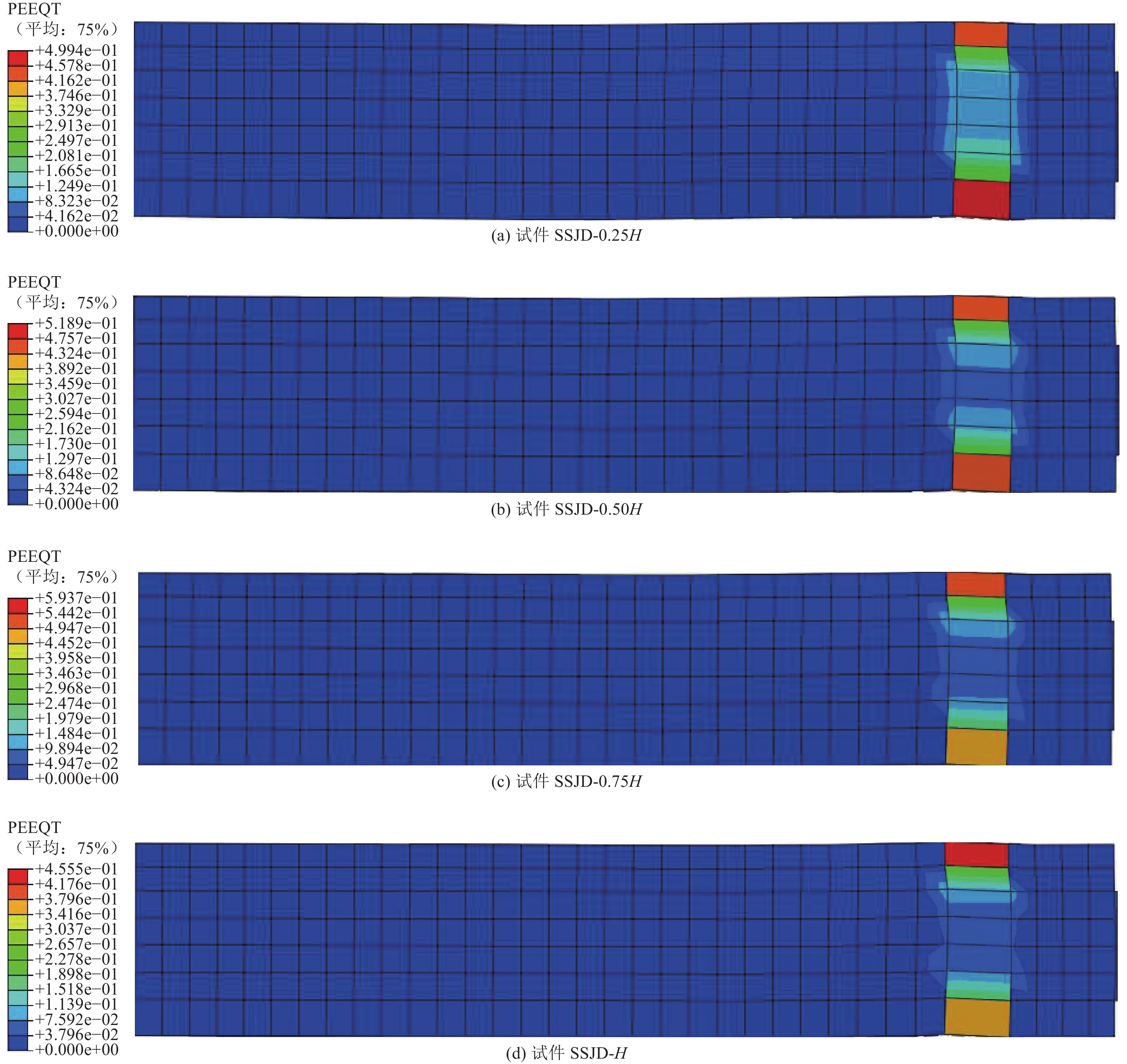

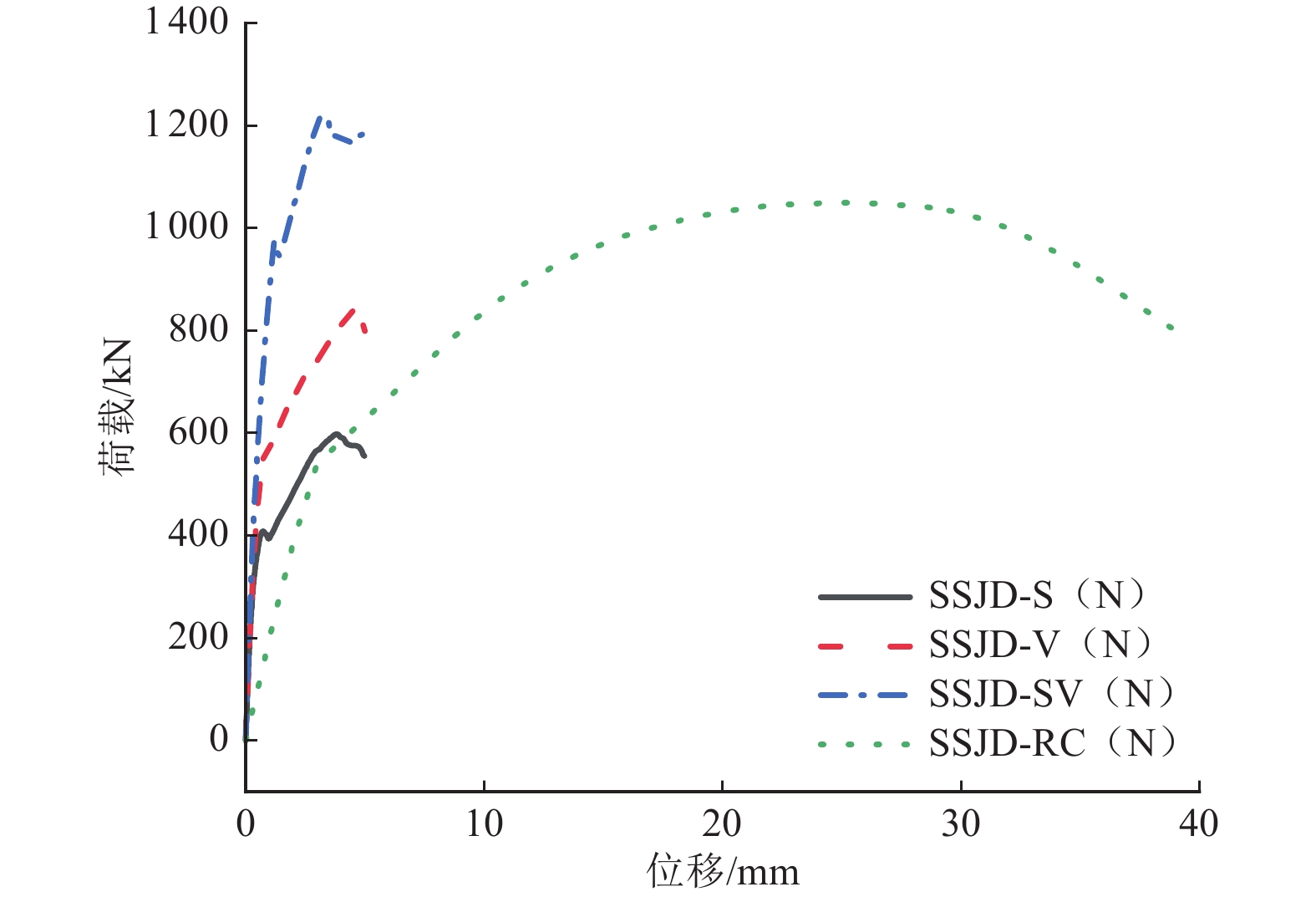

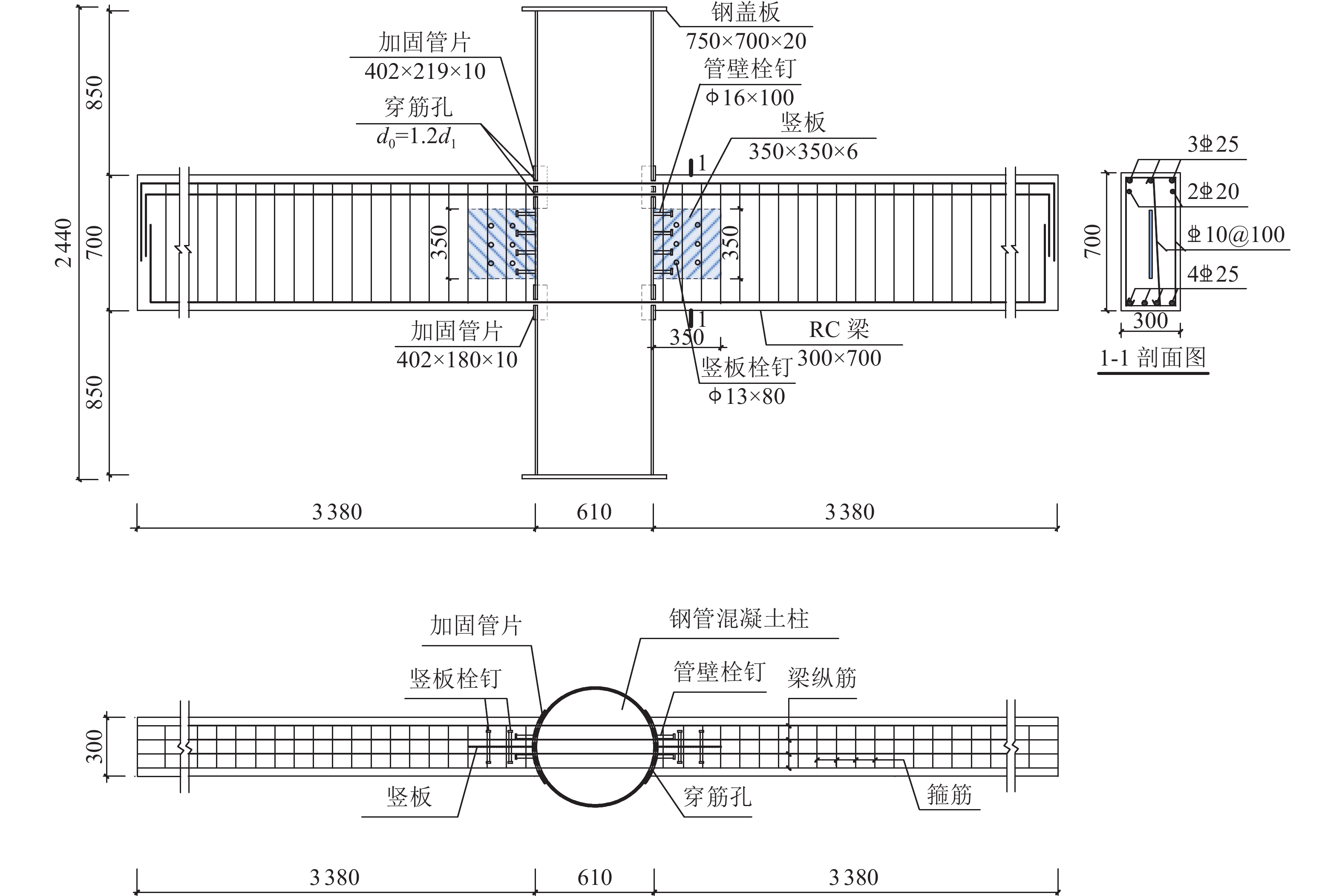

摘要: 建立竖板-栓钉连接钢管混凝土(CFST)柱-钢筋混凝土(RC)梁节点试件(SSJD)拟静力加载试验有限元模型,并在节点损伤情况、梁端荷载-位移曲线等数值模拟结果与试验结果吻合较好的基础上,进一步开展了RC梁混凝土强度、配筋率ρs和连接竖板长度Lb及界面连接情况等对CFST柱-RC梁节点梁端塑性铰区域力学性能的影响。研究结果表明,RC梁混凝土强度对试件SSJD塑性铰区域受力性能的影响较小;适筋范围内RC梁配筋率增加可适当提高试件SSJD承载力和延性;随着连接竖板长度的增加,梁端塑性铰区域外移,梁破坏荷载增大;本研究给出的RC梁与CFST柱之间的界面抗剪承载力模拟值与计算值吻合较好,可用于界面抗剪设计。

-

关键词:

- CFST柱-RC梁节点 /

- 塑性铰 /

- 界面抗剪承载力 /

- 数值模拟 /

- 参数分析

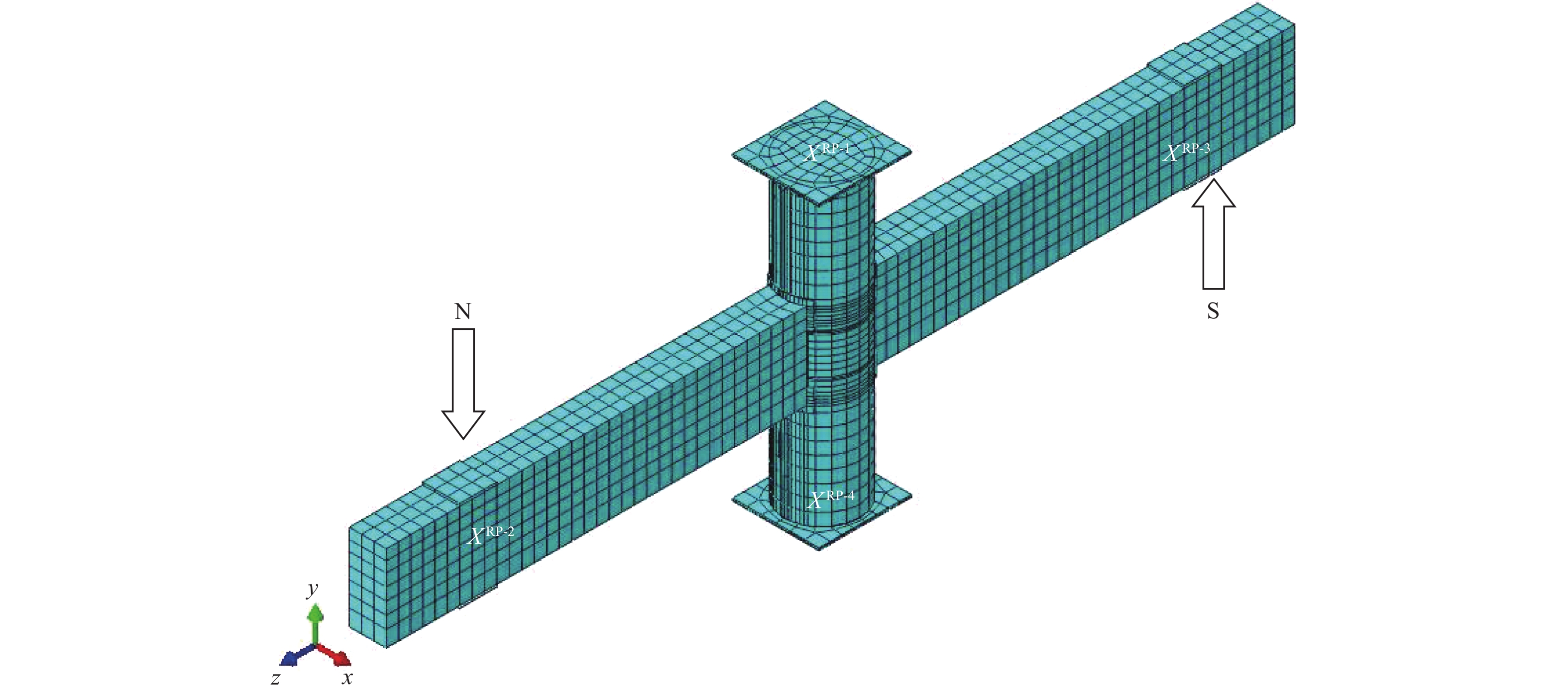

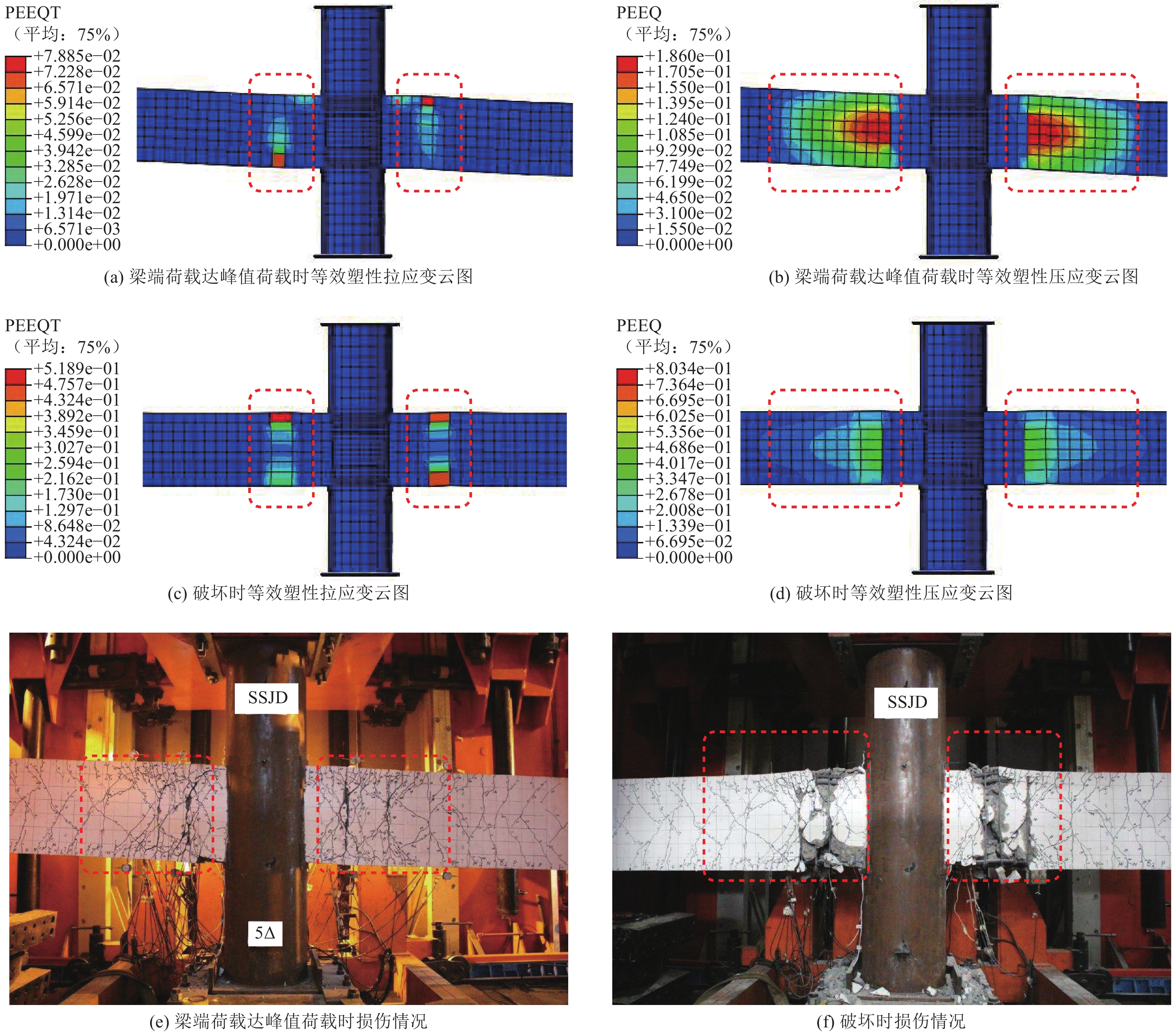

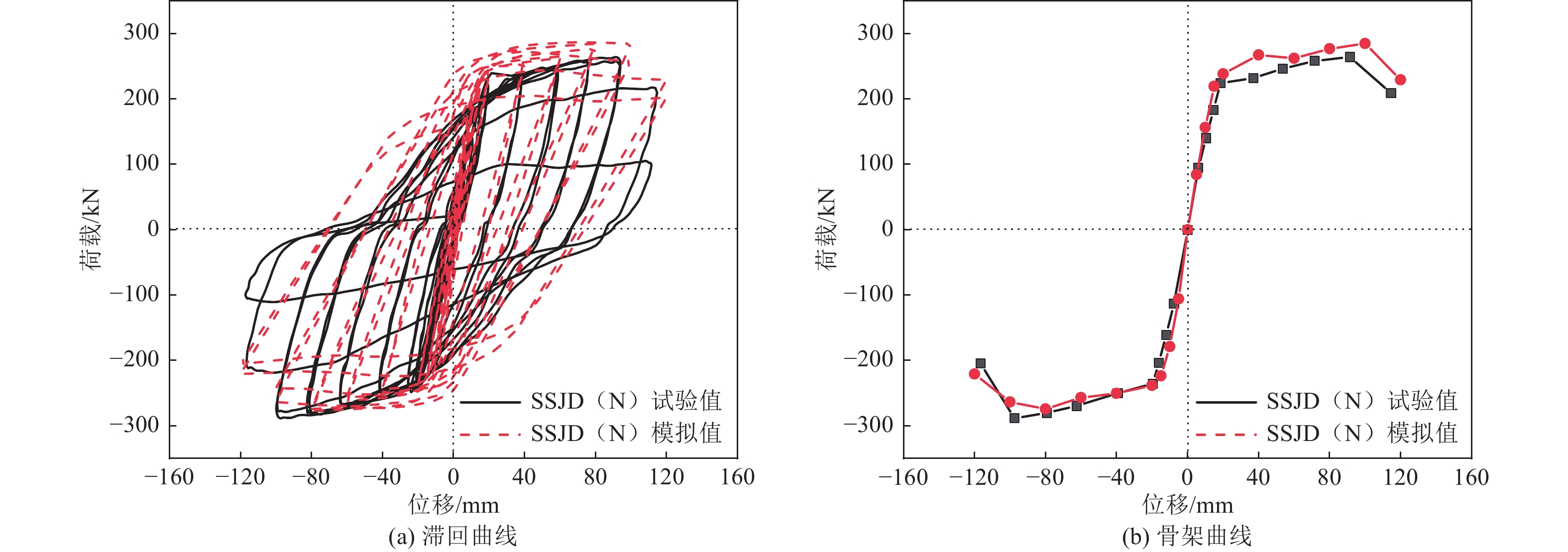

Abstract: The finite element model of the joint specimens (SSJD) of the concrete-filled steel tube (CFST) column-reinforced concrete (RC) beam connected by the vertical plate-stud connection is established, for which the joint specimens are subjected to the pseudo-static loading experiment. On the basis that the numerical simulation results of the joint damage condition and load-displacement curves are in good agreement with the test results, the further numerical simulation analysis is carried out on the influence of the mechanical properties of the plastic hinge zone at the beam end of the joint connected by the steel plate-stud, according to the changes of the RC beam concrete strength, the reinforcement ratio ρs , the length Lb of the connecting vertical plate, and the different connection conditions of the interface. The results show that the change of RC beam concrete strength has little effect on the mechanical performance of the SSJD plastic hinge zone of the specimen; the increase in ρs of the RC beam within the range of suitable reinforcement can appropriately improve the bearing capacity and ductility of the SSJD specimen; with the increase of Lb, the plastic hinge area at the beam end moves outward, and the beam failure load increases. The calculated value of the interface shear capacity is in good agreement with the simulated value, which can be used for interface shear design. -

表 1 混凝土力学性能参数

Table 1. Mechanical property parameters of concrete

混凝土强度等级 弹性模量/MPa 抗压强度/MPa C35 3.34×104 29.2 C50 3.78×104 52.1 表 2 钢材力学性能参数

Table 2. Mechanical property parameters of steel

钢材 直径或厚度/mm 级别 弹性模量/MPa 屈服强度/MPa 极限强度/MPa 钢管 10 Q345 2.0×105 423 569 钢板 6 Q345 2.0×105 409 539 钢筋 10 HRB400 1.8×105 413 607 20 HRB400 2.0×105 430 559 25 HRB400 2.0×105 436 608 栓钉 13 ML15 2.06×105 339 456 16 ML15 2.06×105 340 457 表 3 分析参数设置与主要结果

Table 3. Analysis parameter settings and main results

有限元

模型混凝土

强度等级梁截面

纵筋配筋率

ρs/%连接竖板长度

$ {L_{\rm{b}}} $/mm连接情况 剪跨比 峰值荷载

Pu/kN位移延性系数

μSSJD-0.5H C35 上侧3

1.07/1.00 350 试验模型 4.00 279.59 5.77 SSJD-C25 C25 上侧3

1.07/1.00 350 试验模型 4.00 284.73 5.84 SSJD-C45 C45 上侧3

1.07/1.00 350 试验模型 4.00 276.88 5.50 SSJD-C50 C50 上侧3

1.07/1.00 350 试验模型 4.00 278.40 5.30 SSJD-0.68%ρs C35 上侧3

0.68/0.64 350 试验模型 4.00 185.88 4.64 SSJD-0.84%ρs C35 上侧3

0.84/0.77 350 试验模型 4.00 221.98 4.97 SSJD-1.32%ρs C35 上侧3

1.32/1.25 350 试验模型 4.00 346.36 6.89 SSJD-1.57%ρs C35 上侧3

1.57/1.43 350 试验模型 4.00 409.89 7.80 SSJD-0.25H C35 上侧3

1.07/1.00 175 试验模型 4.00 262.83 6.20 SSJD-0.75H C35 上侧3

1.07/1.00 525 试验模型 4.00 305.11 6.92 SSJD-H C35 上侧3

1.07/1.00 700 试验模型 4.00 334.37 7.54 SSJD-S C35 上侧3

1.07/1.00 0 仅设置管壁栓钉 0.29 597.88 — SSJD-V C35 上侧3

1.07/1.00 350 仅设置竖板 0.29 843.86 — SSJD-SV C35 上侧3

1.07/1.00 350 试验模型 0.29 1 217.57 — SSJD-RC C35 上侧3

1.07/1.00 350 试验模型 1.50 1 049.34 — 表 4 界面抗剪承载力模拟值与计算值

Table 4. Simulated and calculated interface shear capacity

有限元模型 界面抗剪承载力模拟值VF/kN 界面抗剪承载力计算值VC/kN 模拟值/计算值 SSJD-S 597.88 546.89 1.09 SSJD-V 843.86 858.90 0.98 SSJD-SV 1 217.57 1 301.42 0.94 SSJD-RC 1 049.34 981.92 1.07 -

[1] 冯帅克, 郭正兴, 倪路瑶等, 2021. 钢管混凝土柱-混合梁节点抗震性能试验研究. 浙江大学学报(工学版), 55(8): 1464—1472Feng S. K. , Guo Z. X. , Ni L. Y. , et al. , 2021. Experimental study on seismic performance of joints connecting concrete-filled steel tube columns and hybrid beams. Journal of Zhejiang University (Engineering Science), 55(8): 1464—1472. (in Chinese) [2] 李振宝, 杨成苗, 刘春阳, 2019. 梁端局部无粘结钢筋混凝土梁抗弯承载力研究. 震灾防御技术, 14(3): 477—488 doi: 10.11899/zzfy20190302Li Z. B. , Yang C. M. , Liu C. Y. , 2019. Study on the flexural bearing capacity of partially unbonded reinforced concrete beams at beam ends. Technology for Earthquake Disaster Prevention, 14(3): 477—488. (in Chinese) doi: 10.11899/zzfy20190302 [3] 刘威, 2005. 钢管混凝土局部受压时的工作机理研究. 福州: 福州大学.Liu W. , 2005. Research on mechanism of concrete-filled steel tubes subjected to local compression. Fuzhou: Fuzhou University. (in Chinese) [4] 马哲昊, 张纪刚, 梁海志等, 2021. 装配式人工消能塑性铰节点抗震性能试验研究. 建筑结构学报, 42(7): 154—163Ma Z. H. , Zhang J. G. , Liang H. Z. , et al. , 2021. Experimental study on seismic performance of prefabricated joint based on artificial dissipative plastic hinge. Journal of Building Structures, 42(7): 154—163. (in Chinese) [5] 聂建国, 秦凯, 刘嵘, 2006. 方钢管混凝土柱与钢-混凝土组合梁连接的内隔板式节点的抗震性能试验研究. 建筑结构学报, 27(4): 1—9 doi: 10.3321/j.issn:1000-6869.2006.04.001Nie J. G. , Qin K. , Liu R. , 2006. Experimental study on seismic behavior of connections composed of concrete-filled square steel tubular columns and steel-concrete composite beams with interior diaphragms. Journal of Building Structures, 27(4): 1—9. (in Chinese) doi: 10.3321/j.issn:1000-6869.2006.04.001 [6] 时建新, 邹昀, 王城泉等, 2021. 外包波纹钢-混凝土组合梁与波纹钢-钢管混凝土柱节点抗震性能研究. 实验力学, 36(3): 367—377 doi: 10.7520/1001-4888-20-134Shi J. X. , Zou Y. , Wang C. Q. , et al. , 2021. Study on seismic behaviours of corrugated steel web-encased concrete composite beam to corrugated plate-square concrete filled steel tubular column joint. Journal of Experimental Mechanics, 36(3): 367—377. (in Chinese) doi: 10.7520/1001-4888-20-134 [7] 宋毛毛, 2013. 基于ABAQUS的钢-混凝土组合梁钢框架抗震性能研究. 哈尔滨: 哈尔滨工业大学.Song M. M. , 2013. Study on the seismic behavior of steel frame with steel-concrete composite beams based on ABAQUS. Harbin: Harbin Institute of Technology. (in Chinese) [8] 苏佶智, 邢国华, 马煜东等, 2018. 反复荷载作用下锈蚀钢筋混凝土柱力学性能研究. 震灾防御技术, 13(3): 512—523 doi: 10.11899/zzfy20180303Su J. Z. , Xing G. H. , Ma Y. D. , et al. , 2018. Study on mechanical properties of corroded reinforced concrete frame columns under cyclic load. Technology for Earthquake Disaster Prevention, 13(3): 512—523. (in Chinese) doi: 10.11899/zzfy20180303 [9] 王燕, 李庆刚, 董建莉等, 2016. 梁端翼缘削弱型节点空间钢框架抗震性能试验研究. 建筑结构学报, 37(S1): 192—200Wang Y. , Li Q. G. , Dong J. L. , et al. , 2016. Experimental study on seismic behavior of space steel frame with reduced beam section connections. Journal of Building Structures, 37(S1): 192—200. (in Chinese) [10] 王作虎, 杜修力, 邓宗才, 2010. 不同加固方式对混凝土梁柱节点抗震性能的影响. 震灾防御技术, 5(1): 1—8 doi: 10.3969/j.issn.1673-5722.2010.01.001Wang Z. H. , Du X. L. , Deng Z. C. , 2010. An experimental study on the seismic behavior of beam-column joints strengthened with AFRP sheets. Technology for Earthquake Disaster Prevention, 5(1): 1—8. (in Chinese) doi: 10.3969/j.issn.1673-5722.2010.01.001 [11] 尧国皇, 陈宜言, 林松, 2010. 新型钢管混凝土柱-钢筋混凝土梁节点的有限元分析. 特种结构, 27(6): 34—38 doi: 10.3969/j.issn.1001-3598.2010.06.009Yao G. H. , Chen Y. Y. , Lin S. , 2010. FEM analysis on seismic behavior of a new-type joint of CFST column-RC beam. Special Structures, 27(6): 34—38. (in Chinese) doi: 10.3969/j.issn.1001-3598.2010.06.009 [12] 姚玉生, 1981. 抗震节点中梁端塑性铰位置的研究与探讨. 建筑结构, 10(5): 5—11Yao Y. S. , 1981. Research and discussion on the position of the plastic hinge at the beam end in the seismic joint. Building Structure, 10(5): 5—11. (in Chinese) [13] 中华人民共和国住房和城乡建设部, 2015. GB 50010—2010(2015年版) 混凝土结构设计规范. 北京: 中国建筑工业出版社.Ministry of Housing and Urban-Rural Development of the People's Republic of China, 2011. GB 50010-2010 Code for design of concrete structures. Beijing: China Architecture & Building Press. (in Chinese) [14] 中华人民共和国住房和城乡建设部, 2014. GB 50917-2013 钢-混凝土组合桥梁设计规范. 北京: 中国建筑工业出版社.Ministry of Housing and Urban-Rural Development of the People's Republic of China, 2014. GB 50917-2013 Code for design of steel and concrete composite bridges. Beijing: China Architecture & Building Press. (in Chinese) [15] 中华人民共和国住房和城乡建设部, 2015. JGJ/T 101-2015 建筑抗震试验规程. 北京: 中国建筑工业出版社.Ministry of Housing and Urban-Rural Development of the People's Republic of China, 2015. JGJ/T 101-2015 Specification for seismic test of buildings. Beijing: China Architecture & Building Press. (in Chinese) [16] Li Z. B. , Liu Y. S. , Ma H. , et al. , 2019. Seismic performance of full-scale joints composed by concrete-filled steel tube column and reinforced concrete beam with steel plate-stud connections. Advances in Civil Engineering, 2019: 5476909. [17] Liu Q. , Chen S. H. , Lin W. , et al. , 2019. Experimental study on novel energy-dissipating prefabricated beam-column joints. Advances in Civil Engineering, 2019: 8151087. [18] Park C. H. , Lee C. H. , Park H. G. , et al. , 2011. Cyclic seismic testing of cruciform concrete-filled U-shape steel beam-to-H column composite connections. Journal of Korean Society of Steel Construction, 23(4): 503—514. -

下载:

下载: