Performance Test and Comparison of MEMS Accelerometers for Vibration Monitoring of High-Rise Building

-

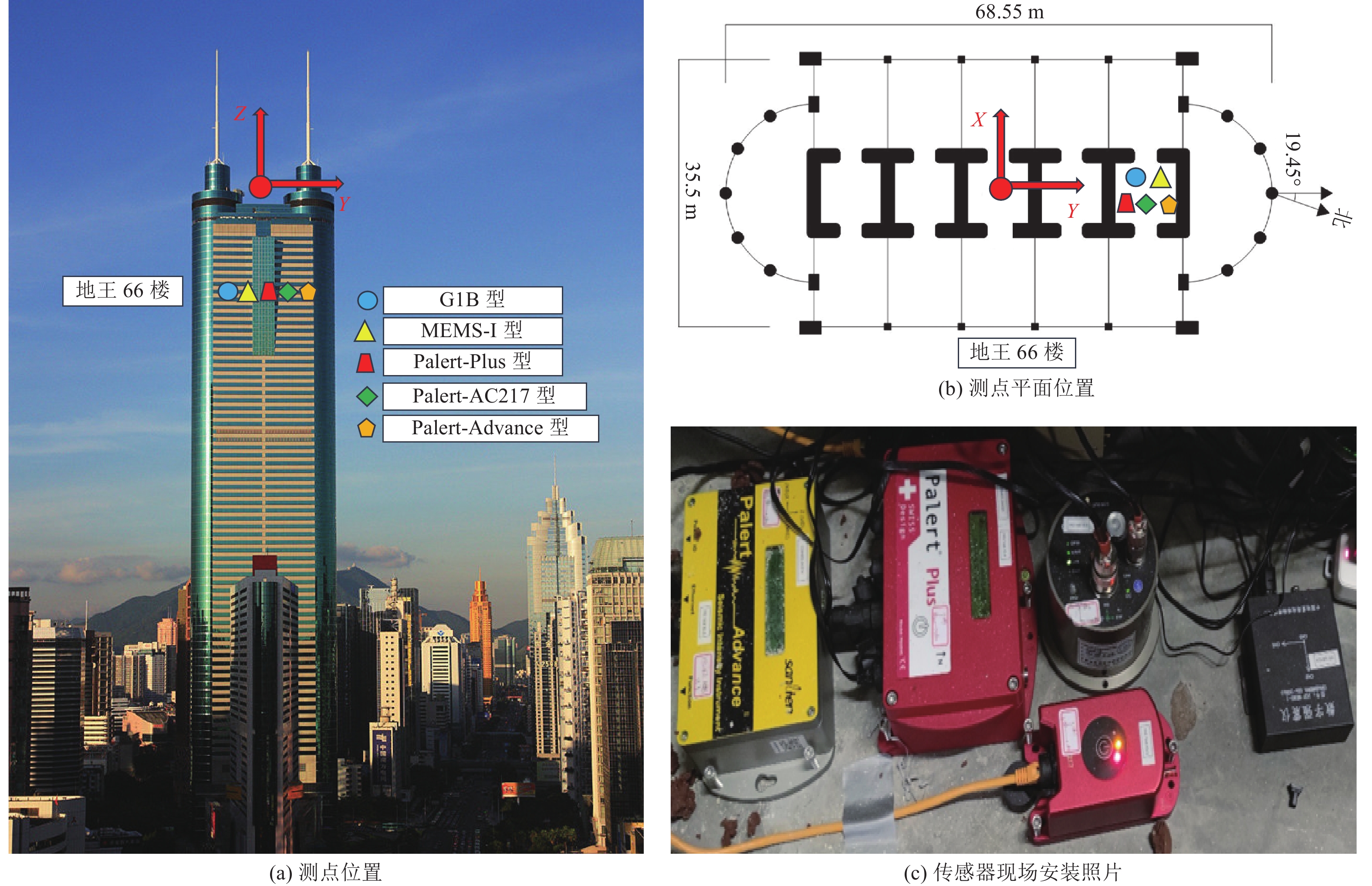

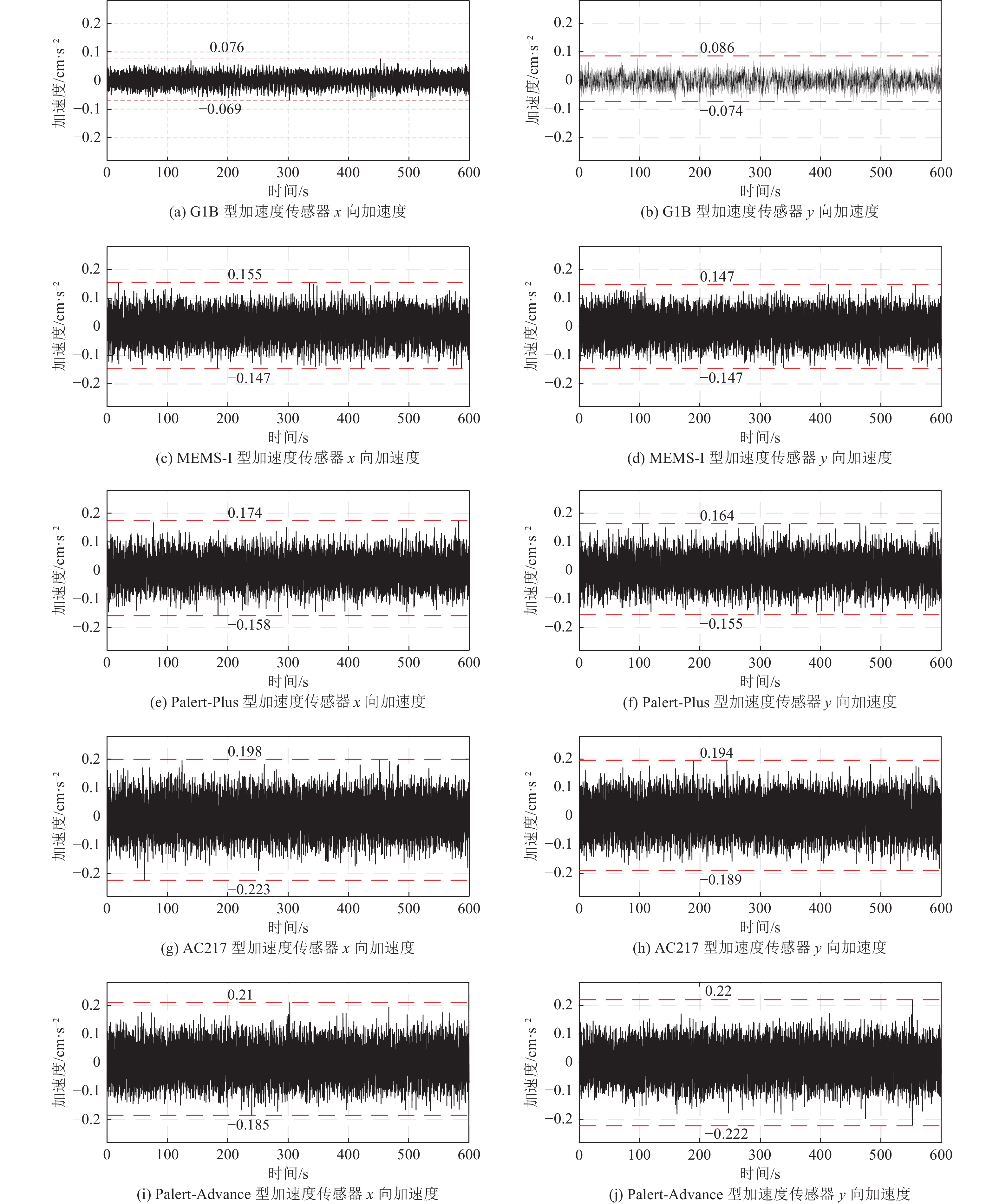

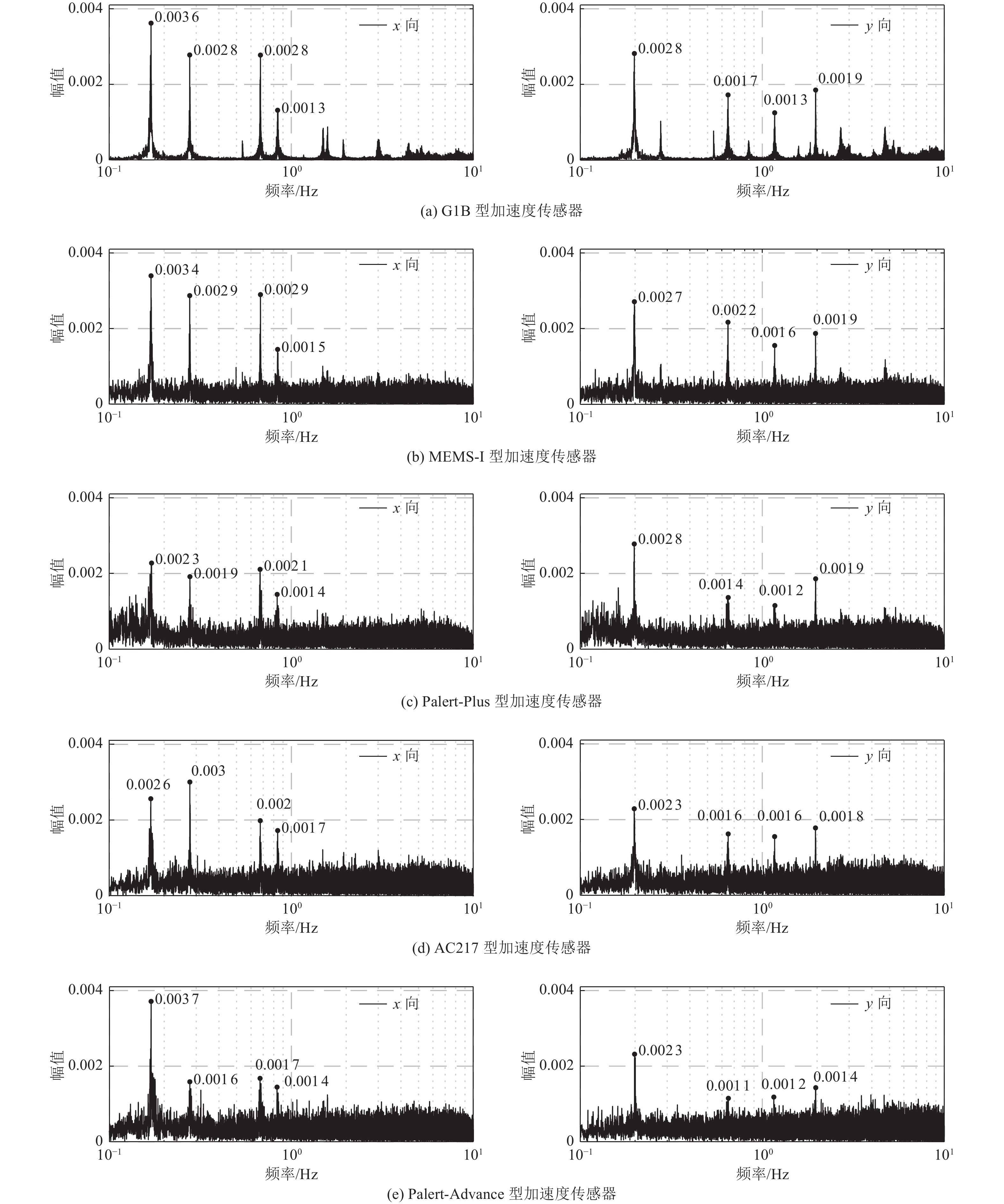

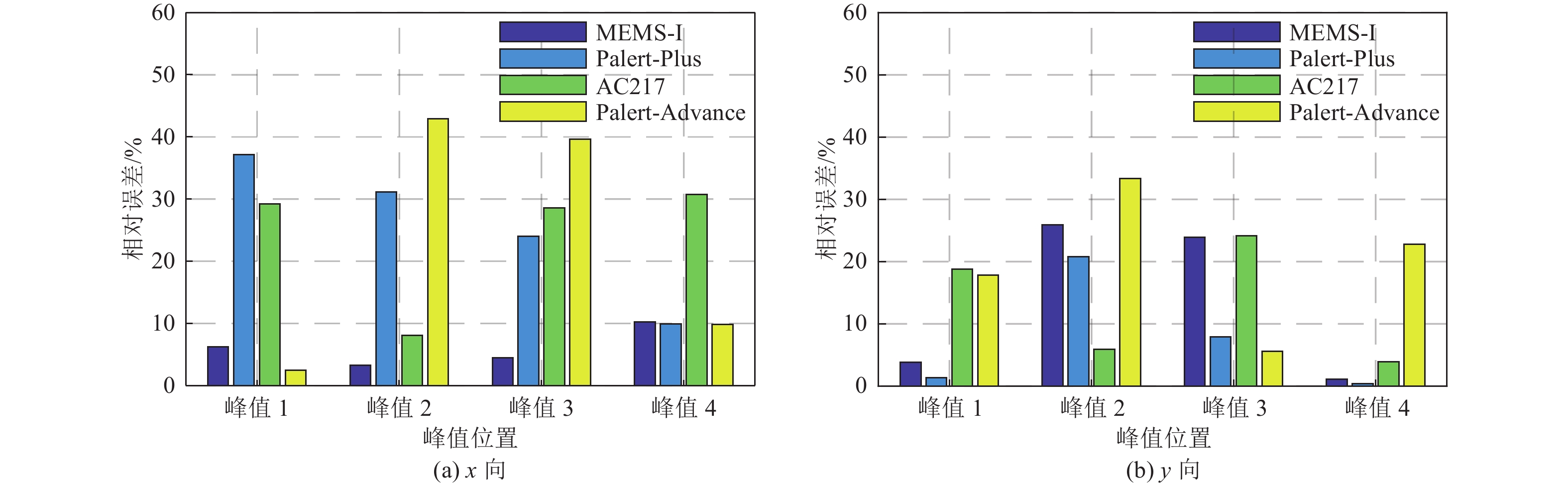

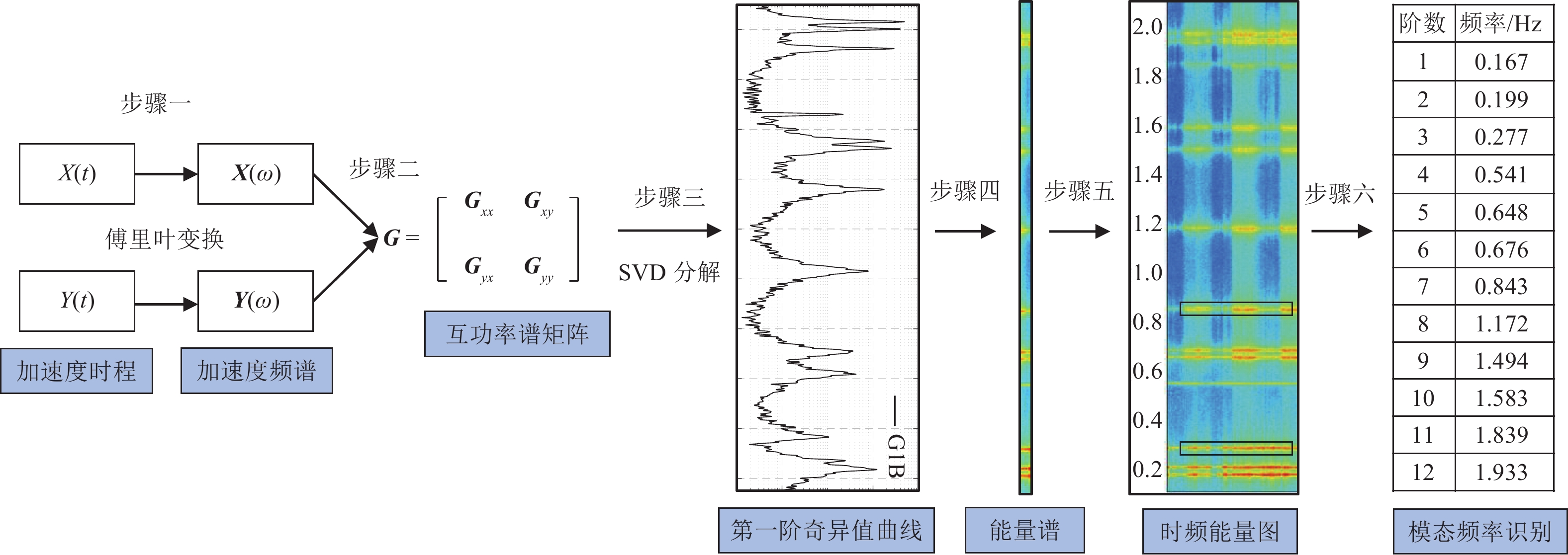

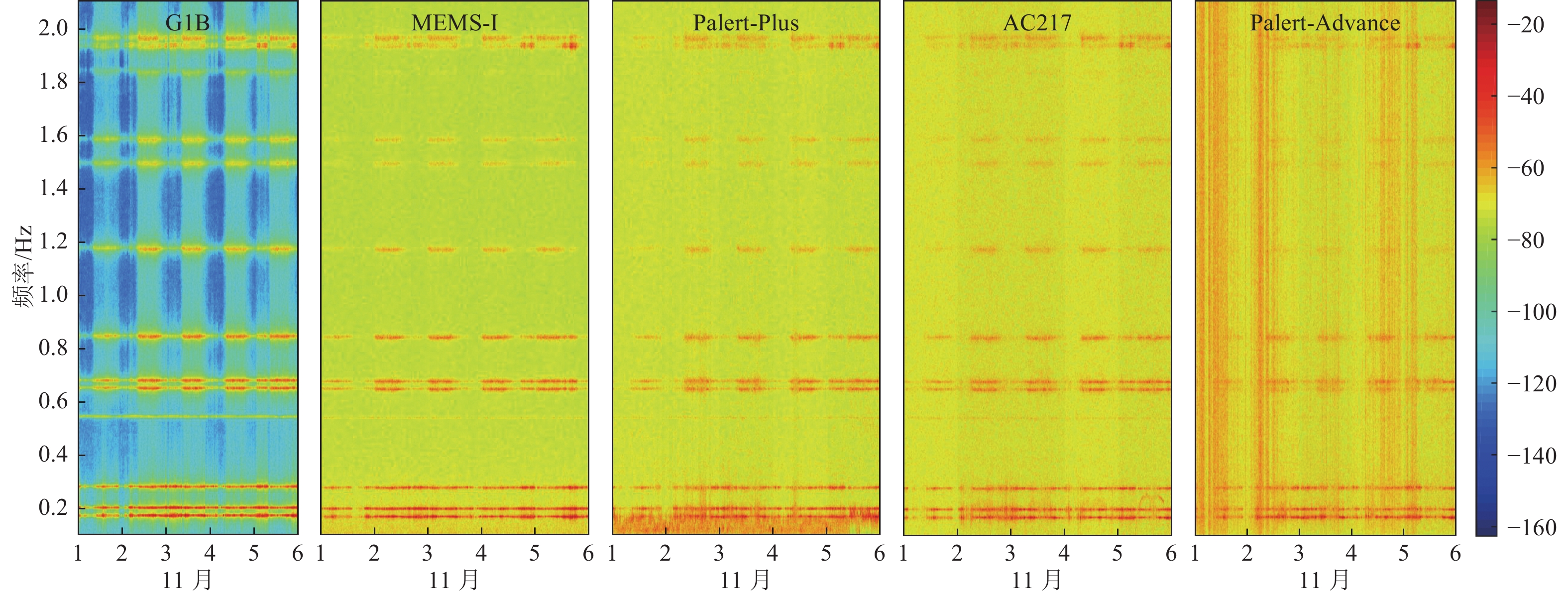

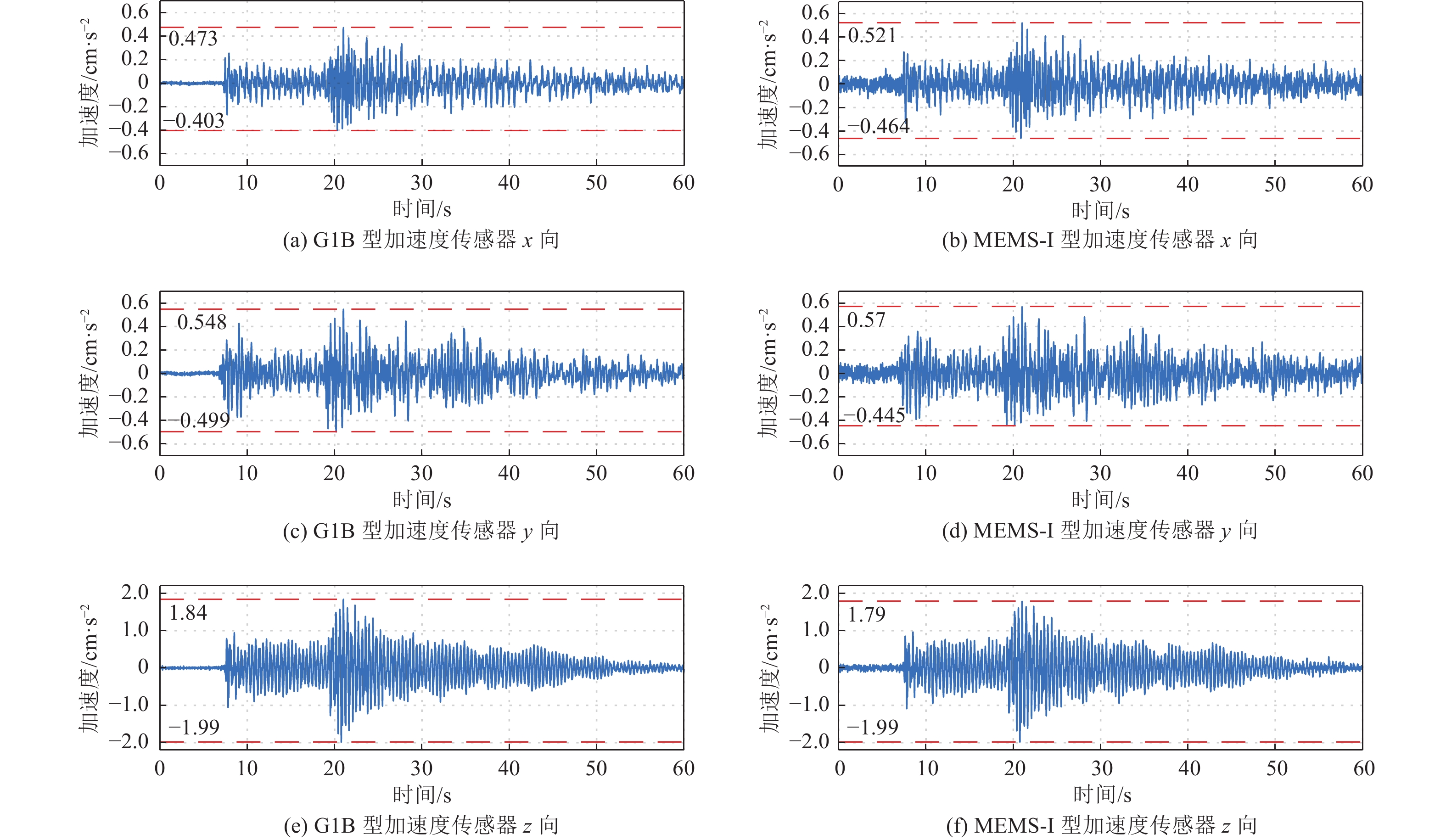

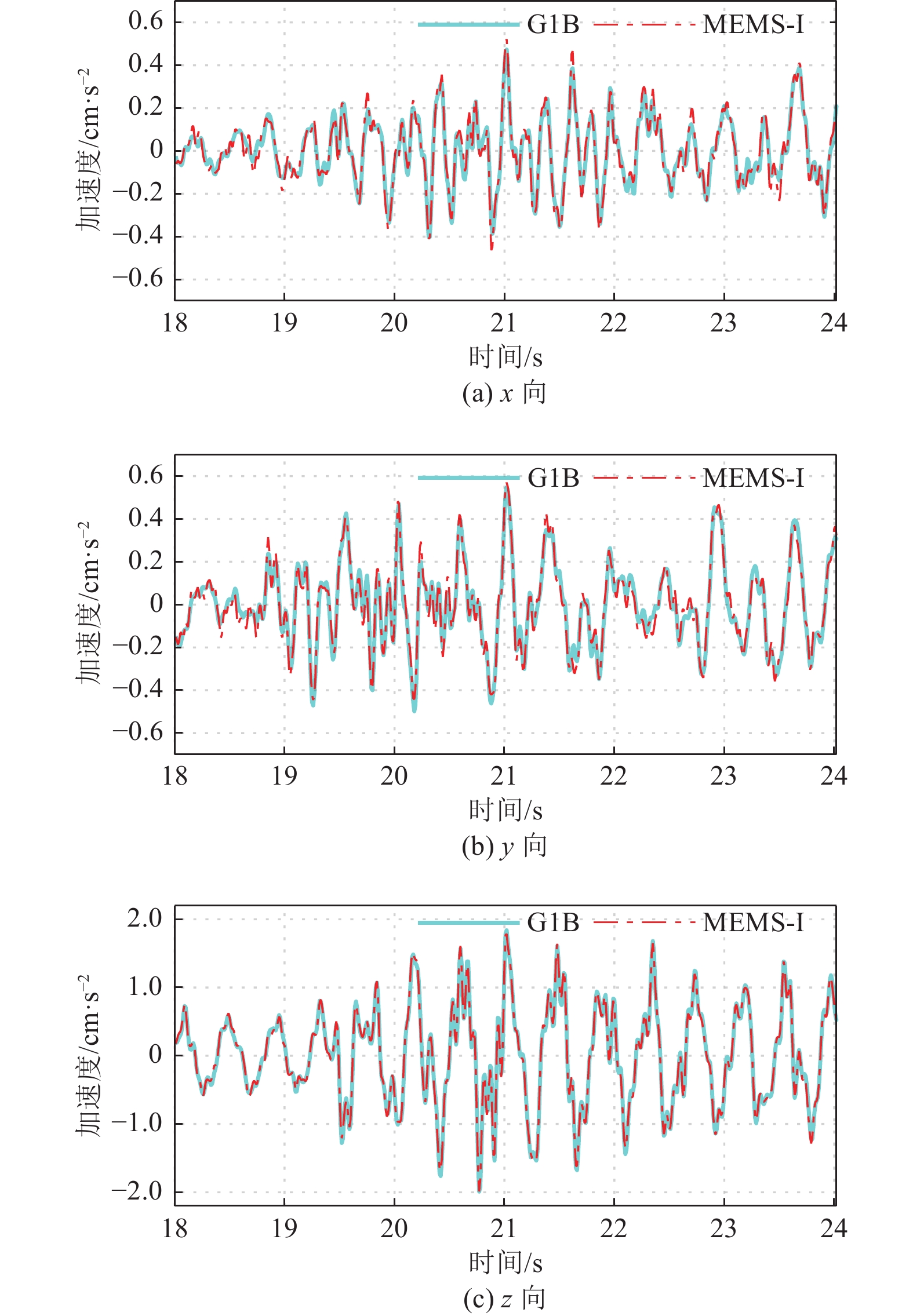

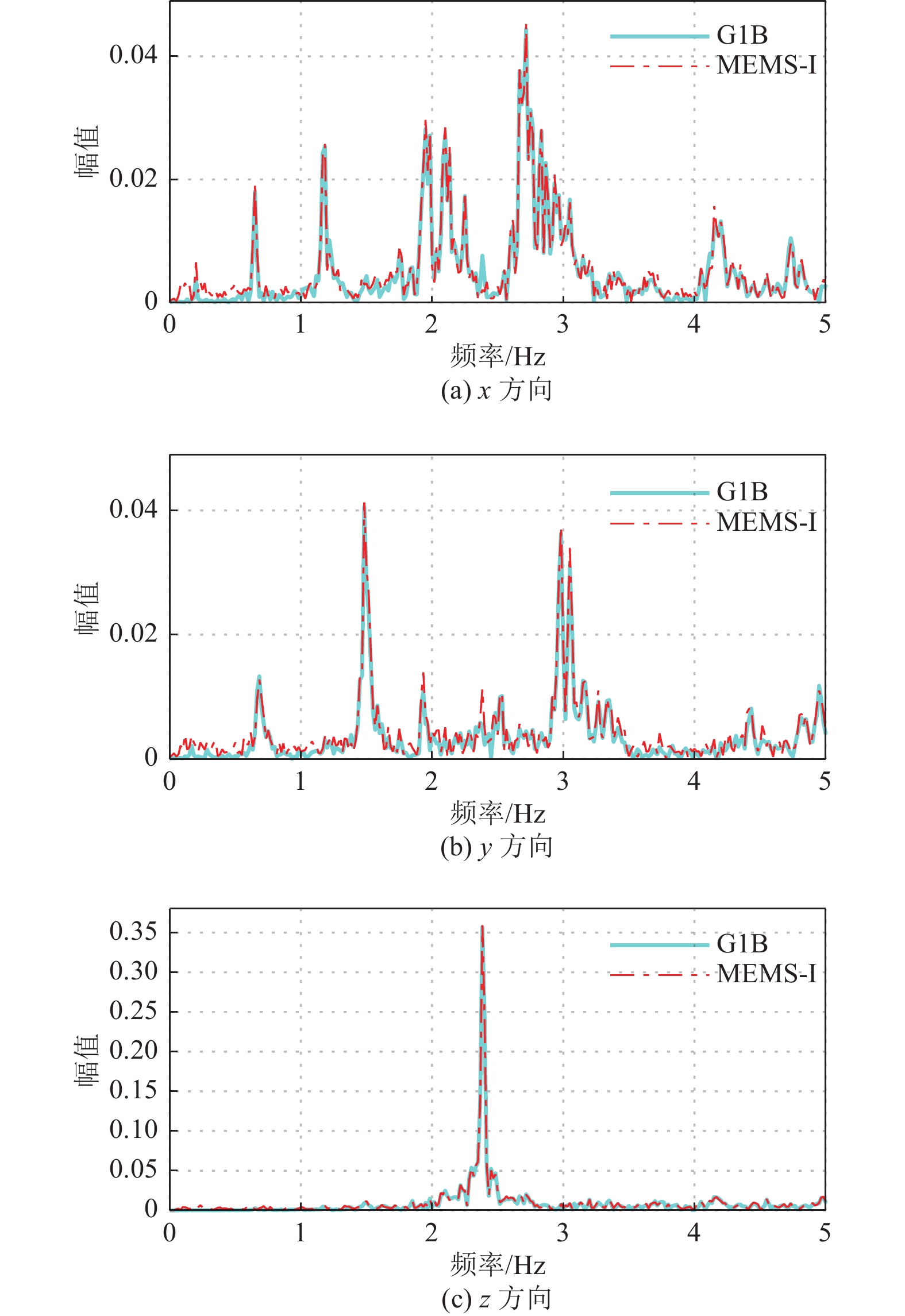

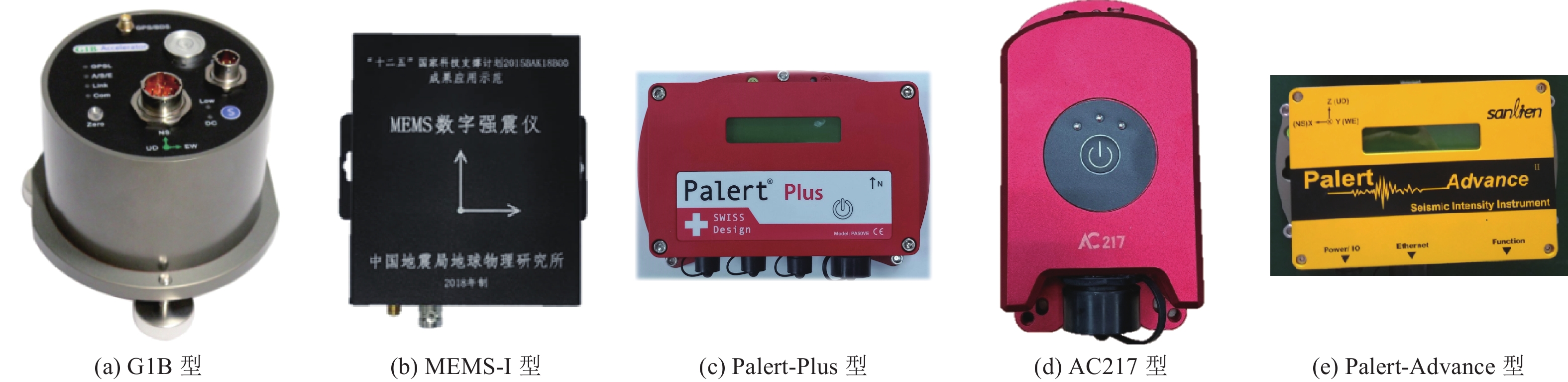

摘要: 为开展MEMS型加速度传感器在超高层建筑振动监测应用中的性能对比测试,选取4种不同类型MEMS型加速度传感器与G1B型力平衡式加速度传感器,将其安装在地王大厦相同测点,对MEMS型、G1B型加速度传感器记录的结构环境振动数据进行时程、频谱和模态频率对比分析,并对其记录的结构地震响应进行时域及频域对比。研究结果表明,不同类型MEMS型加速度传感器仪器噪声均大于G1B型加速度传感器,其中MEMS-I型加速度传感器噪声水平相对较小,与G1B型加速度传感器模态频率识别结果及地震响应监测数据吻合较好,验证了MEMS-I型加速度传感器可较准确地记录到结构强振动响应,适用于超高层建筑日常结构振动监测。

-

关键词:

- 超高层建筑 /

- MEMS型加速度传感器 /

- 结构振动 /

- 模态频率 /

- 性能测试

Abstract: Field test was carried out in this study to evaluate and compare the performance of MEMS accelerometers for the vibration monitoring of high-rise buildings. Four MEMS accelerometers of different types and a G1B-type force-balanced accelerometer were selected and installed on the same location in Diwang Building for testing. The ambient vibration of the building recorded by the MEMS accelerometers was compared with the G1B accelerometer in terms of time history, Fourier spectrum and modal frequency identification. In addition, the earthquake-induced structural responses of the high-rise building recorded by MEMS-I type accelerometer was compared with those recorded by the G1B accelerometer in both time and frequency domain. The test results show that the noise levels of the four MEMS accelerometers are all higher than that of the G1B accelerometer. Among them, the MEMS-I type accelerometer has a relatively lower level of sensor noise and achieves a good match with the G1B accelerometer in terms of modal frequency identification and earthquake-induced structural vibration measurement, which proves that the MEMS-I type accelerometer can record the strong structural vibration with acceptable accuracy and is feasible for daily vibration monitoring of the high-rise buildings.-

Key words:

- High-rise building /

- MEMS accelerometer /

- Structural vibration /

- Modal frequency /

- Field test

-

表 1 传感器技术参数对比

Table 1. Comparison of parameters of different sensors

传感器类型 测量范围/g 频响范围/Hz 动态范围/dB 噪声均方根/(${\text{μ}}{{\rm{g}}}/\sqrt{\rm{H}\rm{z} }$) 功耗/W G1B ±3 0~100 >130 0.5 3 MEMS-I ±2.5 0~80 >90 10.0 <2 Palert-Plus ±2 0~100 >100 25.0 2 AC217 ±4 0~100 >104 25.0 <1 Palert-Advance ±2 0~100 >90 25.0 3 表 2 不同传感器

$x $ 、$y $ 向加速度时程的均方根Table 2. RMS of acceleration measurement of different sensors in

${\boldsymbol{x}} $ and${\boldsymbol{y}} $ directions方向 传感器类型 G1B型 MEMS-I型 Palert-Plus型 AC217型 Palert-Advance型 x 0.015 0.037 0.040 0.048 0.052 y 0.018 0.038 0.042 0.048 0.059 表 3 G1B型加速度传感器实测自振频率识别结果与已有研究结果对比

Table 3. Comparison of modal frequency identification results between G1B accelerometer and references

阶数 G1B型加速度传感器

实测自振频率/Hz郭西锐等(2016)

自振频率/Hz与郭西锐等(2016)

研究的相对误差/%徐枫等(2014)

自振频率/Hz与徐枫等(2014)

研究的相对误差/%1 0.168 6 0.169 7 0.65 0.168 9 0.18 2 0.198 4 0.198 9 0.25 0.199 3 0.45 3 0.276 9 0.277 8 0.32 0.278 2 0.47 4 0.540 2 0.539 4 0.15 0.538 3 0.35 5 0.648 5 0.649 4 0.14 0.642 2 0.98 6 0.676 7 0.677 2 0.07 — — 7 0.841 5 0.844 7 0.38 0.839 3 0.26 8 1.169 0 1.179 0 0.85 1.168 0 0.09 9 1.498 0 1.498 0 0.00 — — 10 1.582 0 1.591 0 0.57 — — 11 1.834 0 1.844 0 0.54 1.852 0 0.97 12 1.929 0 1.943 0 0.72 1.942 0 0.67 13 1.965 0 1.972 0 0.35 1.962 0 0.15 表 4 不同类型加速度传感器监测数据的模态频率识别结果对比

Table 4. Comparison of modal frequencies identified from the measurement of different sensors

阶数 G1B型加速度传感器监测数据的模态频率/Hz MEMS-I型加速度传感器监测数据的模态频率/Hz MEMS-I型与G1B型加速度传感器监测数据的模态频率相对误差/% Palert-Plus型加速度传感器监测数据的模态频率频率/Hz Palert-Plus型与G1B型加速度传感器监测数据的模态频率相对误差/% AC217型加速度传感器监测数据的模态频率频率/Hz AC217型与G1B型加速度传感器监测数据的模态频率相对误差/% Palert-Advance型加速度传感器监测数据的模态频率频率/Hz Palert-Advance型与G1B型加速度传感器监测数据的模态频率相对误差/

%1 0.168 4 0.168 3 0.059 0.168 0 0.238 0.169 1 0.416 0.169 9 0.891 2 0.198 5 0.198 5 0.000 0.198 3 0.101 0.198 6 0.050 0.199 8 0.655 3 0.277 4 0.277 3 0.036 0.277 6 0.072 0.277 1 0.108 0.279 5 0.757 4 0.540 7 0.540 8 0.018 0.539 8 0.166 0.541 1 0.074 — — 5 0.647 8 0.647 8 0.000 0.648 4 0.093 0.648 1 0.046 0.647 9 0.015 6 0.675 9 0.675 9 0.000 0.676 3 0.059 0.675 8 0.015 0.676 9 0.148 7 0.843 3 0.843 1 0.024 0.843 1 0.024 0.842 9 0.047 0.843 4 0.012 8 1.171 8 1.169 8 0.171 1.170 3 0.128 1.170 2 0.137 1.168 6 0.273 9 1.493 7 1.491 2 0.167 1.491 5 0.147 1.491 1 0.174 1.491 0 0.181 10 1.583 1 1.581 4 0.107 1.581 7 0.088 1.583 5 0.025 1.584 2 0.069 11 1.839 4 — — — — — — — — 12 1.933 0 1.933 0 0.000 1.932 5 0.026 1.933 0 0.000 1.931 3 0.088 13 1.964 6 1.964 4 0.010 1.963 2 0.071 1.964 0 0.031 1.962 7 0.097 -

[1] 郭西锐, 王立新, 姜慧等, 2016. 风和温度对地王大厦模态频率的影响研究. 建筑结构, 46(16): 113—120Guo X. R. , Wang L. X. , Jiang H. , et al. , 2016. Study of wind and temperature influences on natural frequencies of Diwang Plaza. Building Structure, 46(16): 113—120. (in Chinese) [2] 李志强, 2007. 金茂大厦的结构健康监测研究. 上海: 同济大学.Li Z. Q., 2007. Research on structure health monitoring of Jin Mao Tower. Shanghai: Tongji University. (in Chinese) [3] 徐枫, 陈文礼, 肖仪清等, 2014. 超高层建筑风致振动的现场实测与数值模拟. 防灾减灾工程学报, 34(1): 51—57Xu F. , Chen W. L. , Xiao Y. Q. , et al. , 2014. Field measurement and numerical simulation of wind-induced vibration of super high-rise building. Journal of Disaster Prevention and Mitigation Engineering, 34(1): 51—57. (in Chinese) [4] Brincker R., Ventura C. E., Andersen P., 2001. Damping estimation by frequency domain decomposition. In: Proceedings of IMAC 19: A Conference on Structural Dynamics. Hyatt Orlando, Kissimmee, Florida: Society for Experimental Mechanics, 698—703. [5] Cochran E. , Lawrence J. , Christensen C. , et al. , 2009. A novel strong-motion seismic network for community participation in earthquake monitoring. IEEE Instrumentation & Measurement Magazine, 12(6): 8—15. [6] D’Alessandro A. , Scudero S. , Vitale G. , 2019. A review of the capacitive MEMS for seismology. Sensors, 19(14): 3093. doi: 10.3390/s19143093 [7] Fu J. H. , Li Z. T. , Meng H. , et al. , 2019. Performance evaluation of low-cost seismic sensors for dense earthquake early warning: 2018-2019 field testing in southwest China. Sensors, 19(9): 1999. doi: 10.3390/s19091999 [8] Hsu T. Y. , Yin R. C. , Wu Y. M. , 2018. Evaluating post-earthquake building safety using economical MEMS seismometers. Sensors, 18(5): 1437. doi: 10.3390/s18051437 [9] Hu R. P. , Xu Y. L. , Zhao X. , 2020. Optimal multi-type sensor placement for monitoring high-rise buildings under bidirectional long-period ground motions. Structural Control and Health Monitoring, 27(6): e2541. [10] Hu X. X. , Wang X. Z. , Chen B. , et al. , 2021. Improved resolution and cost performance of low-cost MEMS seismic sensor through parallel acquisition. Sensors, 21(23): 7970. doi: 10.3390/s21237970 [11] Kijewski-Correa T. , Kwon D. K. , Kareem A. , et al. , 2013. SmartSync: an integrated real-time structural health monitoring and structural identification system for tall buildings. Journal of Structural Engineering, 139(10): 1675—1687. doi: 10.1061/(ASCE)ST.1943-541X.0000560 [12] Lin J. F. , Li X. Y. , Wang J. F. , et al. , 2021. Study of building safety monitoring by using cost-effective MEMS accelerometers for rapid after-earthquake assessment with missing data. Sensors, 21(21): 7327. doi: 10.3390/s21217327 [13] Ni Y. Q. , Xia Y. , Liao W. Y. , et al. , 2009. Technology innovation in developing the structural health monitoring system for Guangzhou New TV Tower. Structural Control and Health Monitoring, 16(1): 73—98. doi: 10.1002/stc.303 [14] Nof R. N. , Chung A. I. , Rademacher H. , et al. , 2019. MEMS accelerometer mini-array (MAMA): a low-cost implementation for earthquake early warning enhancement. Earthquake Spectra, 35(1): 21—38. doi: 10.1193/021218EQS036M [15] Pozzi M. , Zonta D. , Trapani D. , et al. , 2011. MEMS-based sensors for post-earthquake damage assessment. Journal of Physics: Conference Series, 305: 012100 doi: 10.1088/1742-6596/305/1/012100 [16] Spencer Jr. B. F. , Ruiz-Sandoval M. , Kurata N. , 2004. Smart sensing technology: opportunities and challenges. Structural Control and Health Monitoring, 11(4): 349—368. doi: 10.1002/stc.48 [17] Su J. Z. , Xia Y. , Chen L. , et al. , 2013. Long-term structural performance monitoring system for the Shanghai Tower. Journal of Civil Structural Health Monitoring, 3(1): 49—61. doi: 10.1007/s13349-012-0034-z [18] Wang F. , Ma J. M. , Kang X. D. , et al. , 2022. Building response analyses recorded by force-balanced and micro-electro mechanical system accelerometers. Mechanics of Advanced Materials and Structures, 29(11): 1650—1660. doi: 10.1080/15376494.2022.2061658 [19] Wu Y. M. , Chen D. Y. , Lin T. L. , et al. , 2013. A high-density seismic network for earthquake early warning in Taiwan based on low cost sensors. Seismological research letters, 84(6): 1048—1054. doi: 10.1785/0220130085 [20] Wu Y. M. , 2015. Progress on development of an earthquake early warning system using low-cost sensors. Pure and Applied Geophysics, 172(9): 2343—2351. doi: 10.1007/s00024-014-0933-5 [21] Yin R. C. , Wu Y. M. , Hsu T. Y. , 2016. Application of the low-cost MEMS-type seismometer for structural health monitoring: a pre-study. In: Proceedings of IEEE International Instrumentation and Measurement Technology Conference. Taipei, China: IEEE, 1—5. -

下载:

下载: