Seismic Response Analysis of Transfer-purging Chamber in Nuclear Power Plant

-

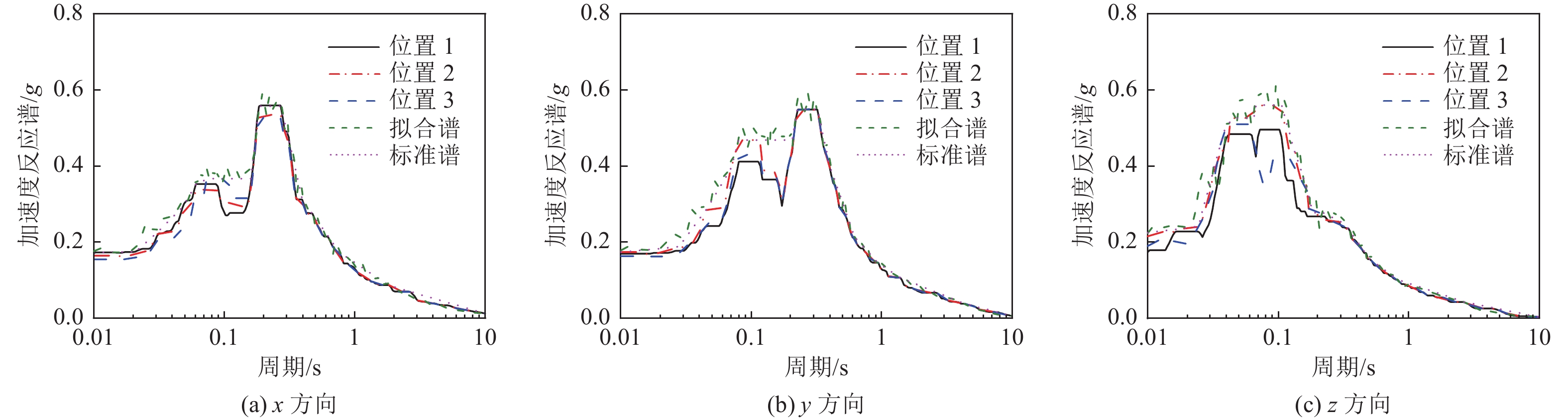

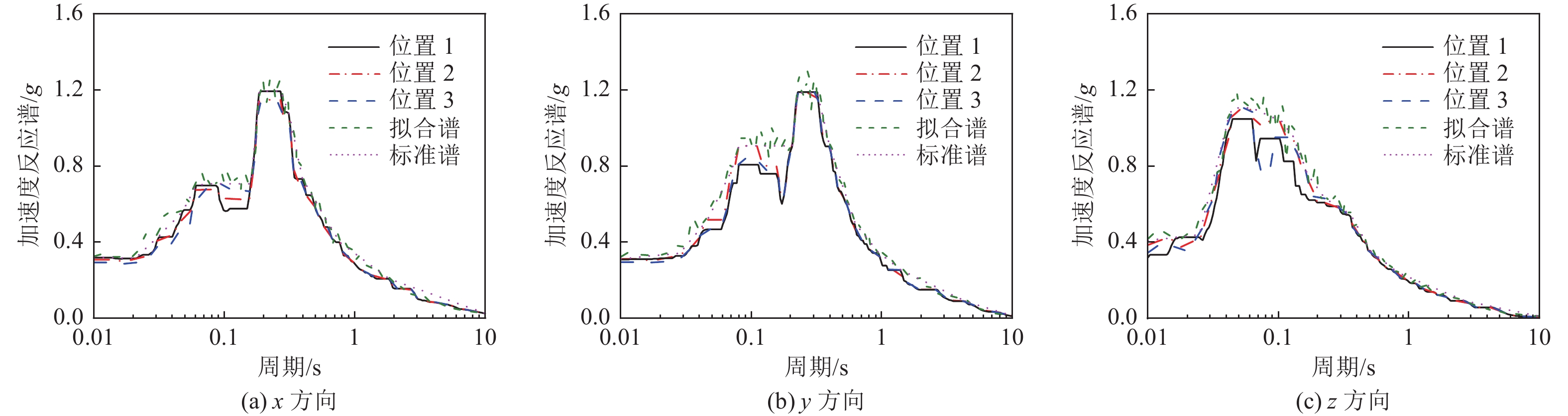

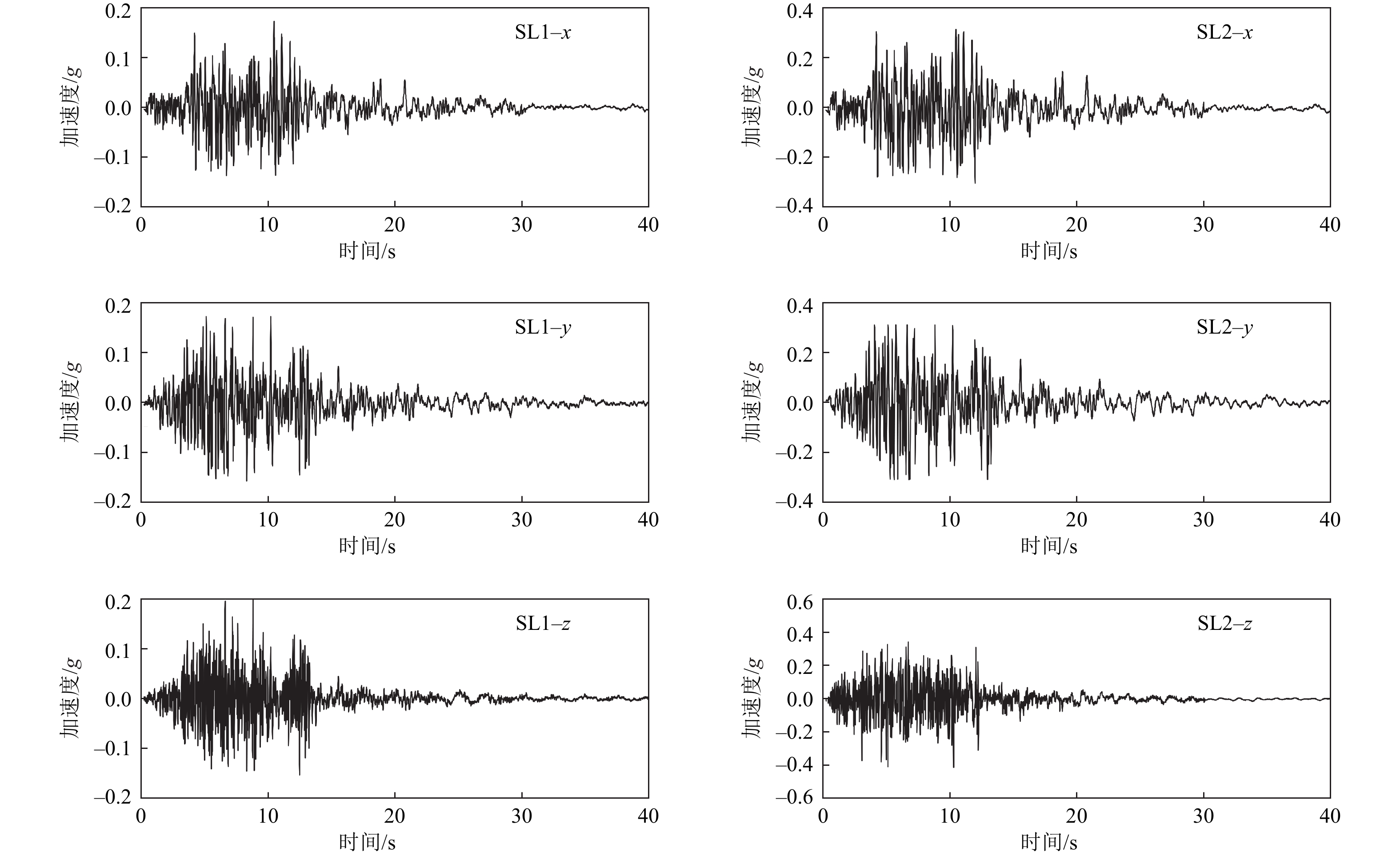

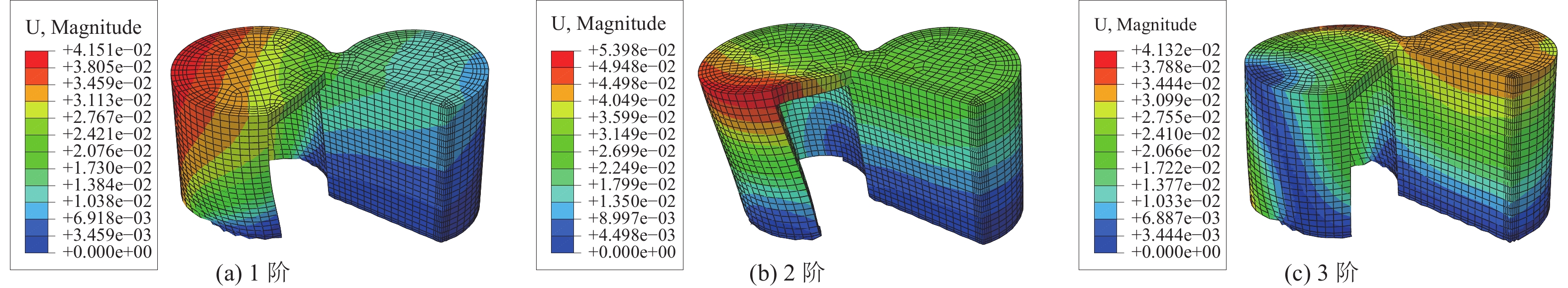

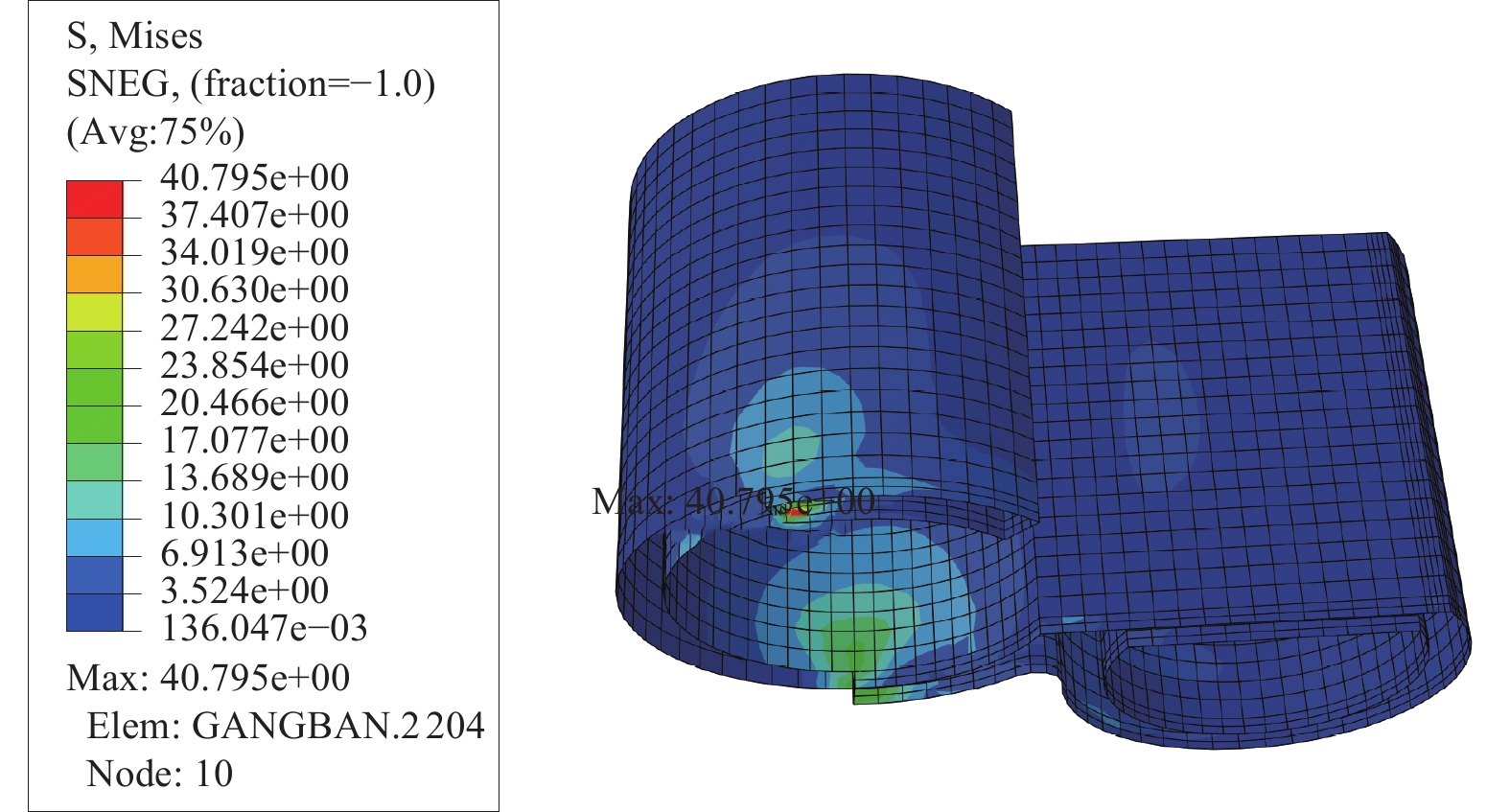

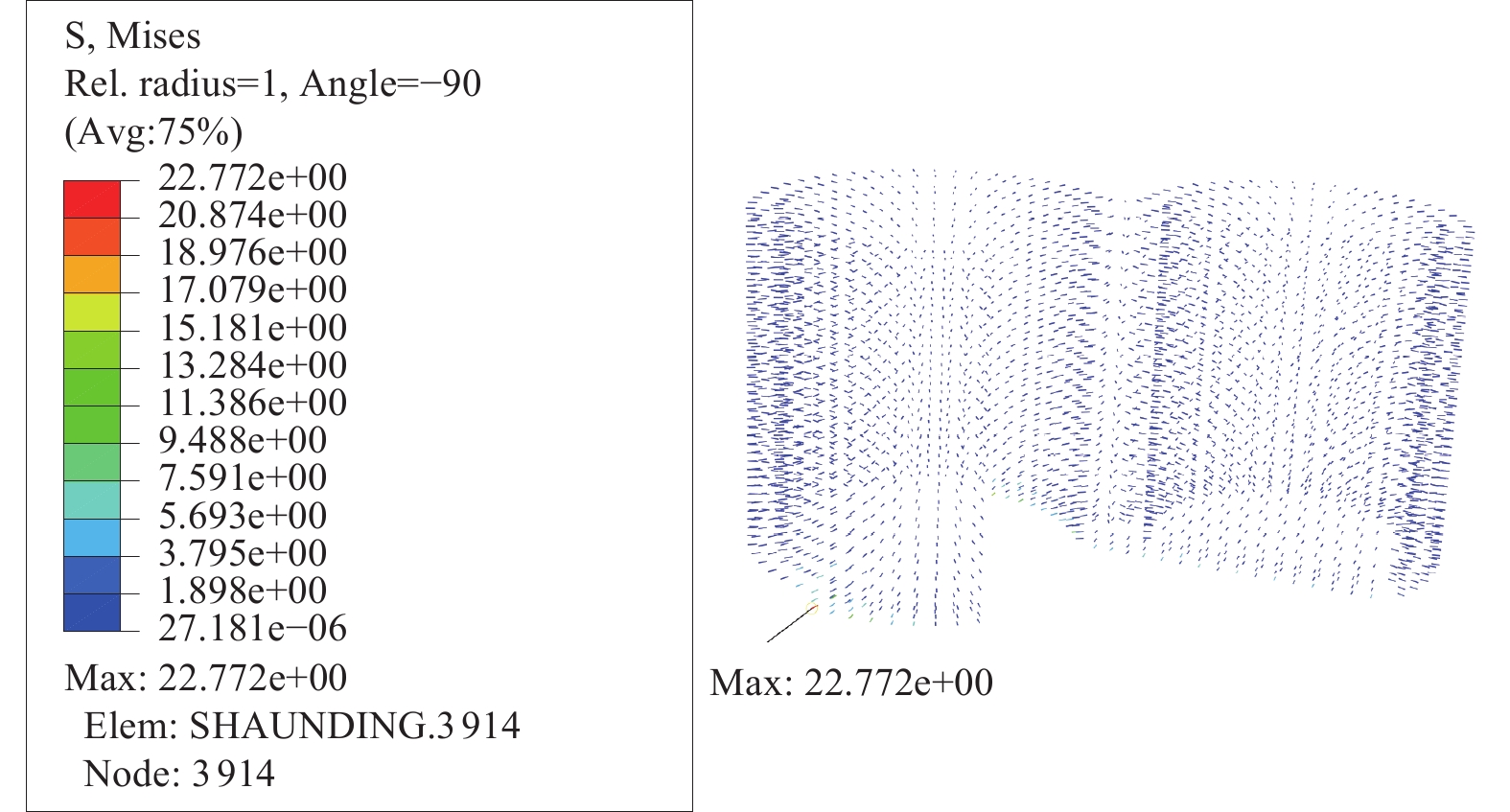

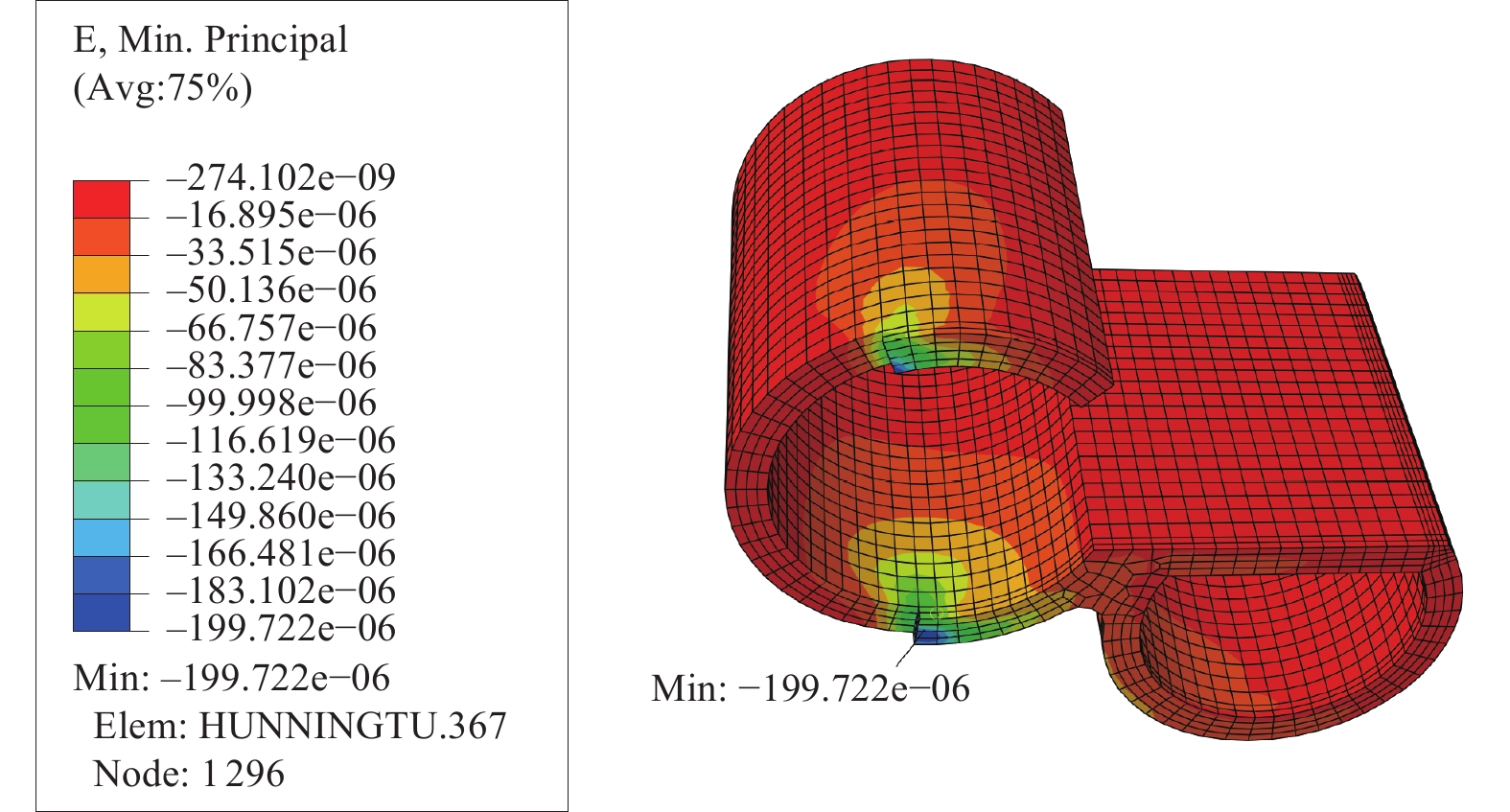

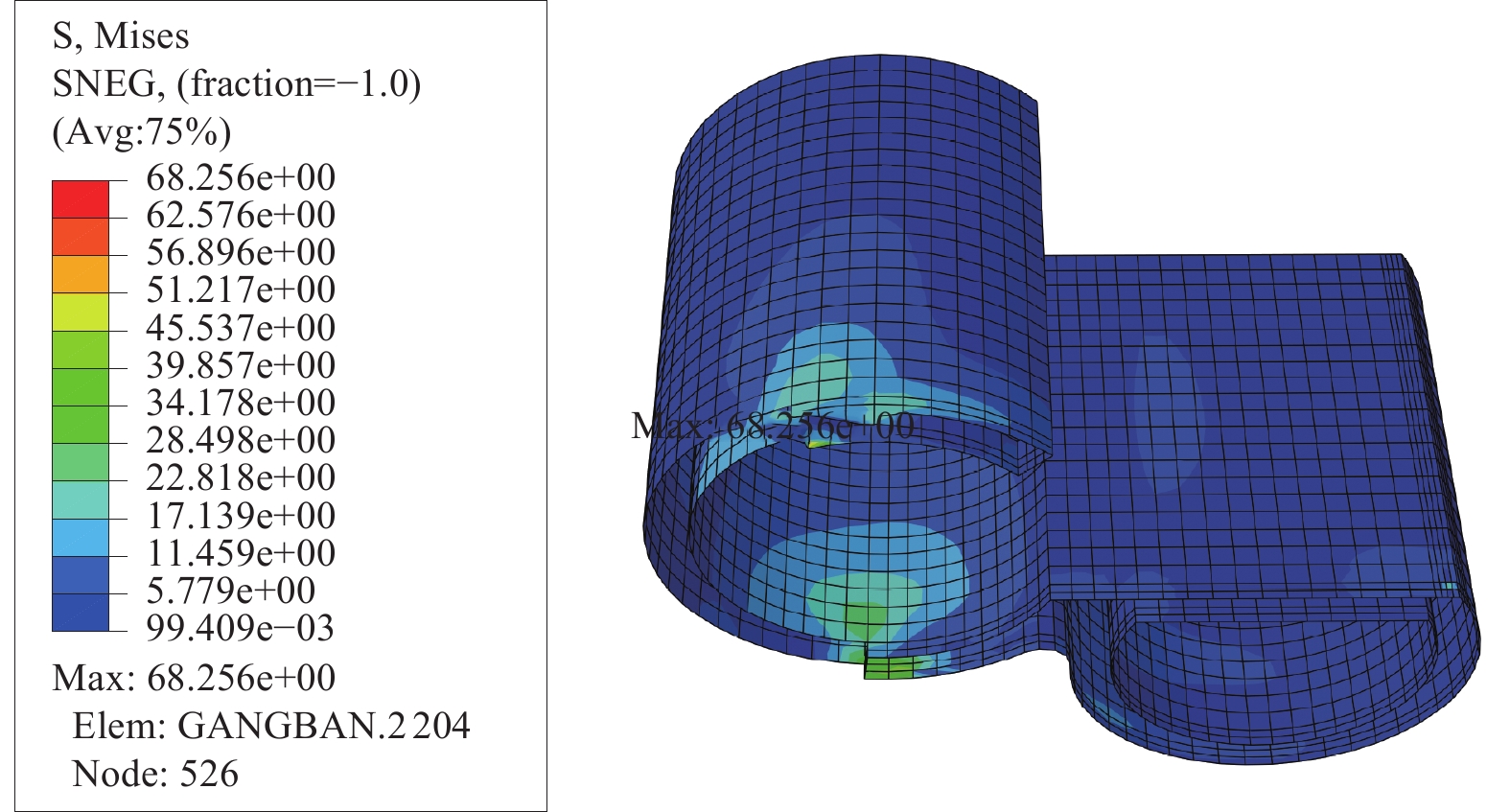

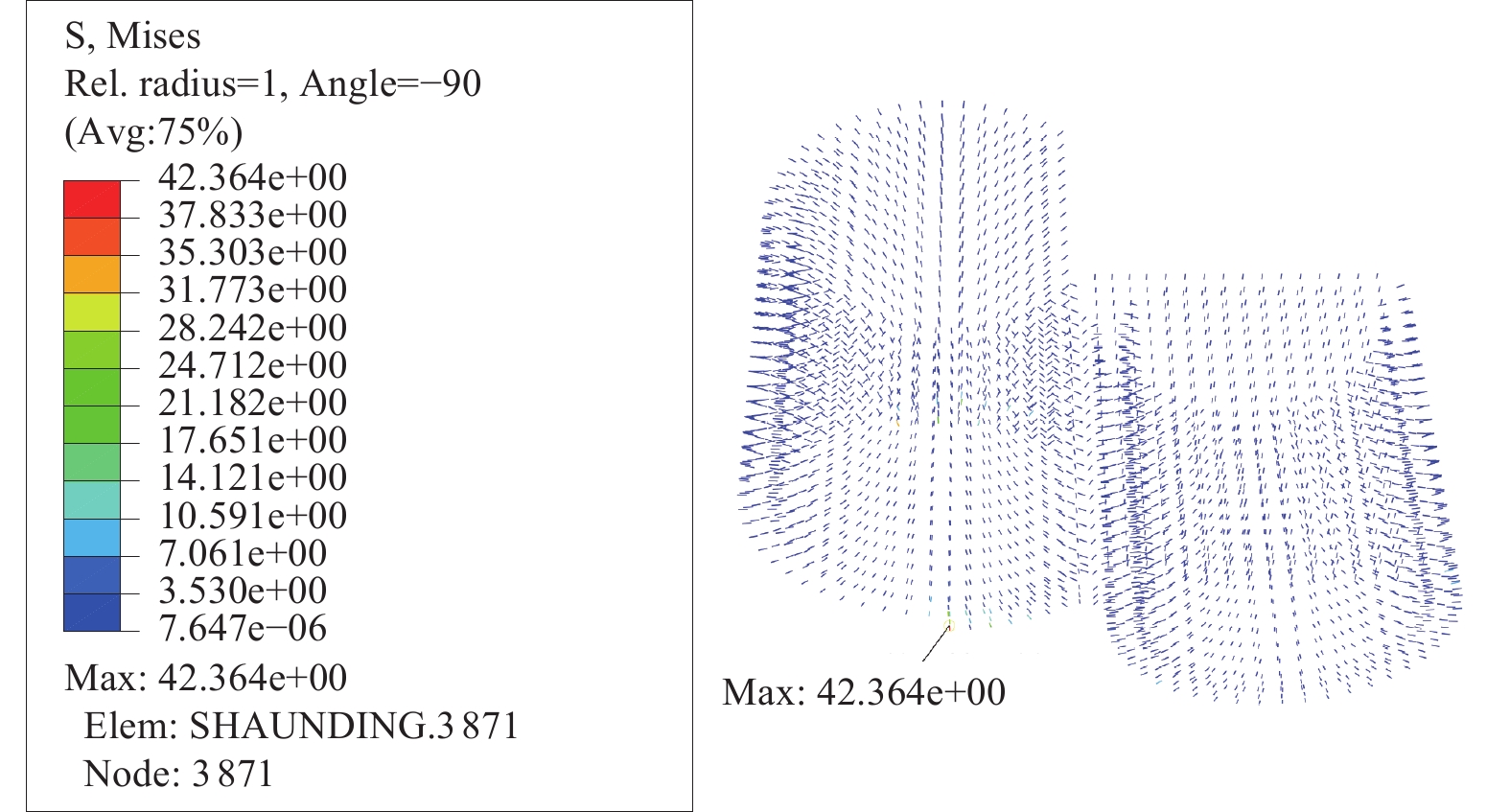

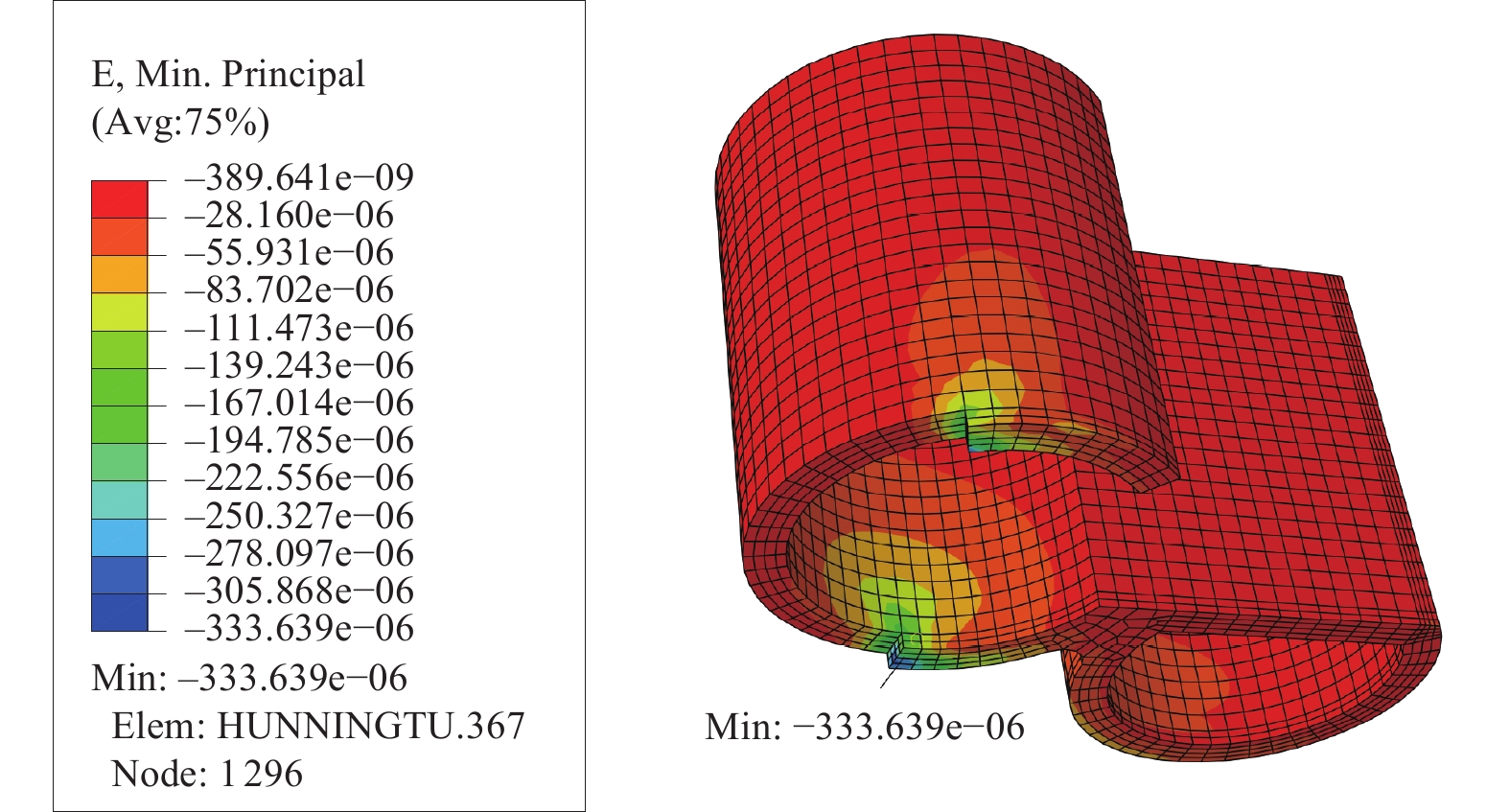

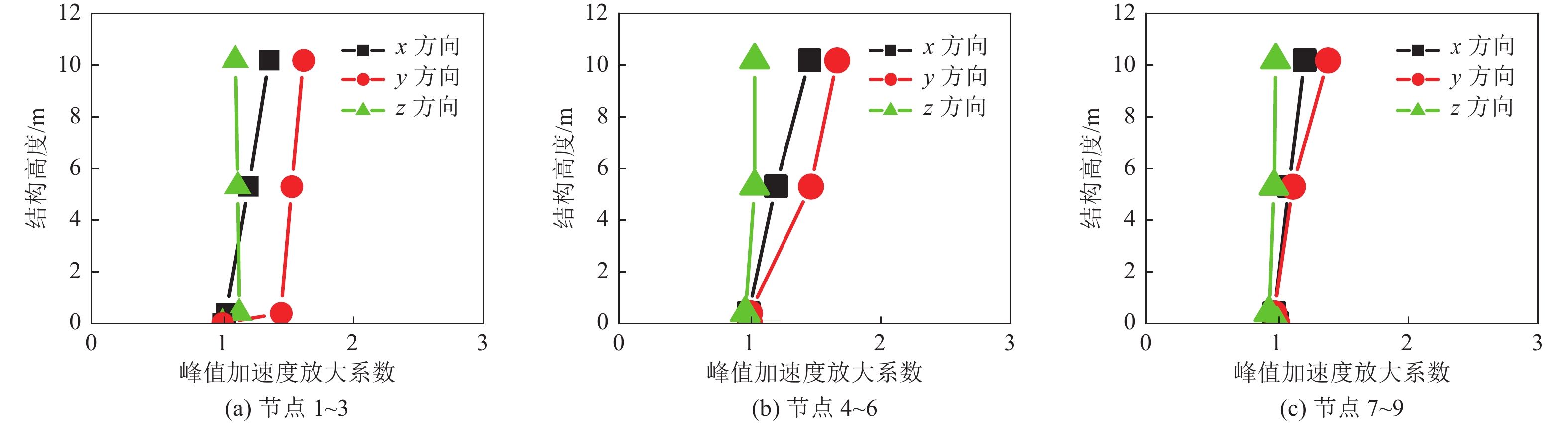

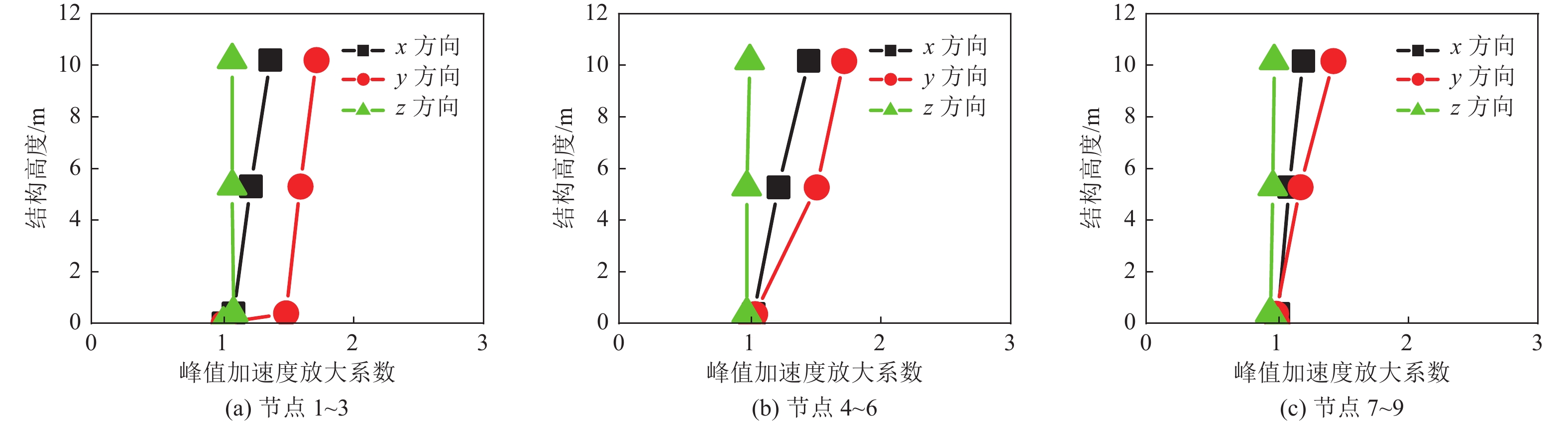

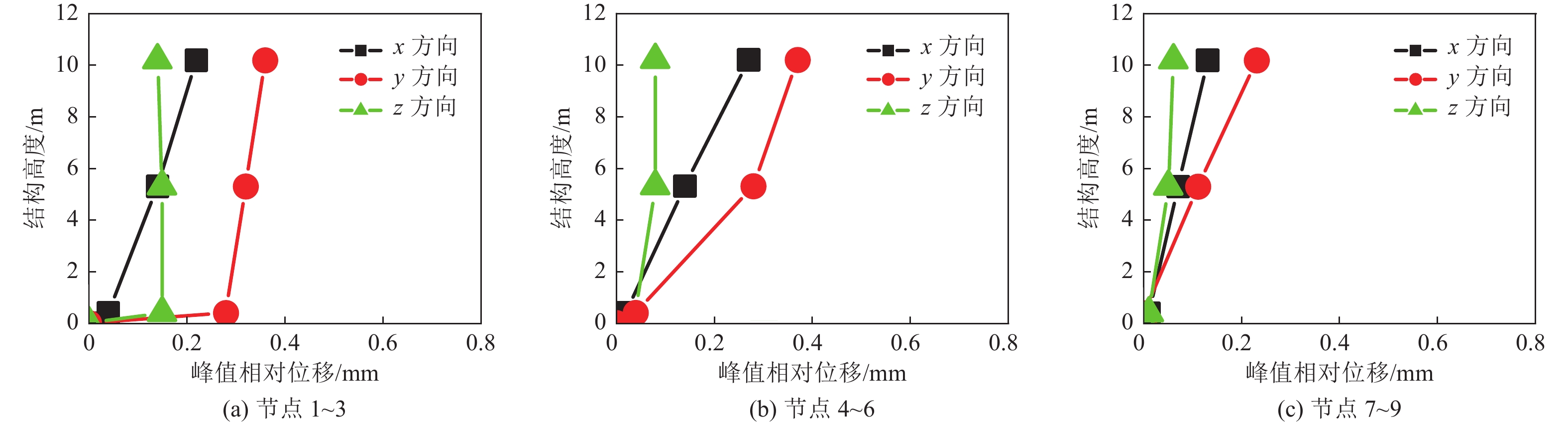

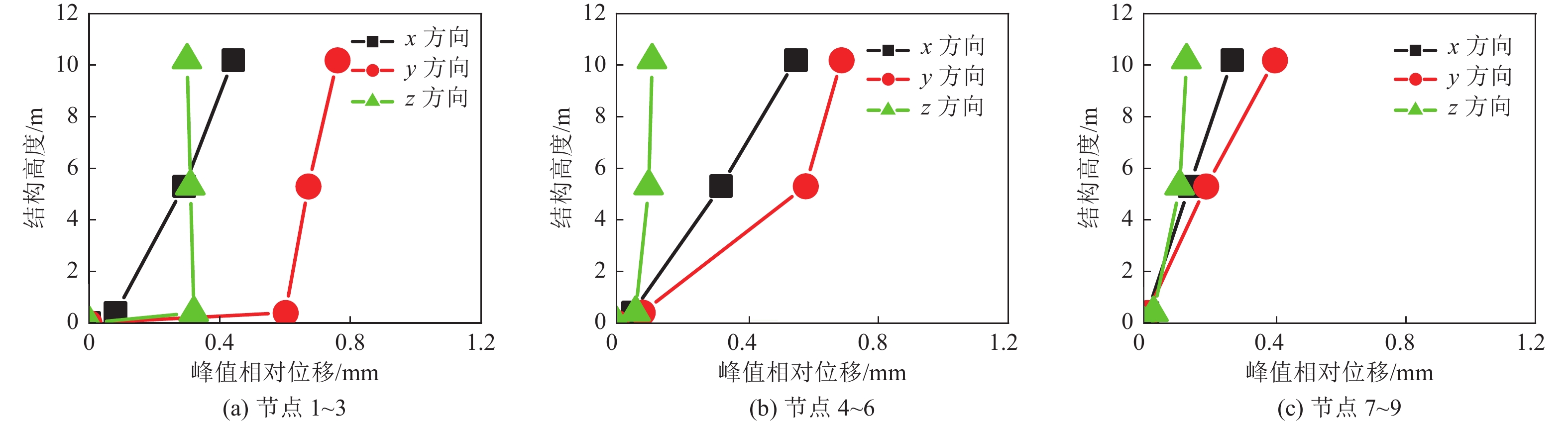

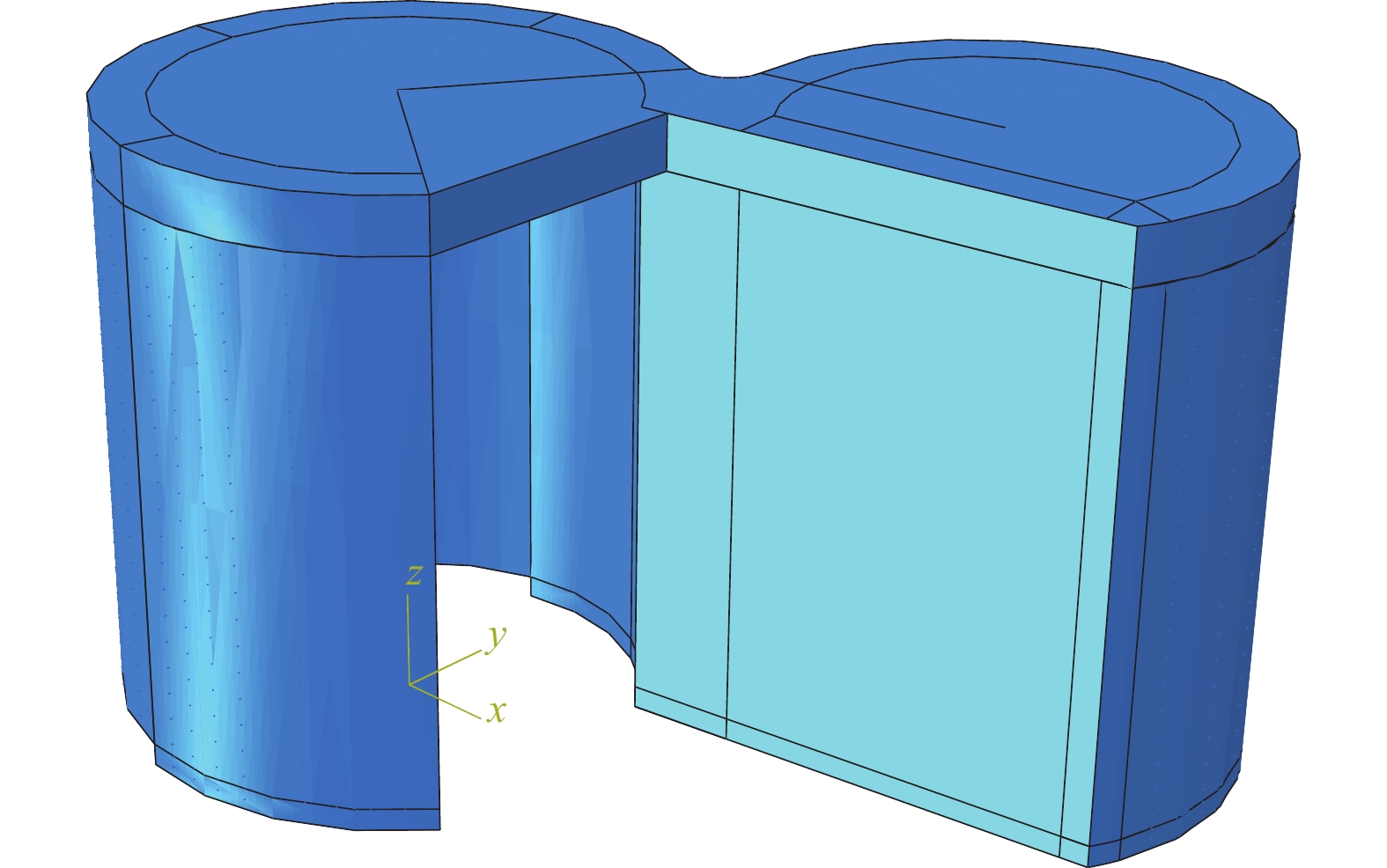

摘要: 转运-清洗间作为核电厂反应堆堆外换料系统中的主要设施,为反应堆换料操作提供了安全可靠的生物屏蔽空间,转运-清洗间采用的是双钢板重混凝土组合结构。本文基于有限元软件ABAQUS对转运-清洗间的抗震性能进行分析,包括地震动激励下结构的峰值应力、应变和动力特性。结果表明,在转运间的底部悬挑边缘部位存在应力集中,但是钢板、栓钉和重混凝土墙仍有充分的安全裕度。转运-清洗间的整体刚度较大,在设计基准地震动激励下结构反应的峰值加速度放大系数及峰值相对位移较小,结构具有良好的安全性和完整性,核电厂转运-清洗间的设计安全可靠。Abstract: The transfer-purging chamber is the main facility of the refueling system of a reactor in nuclear power plants to provides a sealed and biological shielded environment for the refueling operation of the reactor. The transfer-purging chamber adopts the double steel plates reinforced concrete structure. Based on ABAQUS, the peak stress, strain and dynamic characteristics of the transfer-purging chamber under the excitation of ground motions are analyzed. The results show that there is stress concentration at the bottom cantilever edge of the transfer chamber, however, the steel plate, bolt and concrete still have sufficient safety margin. The stiffness of the transfer-purging chamber is great, the peak acceleration amplification coefficient and peak relative displacement of the structure are small under the excitation of design basis ground motions. The structure has good safety performance and integrity, and the design of the nuclear power structure transfer-purging chamber is safe and reliable.

-

表 1 材料本构关系的主要参数

Table 1. Main parameters of material constitutive relationship

材料 参数 数值 钢材(Q355) 弹性模量E/MPa 206000 屈服强度/MPa 355 泊松比 0.3 ML15 弹性模量E/MPa 210000 屈服强度/MPa 270 泊松比 0.3 重混凝土(C40) 密度/Kg·m−3 3700 弹性模量/MPa 50000 抗压应变设计值 1450×10−6 泊松比 0.2 膨胀角/° 35 偏心率 0.1 双轴抗压强度$ {f}_{b_0} $与单轴抗压强度$ {f}_{e_0} $的比值 1.16 粘性参数 0.66667 -

[1] 葛琪, 熊峰, 何涛, 2018. 钢板混凝土组合墙试验和有限元分析. 东南大学学报(自然科学版), 48(5): 885—895Ge Q. , Xiong F. , He T. , 2018. Testing and finite element analysis on steel-plate concrete composite wall. Journal of Southeast University (Natural Science Edition), 48(5): 885—895. (in Chinese) [2] 侯春林, 李小军, 戴志军, 2012. 人造地震动多阻尼反应谱拟合优化算法. 国际地震动态, (6): 303. [3] 李楠, 谷继品, 2008. 中国实验快堆转运-清洗室的力学分析. 原子能科学技术, 42(S2): 509—511Li N. , Gu J. P. , 2008. Numerical analysis of transfer and purge chamber for China experimental fast reactor. Atomic Energy Science and Technology, 42(S2): 509—511. (in Chinese) [4] 李小军, 李晓虎, 2017. 核电工程双钢板混凝土组合剪力墙面内受弯性能研究. 工程力学, 34(9): 43—53 doi: 10.6052/j.issn.1000-4750.2016.08.0665Li X. J. , Li X. H. , 2017. Study on in-plane flexural behavior of double steel plates and concrete infill composite shear walls for nuclear engineering. Engineering Mechanics, 34(9): 43—53. (in Chinese) doi: 10.6052/j.issn.1000-4750.2016.08.0665 [5] 刘晶波, 王冬亮, 王宗纲等, 2019. 核工程双钢板-混凝土组合剪力墙面内受剪性能试验研究. 地震工程与工程振动, 39(5): 19—27Liu J. B. , Wang D. L. , Wang Z. G. , et al. , 2019. Experimental study on in-plane shear behavior of double-skin-composite shear walls in nuclear engineering. Earthquake Engineering and Engineering Dynamics, 39(5): 19—27. (in Chinese) [6] 熊峰, 何涛, 周宁, 2015. 核电站双钢板混凝土剪力墙抗剪强度研究. 湖南大学学报(自然科学版), 42(9): 33—41 doi: 10.3969/j.issn.1674-2974.2015.09.005Xiong F. , He T. , Zhou N. , 2015. Study on the shear strength of double steel plate composite shear wall in nuclear plant. Journal of Hunan University (Natural Sciences), 42(9): 33—41. (in Chinese) doi: 10.3969/j.issn.1674-2974.2015.09.005 [7] 张有佳, 李小军, 2015. 基于钢板弹性屈曲理论的组合墙轴压试验研究. 应用基础与工程科学学报, 23(6): 1198—1209Zhang Y. J. , Li X. J. , 2015. Axial compression experimental study of composite walls based on steel plate elastic buckling theory. Journal of Basic Science and Engineering, 23(6): 1198—1209. (in Chinese). [8] 张有佳, 李小军, 贺秋梅等, 2016. 钢板混凝土组合墙体局部稳定性轴压试验研究. 土木工程学报, 49(1): 62—68Zhang Y. J. , Li X. J. , He Q. M. , et al. , 2016. Experimental study on local stability of composite walls with steel plates and filled concrete under concentric loads. China Civil Engineering Journal, 49(1): 62—68. (in Chinese) [9] 中华人民共和国住房和城乡建设部, 2011. GB 50010—2010 混凝土结构设计规范. 北京: 中国建筑工业出版社.Ministry of Housing and Urban-Rural Development of the People’s Republic of China, 2011. GB 50010—2010 Code for design of concrete structures. Beijing: China Architecture & Building Press. (in Chinese) [10] 中华人民共和国住房和城乡建设部, 国家市场监督管理总局, 2019. GB 50267—2019 核电厂抗震设计标准. 北京: 中国计划出版社.Ministry of Housing and Urban-Rural Development of the People’s Republic of China, State Administration for Market Regulation, 2019. GB 50267—2019 Standard for seismic design of nuclear power plants. Beijing: China Planning Press. (in Chinese) [11] Akiyama H. , Sekimoto H. , Fukihara M. , et al. , 1991. A compression and shear loading test of concrete filled steel bearing wall. In: Transactions of the 11th international conference on structural mechanics in reactor technology (SMiRT-11). Tokyo, 323—328. -

下载:

下载: