Behavior of High Ductility FRP-confined Large-size Concrete Columns Under Axial Compression

-

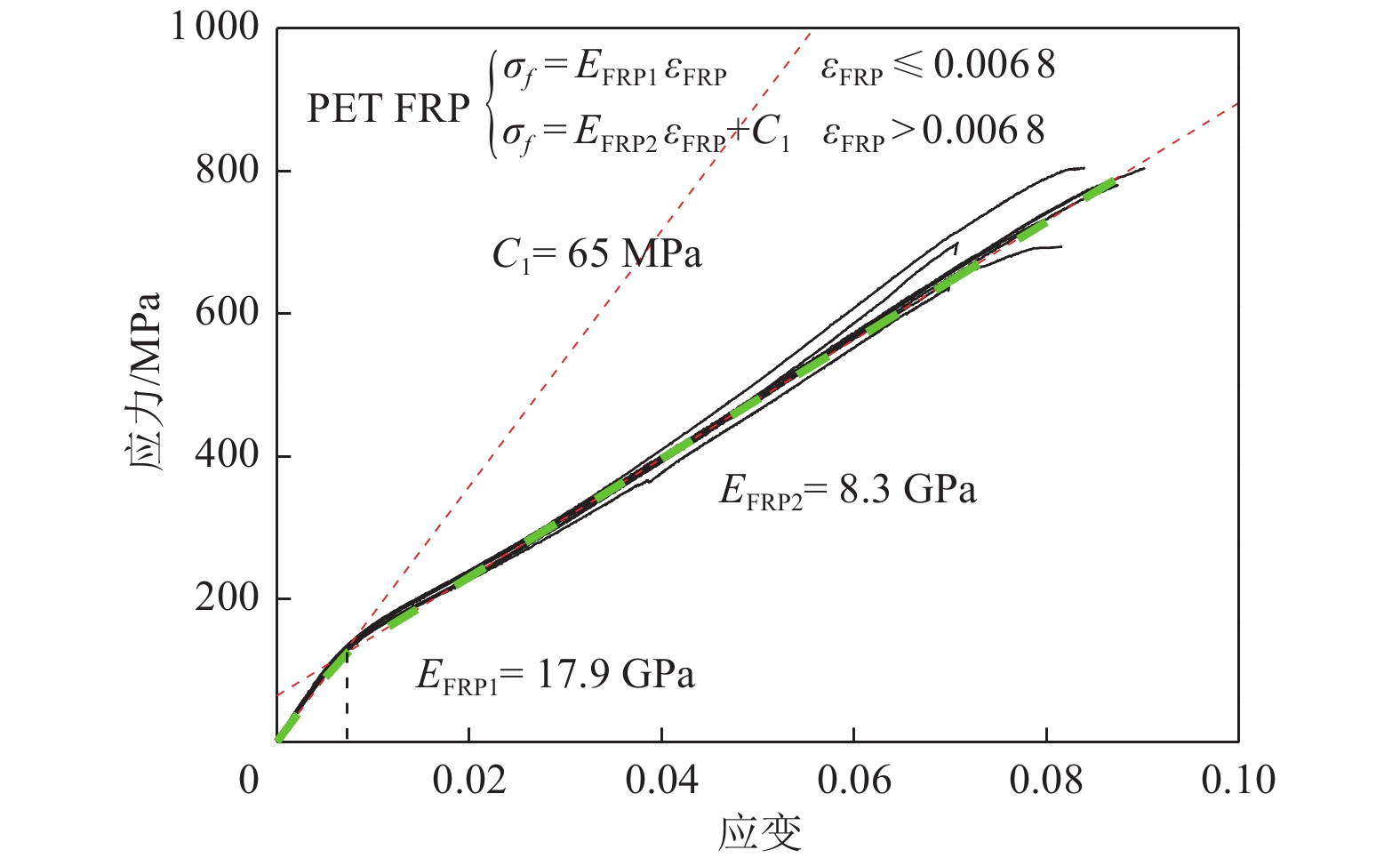

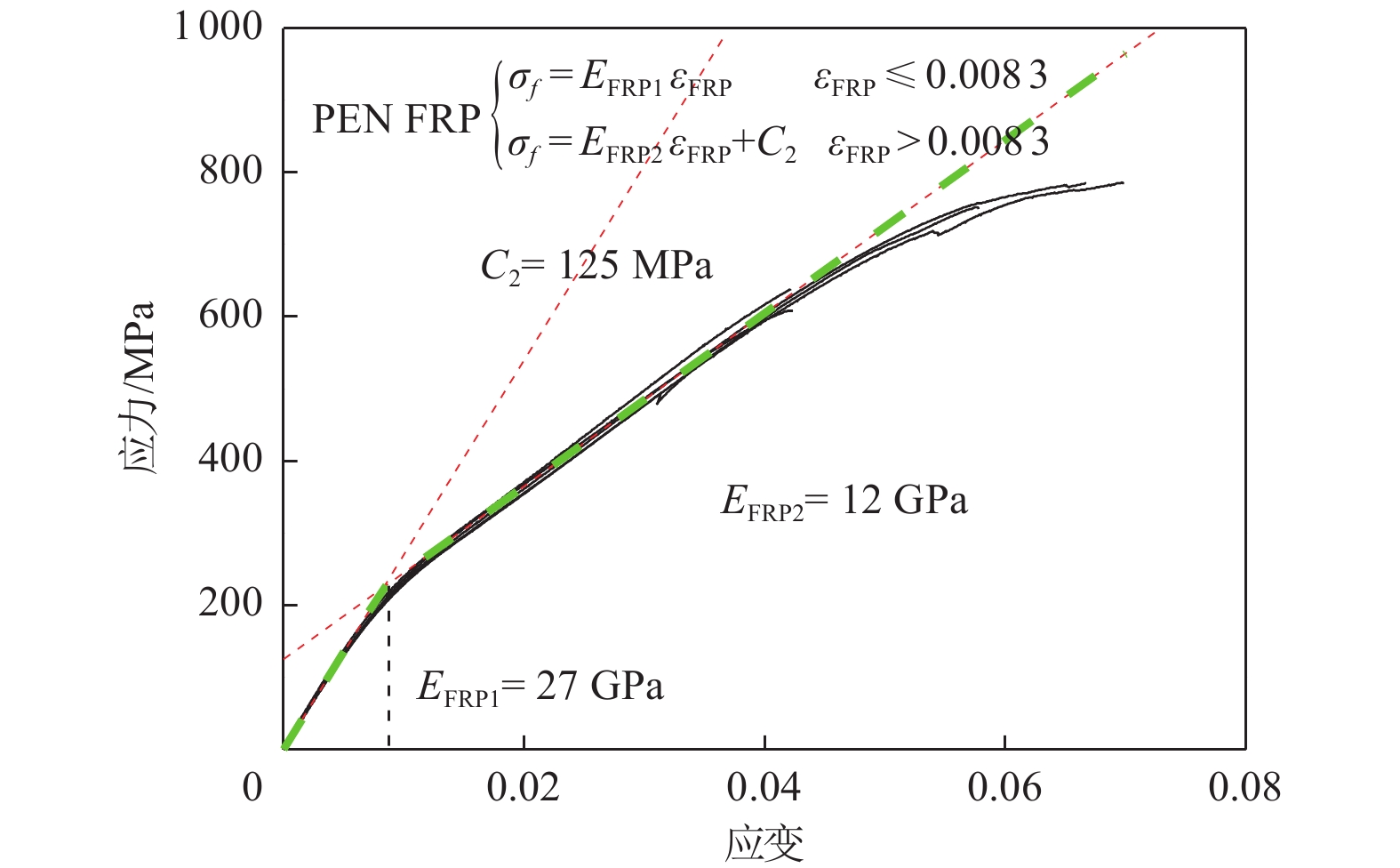

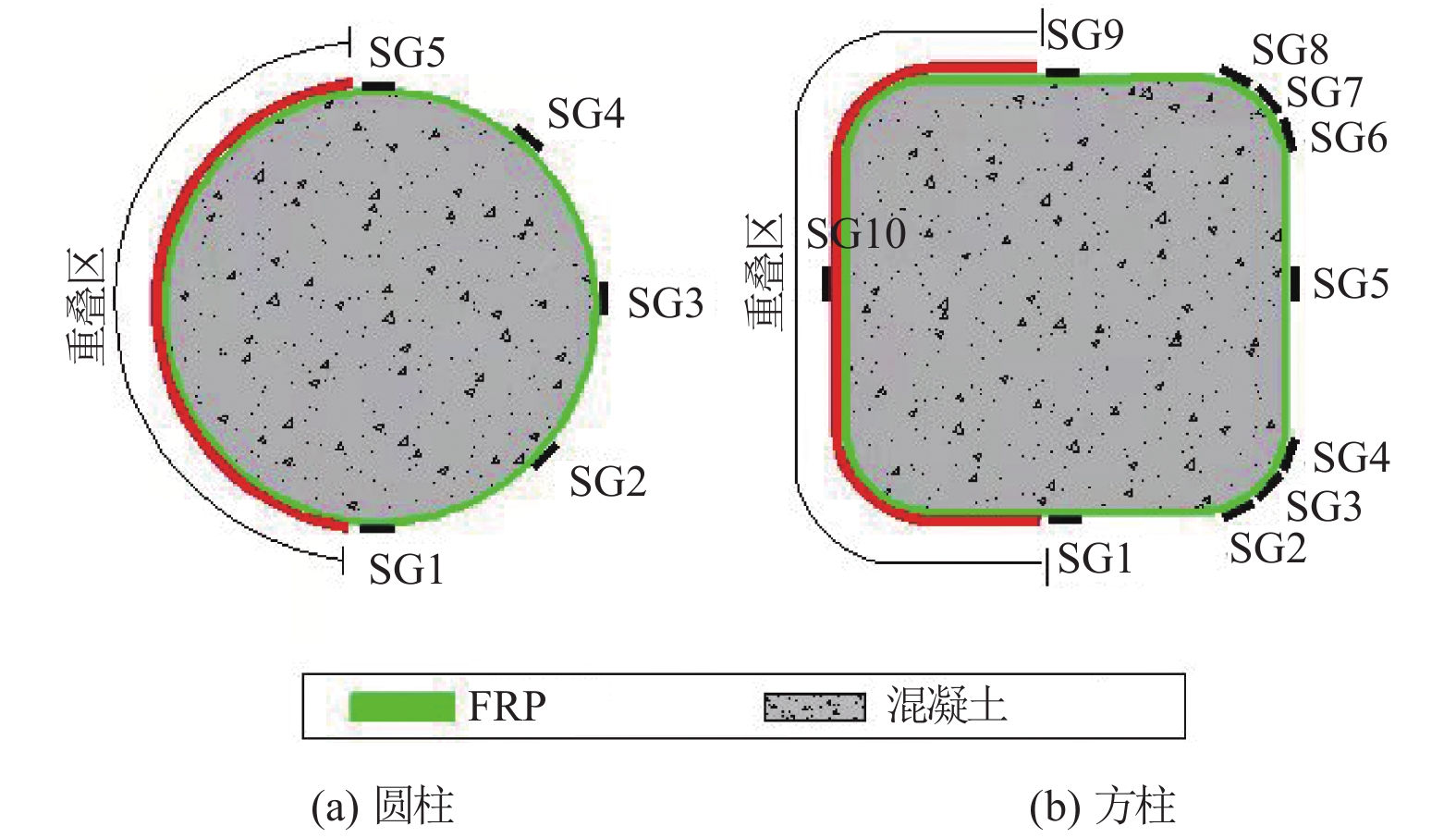

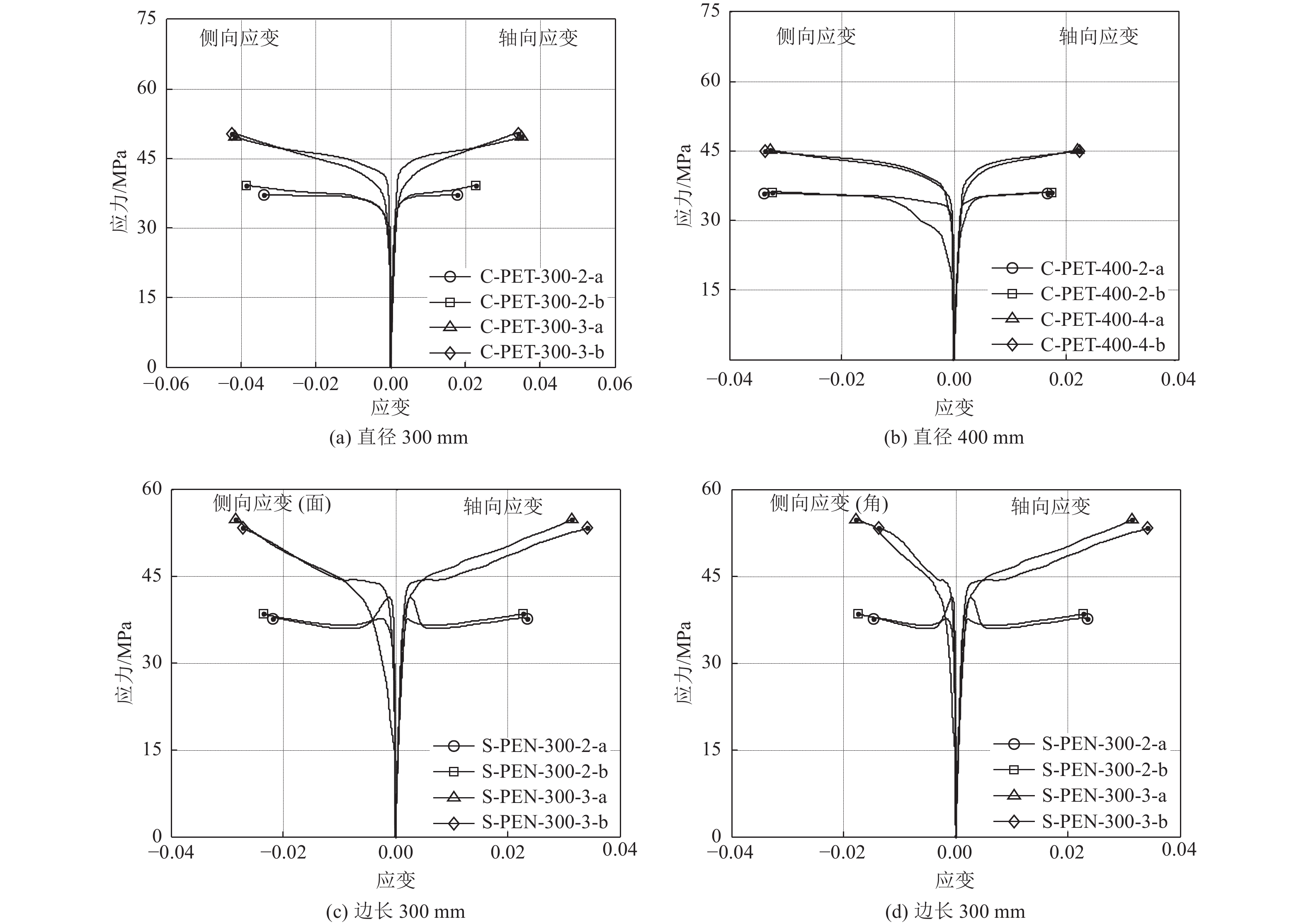

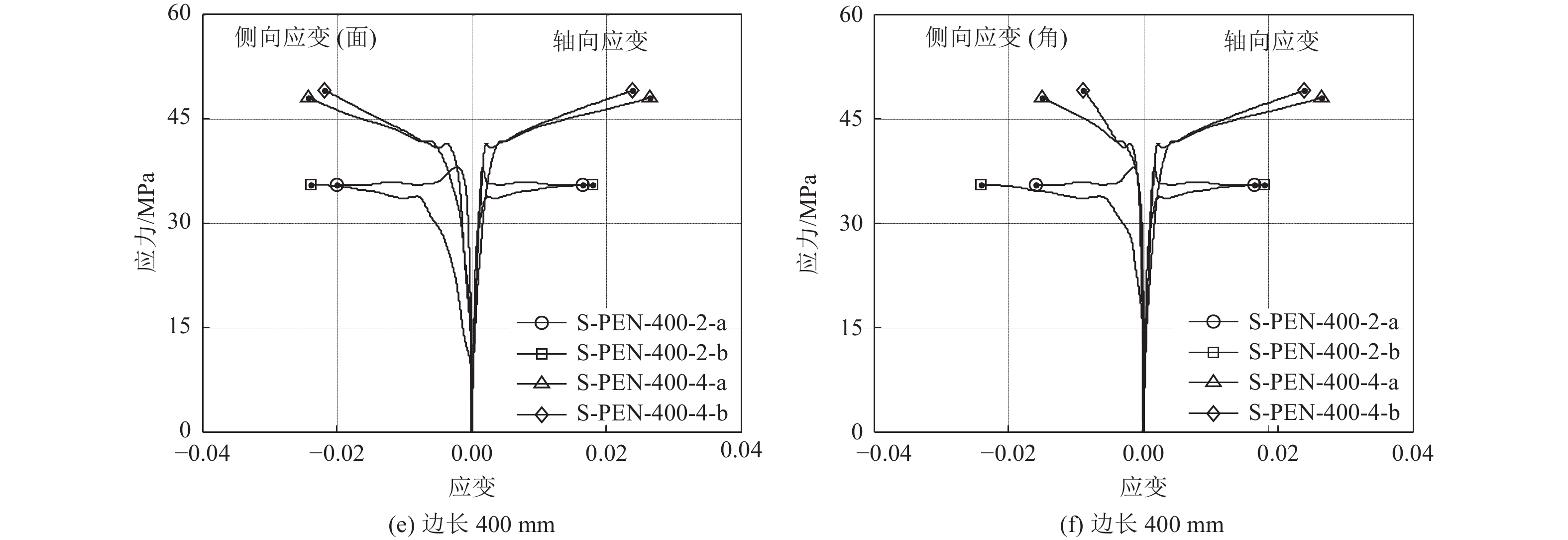

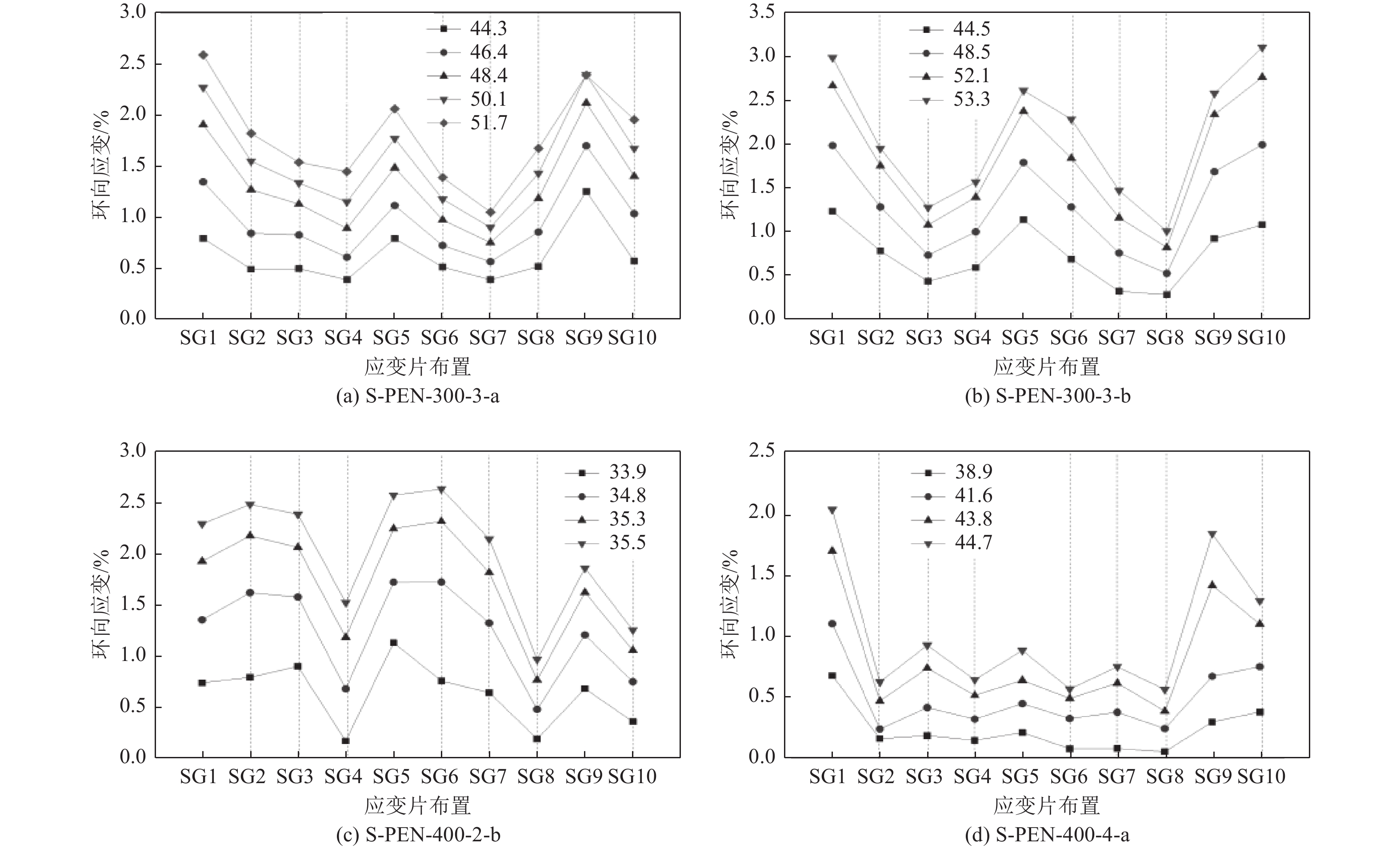

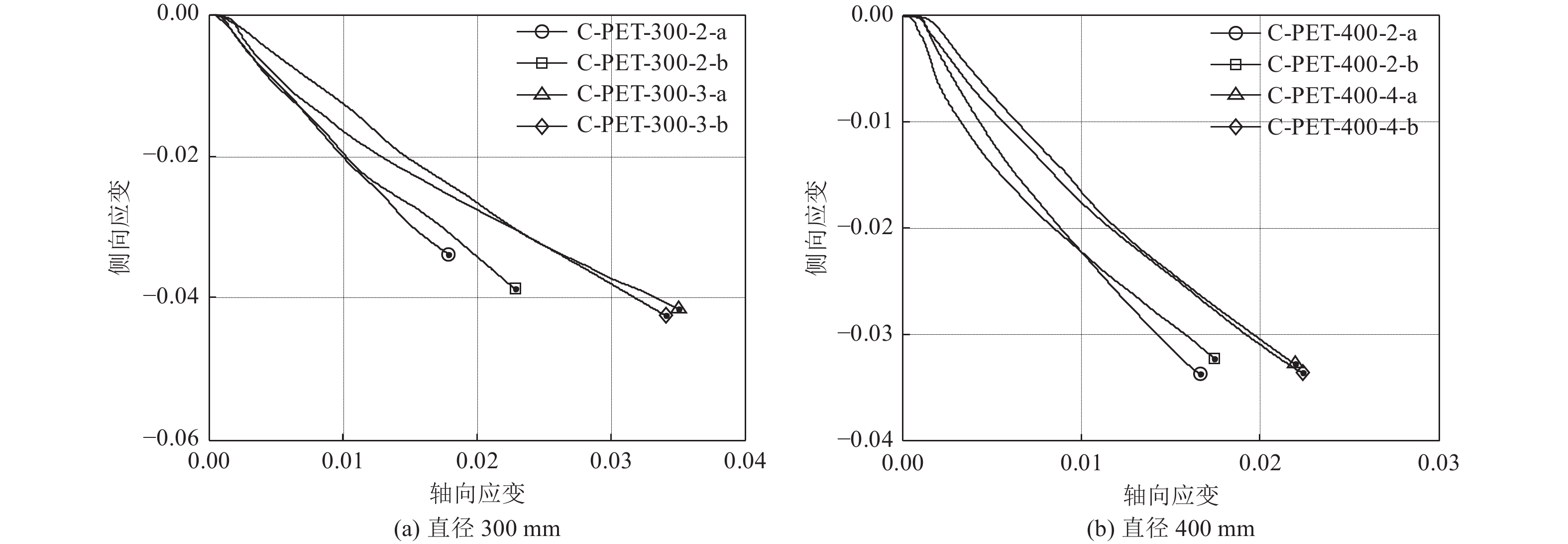

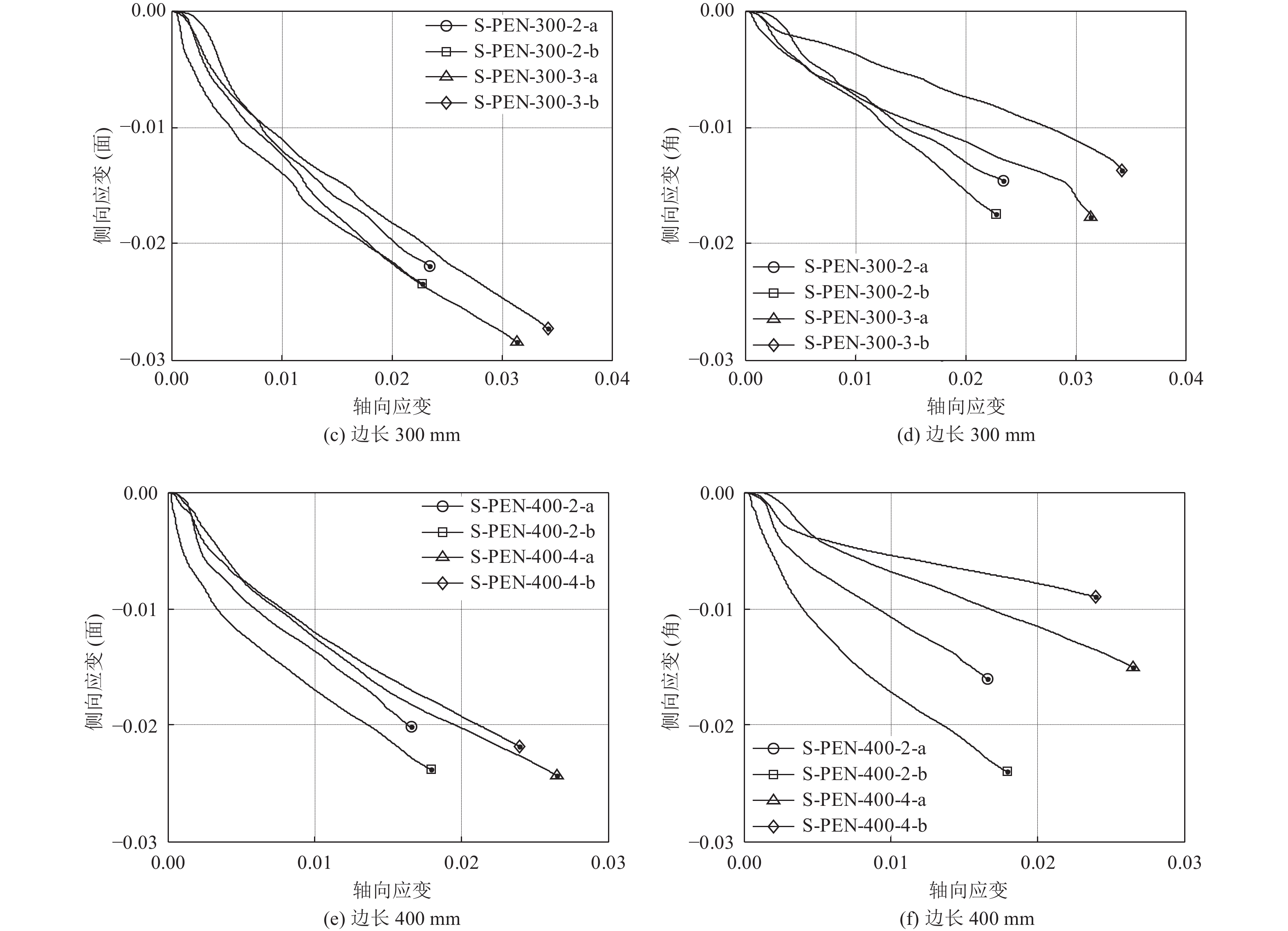

摘要: 现有纤维增强复合材料(FRP)约束混凝土短柱的研究多基于小尺寸试件,对大尺寸试件的研究较少。聚对苯二甲酸乙二醇酯纤维增强复合材料(PET FRP)和聚萘二甲酸乙二醇酯纤维增强复合材料(PEN FRP)是由回收废弃塑料制成的环保型高延性FRP。高延性FRP具有超过5%的断裂应变,超过传统FRP断裂应变(1.5~3%)。本研究对8个PET FRP约束混凝土圆柱(直径300、400 mm试件各4个)与8个PEN FRP约束混凝土方柱(边长300、400 mm试件各4个)进行轴压力学性能试验,研究构件截面形状、FRP层数等参数对试件轴压力学性能的影响。试验结果表明:高延性FRP约束混凝土柱应力-应变曲线由3个不同的部分组成;部分高延性FRP约束混凝土柱应力-应变曲线第2段出现了下降段,与约束刚度较小有关;相同尺寸的试件,随着高延性FRP层数(厚度)的增加,试件承载力提高,延性更好;对于PEN FRP约束混凝土方柱,在同一轴向变形、高度区域处,环向面应变较环向角应变大,且环向面应变的增加值大于角区域;采用现有高延性FRP约束混凝土柱模型,对约束圆形和方形混凝土柱轴压力学性能提供相对合理的预测。Abstract: Most of the existing researches on fiber reinforced polymer (FRP) composite-confined concrete short columns are based on small size specimens, and large-size columns have not been fully studied. PET (Polyethylene Terephthalate) FRP and PEN (Polyethylene Naphthalene) FRP are environmentally friendly large rupture strain FRPs made from recycled waste plastic. Compared with traditional FRP, high ductility FRP materials have a fracture strain larger than 5%, which is far larger than that of traditional FRP materials with the value of 1.5~3%. In recent years, high ductility FRP has become a research hotspot all over the world. In this paper, the axial compressive behavior of 8 PET FRP-confined concrete columns and 8 PEN FRP-confined concrete columns were experimentally studied. The main research parameters included the shape of specimens and the number of FRP layers. Results show that the stress-strain curve of high ductility FRP-confined concrete columns has three different parts; the second part of stress-strain curve of partially high ductility FRP-confined concrete columns appears a descending section, which is related to the small constraint stiffness; the bearing capacity and ductility of same size specimens increase with the increase of FRP thickness; The middle strain is larger than corner strain of PEN FRP-confined concrete square columns at the same axial deformation. Moreover, the existing stress strain models for high ductility FRP-confined concrete were evaluated with the test results.

-

表 1 试件编号及参数

Table 1. Details of specimens

试件编号 直径或边长/mm 高度/mm 角半径/mm 材料类型 FRP层数/层 C-PET-300-2-a,b 300 600 — PET FRP 2 C-PET-300-3-a,b 300 600 — PET FRP 3 C-PET-400-2-a,b 400 800 — PET FRP 2 C-PET-400-4-a,b 400 800 — PET FRP 4

S-PEN-300-2-a,b

300

600

60

PEN FRP

2

S-PEN-300-3-a,b

300

600

60

PEN FRP

3

S-PEN-400-2-a,b

400

800

80

PEN FRP

2

S-PEN-400-4-a,b

400

800

80

PEN FRP

4表 2 圆柱主要试验结果

Table 2. Key results of circular column tests

试件编号 fcu ′ /MPa εcu/% εh,rup/% 最大环向应变对应的应变片编号 C-PET-300-2-a 37.2 1.79 3.38 SG1 C-PET-300-2-b 39.2 2.28 3.86 SG5 C-PET-300-3-a

49.6

3.51

4.16

SG1C-PET-300-3-b 50.4 3.41 4.24 SG4 C-PET-400-2-a 35.9 1.67 3.38 SG1 C-PET-400-2-b 36.2 1.75 3.23 SG2 C-PET-400-4-a 45.2 2.19 3.28 SG5 C-PET-400-4-b 45.0 2.24 3.36 SG1 表 3 方柱主要试验结果

Table 3. Key results of square column tests

试件编号 fcu ′ /MPa εcu/% εh,c/% εh,s/% 最大环向应变对应的应变片编号 S-PEN-300-2-a 37.6 2.34 1.46 2.19 SG9 S-PEN-300-2-b 38.4 2.28 1.75 2.34 SG1 S-PEN-300-3-a 54.8 3.14 1.77 2.84 SG1 S-PEN-300-3-b 53.3 3.42 1.37 2.73 SG1 S-PEN-400-2-a 35.5 1.66 1.60 2.01 SG9 S-PEN-400-2-b 35.5 1.79 2.40 2.38 SG5 S-PEN-400-4-a 47.9 2.64 1.50 2.43 SG9 S-PEN-400-4-b 49.0 2.39 0.90 2.18 SG1 -

[1] 蔡静, 2015. 大尺寸CFRP约束混凝土方柱的轴心抗压试验研究. 湖南大学硕士论文.Cai J, 2015. Experimental research on large-scale square concrete columns confined with wrapped CFRP under axial compressive. Hunan University. (in Chinese) [2] 邓宗才, 顾佳培, 2019. FRP管约束活性粉末混凝土方柱抗震性能研究. 震灾防御技术, 14(4): 769—780 doi: 10.11899/zzfy20190408Deng Z. C. , Gu J. P. , 2019. Research on seismic performance of reactive powder concrete square columns confined with FRP tubes. Technology for Earthquake Disaster Prevention, 14(4): 769—780. (in Chinese) doi: 10.11899/zzfy20190408 [3] 龙跃凌, 戴建国, 2010. 新型大断裂应变FRP约束混凝土圆柱的轴压性能. 混凝土, 07: 44-47Long Y L, Dai J G, 2010. Behavior of circular concrete columns confined by new-typed large rupture strain FRP under axial compression. Concrete, 07: 44-47. (in Chinese) [4] ASTM, 2002. Standard test method for static modulus of elasticity and poission’s ratio of concrete in compression ASTM C469. American Society for Testing and Materials. [5] ASTM, 2008. D3039/D3039M. Standard test method for tensile properties of polymer matrix composite materials, American Society for Testing and Materials. [6] Bai Y L, Dai J G, Mohammadi M, Lin G, Mei S J, 2019. Stiffness-based design-oriented compressive stress-strain model for large-rupture-strain (LRS) FRP-confined concrete. Composites Structures, 223: 110953. doi: 10.1016/j.compstruct.2019.110953 [7] Dai J G, Bai Y L, Teng J G, 2011. Behavior and modeling of concrete confined with FRP composites of large deformability[J]. Journal of Composites for Construction, 15(6): 963-973. doi: 10.1061/(ASCE)CC.1943-5614.0000230 [8] Han Q, Yuan W Y, Bai Y L, Du X L, 2020. Compressive behavior of large rupture strain (LRS) FRP-confined square concrete columns: experimental study and model evaluation. Materials and Structures, 53: 59. doi: 10.1617/s11527-020-01495-8 [9] Han Q, Yuan W Y, Ozbakkaloglu T, and Bai Y L, 2020. Compressive behavior for recycled aggregate concrete confined with recycled polyethylene naphthalate composites. Constr. Build. Mater, 261: 120498. doi: 10.1016/j.conbuildmat.2020.120498 [10] Hollaway L C, Teng J G, 2008. Strengthening and rehabilitation of civil infrastructures using fibre- reinforced polymer (FRP) composites. Cambridge, UK: Woodhead Publishing. [11] Ozbakkaloglu T, Lim J C, Vincent T, 2013. FRP-confined concrete in circular sections: Review and assessment of stress-strain models. Engineering Structures, 49: 1068-1088. doi: 10.1016/j.engstruct.2012.06.010 [12] Pimanmas A, Saleem S, 2019. Evaluation of existing stress-strain models and modeling of PET FRP-confined concrete. J Mater Civ Eng, 31(12): 04019303. doi: 10.1061/(ASCE)MT.1943-5533.0002941 [13] Popovics S, 1973. A numerical approach to the complete stress-strain curve of concrete. Cement and concrete research, 3(5), 583-599. doi: 10.1016/0008-8846(73)90096-3 [14] Saleem S, Hussain Q, Pimanmas A, 2016. Compressive Behavior of PET FRP-Confined Circular, Square, and Rectangular Concrete Columns. Journal of Composites for Construction, 21(3): 04016097. [15] Teng J G, Chen J F, Smith S T, et al. FRP-strengthened RC structures. John Wiley & Sons, Ltd; 2002. [16] Wang L M, Wu Y F, 2008. Effect of corner radius on the performance of CFRP confined square concrete columns: Test. Engineering Structures, 30(2): 493-505. doi: 10.1016/j.engstruct.2007.04.016 [17] Xiao Y, 2009. Applications of FRP composites in concrete columns. Advance in Structural Enginerring, 7(4), 335-343. [18] Zeng J J, Lin G, Teng J G, Li LJ, 2018. Behavior of large-scale FRP-confined rectangular RC columns under axial compression. Engineering Structures, (174): 629-645. -

下载:

下载: