Parameter Analysis of Prefabricated Double Column Piers with Embedded Flange Connection

-

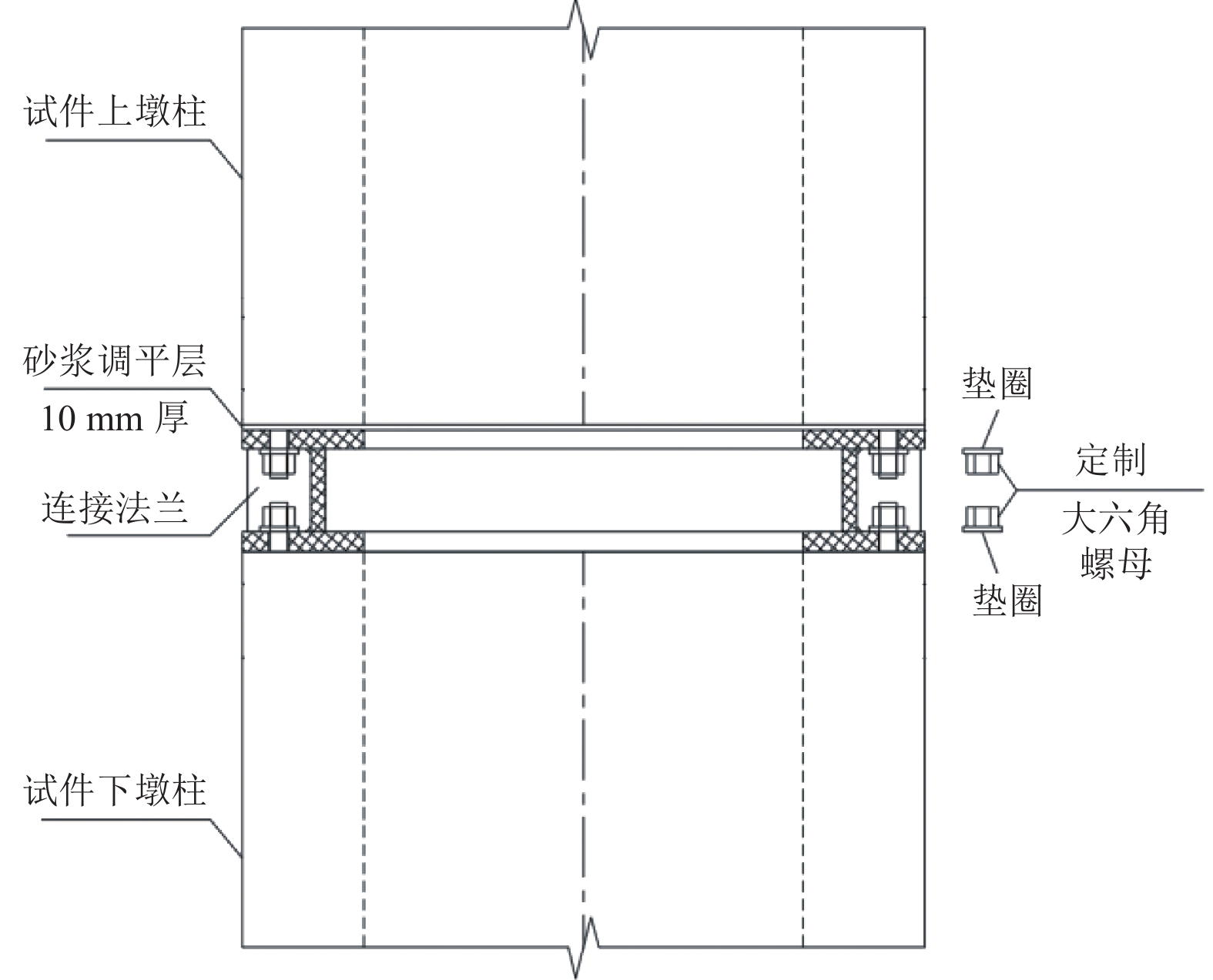

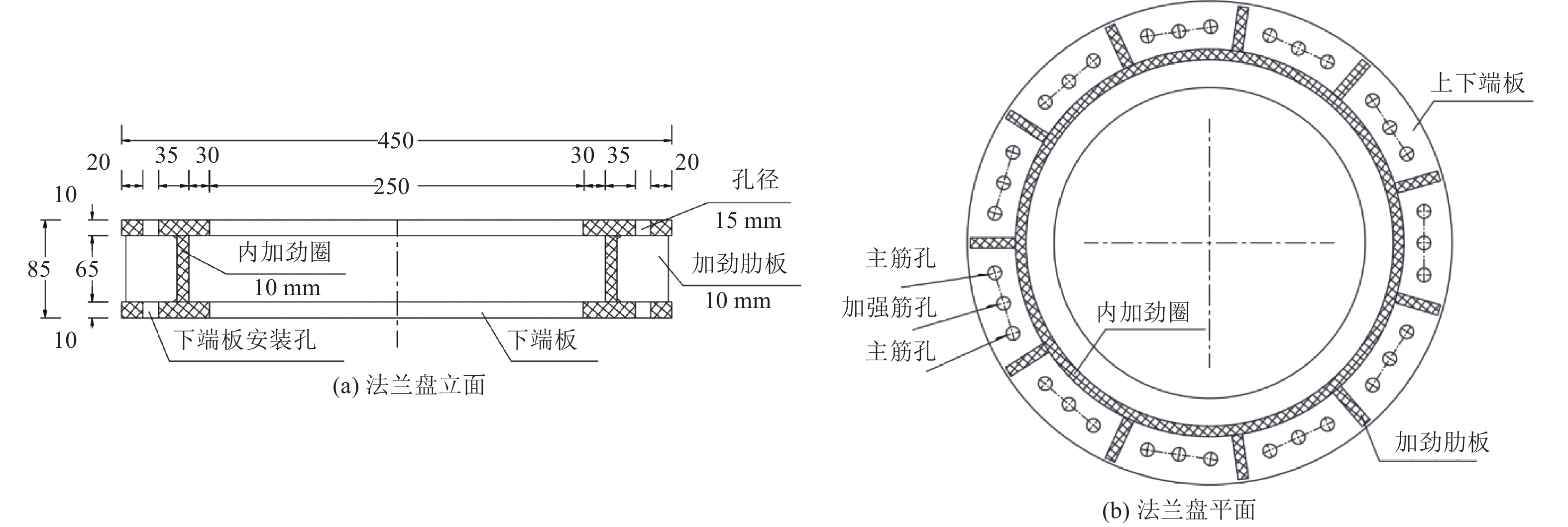

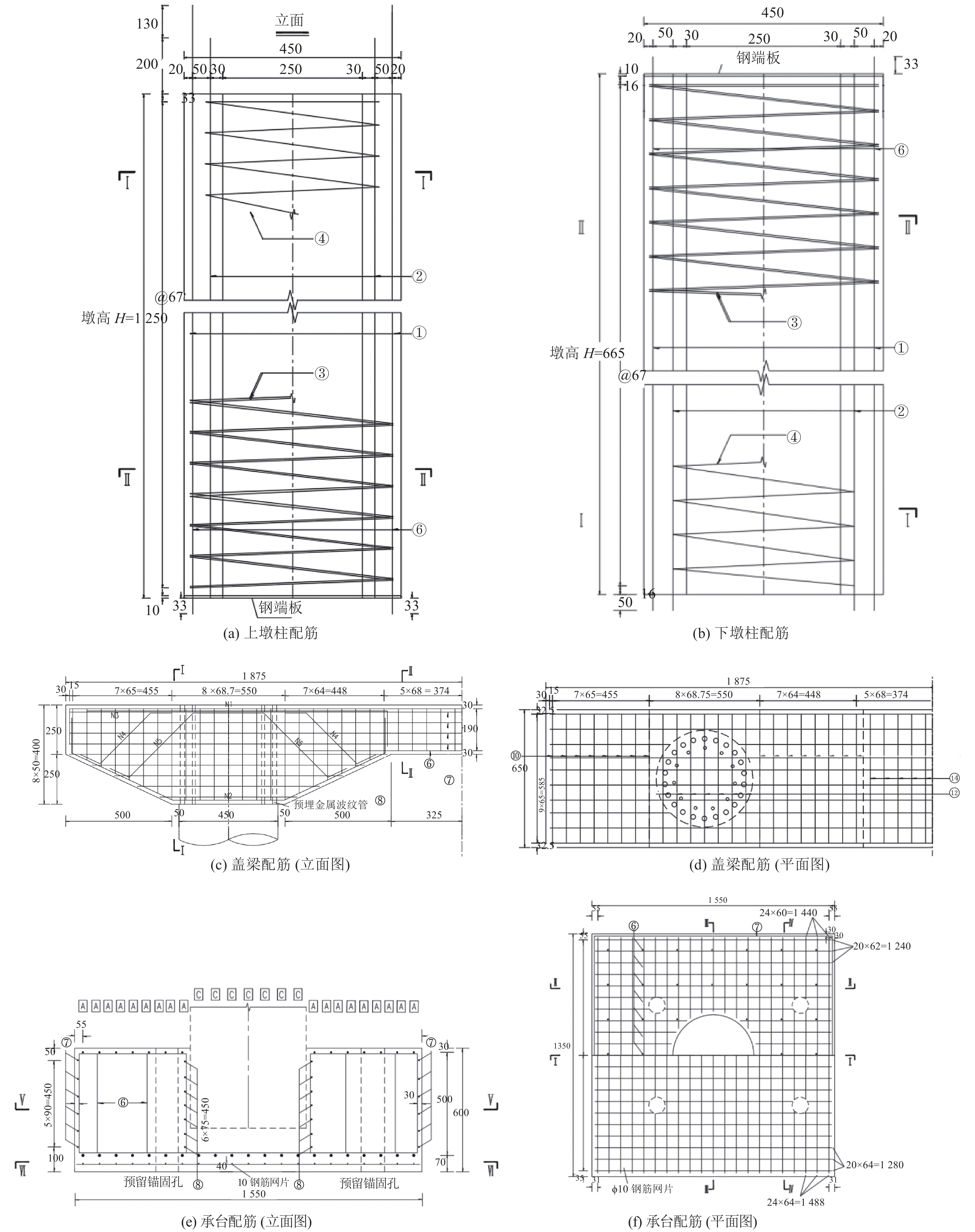

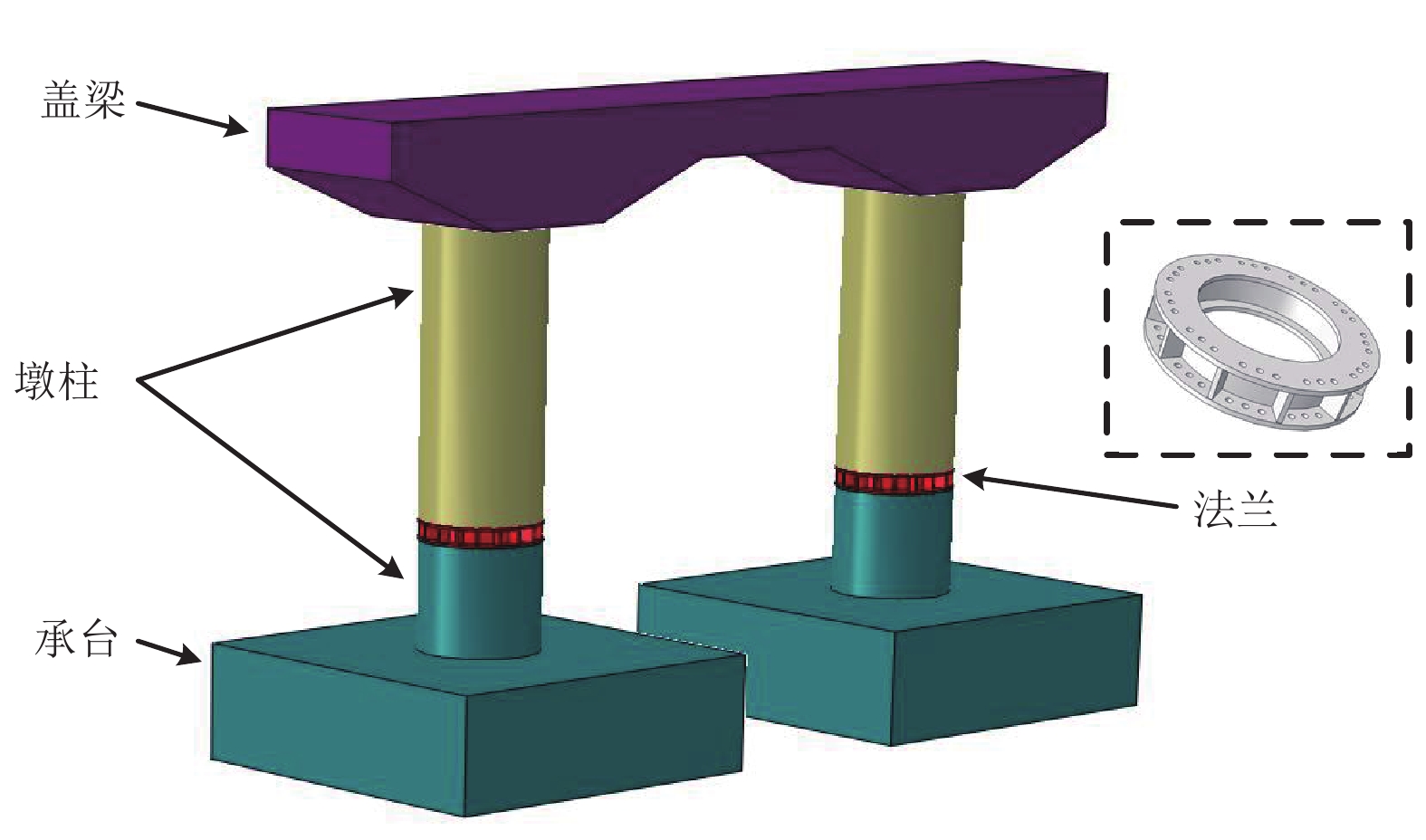

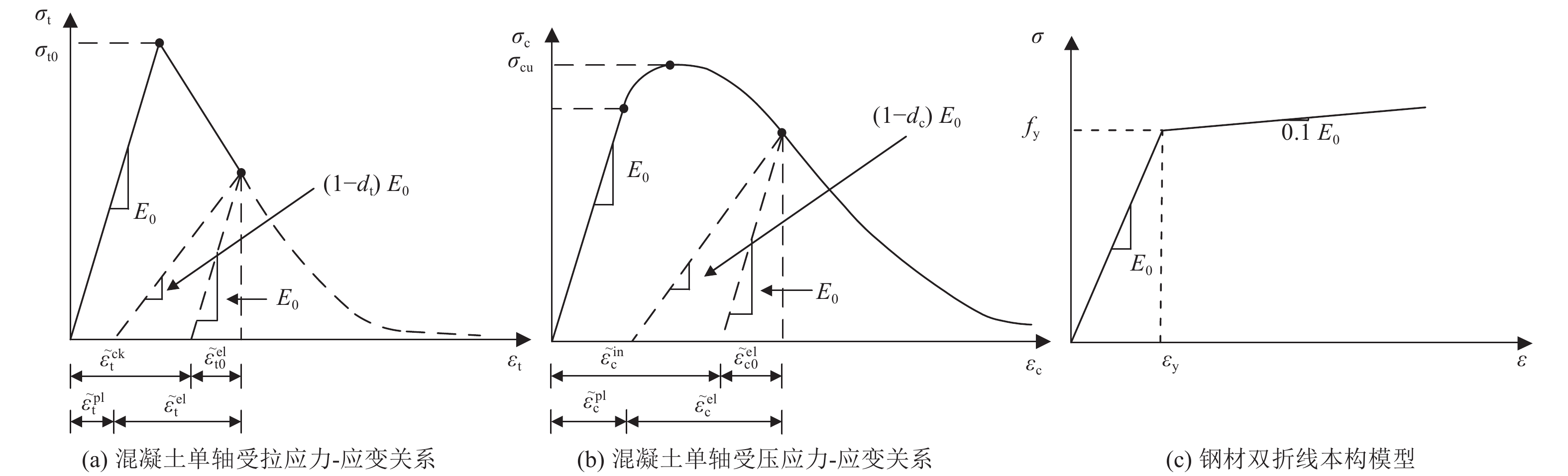

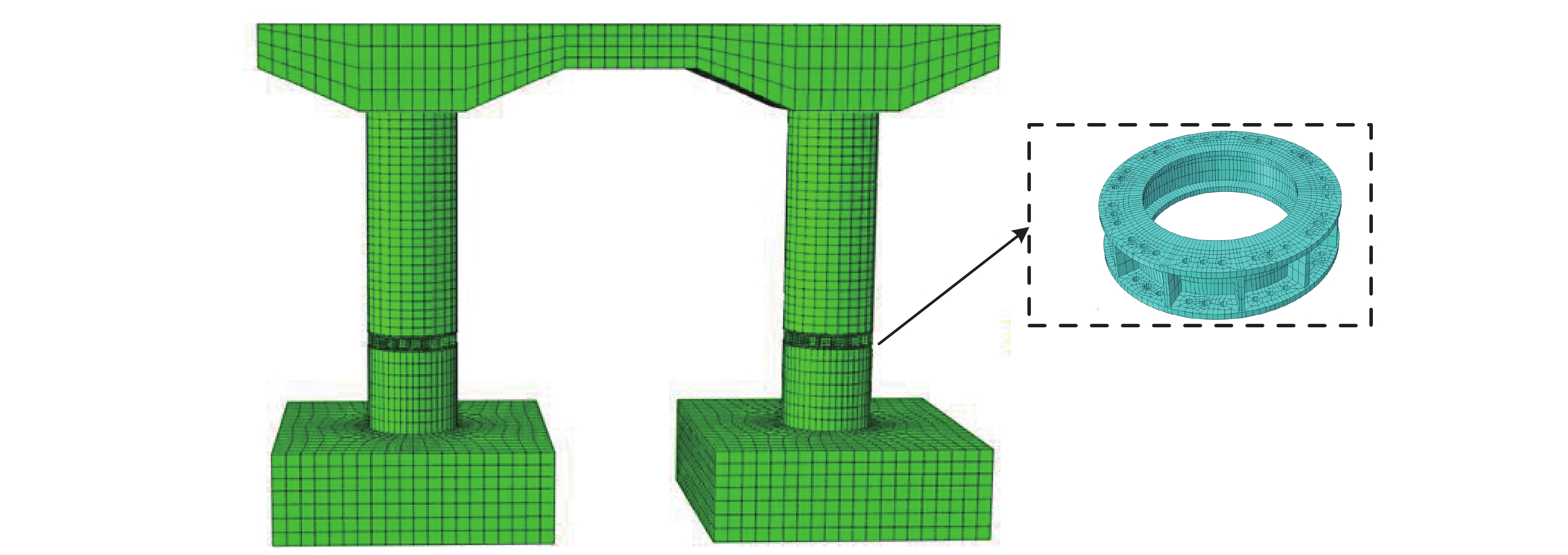

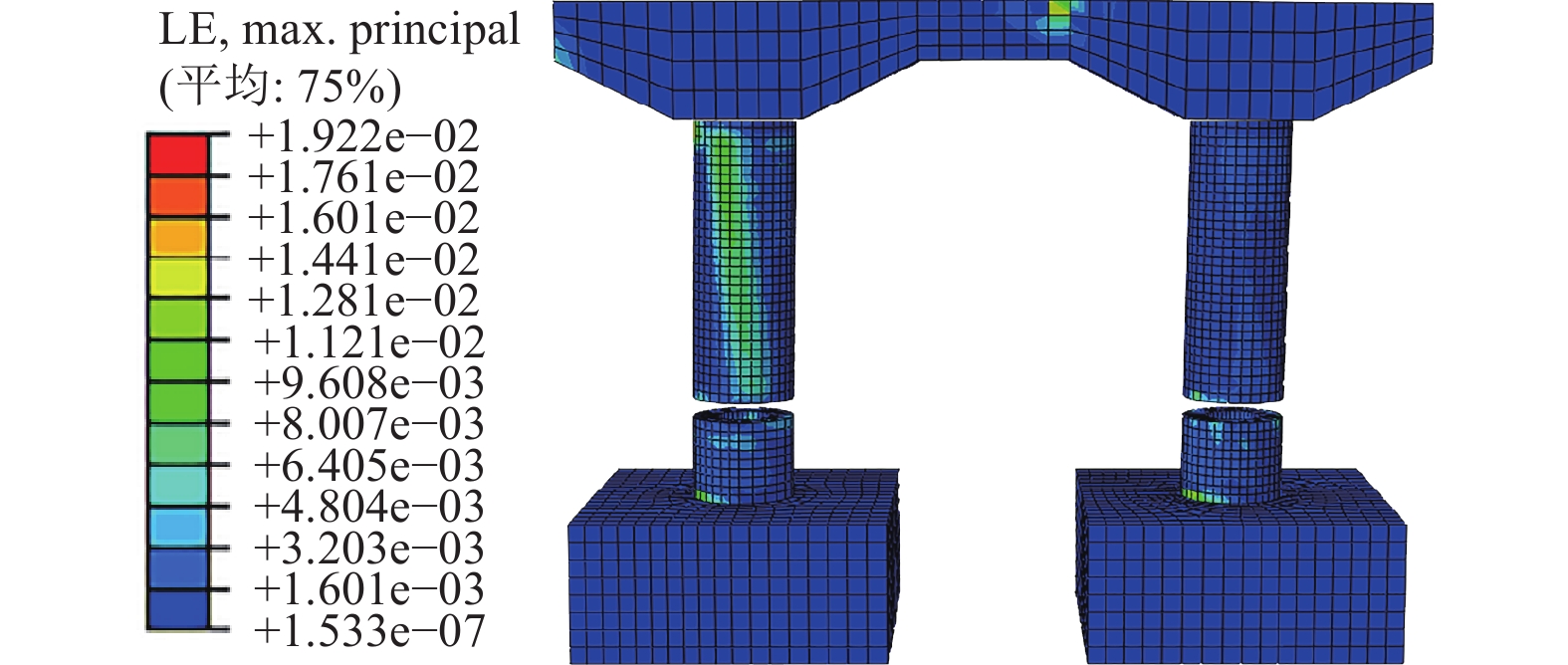

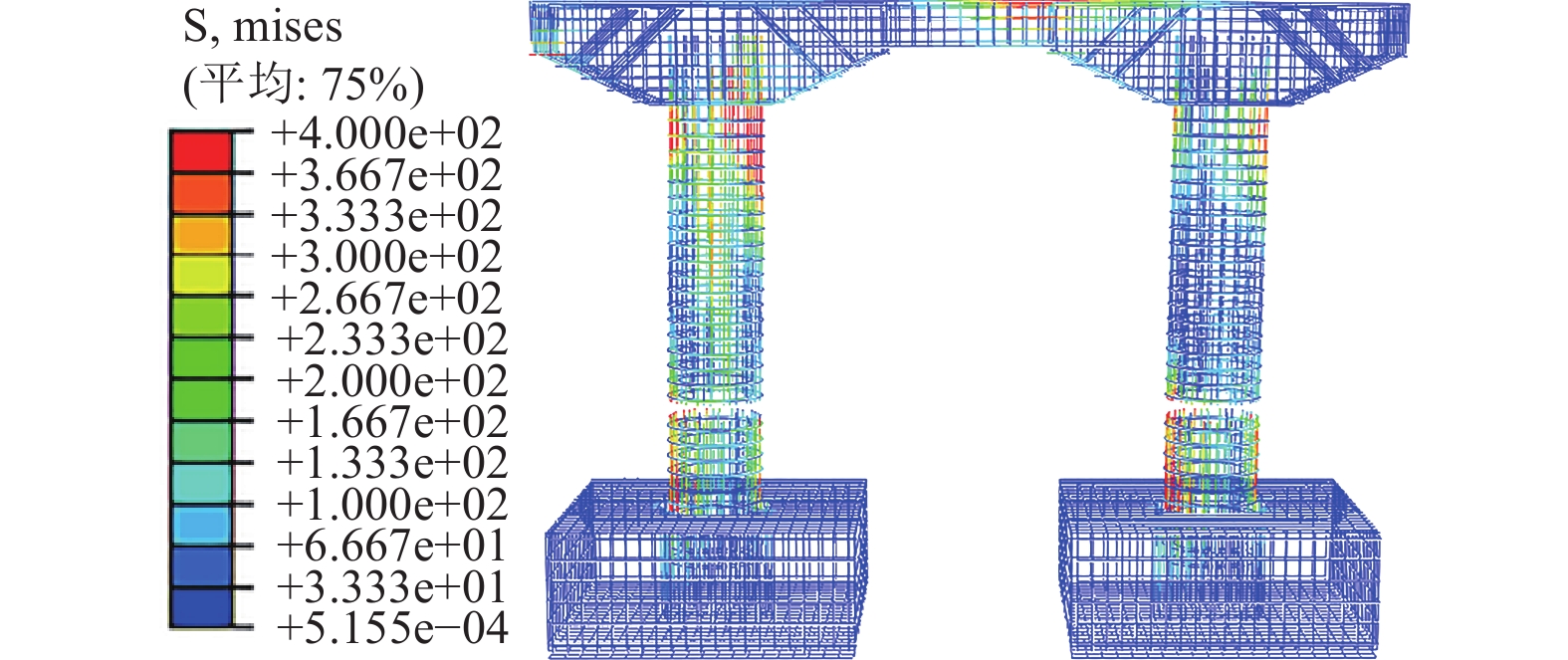

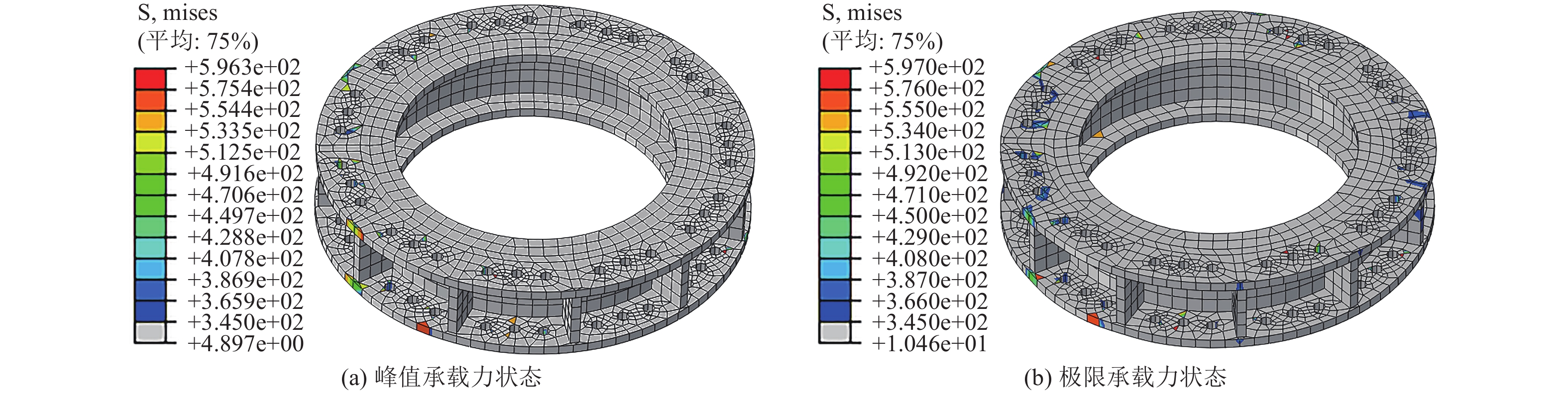

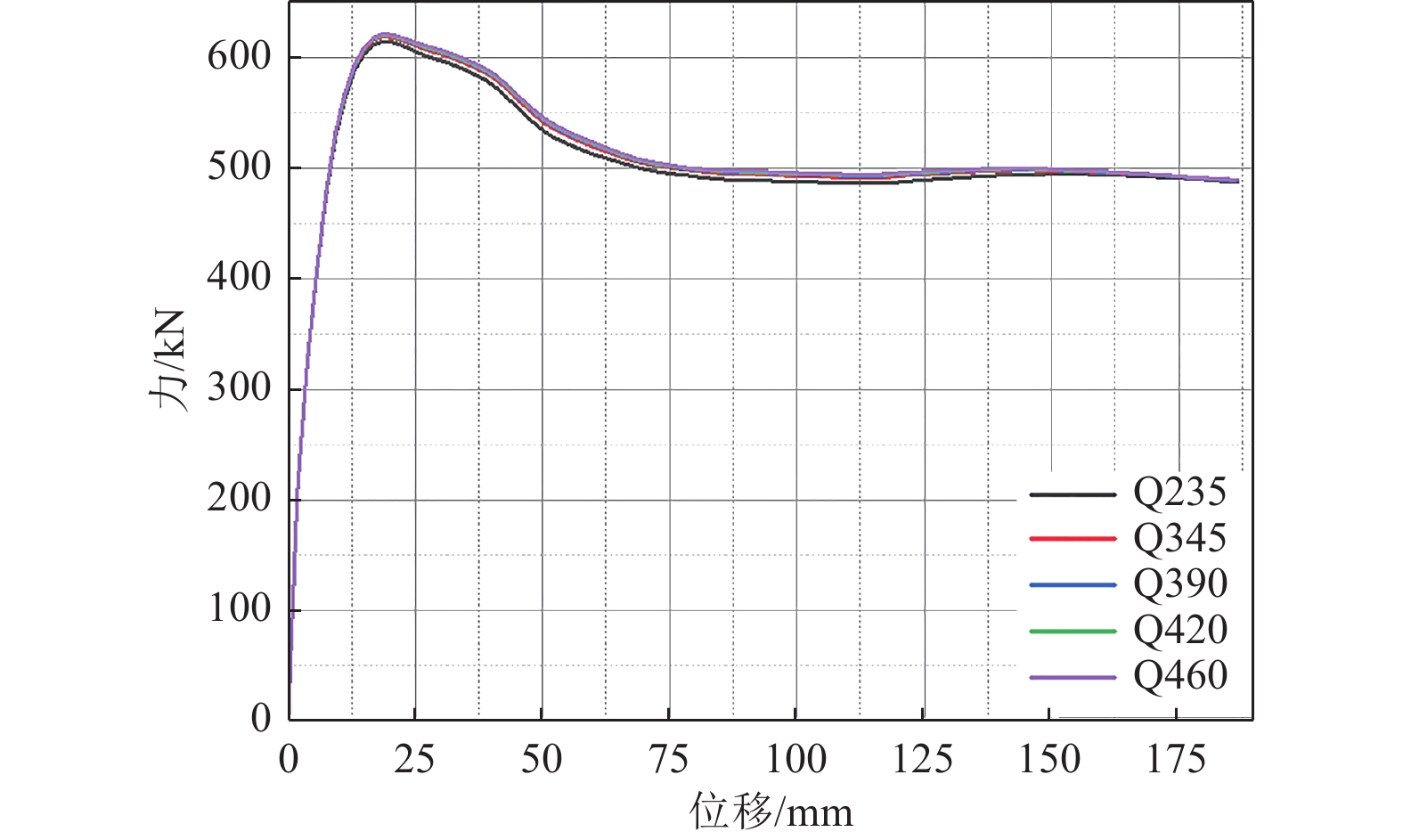

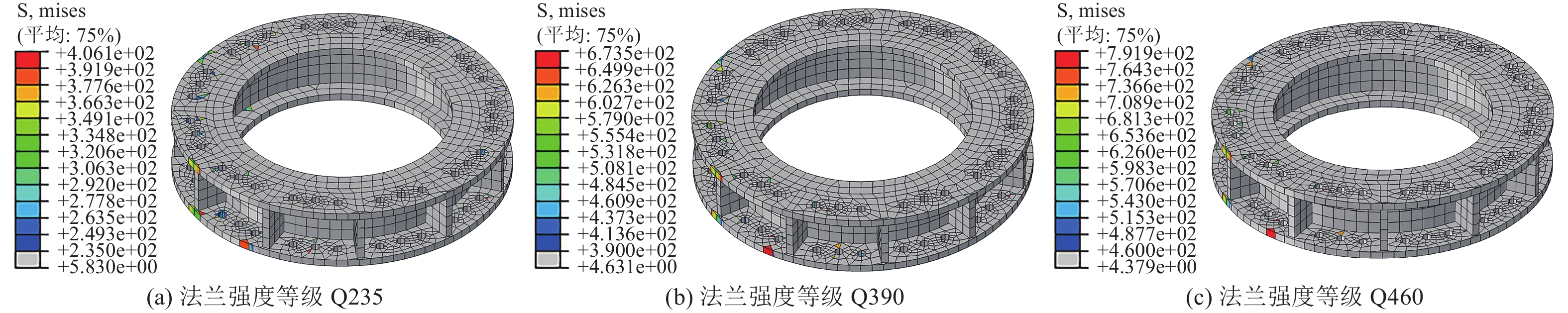

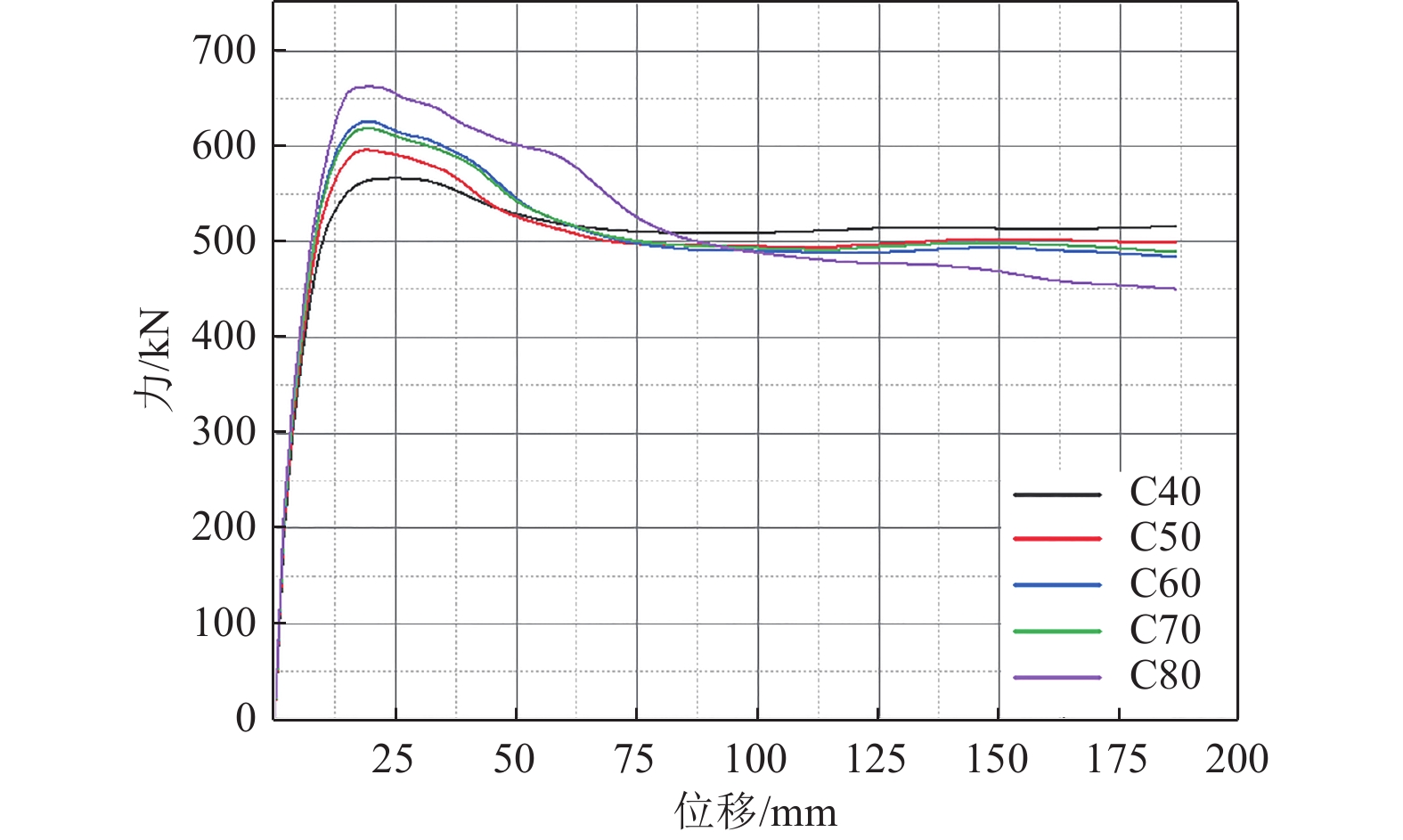

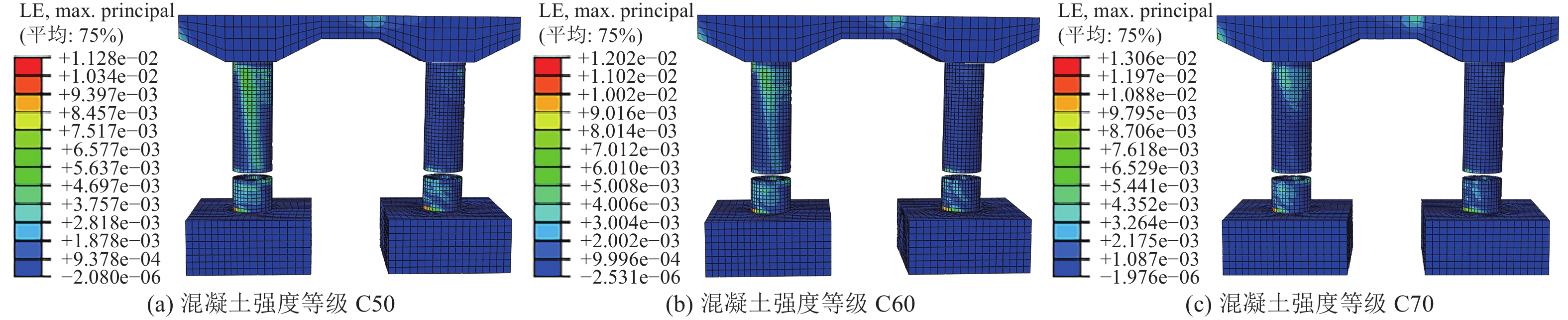

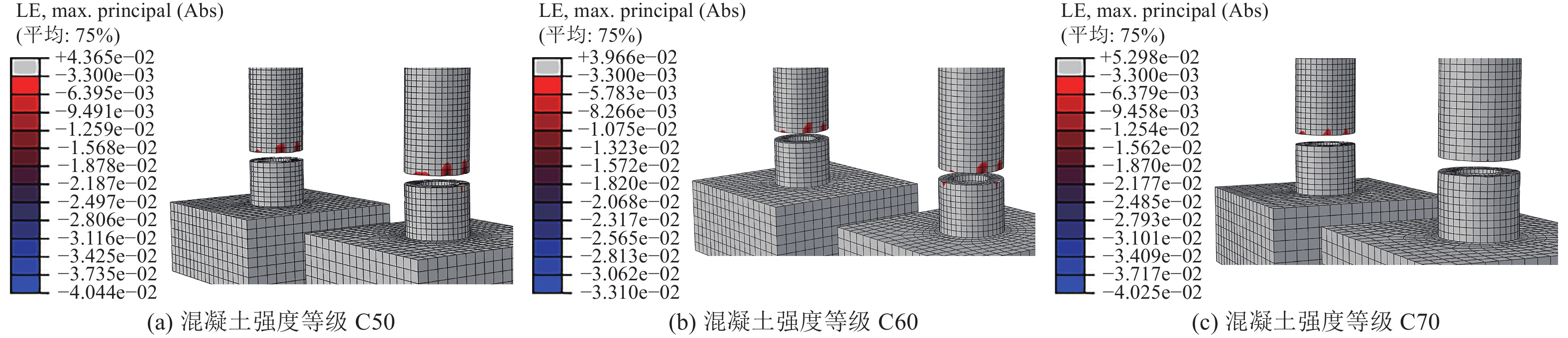

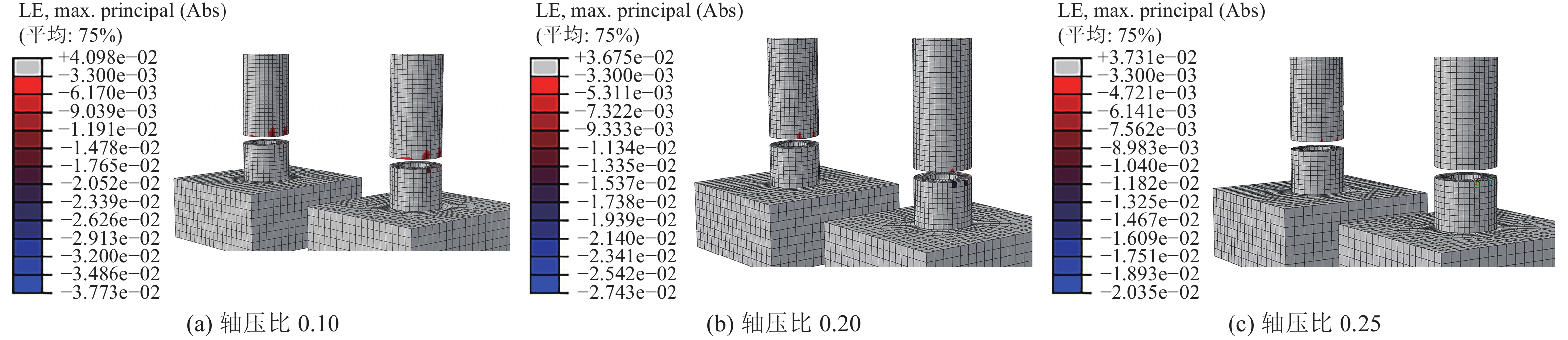

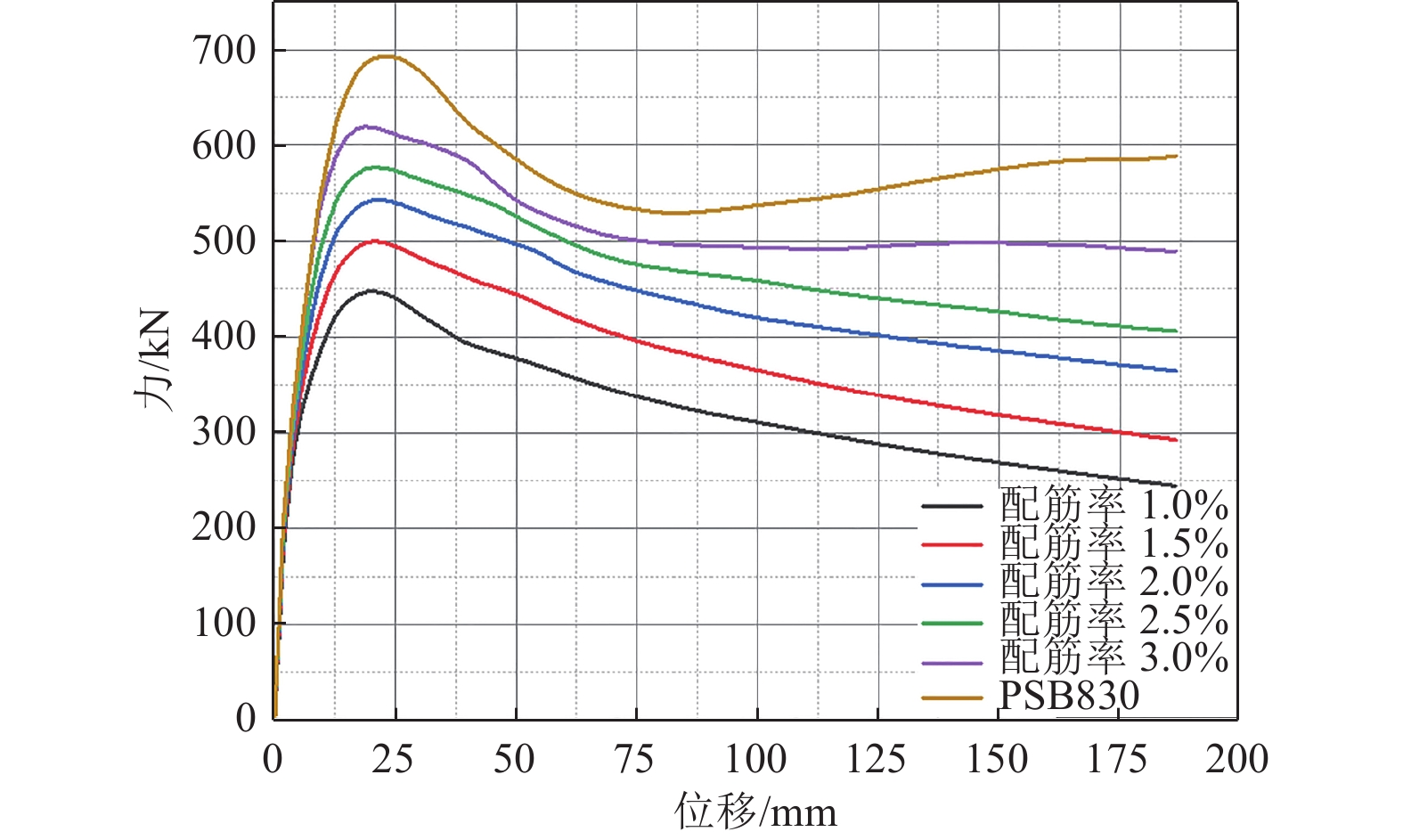

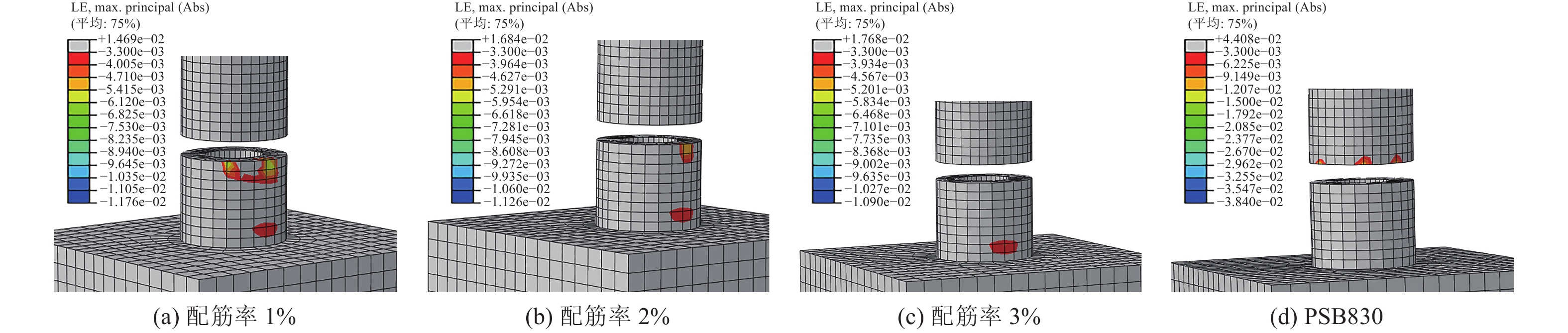

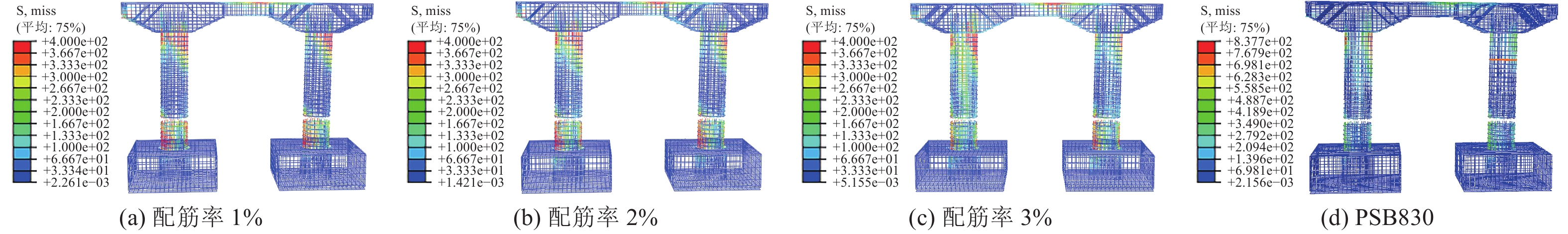

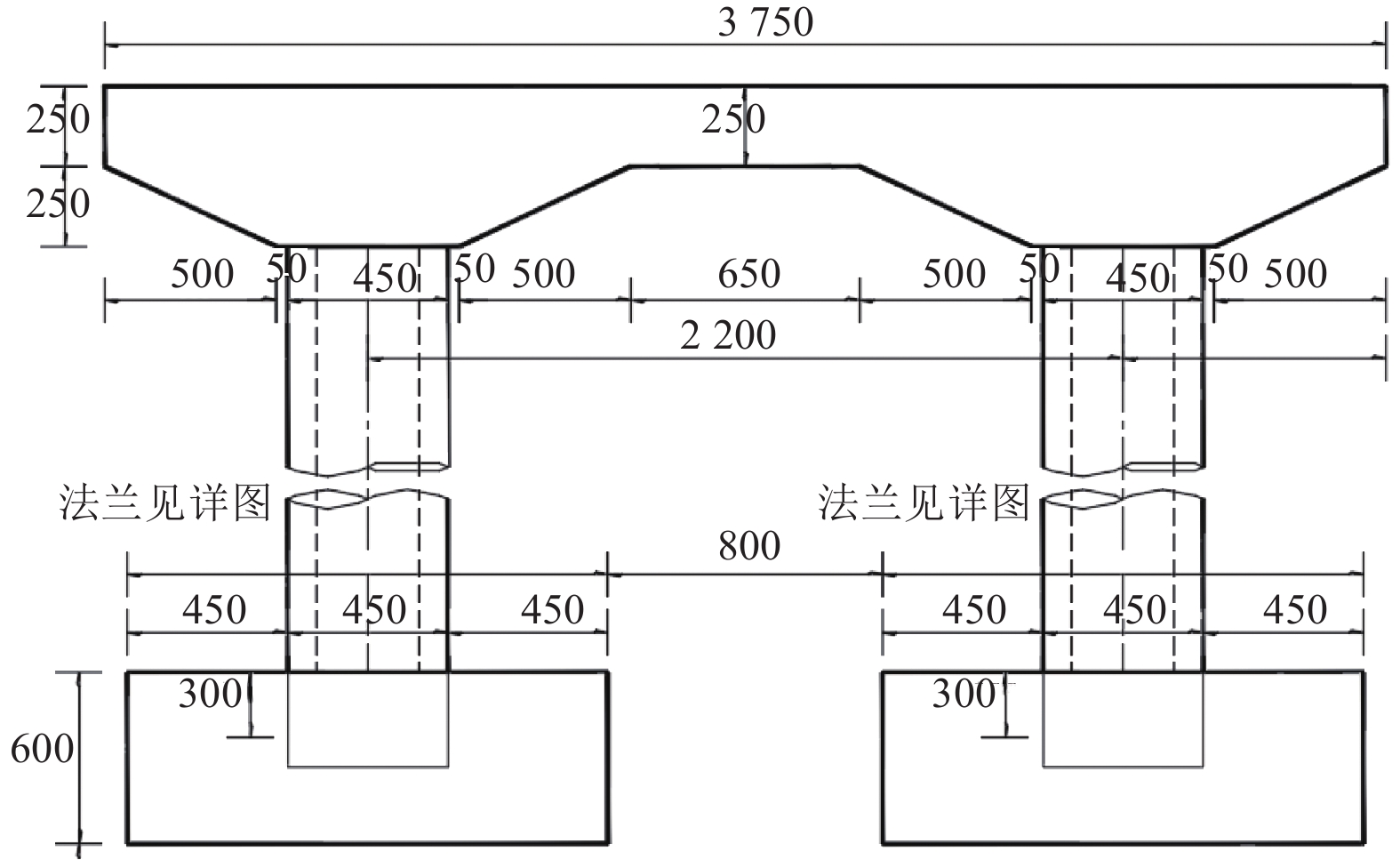

摘要: 本文基于实际工程对内嵌式法兰连接预制拼装双柱墩参数进行了分析,将法兰设置在塑性铰区以外,设计1∶3缩尺模型,通过分析不同法兰强度等级、混凝土强度等级、轴压比和配筋率的内嵌式法兰连接预制拼装双柱墩模型,得到不同情况下推覆曲线和损伤破坏状态,分析各参数的影响。研究结果表明,法兰强度等级对结构的影响较小,配筋率对结构承载力和延性的影响较大,结构最终失效主要表现在塑性铰区域,法兰存在一定程度的翘起。Abstract: The embedded flange connection for prefabricated double piers was proposed in this paper based on actual engineering. The flange was set outside the plastic hinge region and a dimension 1∶3 scaled-down model has been designed.The pushover curve and damage state was derived through different analyze of flange strength, concrete strength, axial compression ratio, and it was applied to analyze and explain the influence of each parameter on the structure from the aspect of stress and strain state. The results show that flange strength has little effect on the structure while reinforcement ratio has great influence on the bearing capacity and ductility of the structure. The final failure of the structure is mainly in the area of flange joints.

-

表 1 参数工况

Table 1. Parameter cases

组别 编号 法兰强度等级 混凝土强度等级 轴压比 配筋率/% 主筋类型 A A1 Q235 C70 0.05 3 HRB400 X Q345 C70 0.05 3 HRB400 A3 Q390 C70 0.05 3 HRB400 A4 Q420 C70 0.05 3 HRB400 A5 Q460 C70 0.05 3 HRB400 B B1 Q345 C40 0.05 3 HRB400 B2 Q345 C50 0.05 3 HRB400 B3 Q345 C60 0.05 3 HRB400 X Q345 C70 0.05 3 HRB400 B5 Q345 C80 0.05 3 HRB400 C C1 Q345 C70 0.05 3 HRB400 C2 Q345 C70 0.10 3 HRB400 C3 Q345 C70 0.15 3 HRB400 X Q345 C70 0.20 3 HRB400 C5 Q345 C70 0.25 3 HRB400 D D1 Q345 C70 0.05 1 HRB400 D2 Q345 C70 0.05 1.5 HRB400 D3 Q345 C70 0.05 2 HRB400 D4 Q345 C70 0.05 2.5 HRB400 X Q345 C70 0.05 3 HRB400 E X Q345 C70 0.05 3 HRB400 E2 Q345 C70 0.05 3 PSB830 表 2 不同轴压比构件延性系数

Table 2. Ductility coefficients of structures with different axial compression ratios

轴压比 峰值承载力/kN 峰值位移/mm 极限承载力/kN 极限位移/mm 屈服承载力/kN 屈服位移/mm 延性系数 0.05 619.25 18.7 526.36 55.13 464.44 7.16 7.7 0.10 656.51 16.8 558.03 43.49 492.38 6.85 6.3 0.15 685.99 15.9 583.09 38.24 514.49 6.43 5.9 0.20 718.69 14.9 610.89 34.55 539.02 6.17 5.5 0.25 744.58 13.1 632.89 30.71 558.44 5.78 5.3 -

[1] 方明山, 2015. 港珠澳大桥非通航孔桥下部预制墩台设计关键技术. 中外公路, 35(1): 112—117. doi: 10.3969/j.issn.1671-2579.2015.01.025 [2] 冯军军, 刘麟, 顾伯勤, 2010. 基于ABAQUS的承受外弯矩作用的螺栓法兰连接的参数化研究. 润滑与密封, 35(10): 55—58 doi: 10.3969/j.issn.0254-0150.2010.10.014Feng J. J. , Liu L. , Gu B. Q. , 2010. Parametric study of the bolted flanged connections subjected to external bending moments based on ABAQUS. Lubrication Engineering, 35(10): 55—58. (in Chinese) doi: 10.3969/j.issn.0254-0150.2010.10.014 [3] 高旭, 曾国英, 2010. 螺栓法兰连接结构有限元建模及动力学分析. 润滑与密封, 35(4): 68—71 doi: 10.3969/j.issn.0254-0150.2010.04.016Gao X. , Zeng G. Y. , 2010. The finite element modeling and dynamic analysis of bolts-flanges connecting structure. Lubrication Engineering, 35(4): 68—71. (in Chinese) doi: 10.3969/j.issn.0254-0150.2010.04.016 [4] 李伟, 段瑞春, 杨长生等, 2016. 螺栓法兰连接的数值模拟及接触收敛分析. 重庆大学学报, 39(5): 10—16 doi: 10.11835/j.issn.1000-582X.2016.05.002Li W. , Duan R. C. , Yang C. S. , et al. , 2016. The numerical simulation of bolted flange joints and the contact convergence analysis. Journal of Chongqing University, 39(5): 10—16. (in Chinese) doi: 10.11835/j.issn.1000-582X.2016.05.002 [5] 刘学春, 杨志炜, 王鹤翔等, 2017. 螺栓装配多高层钢结构梁柱连接抗震性能研究. 建筑结构学报, 38(6): 34—42Liu X. C. , Yang Z. W. , Wang H. X. , et al. , 2017. Seismic performance of beam-column connection in bolted assembled multi-high-rise steel structure. Journal of Building Structures, 38(6): 34—42. (in Chinese) [6] 王志强, 葛继平, 魏红一, 2008. 东海大桥预应力混凝土桥墩抗震性能分析. 同济大学学报(自然科学版), 36(11): 1462—1466, 1500Wang Z. Q. , Ge J. P. , Wei H. Y. , 2008. Seismic performance of prestressed concrete bridge column of East Sea Bridge. Journal of Tongji University (Natural Science), 36(11): 1462—1466, 1500. (in Chinese) [7] 王志强, 葛继平, 魏红一等, 2009. 节段拼装桥墩抗震性能研究进展. 地震工程与工程振动, 29(4): 147—154Wang Z. Q. , Ge J. P. , Wei H. Y. , et al. , 2009. Recent development in seismic research of segmental bridge columns. Earthquake Engineering and Engineering Vibration, 29(4): 147—154. (in Chinese) [8] 徐嘉毅, 郭勇, 张大长, 2019. 圆钢管刚性异形法兰轴拉承载力特性分析及设计方法. 钢结构, 34(9): 50—55Xu J. Y. , Guo Y. , Zhang D. C. , 2019. Bearing capacity characteristic analysis and design method of special-shaped rigid flange of circular steel tube under axial tension. Steel Construction, 34(9): 50—55. (in Chinese) [9] 张爱林, 吴靓, 姜子钦等, 2017. 端板型装配式钢结构梁柱节点受力机理研究. 工业建筑, 47(7): 6—12Zhang A. L. , Wu L. , Jiang Z. Q. , et al. , 2017. Tress mechanism of prefabricated beam-column connection of steel structure with end plate. Industrial Construction, 47(7): 6—12. (in Chinese) [10] 张爱林, 李超, 姜子钦等, 2018. 装配式钢结构梁柱-柱法兰连接节点受力机理研究. 工业建筑, 48(5): 11—17Zhang A. L. , Li C. , Jiang Z. Q. , et al. , 2018. Research on stress mechanism of beam-column flange connections of prefabricated steel structure. Industrial Construction, 48(5): 11—17. (in Chinese) [11] 左恒, 陶忠, 刘贝, 2019. 新型法兰盘外环板式钢节点抗震性能试验研究. 建筑结构, 49(11): 82—86, 81Zuo H. , Tao Z. , Liu B. , 2019. Experimental study on seismic performance of a new type of flanged outer ring plate steel joint. Building Structure, 49(11): 82—86, 81. (in Chinese) [12] Abidelah A. , Bouchaïr A. , Kerdal D. E. , 2012. Experimental and analytical behavior of bolted end-plate connections with or without stiffeners. Journal of Constructional Steel Research, 76: 13—27. doi: 10.1016/j.jcsr.2012.04.004 [13] Bai R. , Chan S. L. , Hao J. P. , 2015. Improved design of extended end-plate connection allowing for prying effects. Journal of Constructional Steel Research, 113: 13—27. doi: 10.1016/j.jcsr.2015.05.008 [14] Baniotopoulo C. C. , Abdalla K. M. , 1995. Sensitivity analysis results on the separation problem of bolted steel column-to-column connections. International Journal of Solids and Structures, 32(2): 251—265. doi: 10.1016/0020-7683(94)00136-K [15] Blachowski B. , Gutkowski W. , 2016. Effect of damaged circular flange-bolted connections on behaviour of tall towers, modelled by multilevel substructuring. Engineering Structures, 111: 93—103. doi: 10.1016/j.engstruct.2015.12.018 [16] Coelho A. M. G. , Simão P. D. , Bijlaard F. S. K. , 2010. Stability design criteria for steel column splices. Journal of Constructional Steel Research, 66(10): 1261—1277. doi: 10.1016/j.jcsr.2010.05.002 [17] Deng H. Z. , Song X. Q. , Chen Z. H. , et al. , 2018. Experiment and design methodology of a double-layered flange connection in axial loads. Engineering Structures, 175: 436—456. doi: 10.1016/j.engstruct.2018.08.040 [18] Hu J. Y. , Hong W. K. , Park S. C. , 2017. Experimental investigation of precast concrete based dry mechanical column–column joints for precast concrete frames. The Structural Design of Tall and Special Buildings, 26(5): e1337. doi: 10.1002/tal.1337 [19] Kapur J. , Yen W. P. , Dekelbab W. , et al. , 2012. Best practices regarding performance of ABC connections in bridges subjected to multihazard and extreme events. Washington: National Cooperative Highway Research Program. [20] Lindner J. , 2008. Old and new solutions for contact splices in columns. Journal of Constructional Steel Research, 64(7—8): 833—844. [21] Liu X. C. , Pu S. H. , Zhang A. L. , et al. , 2017. Performance analysis and design of bolted connections in modularized prefabricated steel structures. Journal of Constructional Steel Research, 133: 360—373. doi: 10.1016/j.jcsr.2017.02.025 [22] Liu X. C. , He X. N. , Wang H. X. , et al. , 2018. Bending-shear performance of column-to-column bolted-flange connections in prefabricated multi-high-rise steel structures. Journal of Constructional Steel Research, 145: 28—48. doi: 10.1016/j.jcsr.2018.02.017 [23] Mohamadi-Shooreh M. R. , Mofid M. , 2008. Parametric analyses on the initial stiffness of flush end-plate splice connections using FEM. Journal of Constructional Steel Research, 64(10): 1129—1141. doi: 10.1016/j.jcsr.2007.09.010 [24] Nzabonimpa J. D. , Hong W. K. , Kim J. , 2017a. Mechanical connections of the precast concrete columns with detachable metal plates. The Structural Design of Tall and Special Buildings, 26(17): e1391. doi: 10.1002/tal.1391 [25] Nzabonimpa J. D. , Hong W. K. , Kim J. , 2017b. Nonlinear finite element model for the novel mechanical beam-column joints of precast concrete-based frames. Computers & Structures, 189: 31—48. [26] Nzabonimpa J. D. , Hong W. K. , Park S. C. , 2017c. Experimental investigation of dry mechanical beam–column joints for precast concrete based frames. The Structural Design of Tall and Special Buildings, 26(1): e1302. doi: 10.1002/tal.1302 [27] Nzabonimpa J. D. , Hong W. K. , 2018a. Use of laminated mechanical joints with metal and concrete plates for precast concrete columns. Materials and Structures, 51(3): 76. doi: 10.1617/s11527-018-1207-y [28] Nzabonimpa J. D. , Hong W. K. , 2018b. Structural performance of detachable precast composite column joints with mechanical metal plates. Engineering Structures, 160: 366—382. doi: 10.1016/j.engstruct.2018.01.038 [29] Shahawy M. A. , 2003. Prefabricated bridge elements and systems to limit traffic disruption during construction. Washington: Transportation Research Board. [30] Snijder H. H. , Hoenderkamp J. C. D. , 2008. Influence of end plate splices on the load carrying capacity of columns. Journal of Constructional Steel Research, 64(7—8): 845—853. [31] Tagawa H. , Liu Y. D. , 2014. Stiffening of bolted end-plate connections with steel member assemblies. Journal of Constructional Steel Research, 103: 190—199. doi: 10.1016/j.jcsr.2014.09.005 [32] Wang J. F. , Chen L. P. , 2012. Experimental investigation of extended end plate joints to concrete-filled steel tubular columns. Journal of Constructional Steel Research, 79: 56—70. doi: 10.1016/j.jcsr.2012.07.016 [33] Wang J. F. , Zhang L. , Spencer Jr. B. F. , 2013. Seismic response of extended end plate joints to concrete-filled steel tubular columns. Engineering Structures, 49: 876—892. doi: 10.1016/j.engstruct.2013.01.001 [34] Wang Z. Q. , Li T. T. , Qu H. Y. , et al. , 2019. Seismic performance of precast bridge columns with socket and pocket connections based on quasi-static cyclic tests: experimental and numerical study. Journal of Bridge Engineering, 24(11): 04019105. doi: 10.1061/(ASCE)BE.1943-5592.0001463 -

下载:

下载: