Research on Vibration Attenuation of Free Field Soil under Pile Driving Load

-

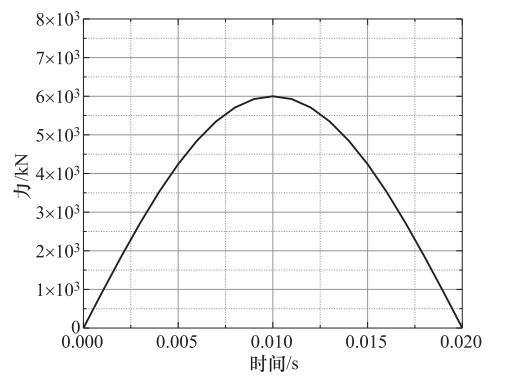

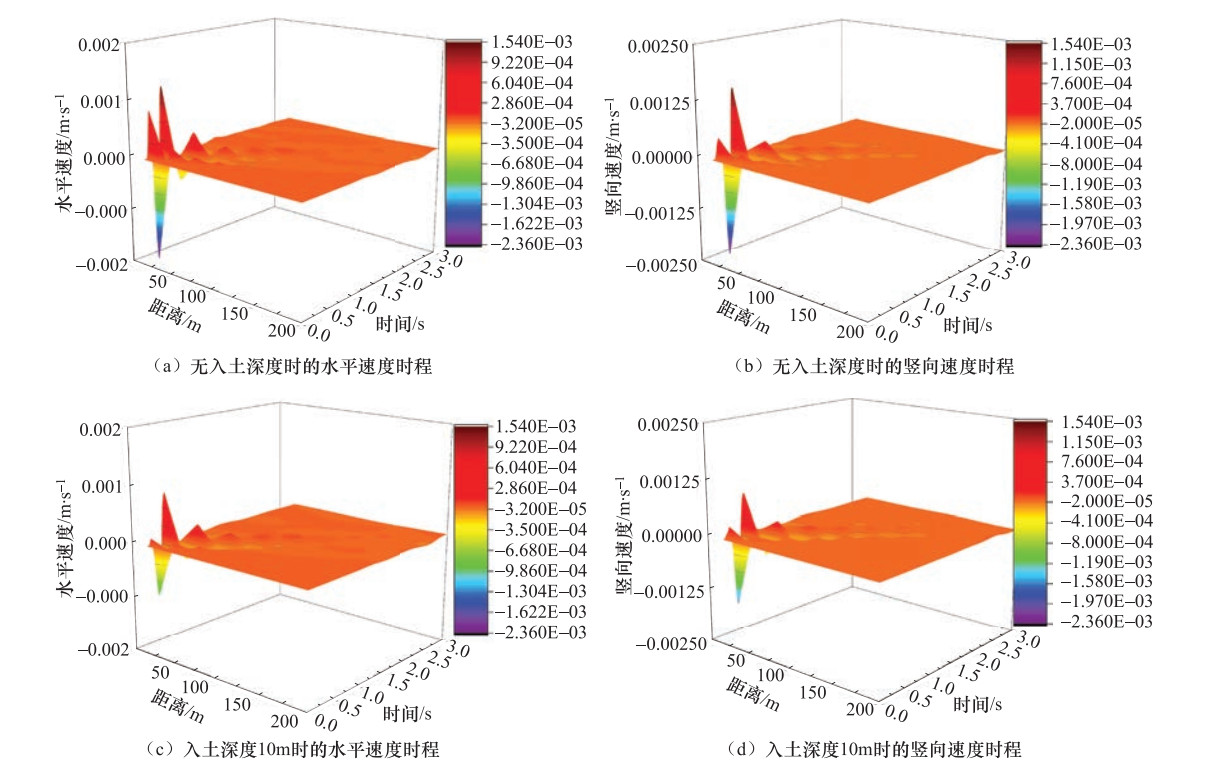

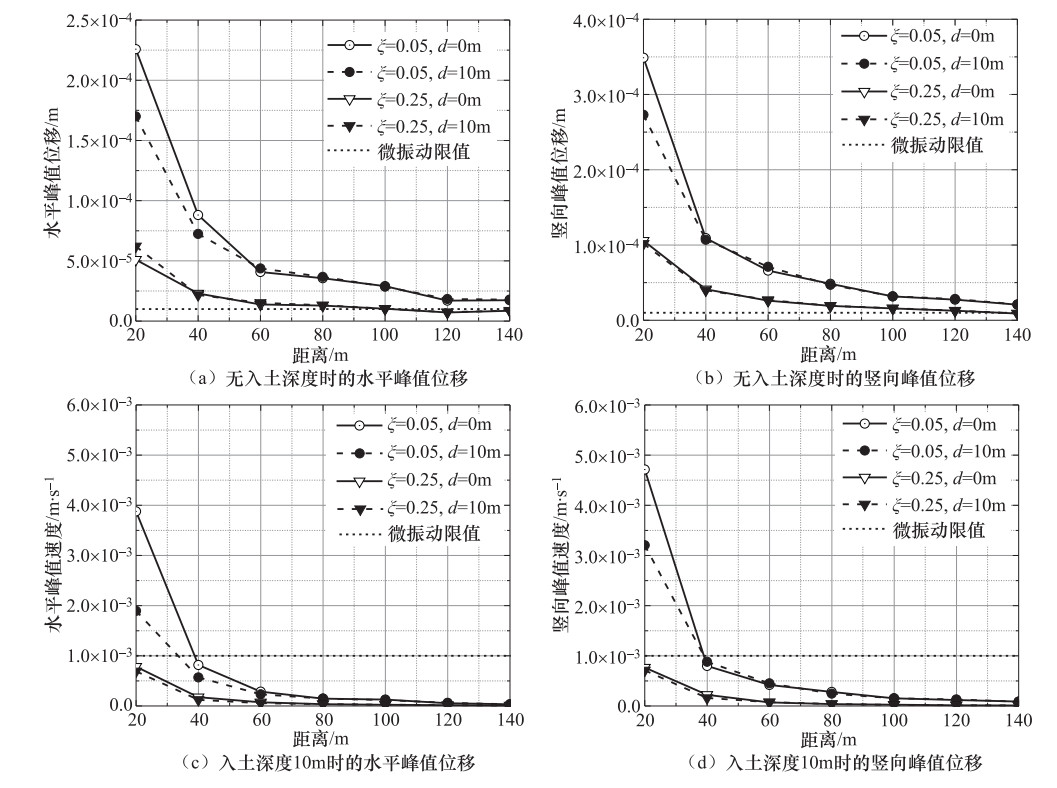

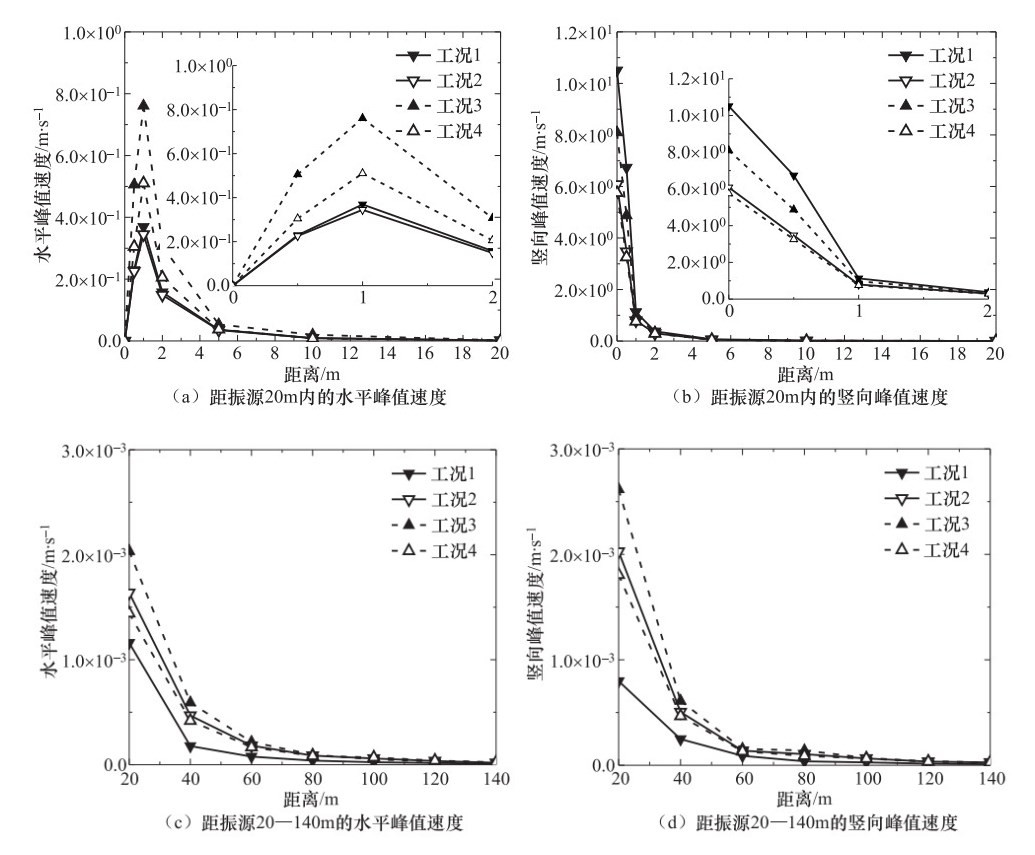

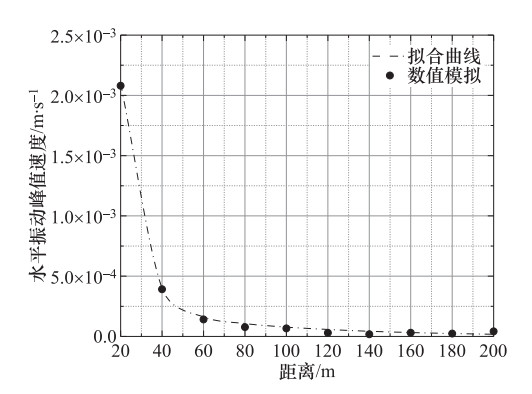

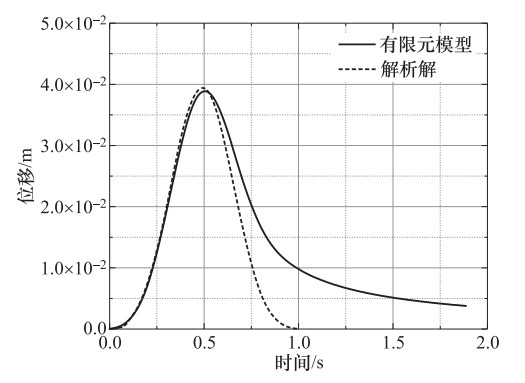

摘要: 为研究打桩荷载作用下自由场土体振动衰减规律,建立了考虑桩-土相互作用的二维有限元数值模型,并通过Lamb问题解析解验证了数值模型的有效性。通过分析打桩深度、土体阻尼比、打桩荷载等级和土质条件等因素的影响,研究了土体表面振动特性及振动衰减规律。参数分析表明,打桩深度对微振动的影响较小,在距振源一定距离处的土体表面振动响应基本保持一致;土体阻尼比对土体表面振动的影响显著,阻尼比越小,土体表面振动响应越剧烈;不同场地软硬条件影响微振动的限制距离,在一定距离范围内,土质越软,土体表面振动响应越显著,防振距离越长。基于参数分析结果,对峰值速度衰减曲线进行拟合,拟合公式计算结果与模拟结果较吻合,可为振动敏感建筑场地的选择提供参考。Abstract: In order to study the propagation and attenuation law of pile driving vibration load in free field soil, a two-dimensional finite element numerical model considering pile-soil interaction is established, and the validity of the numerical model is verified by analytical solution of Lamb problem. By analyzing the influence of factors such as pile depth, soil damping ratio, pile load level, and soil condition, the characteristics of soil surface vibration and the law of vibration attenuation are studied. The parameter analysis shows that the impact of pile driving depth on microvibration is small, and the vibration response of the soil surface is basically the same at a certain distance from the vibration source; The soil damping ratio has a significant effect on the soil surface vibration, with the decrease of the damping ratio, the vibration response of the soil surface becomes more severe; different soil conditions affect the limit distance of the microvibration, within a certain distance, the softer the soil quality, the more significant the vibration response of the soil surface, and the longer the vibration-proof distance.Based on the above-mentioned parameter analysis results, the peak velocity attenuation curve is fitted, and the settlement result of the fitting formula is in good agreement with the simulation result, which can provide a reference for the selection of vibration-sensitive building sites.

-

Key words:

- Soil characteristics /

- Dynamic Response /

- Vibration load /

- Finite element analysis

-

表 1 材料参数

Table 1. Material parameters

工况 材料 密度/kg·m-3 弹性模量/MPa 泊松比 工况1 黏土1(0—200m) 2000 30 0.35 工况2 黏土2(0—200m) 2100 60 0.35 工况3 黏土1(0—100m) 2000 30 0.35 黏土2(100—200m) 2100 60 0.35 工况4 黏土1(0—100m) 2100 60 0.35 黏土2(100—200m) 2000 30 0.35 桩 2500 2×103 0.20 表 2 工况1水平振动速度衰减公式系数取值

Table 2. The coefficient of velocity attenuation formula of horizontal vibration in working condition 1

影响系数 ξ=0.05 ξ=0.15 ξ=0.25 2000kN 4000kN 6000kN 2000kN 4000kN 6000kN 2000kN 4000kN 6000kN a 0.0124 0.0248 0.0371 0.0019 0.0038 0.0057 0.0017 0.0035 0.0052 b -0.0987 -0.0987 -0.0987 -0.0809 -0.0809 -0.0809 -0.0790 -0.0790 -0.0790 c 3.08×10-4 6.17×10-4 6.17×10-4 6.17×10-4 1.57×10-5 2.35×10-5 4.61×10-5 9.22×10-5 1.38×10-4 d -0.0182 -0.0182 -0.0182 -0.0148 -0.0148 -0.0148 -0.0148 -0.0148 -0.0148 表 3 工况2水平振动速度衰减公式系数取值

Table 3. The coefficient of velocity attenuation formula of horizontal vibration in working condition 2

影响系数 ξ=0.05 ξ=0.15 ξ=0.25 2000kN 4000kN 6000kN 2000kN 4000kN 6000kN 2000kN 4000kN 6000kN a 0.0161 0.0321 0.0482 0.0022 0.0044 0.0066 0.0019 0.0038 0.0056 b -0.1083 -0.1083 -0.1083 -0.0782 -0.0782 -0.0782 -0.0828 -0.0828 -0.0828 c 3.38×10-4 6.75×10-4 0.001 1.24×10-4 2.47×10-4 3.71×10-4 5.60×10-5 1.12×10-4 1.68×10-4 d -0.0148 -0.0148 -0.0148 -0.0148 -0.0148 -0.0148 -0.0148 -0.0148 -0.0148 表 4 工况1竖向振动速度衰减公式系数取值

Table 4. The coefficient of the attenuation formula of vertical vibration velocity in working condition 1

影响系数 ξ=0.05 ξ=0.15 ξ=0.25 2000kN 4000kN 6000kN 2000kN 4000kN 6000kN 2000kN 4000kN 6000kN a 0.0118 0.0237 0.0355 0.0016 0.0033 0.0049 0.0027 0.0055 0.0082 b -0.0851 -0.0851 -0.0851 -0.1120 -0.1120 -0.1120 -0.1151 -0.1151 -0.1151 c 2.60×10-4 5.20×10-4 7.80×10-4 1.55×10-4 3.09×10-4 4.64×10-4 1.77×10-4 3.53×10-4 5.30×10-4 d -0.0182 -0.0182 -0.0182 -0.0182 -0.0182 -0.0182 -0.0182 -0.0182 -0.0182 表 5 工况2竖向振动速度衰减公式系数取值

Table 5. The coefficient of the attenuation formula of vertical vibration velocity in working condition 2

影响系数 ξ=0.05 ξ=0.15 ξ=0.25 2000kN 4000kN 6000kN 2000kN 4000kN 6000kN 2000kN 4000kN 6000kN a 0.0119 0.0237 0.0356 0.0108 0.0216 0.0324 0.0028 0.0055 0.0083 b -0.0857 -0.0857 -0.0857 -0.1544 -0.1544 -0.1544 -0.1132 -0.1132 -0.1132 c 3.21×10-4 6.41×10-4 9.62×10-4 2.91×10-4 5.82×10-4 8.73×10-4 1.64×10-4 3.29×10-4 4.93×10-4 d -0.0182 -0.0182 -0.0182 -0.0182 -0.0182 -0.0182 -0.0182 -0.0182 -0.0182 -

陈龙珠, 陈胜立, 梁发云, 2002.饱和地基竖向振动的衰减特性.上海交通大学学报, 36(3):376—381. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=shjtdxxb200203022 杜修力, 赵密, 王进廷, 2006.近场波动模拟的人工应力边界条件.力学学报, 38(1):49—56. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=lxxb200601007 韩云山, 董彦莉, 王元龙等, 2015.不同夯击方式下地表土体振动衰减规律研究.中北大学学报(自然科学版), 36(4):475—480, 487. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hbgxyxb201504015 李润, 简文彬, 康荣涛, 2011.强夯加固填土地基振动衰减规律研究.岩土工程学报, 33(S1):246—250. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=7508279 廖振鹏, 2002.工程波动理论导论.北京:科学出版社. 刘晶波, 王振宇, 杜修力等, 2005.波动问题中的三维时域粘弹性人工边界.工程力学, 22(6):46—51. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gclx200506008 刘毓氚, 刘一鸣, 2012.桩基础对邻近场地冲击荷载的响应分析.岩土力学, 33(9):2796—2802. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ytlx201209037 马蒙, 刘维宁, 王文斌, 2013.轨道交通地表振动局部放大现象成因分析.工程力学, 30(4):275—280, 309. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gclx201304040 陶连金, 张波, 王文沛等, 2011.冲击作用下地层振动衰减规律的现场试验研究.地震工程与工程振动, 31(4):33—39. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dzgcygczd201104005 滕忻利, 2008.强夯引发的环境振动效应分析与评价.北京: 北京交通大学. 王雨林, 刘勇健, 2005.基于波动理论的PHC桩桩锤选择研究.广东土木与建筑, (11):12—15, 25. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gdtmyjz200511005 向国威, 叶冠林, 王建华, 2012.冲击振动在砂土中传播的模型试验研究.上海交通大学学报, 46(1):136—141. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=shjtdxxb201201028 中华人民共和国住房和城乡建设部, 中华人民共和国国家质量监督检验检疫总局, 2015.GB 51076—2015电子工业防微振工程技术规范.北京: 中国计划出版社, 2015. Deeks A. J., Randolph M. F., 1994. Axisymmetric time-domain transmitting boundaries. Journal of Engineering Mechanics, 120(1): 25—42. doi: 10.1061/(ASCE)0733-9399(1994)120:1(25) Ekanayake S. D., Liyanapathirana D. S., Leo C. J., 2013. Influence zone around a closed-ended pile during vibratory driving. Soil Dynamics and Earthquake Engineering, 53: 26—36. doi: 10.1016/j.soildyn.2013.06.005 Henke S., 2010. Influence of pile installation on adjacent structures. International Journal for Numerical and Analytical Methods in Geomechanics, 34(11): 1191—1210. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.1002/nag.859 Kausel E., 2006. Fundamental solutions in elastodynamics: A compendium.Cambridge:Cambridge University Press. Lamb H., 1904. On the propagation of tremors over the surface of an elastic solid. Philosophical Transactions of the Royal Society of London, 203(359-371): 1—42. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=J-STAGE_2074456 Lysmer J., Kuhlemeyer A. M., 1969. Finite dynamic model for infinite media. Journal of the Engineering Mechanics Division, 95(4): 759—877. http://ci.nii.ac.jp/naid/10018723298 Masoumi H. R., Degrande G., Lombaert G., 2007. Prediction of free field vibrations due to pile driving using a dynamic soil–structure interaction formulation. Soil Dynamics and Earthquake Engineering, 27(2): 126—143. doi: 10.1016/j.soildyn.2006.05.005 Thandavamoorthy T. S., 2004. Piling in fine and medium sand-A case study of ground and pile vibration. Soil Dynamics and Earthquake Engineering, 24(4): 295—304. doi: 10.1016/j.soildyn.2003.12.005 -

下载:

下载: