Analysis of Technical Performance of Underground Structure Seismic Truncated Columns with Replaceable Column Foot

-

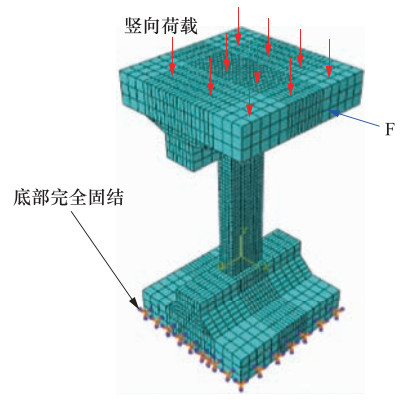

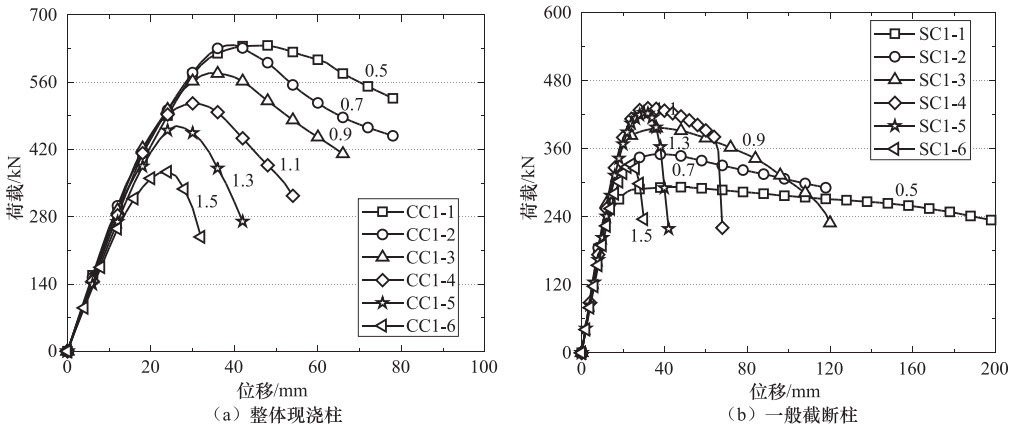

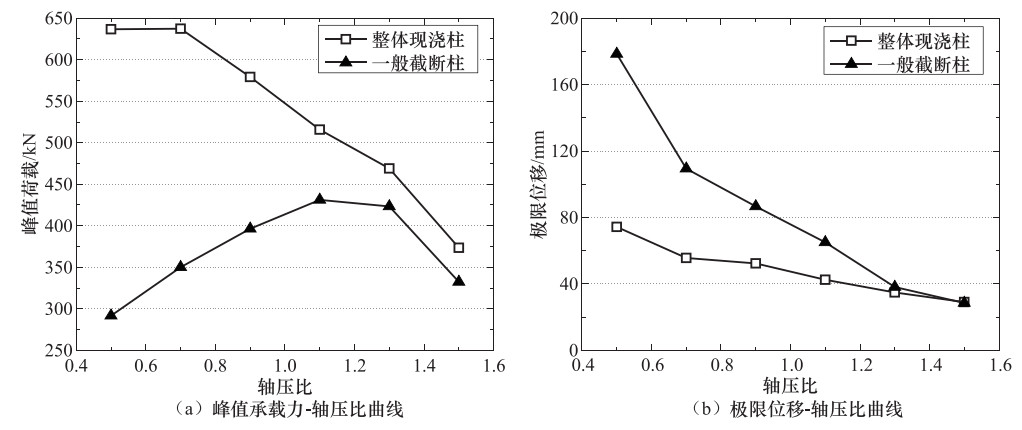

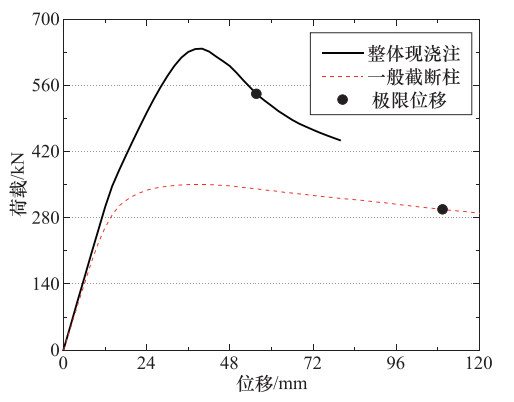

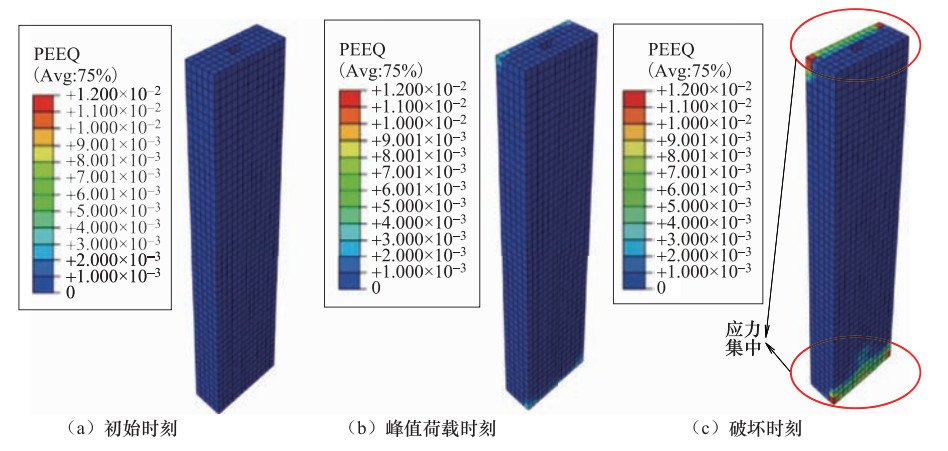

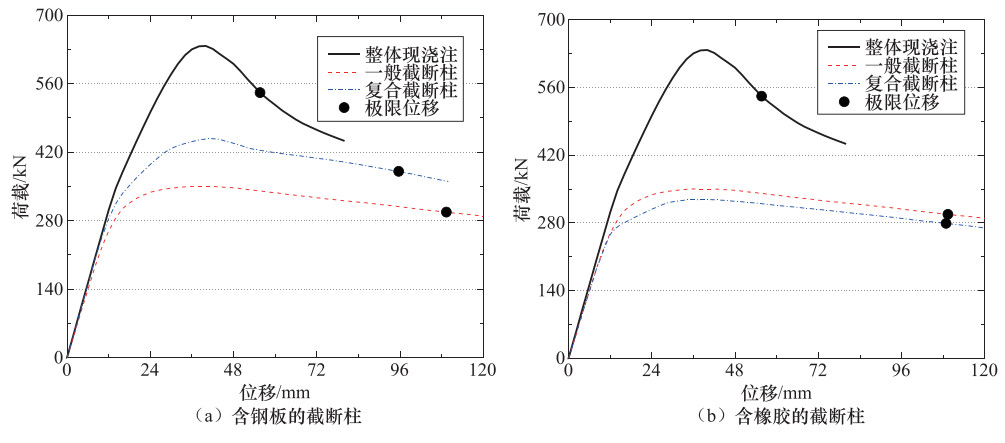

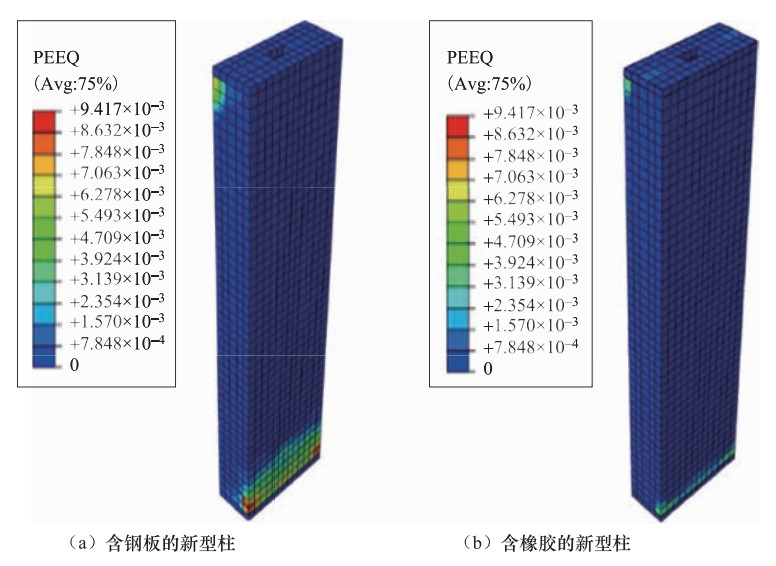

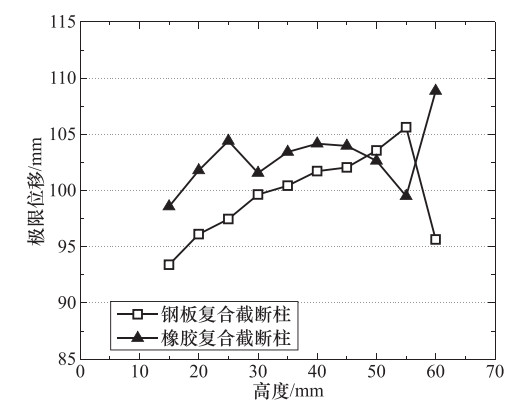

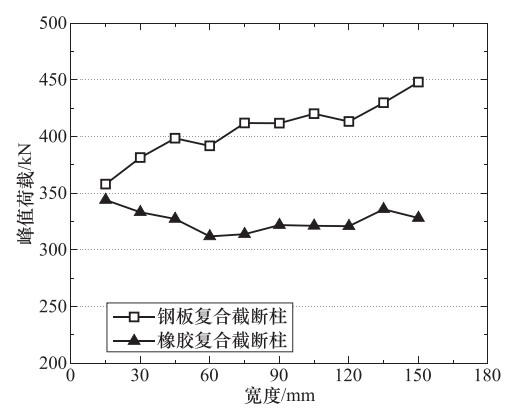

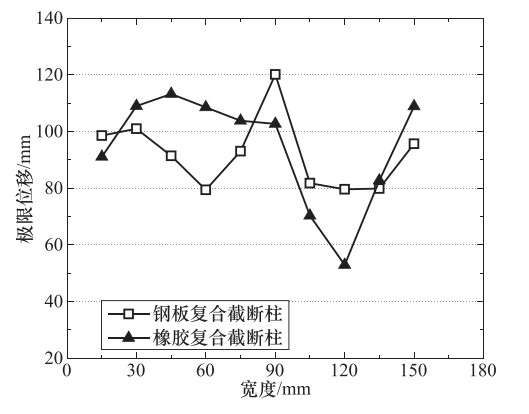

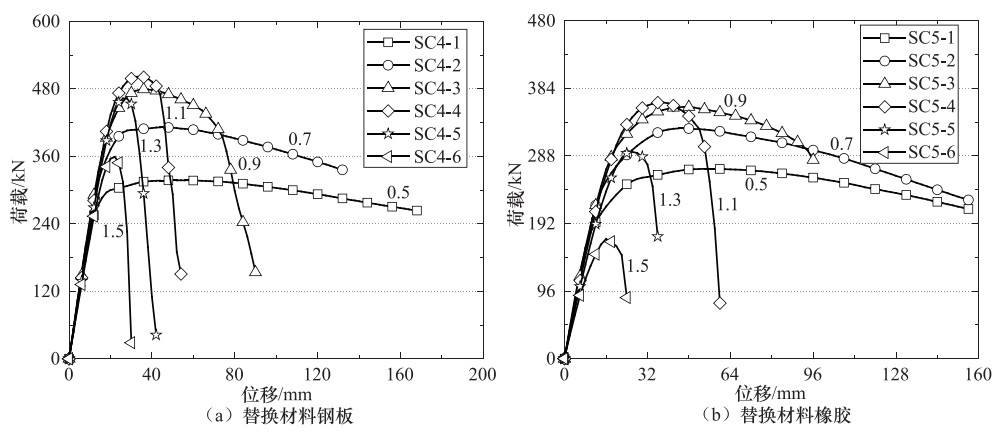

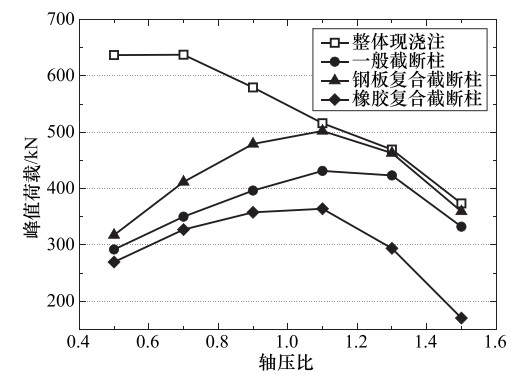

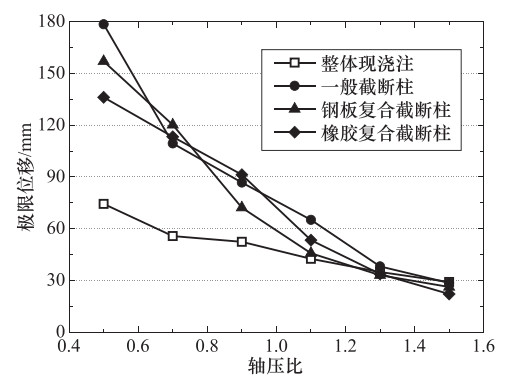

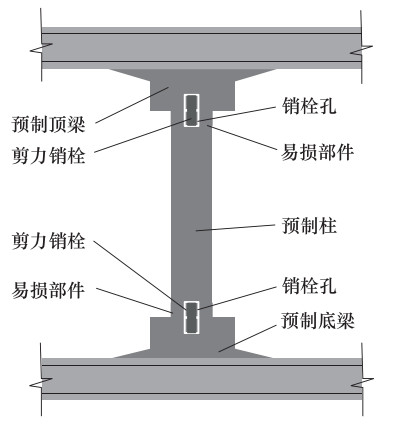

摘要: 基于功能可快速恢复的抗震韧性设计目标,结合提升中柱水平变形能力的地下结构抗震截断柱技术,提出了可有效避免由于柱脚应力集中产生的破坏和震后可快速更换的地下结构中柱设计思路,其中复合截断中柱与顶、底纵梁采用剪力销栓连接,柱脚部采用局部增强或增韧可更换材料进一步替代。采用数值模型分析了复合柱的承载力、变形能力以及柱脚采用不同材料时对复合柱变形和承载力的影响规律,并与整体现浇柱进行了对比。结果表明:一般截断柱的承载能力明显低于整体现浇柱,但其变形能力远远优于整体现浇柱。随着中柱变形的增加,一般截断柱中柱柱脚位置出现明显的“应力集中”现象,局部增强或增韧材料的采用可有效避免复合截断柱脚部因应力集中而产生的破坏,提高了复合截断柱的水平变形能力。Abstract: In order to design a technique for rapid recovery of seismic damage, by combining with the seismic interception column technology of the underground structure to improve the horizontal deformation capacity of the middle column, we propose the design idea of the column in the underground structure which can effectively avoid the damage caused by the stress concentration of the column foot and can be quickly replaced after the earthquake. The design idea of the column, wherein the composite truncated middle column and the top and bottom longitudinal beams are connected by a shear pin, and the column foot is further replaced by a partially enhanced or toughened replaceable material. The numerical model was used to analyze the bearing capacity and deformation capacity of the composite column and the influence of different materials on the deformation and bearing capacity of the composite column, and the results were compared with the overall cast-in-place column. We find that the bearing capacity of the general cut-off column is significantly lower than that of the overall cast-in-situ column, but its deformation ability is far greater than that of the overall cast-in-situ column. With the increase of the deformation of the middle column, the position of the column foot in the general cut column shows obvious "stress concentration" phenomenon. The use of local reinforcing or toughening material can effectively avoid the damage caused by the stress concentration of the foot of the composite truncated column and improve the horizontal deformation ability of the composite truncated column.

-

表 1 模型变化参数

Table 1. Parameters of models

试件编号 结构形式 轴压比 材料 α β 试件编号 结构形式 轴压比 材料 α β CC1-1 整体柱 0.5 混凝土 SC3-1 截断柱 0.7 橡胶 0.750 0.075 CC1-2 整体柱 0.7 混凝土 SC3-2 截断柱 0.7 橡胶 0.750 0.100 CC1-3 整体柱 0.9 混凝土 SC3-3 截断柱 0.7 橡胶 0.750 0.125 CC1-4 整体柱 1.1 混凝土 SC3-4 截断柱 0.7 橡胶 0.750 0.150 CC1-5 整体柱 1.3 混凝土 SC3-5 截断柱 0.7 橡胶 0.750 0.175 CC1-6 整体柱 1.5 混凝土 SC3-6 截断柱 0.7 橡胶 0.750 0.200 SC1-1 截断柱 0.5 混凝土 SC3-7 截断柱 0.7 橡胶 0.750 0.225 SC1-2 截断柱 0.7 混凝土 SC3-8 截断柱 0.7 橡胶 0.750 0.250 SC1-3 截断柱 0.9 混凝土 SC3-9 截断柱 0.7 橡胶 0.750 0.275 SC1-4 截断柱 1.1 混凝土 SC3-10 截断柱 0.7 橡胶 0.750 0.300 SC1-5 截断柱 1.3 混凝土 SC3-11 截断柱 0.7 橡胶 0.075 0.300 SC1-6 截断柱 1.5 混凝土 SC3-12 截断柱 0.7 橡胶 0.150 0.300 SC2-1 截断柱 0.7 钢板 0.750 0.075 SC3-13 截断柱 0.7 橡胶 0.225 0.300 SC2-2 截断柱 0.7 钢板 0.750 0.100 SC3-14 截断柱 0.7 橡胶 0.300 0.300 SC2-3 截断柱 0.7 钢板 0.750 0.125 SC3-15 截断柱 0.7 橡胶 0.375 0.300 SC2-4 截断柱 0.7 钢板 0.750 0.150 SC3-16 截断柱 0.7 橡胶 0.450 0.300 SC2-5 截断柱 0.7 钢板 0.750 0.175 SC3-17 截断柱 0.7 橡胶 0.525 0.300 SC2-6 截断柱 0.7 钢板 0.750 0.200 SC3-18 截断柱 0.7 橡胶 0.600 0.300 SC2-7 截断柱 0.7 钢板 0.750 0.225 SC3-19 截断柱 0.7 橡胶 0.675 0.300 SC2-8 截断柱 0.7 钢板 0.750 0.250 SC4-1 截断柱 0.5 钢板 0.450 0.300 SC2-9 截断柱 0.7 钢板 0.750 0.275 SC4-2 截断柱 0.7 钢板 0.450 0.300 SC2-10 截断柱 0.7 钢板 0.750 0.300 SC4-3 截断柱 0.9 钢板 0.450 0.300 SC2-11 截断柱 0.7 钢板 0.075 0.300 SC4-4 截断柱 1.1 钢板 0.450 0.300 SC2-12 截断柱 0.7 钢板 0.150 0.300 SC4-5 截断柱 1.3 钢板 0.450 0.300 SC2-13 截断柱 0.7 钢板 0.225 0.300 SC4-6 截断柱 1.5 钢板 0.450 0.300 SC2-14 截断柱 0.7 钢板 0.300 0.300 SC5-1 截断柱 0.5 橡胶 0.225 0.300 SC2-15 截断柱 0.7 钢板 0.375 0.300 SC5-2 截断柱 0.7 橡胶 0.225 0.300 SC2-16 截断柱 0.7 钢板 0.450 0.300 SC5-3 截断柱 0.9 橡胶 0.225 0.300 SC2-17 截断柱 0.7 钢板 0.525 0.300 SC5-4 截断柱 1.1 橡胶 0.225 0.300 SC2-18 截断柱 0.7 钢板 0.600 0.300 SC5-5 截断柱 1.3 橡胶 0.225 0.300 SC2-19 截断柱 0.7 钢板 0.675 0.300 SC5-6 截断柱 1.5 橡胶 0.225 0.300 表 2 橡胶材料实验数据

Table 2. Experiment data of the rubber material

单轴拉伸 双轴拉伸 平面剪切 应力/Mpa 应变 应力/Mpa 应变 应力/Mpa 应变 0.054 0.038 0.089 0.02 0.055 0.069 0.152 0.133 0.255 0.14 0.324 0.2828 0.254 0.221 0.503 0.42 0.758 1.3862 0.362 0.345 0.958 1.49 1.296 3.0345 0.459 0.46 1.703 2.75 1.779 4.0621 0.583 0.6242 2.413 3.45 0.626 0.851 0.73 1.4268 -

杜修力, 王刚, 路德春, 2016.日本阪神地震中大开地铁车站地震破坏机理分析.防灾减灾工程学报, 36(2):165-171. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dzxk201602001 杜修力, 马超, 路德春等, 2017.大开地铁车站地震破坏模拟与机理分析.土木工程学报, 50(1):53-62. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=tmgcxb201701007 杜修力, 王子理, 刘洪涛, 2018.基于韧性设计的一种地下框架结构抗震新体系研究.震灾防御技术, 13(3):493-501. http://zzfy.eq-j.cn/zzfyjs/ch/reader/view_abstract.aspx?flag=1&file_no=20180301&journal_id=zzfyjs 刘如山, 邬玉斌, 杜修力, 2010.用纤维模型对地下结构地震破坏的数值模拟分析.北京工业大学学报, 36(11):1488-1495. doi: 10.11936/bjutxb2010111488 马超, 2017.地铁车站结构地震塌毁过程模拟及破坏机理分析.北京: 北京工业大学. 邬玉斌, 2008.地铁车站地震反应和破坏机理分析.哈尔滨: 中国地震局工程力学研究所. http://cdmd.cnki.com.cn/Article/CDMD-85406-2009057360.htm An X. H., Shawky A. A., Maekawa K., 1997. The collapse mechanism of a subway station during the Great Hanshin earthquake. Cement and Concrete Composites, 19(3):241-257. doi: 10.1016/S0958-9465(97)00014-0 Iida H., Hiroto T., Yoshida N., et al., 1996, Damage to Daikai subway station. Soils and Foundations, 36:283-300. doi: 10.3208/sandf.36.Special_283 -

下载:

下载: