Anti-seismic Analysis of Gas Pipeline Crossing through the Kezil Thrustfault Fault

-

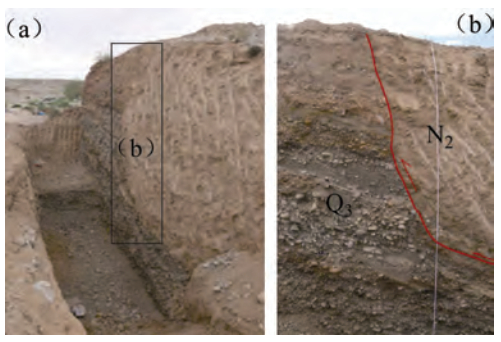

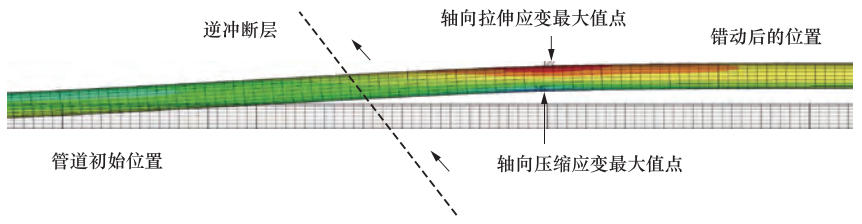

摘要: 输气管道作为1种薄壁壳体结构,逆冲断层引起的管道压缩变形容易使其破坏。本文以大北南疆输气管道工程为例,探讨了穿越克孜尔逆冲断层的输气管道地震安全问题。在确定管道穿越处的断层倾角、设防断层位错量、表征管土相互作用的土弹簧参数以及钢管容许应变等参数后,采用壳有限元方法,分析了穿越克孜尔逆冲断层的输气管道变形反应。分析结果显示,管道在逆冲断层作用下以压缩应变为主,管道内的最大轴向压缩应变的幅值随着交角的减小而减小。在通过探槽等方法确定断层活动位置后,该管道若以小于或等于11°的交角通过克孜尔断裂,断层引起的最大轴向压缩应变和拉伸应变均在管道相应的容许应变范围内,满足相关规范的抗震要求。Abstract: As a thin-walled shell structure, the gas supply pipeline is easy to be damaged with large compression deformation caused by thrust fault movement. Taking the Dabei-South xinjiang pipeline project as an example, this paper discusses the seismic safety of gas pipeline crossing the Kezil thrust fault. The shell finite element modal was used to analyze the large deformation reaction of the gas pipeline under this thrust fault after determining the fault plane inclination angle, the fortified fault displacement, the soil spring parameters representing the pipe-soil interaction and the allowable strain of the steel pipe. The FEM results show that the main strain response of the pipe under thrust fault movement is the compression strain, and the amplitude of the maximum axial compression strain in the pipeline decreases with the decrease of the intersection angle.We found that in order to meet the requirements by the national seismic code of oil/gas pipeline, the maximum axial compression strain and tensile strain caused by the fault have to be within the permissble strain range of this pipe when the crossing angle is less than or equal to 11°.

-

Key words:

- Gas pipeline /

- Thrust fault /

- Shell finite element model /

- Seismic analysis

-

表 1 3个方向土弹簧参数

Table 1. Three-direction soil spring parameters

土弹簧参数 管轴方向 水平横向 垂直方向(向上) 垂直方向(向下) 最大作用力/N·m-1 fs=1.1×104 Pu=8.8×105 qu=4.1×104 qul=2.5×105 屈服位移/m Zu=0.004 Xu=0.058 Yu=0.018 Yul=0.051 表 2 管道以不同的交角穿越逆冲断层的分析结果

Table 2. Analysis result of pipeline crossing thrust fault with different crossing angles

工况 交角/° 最大轴向拉伸应变/% 容许拉伸应变/% 最大轴向压缩应变/% 容许压缩应变/% 1 0.02 0.432 1.29 -0.342 -0.75 2 2 0.421 1.29 -0.381 -0.75 3 6 0.399 1.29 -0.518 -0.75 4 10 0.388 1.29 -0.661 -0.75 5 11 0.386 1.29 -0.703 -0.75 6 12 0.384 1.29 -0.7502 -0.75 7 13 0.383 1.29 -0.7915 -0.75 8 16 0.382 1.29 -0.887 -0.75 9 20 0.383 1.29 -1.01 -0.75 10 25 0.384 1.29 -1.18 -0.75 11 30 0.383 1.29 -1.36 -0.75 12 60 0.357 1.29 -2.09 -0.75 13 90 0.340 1.29 -2.31 -0.75 -

常想德, 胡伟华, 2016.大北至南疆利民3号阀室输气管道工程场地地震安全性评价报告.乌鲁木齐: 新疆防御自然灾害研究所. 冯启民, 赵林, 2001.跨越断层埋地管道屈曲分析.地震工程与工程振动, 21(4):81-87. http://cdmd.cnki.com.cn/Article/CDMD-10615-1016098645.htm 郭恩栋, 冯启民, 1999.跨断层埋地钢管道抗震计算方法研究.地震工程与工程振动, 19(4):43-47. doi: 10.3969/j.issn.1000-1301.1999.04.007 国家发展和改革委员会, 2004.SY/T 0450-2004输油(气)钢质管道抗震设计规范.北京:石油工业出版社. 侯忠良, 1990.地下管线抗震.北京:学术书刊出版社. 金浏, 李鸿晶, 2010.穿越逆冲断层的埋地管道非线性反应分析.防灾减灾工程学报, 30(2):130-134. http://d.old.wanfangdata.com.cn/Periodical/dzxk201002003 刘爱文, 张素灵, 胡聿贤等, 2002.地震断层作用下埋地管线的反应分析.地震工程与工程振动, 22(2):22-27. doi: 10.3969/j.issn.1000-1301.2002.02.004 刘爱文, 胡聿贤, 赵凤新等, 2004.地震断层作用下埋地管线壳有限元分析的等效边界方法.地震学报, 26(增刊):141-147. 刘爱文, 胡聿贤, 李小军等, 2005.大口径埋地钢管在地震断层作用下破坏模式的研究.工程力学, 22(3):82-87. doi: 10.3969/j.issn.1000-4750.2005.03.016 刘学杰, 孙绍平, 2005.地下管道穿越断层的应变设计方法.特种结构, 22(2):81-85. doi: 10.3969/j.issn.1001-3598.2005.02.028 史航, 王丽, 栾鲁滨, 2009.兰成渝管道的抗震设计.油气储运, 28(10):57-59. http://d.old.wanfangdata.com.cn/Periodical/yqcy200910016 田勤俭, 丁国瑜, 郝平, 2006.南天山及塔里木北缘构造带西段地震构造研究.地震地质, 28(2):213-223. doi: 10.3969/j.issn.0253-4967.2006.02.005 徐锡伟, 闻学泽, 叶建青等, 2008.汶川MS 8.0地震地表破裂带及其发震构造.地震地质, 30(3):597-629. http://d.old.wanfangdata.com.cn/Periodical/dzdz200803003 赵雷, 唐晖, 彭小波等, 2010.埋地钢管在逆断层作用下失效模式研究.应用基础与工程科学学报, 18(增刊):111-118. http://www.cnki.com.cn/Article/CJFDTOTAL-YJGX2010S1018.htm 中华人民共和国住房和城乡建设部, 2009.GB 50470-2008油气输送管道线路工程抗震技术规范.北京:中国计划出版社. Kennedy R. P., Chow A. W., Williamson R. A., 1977. Fault movement effects on buried oil pipeline. Transportation Engineering Journal of ASCE, 103(5):617-633. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=Doaj000004190648 Newmark N. M., Hall W. J., 1975. Pipeline design to resist large fault displacement. Proceedings of U.S. National Conference on Earthquake Engineering. Ann Arbor MI, 416-425. http://cn.bing.com/academic/profile?id=cd01ed1004275d92058805477f7c872c&encoded=0&v=paper_preview&mkt=zh-cn Takada S., Liang J. W., Li T. Y., 1998. Shell model response of buried pipelines to large fault movements. Journal of Structural Engineering, JSCE, 44A:1637-1646. http://cn.bing.com/academic/profile?id=4968f02614fabf0188ca337191357d9f&encoded=0&v=paper_preview&mkt=zh-cn Wang L. R. L., Yeh Y. H., 1985. A refined seismic analysis and design of buried pipeline for fault movement. Earthquake Engineering & Structural Dynamics, 13(1):75-96. http://cn.bing.com/academic/profile?id=f8aa415db8fb566e712da4dee2b8922e&encoded=0&v=paper_preview&mkt=zh-cn -

下载:

下载: