Study on Mechanical Properties of Corroded Reinforced Concrete Frame Columns Under Cyclic Load

-

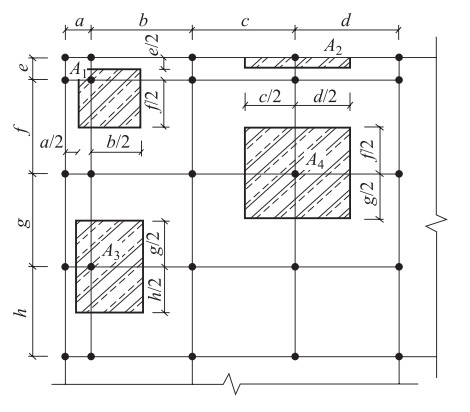

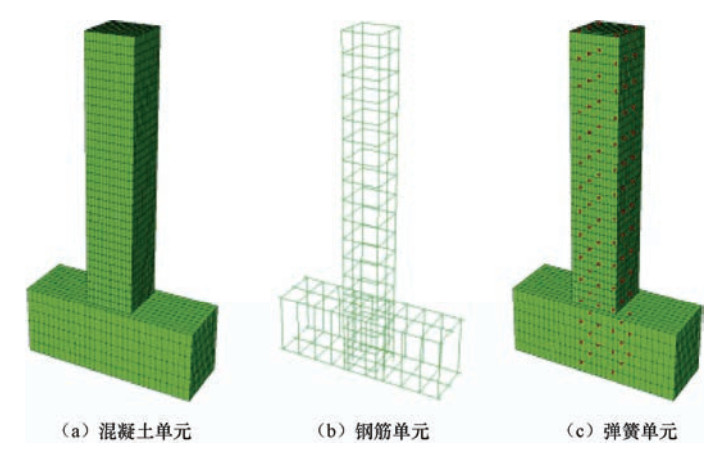

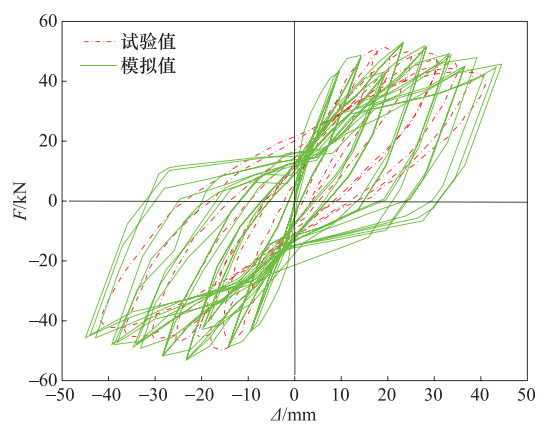

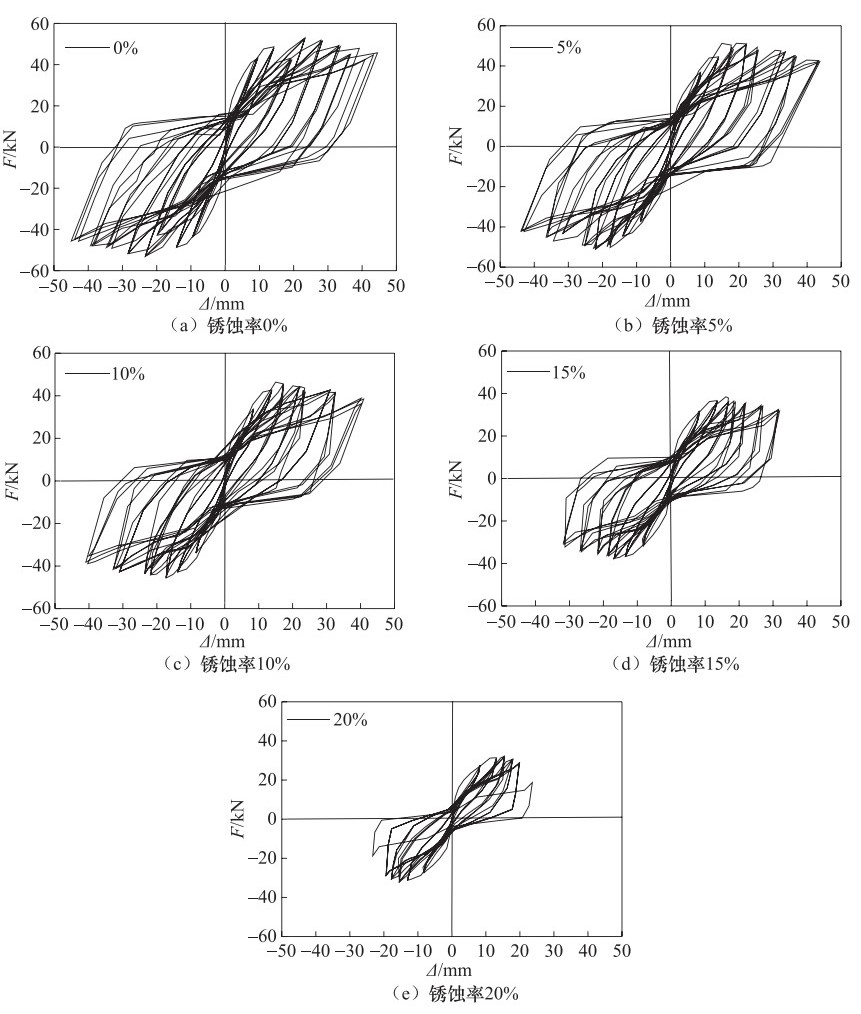

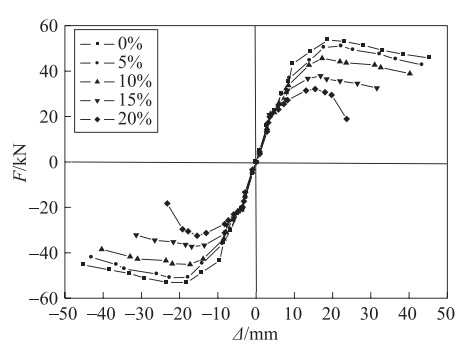

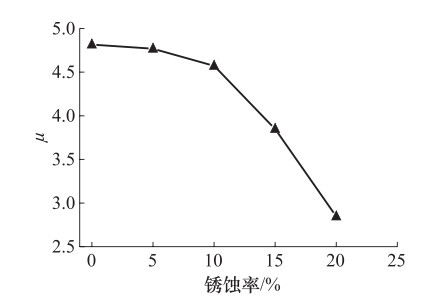

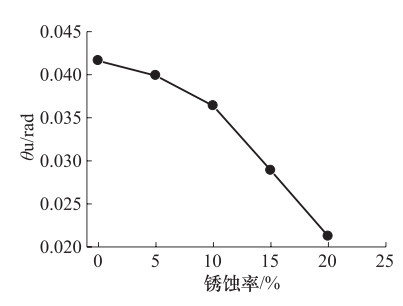

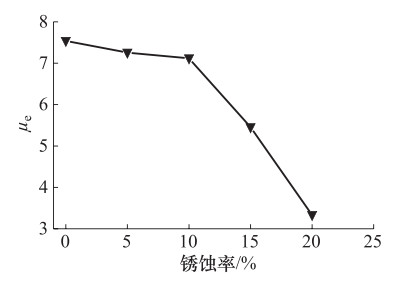

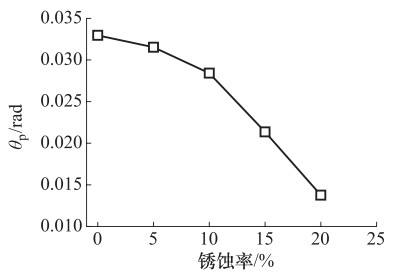

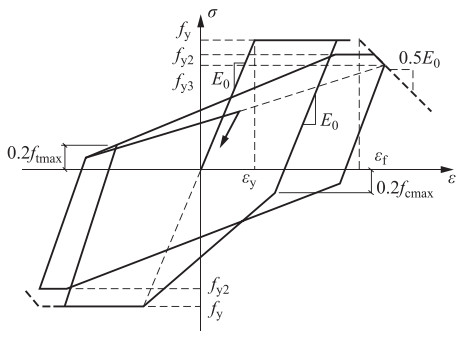

摘要: 采用有限元软件ABAQUS,以锈蚀率(0%、5%、10%、15%和20%)为变量,对5根钢筋混凝土柱的力学性能进行了数值模拟,研究各试件的滞回性能、骨架曲线、延性及耗能能力,分析钢筋锈蚀率对承载力、延性、耗能和塑性铰转动能力的影响。研究结果表明:模拟分析得到的锈蚀钢筋混凝土柱的强度和变形与试验结果吻合较好,建立的有限元模型可用于锈蚀钢筋混凝土柱的力学性能分析;混凝土开裂前,锈蚀构件的力学性能基本与未锈蚀构件相同,混凝土开裂后,构件的承载力、屈服荷载、极限位移、延性等均随钢筋锈蚀率的增大而降低;轻度锈蚀构件的滞回性能和破坏形式与未锈蚀构件类似,随着钢筋锈蚀率逐渐增大,滞回环的饱满程度降低,“捏拢”现象严重,滞回曲线由“弓形”逐渐发展成“反S形”,耗能能力降低,破坏形式趋于脆性破坏,位移延性系数、平均耗能系数等指标逐渐下降。Abstract: The numerical simulation of the mechanical properties of five corroded reinforced concrete columns with different degree of corrosion was presented with the finite element software ABAQUS. Hysteretic behavior, skeleton curve, ductility and energy dissipation capacity of specimens was studied. The influence of corrosion amount on bearing capacity, ductility, energy dissipation capacity and plastic hinge rotation capability were analyzed. Our results show that the strength and deformation of the specimens obtained by simulation are in good agreement with the test results. The numerical model established in this paper can be used for the mechanical properties analysis of corroded reinforced concrete columns. Before the cracking of concrete, the corrosion of steel bars has no obviously effect on the mechanical properties of concrete bending members. After the cracking of concrete, bearing capacity, yield load, ultimate displacement and ductility of specimens decrease with the increase of the corrosion rate. The hysteresis behavior and the failure mode of mildly corroded specimens are similar to those of non-corroded specimens. As the increase of corrosion amount, the hysteresis loop gradually deflates, and its pinch phenomenon is more serious. The shape of hysteresis curve gradually develops from bow-shaped to anti-S-shaped. The failure mode of specimens tend to be brittle failure. The displacement ductility factor, coefficient of average energy dissipation and other indicators decrease too.

-

Key words:

- Corrosion /

- Reinforced concrete column /

- Mechanical properties /

- Numerical simulation

-

表 1 CDP模型塑性参数取值

Table 1. The plastic parameters of the CDP model

参数 Ψ/° φ fb0/fc0 Kc μ ωt ωc 数值 33 0.1 1.16 0.667 0.001 0 0.3 表 2 承载力、变形参数试验值与模拟值对比

Table 2. Comparison of bearing capacity and deformation parameters between numerical simulation and physical test

开裂荷载/kN 屈服荷载/kN 极限荷载/kN 延性比 侧移角/rad 试验实测 20.00 41.78 50.15 4.46 0.038 有限元计算 20.47 43.41 53.85 4.75 0.041 相对误差/% 2.35 3.90 7.38 6.56 7.89 表 3 滞回环能量试验值与模拟值对比

Table 3. Comparison of hysteresis loop energy between numerical simulation and physical test

循环次数 试验值/kN·mm 模拟值/kN·mm 相对误差/% 1st 201.45 178.19 -11.54 2nd 590.07 463.68 -21.42 3rd 730.58 710.88 -2.69 4th 828.98 951.38 14.76 5th 1187.56 1270.92 7.02 6th 1929.19 1936.33 0.37 7th 2258.10 2332.90 3.31 8th 2825.36 3000.31 6.19 表 4 锈蚀钢筋计算参数

Table 4. Calculation parameters of corroded steel bars

钢筋截面锈蚀率/% 钢筋直径/mm 屈服强度/Mpa 极限塑性变形率/% 粘结强度降低系数 0 14.00 415.60 10.44 1 5 13.64 410.55 9.80 0.664 10 13.28 404.93 9.16 0.369 15 12.91 398.66 8.52 0.206 20 12.52 391.60 7.87 0.115 -

程玲, 贡金鑫, 李颖, 2012.基于Pushover方法分析的受腐蚀钢筋混凝土柱抗震性能评价.振动与冲击, 31(10):19-23. http://d.old.wanfangdata.com.cn/Periodical/zdycj201210005 丁发兴, 余志武, 欧进萍, 2008.混凝土单轴受力损伤本构模型.长安大学学报(自然科学版), 28(4):70-73. doi: 10.3321/j.issn:1671-8879.2008.04.016 蒋连接, 袁迎曙, 2011a.反复荷载下锈蚀钢筋混凝土压弯构件刚度退化的试验研究.混凝土, (5):3-6. http://d.old.wanfangdata.com.cn/Periodical/hnt201105002 蒋连接, 袁迎曙, 2011b.锈蚀钢筋混凝土压弯构件的恢复力模型.混凝土, (6):29-32, 40. http://d.old.wanfangdata.com.cn/Periodical/xajzkjdx200502002 李小军, 于爱勤, 甘朋霞等, 2008.汶川8.0级地震北川县城区灾害调查与分析.震灾防御技术, 3(4):352-362. doi: 10.3969/j.issn.1673-5722.2008.04.004 李悦, 颜超, 辜中伟, 2013.钢筋混凝土锈蚀膨胀力的数值模拟研究.建筑技术, 44(3):198-201. http://d.old.wanfangdata.com.cn/Periodical/jzjs201303001 刘婕, 2016.考虑钢筋局部锈蚀影响的混凝土桥梁抗震性能研究.杭州:浙江大学. 龙渝川, 李正良, 2011.模拟混凝土滞回行为的各向异性损伤模型.工程力学, 28(8):62-69. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201101701170 马颖, 贡金鑫, 赵顺波, 2011.锈蚀钢筋混凝土圆柱抗震性能的试验研究.防灾减灾工程学报, 31(2):152-159. http://d.old.wanfangdata.com.cn/Periodical/dzxk201102005 曲哲, 叶列平, 2009."破坏-安全"结构抗震理念及其应用.震灾防御技术, 4(3):241-255. doi: 10.3969/j.issn.1673-5722.2009.03.001 曲哲, 2010.摇摆墙-框架结构抗震损伤机制控制及设计方法研究.北京:清华大学. 史庆轩, 牛荻涛, 颜桂云, 2000.反复荷载作用下锈蚀钢筋混凝土压弯构件恢复力性能的试验研究.地震工程与工程振动, 20(4):44-50. doi: 10.3969/j.issn.1000-1301.2000.04.007 邢国华, 牛狄涛, 2014.锈蚀钢筋混凝土梁的受弯分析模型.中南大学学报(自然科学版), 45(1):193-201. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=SciencePaper201404040000013073 闫培雷, 孙柏涛, 陈洪富, 2010.汶川地震震中某钢筋混凝土框架结构的非线性地震反应分析.震灾防御技术, 5(3):364-369. doi: 10.3969/j.issn.1673-5722.2010.03.013 阎红霞, 杨庆山, 张丽英, 2010.ABAQUS在超高层结构动力弹塑性分析中的应用.震灾防御技术, 5(1):108-115. doi: 10.3969/j.issn.1673-5722.2010.01.013 张誉, 蒋利学, 张伟平等, 2003.混凝土结构耐久性概论.上海:上海科学技术出版社. Berto L., Vitaliani R., Saetta A., et al., 2009. Seismic assessment of existing RC structures affected by degradation phenomena. Structural Safety, 31(4):284-297. doi: 10.1016/j.strusafe.2008.09.006 Bhargava K., Ghosh A. K., Mori Y., et al., 2008. Suggested empirical models for corrosion-induced bond degradation in reinforced concrete. Journal of Structural Engineering, 134(2):221-230. doi: 10.1061/(ASCE)0733-9445(2008)134:2(221) Kivell A., Palermo A., Scott A., 2015. Complete model of corrosion-degraded cyclic bond performance in reinforced concrete. Journal of Structural Engineering, 141(9):04014222. doi: 10.1061/(ASCE)ST.1943-541X.0001195 Mehta P K., 1991. Durability of concrete-fifty years of progress. In: Malhotra V. M., Proceedings of the Second International Conference on Durabilitay of Concrete. Detroit: American Concrete Institute, 795-802. Yalciner H., Sensoy S., Eren O., 2012. Time-dependent seismic performance assessment of a single-degree-of-freedom frame subject to corrosion. Engineering Failure Analysis, 19:109-122. doi: 10.1016/j.engfailanal.2011.09.010 -

下载:

下载: